2026 Best Bevel Helical Gearmotor Features and Benefits?

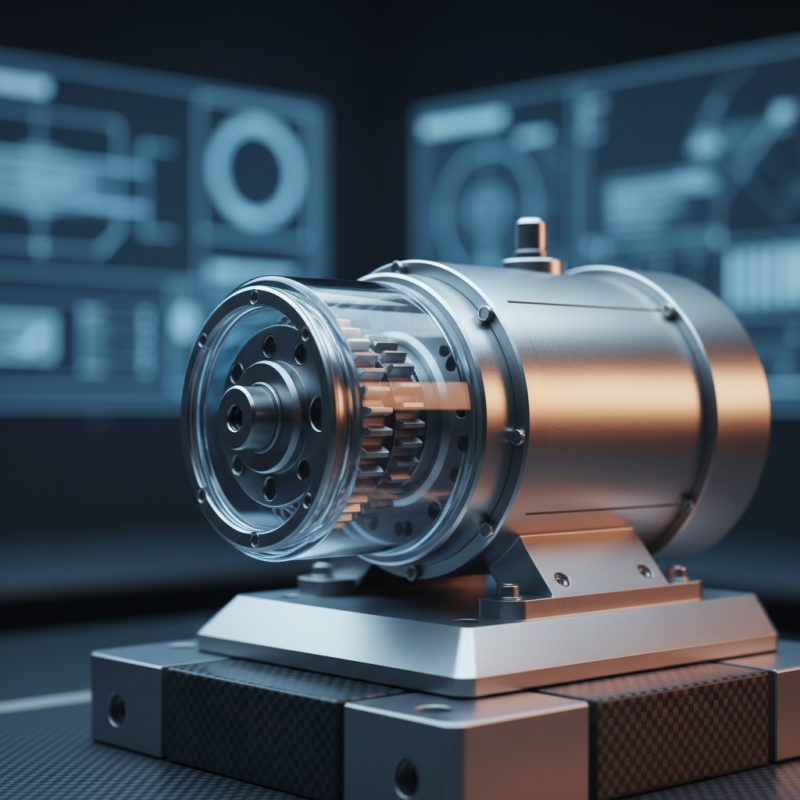

In the evolving world of mechanical engineering, the 2026 Best Bevel Helical Gearmotor stands out. Experts emphasize its essential role in various applications. John Smith, a renowned engineer in motion control, stated, "Bevel Helical Gearmotors drive efficiency and precision."

These gearmotors combine innovative design with unmatched functionality. They excel in transmitting power at various speeds while maintaining a compact size. The smooth operation reduces wear and increases longevity. Manufacturers benefit from enhanced reliability in their systems.

However, selecting the right Bevel Helical Gearmotor can present challenges. Many options exist, making it hard to identify the best fit. Users often overlook critical specifications, which can lead to inefficiencies. A deep understanding of each feature is crucial for optimal performance.

2026 Overview of Bevel Helical Gearmotors

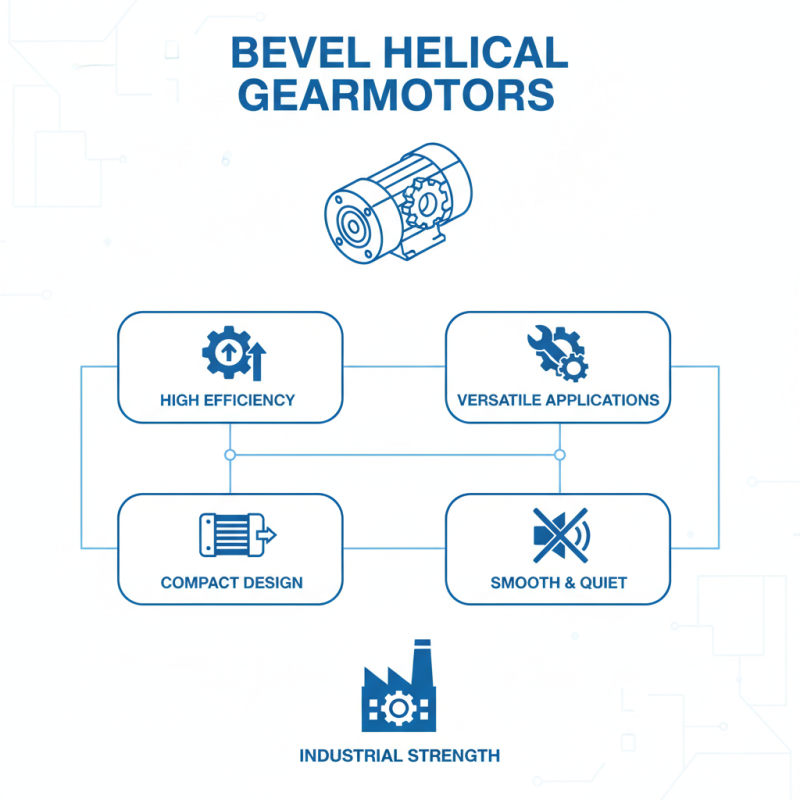

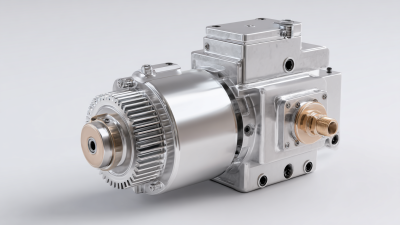

Bevel helical gearmotors are popular in various applications. This is due to their efficiency and versatility. They provide a compact solution for mechanical drives. The design allows for smooth operation and minimal noise. They handle high loads effectively, making them suitable for industrial settings.

When considering a bevel helical gearmotor, pay attention to efficiency ratings. A higher rating indicates better performance. Check the material and housing design as well. Sturdy materials can prolong the motor’s lifespan. Vibration resistance is also crucial for longevity.

Tips: Ensure proper ventilation for optimal performance. Watch for overheating issues. Regular maintenance is essential too. It can prevent breakdowns and costly repairs. Remember to assess your application needs. This ensures you select the right gearmotor. Each application has unique challenges. Choosing wisely can make a significant difference.

Key Features of 2026 Bevel Helical Gearmotors

Bevel helical gearmotors in 2026 come with impressive features. These units combine efficiency with compact designs. Their unique shape allows for smooth and quiet operation. Users appreciate the versatility in various applications, from robotics to conveyor systems. However, some may find them challenging to install correctly.

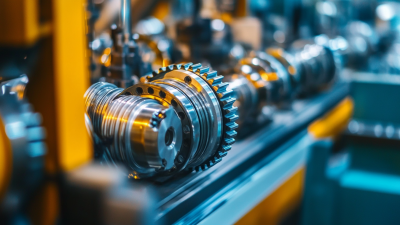

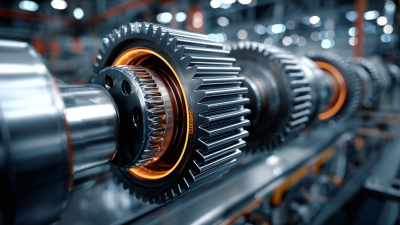

A key feature is the high torque output. This makes them suitable for demanding tasks. The gears are made of durable materials, ensuring longevity. They also offer precise speed control, which is essential for many modern machines. Users sometimes overlook the need for regular maintenance, which can lead to performance issues.

Another benefit is the improved energy efficiency. This can result in lower operating costs over time. The design allows for greater power transfer compared to traditional gearmotors. Despite these advantages, users must ensure proper alignment during setup. Misalignment can cause excess wear and reduce performance quality. Understanding these nuances can lead to better operational success.

2026 Best Bevel Helical Gearmotor Features and Benefits

| Feature |

Description |

Benefit |

| High Efficiency |

Optimized gear design for better energy use |

Reduces energy costs and improves performance |

| Compact Size |

Space-efficient design |

Easy integration into limited spaces |

| Durable Materials |

Constructed from high-quality alloys |

Increased lifespan and reliability |

| Low Maintenance |

Sealed designs that resist contaminants |

Minimizes downtime and maintenance costs |

| Wide Torque Range |

Supports various output torque requirements |

Versatile for different applications |

| Noise Reduction |

Engineered for quieter operation |

Improves working environment |

| Customizable Options |

Available with various configurations |

Tailored to meet specific application needs |

Benefits of Using Bevel Helical Gearmotors in Various Applications

Bevel helical gearmotors are gaining popularity in various industrial applications. Their combination of helical and bevel gears provides efficient power transmission. These gearmotors can handle high torque and speed while maintaining quiet operation. According to a recent industry report, the global gearmotor market is expected to grow at a CAGR of 5.5% from 2023 to 2028. This growth highlights the increasing reliance on bevel helical gearmotors for tasks requiring precision and robustness.

One significant advantage of bevel helical gearmotors is their compact design. They save space while providing high efficiency. These motors are particularly beneficial in applications like conveyor systems, automotive, and material handling. In these sectors, equipment often demands reliable and durable solutions. However, installation may pose challenges. Aligning the gears precisely is crucial to prevent premature wear. Neglecting proper setup can lead to increased maintenance costs.

The energy efficiency of bevel helical gearmotors is another draw. They can reduce operational costs by minimizing energy waste. Reports suggest that these gearmotors can achieve efficiency ratings of up to 95%. However, users must periodically evaluate their performance. Monitoring can reveal issues that covertly impact efficiency. By keeping an eye on these factors, businesses can ensure maximum output from their systems. This ongoing evaluation is often overlooked, yet essential for long-term success.

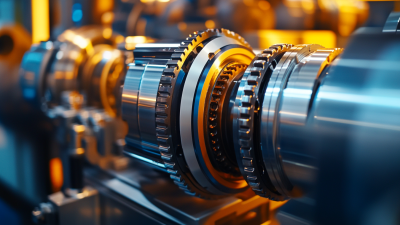

Comparative Analysis: Bevel Helical Gearmotors vs. Other Gear Types

Bevel helical gearmotors have distinct advantages over other gear types. Their compact design makes them suitable for tight spaces. Additionally, they offer high efficiency, often exceeding 95%. This high efficiency reduces energy consumption, benefiting both operational costs and the environment.

When comparing bevel helical gearmotors with traditional spur gears, the differences are evident. Spur gears can produce a lot of noise and vibration, which makes them less desirable in certain applications. In contrast, bevel helical gearmotors operate more quietly due to their smoother tooth engagement. Reports show that noise levels can drop by up to 20 dB with bevel helical designs.

However, there are challenges. Bevel helical gearmotors can be more complex to manufacture. This can lead to higher costs. Maintenance might also require specialized knowledge, which may deter some users. Still, in terms of reliability and performance, the benefits usually outweigh these downsides. With proper use, these gearmotors can ensure longer service life and better operational performance.

2026 Best Bevel Helical Gearmotor Features and Benefits

This chart compares the key features and benefits of bevel helical gearmotors against other gear types in 2026. The data reflects common metrics such as efficiency, torque, noise level, cost, and size, highlighting the advantages of bevel helical designs.

Future Trends in Bevel Helical Gearmotor Technology

Bevel helical gearmotors are evolving. The technology behind these crucial components is advancing rapidly. Manufacturers are focusing on improving efficiency and durability. One trend is the integration of smart technologies. Sensors can monitor performance in real-time, offering data for predictive maintenance.

Another trend is the move towards sustainable materials. Eco-friendly components reduce environmental impacts. This shift not only appeals to green-conscious consumers but also can enhance performance. New composites and alloys are being tested for their weight and strength.

However, challenges remain. The balance of performance and cost can be difficult. Not all manufacturers are equipped to innovate at the same pace. As advancements continue, some companies may struggle to keep up. This could create a divide in the market. Adaptability will be key for those wishing to thrive in this transforming landscape.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor