2025 Guide: Maximizing Efficiency with Innomotics Mky Gearbox in Industrial Applications

In the fast-paced world of industrial applications, maximizing efficiency is crucial for maintaining competitiveness and profitability. The integration of advanced technologies has prompted manufacturers to seek innovative solutions to enhance operational performance. According to a recent report by the International Energy Agency, optimizing industrial machinery can lead to energy savings of up to 30%, ultimately driving down costs and improving environmental sustainability. In this context, the Innomotics Mky Gearbox emerges as a transformative component that can significantly streamline processes across various sectors, from manufacturing to logistics.

The Mky Gearbox is engineered to provide higher efficiency and reliability, answering industry demands for robust, durable machinery that can withstand rigorous operational conditions. Studies show that gearboxes account for approximately 20% of energy losses in mechanical systems, making their optimization a high priority for engineers. Implementing the Innomotics Mky Gearbox allows companies to capitalize on innovative design features and materials that reduce friction and enhance power transmission, ultimately leading to superior performance and reduced downtime.

To fully leverage the capabilities of the Innomotics Mky Gearbox, industries must adopt a strategic approach that combines technology with best practices. By embracing a digital transformation alongside the adoption of this advanced gearbox, organizations can not only maximize efficiency but also gain valuable insights through real-time monitoring and predictive maintenance. This guide aims to provide essential tips for harnessing the potential of the Innomotics Mky Gearbox, ensuring that businesses can meet the rising demands of the industry effectively while achieving operational excellence.

Understanding Innomotics Mky Gearbox: Features and Benefits

The Innomotics Mky Gearbox is engineered to meet the high demands of industrial applications while ensuring reliability and performance. One of its standout features is its advanced gear geometry, which significantly enhances efficiency and minimizes energy loss. This design not only improves the overall operational effectiveness but also reduces wear and tear on the system, contributing to a longer lifespan and decreased maintenance costs.

When integrating the Innomotics Mky Gearbox into your operations, consider these tips: Firstly, always align the gearbox properly with the motor to prevent undue stress and potential damage. Secondly, regularly monitor lubrication levels and the condition of seals to ensure optimal performance. Lastly, assess your system’s load requirements to select the correct size and configuration of the gearbox, which can lead to better energy efficiency and output.

The benefits of using the Mky Gearbox extend beyond efficiency; it also includes noise reduction and vibration control. Its compact design facilitates easy installation and space-saving options, making it a versatile choice for various industrial settings. By understanding these features and implementing best practices, companies can significantly enhance their operational efficiency while ensuring robust performance in their applications.

Key Industrial Applications for Innomotics Mky Gearbox

The Innomotics Mky Gearbox is transforming various industrial applications by significantly enhancing efficiency and performance. This gearbox is particularly effective in sectors such as materials handling, food processing, and mining. According to a recent industry report from MarketsandMarkets, the global market for industrial gearboxes is projected to reach $40.5 billion by 2025, highlighting a robust demand for high-performance gear solutions like the Mky. These applications benefit from the Mky Gearbox’s compact design and ability to handle high loads while maintaining energy efficiency.

In materials handling, the Mky Gearbox is essential for conveyor systems, where reliability and uptime are critical. An analysis from ResearchAndMarkets indicates that the materials handling equipment market could grow at a CAGR of 4.5%, demonstrating the need for efficient power transmission solutions. In the food processing industry, the stringent hygiene and efficiency requirements are perfectly met by the Mky Gearbox, which features easy cleaning and maintenance capabilities. Moreover, for mining operations, where energy consumption is a significant cost factor, adopting the Innomotics Mky Gearbox can lead to cost reductions of up to 20%, as stated in the annual report by the International Energy Agency (IEA). This emphasizes the importance of integrating advanced gear technologies for sustainable industrial growth.

2025 Guide: Maximizing Efficiency with Mky Gearbox in Industrial Applications

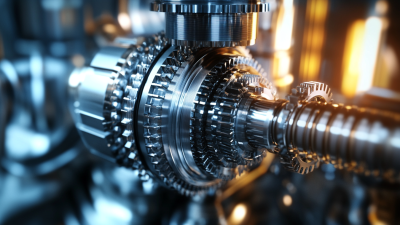

Enhancing Operational Efficiency with Mky Gearbox Technology

The Mky gearbox technology by Innomotics is at the forefront of innovation,

transforming how industries operate. With its advanced engineering, the Mky gearbox is designed to enhance operational

efficiency across various industrial applications. Its unique features, such as high torque density

and compact design, enable manufacturers to optimize their processes. By reducing energy consumption

and minimizing wear and tear, these gearboxes contribute significantly to lower operational costs and increased productivity.

Moreover, the adaptability of the Mky gearbox technology allows it to

seamlessly integrate into existing systems. This flexibility ensures that industries can upgrade their machinery

without the need for extensive modifications. The reliability and durability of the Mky gearbox also stand out, making it

an ideal choice for applications that demand continuous operation under harsh conditions. By investing in this

cutting-edge gearbox technology, companies can not only meet their efficiency goals but also sustain competitive

advantages in the ever-evolving industrial landscape.

Maintenance Best Practices for Innomotics Mky Gearbox

Proper maintenance of the Innomotics Mky gearbox is essential for optimizing its performance in industrial applications. Regular inspection is the cornerstone of an effective maintenance routine. It's crucial to check for any signs of wear or damage, including leaks, unusual noises, or overheating. Scheduling routine inspections every few months allows for early detection of potential issues, which can prevent costly downtime and repairs. Utilizing vibration analysis and thermal imaging can further enhance these evaluations, identifying problems before they escalate.

Another best practice involves maintaining proper lubrication. The Mky gearbox relies on quality lubricants to minimize friction and wear, thereby extending its lifespan. It’s advisable to adhere to the manufacturer’s specifications for lubricant type and change intervals. Over time, lubricants can degrade, requiring analysis and replacement to ensure optimal performance. Moreover, keeping a clean environment around the gearbox and ensuring that vents and breathers are unobstructed can help mitigate contamination risks, contributing to the unit's efficiency and longevity.

Comparative Analysis: Innomotics Mky Gearbox vs. Competitors

In the realm of industrial applications, the efficiency of gear systems can significantly influence production outcomes. A comparative analysis reveals that the Innomotics Mky gearbox stands out in several key areas against its competitors. With superior energy efficiency and reduced maintenance costs, the Mky gearbox allows for smoother operations, which can lead to enhanced productivity levels in manufacturing settings. Its design not only minimizes energy losses but also enables robust performance under various loads, making it a dependable choice for industries seeking optimization.

Tips for Maximizing Efficiency with Innomotics Mky Gearbox:

- Regular Maintenance: Schedule consistent inspections to ensure the gearbox operates at peak performance. This includes checking lubrication levels and monitoring for wear and tear.

- Load Management: Ensure that the gearbox operates within its specified load limits to avoid unnecessary strain, which can lead to premature failures.

- Training Staff: Providing training for staff on the proper handling and operations of the gearbox can prevent misuse and reduce the risk of operational downtime.

By focusing on these aspects, companies can leverage the advanced features of the Mky gearbox to enhance their operational efficiency and stay ahead in a competitive landscape.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor