Unlocking Efficiency: The Advantages of Siemens Gearmotors for Global Industry Leaders

In today's rapidly advancing industrial landscape, efficiency, reliability, and adaptability are paramount for competitive advantage. According to a recent report by MarketsandMarkets, the global gearmotor market is projected to reach $12.21 billion by 2025, growing at a CAGR of 5.6%. As industries seek optimal solutions,

Siemens' gearmotors have emerged as a preferred choice among global leaders for their superior performance and energy efficiency.

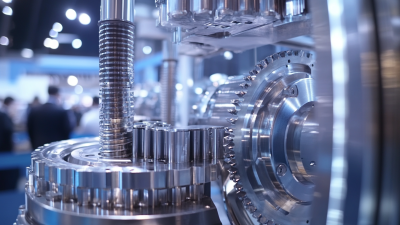

Specifically, the Gearmotorsiemensgearbox combines advanced engineering with cutting-edge technology, providing seamless integration across various applications, thereby driving operational excellence. This blog will explore the benefits of Siemens gearmotors, emphasizing how they are positioned to meet the evolving demands of modern industries while enhancing productivity and reducing costs.

Specifically, the Gearmotorsiemensgearbox combines advanced engineering with cutting-edge technology, providing seamless integration across various applications, thereby driving operational excellence. This blog will explore the benefits of Siemens gearmotors, emphasizing how they are positioned to meet the evolving demands of modern industries while enhancing productivity and reducing costs.

Benefits of Siemens Gearmotors in Enhancing Industrial Operations Efficiency

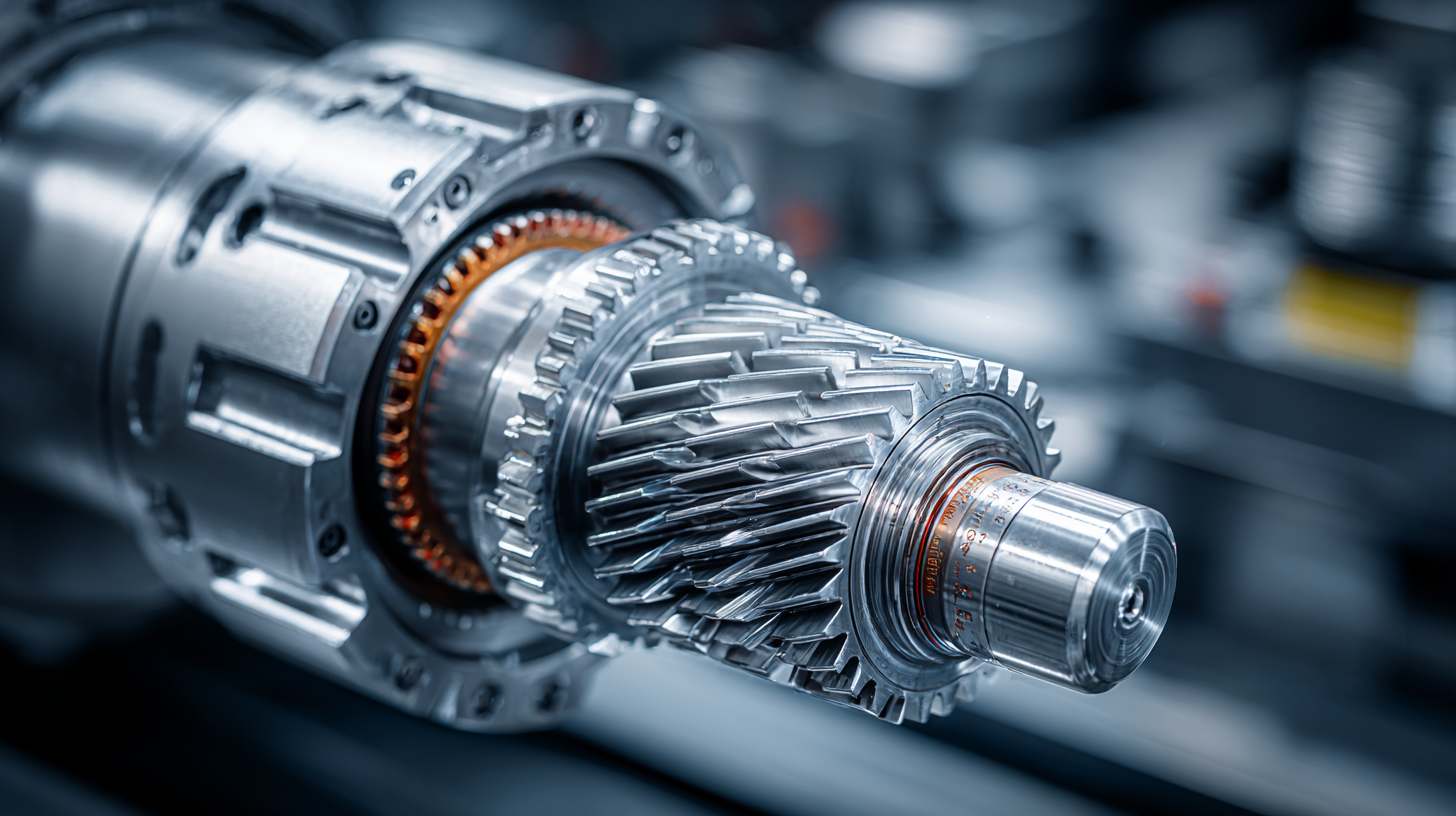

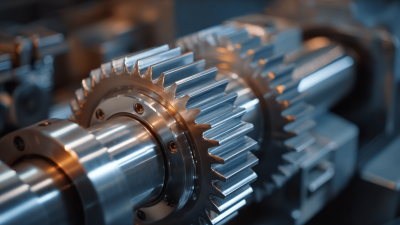

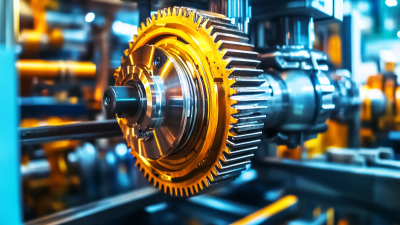

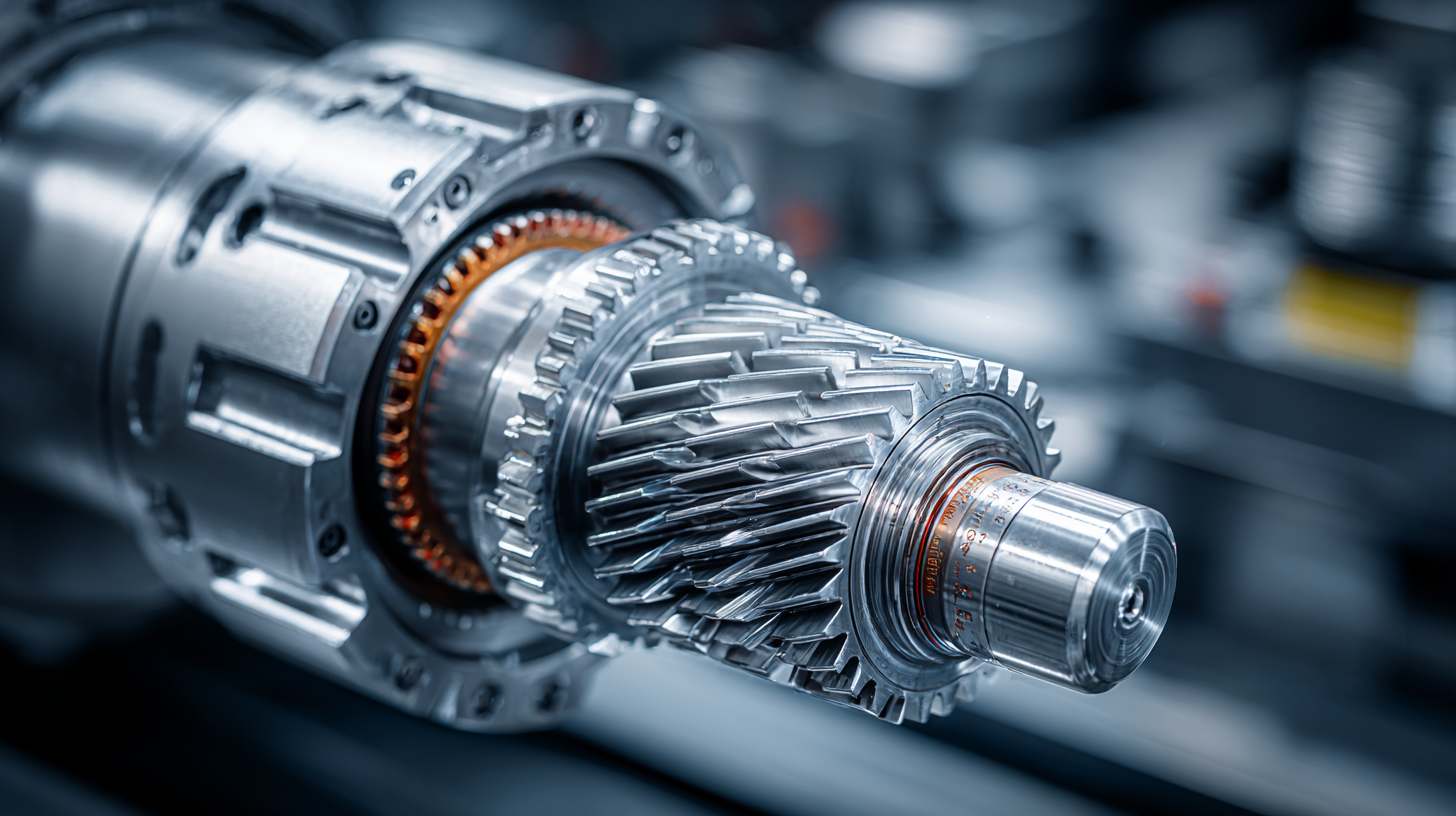

Siemens gearmotors offer a transformative approach to enhancing industrial operations efficiency, providing global industry leaders with the tools to maximize productivity. One primary benefit of these gearmotors is their superior energy efficiency, which significantly reduces operational costs. By integrating advanced motor technology with sturdy gear designs, Siemens gearmotors minimize energy losses during operation, ensuring that a greater portion of energy consumption is converted into useful work.

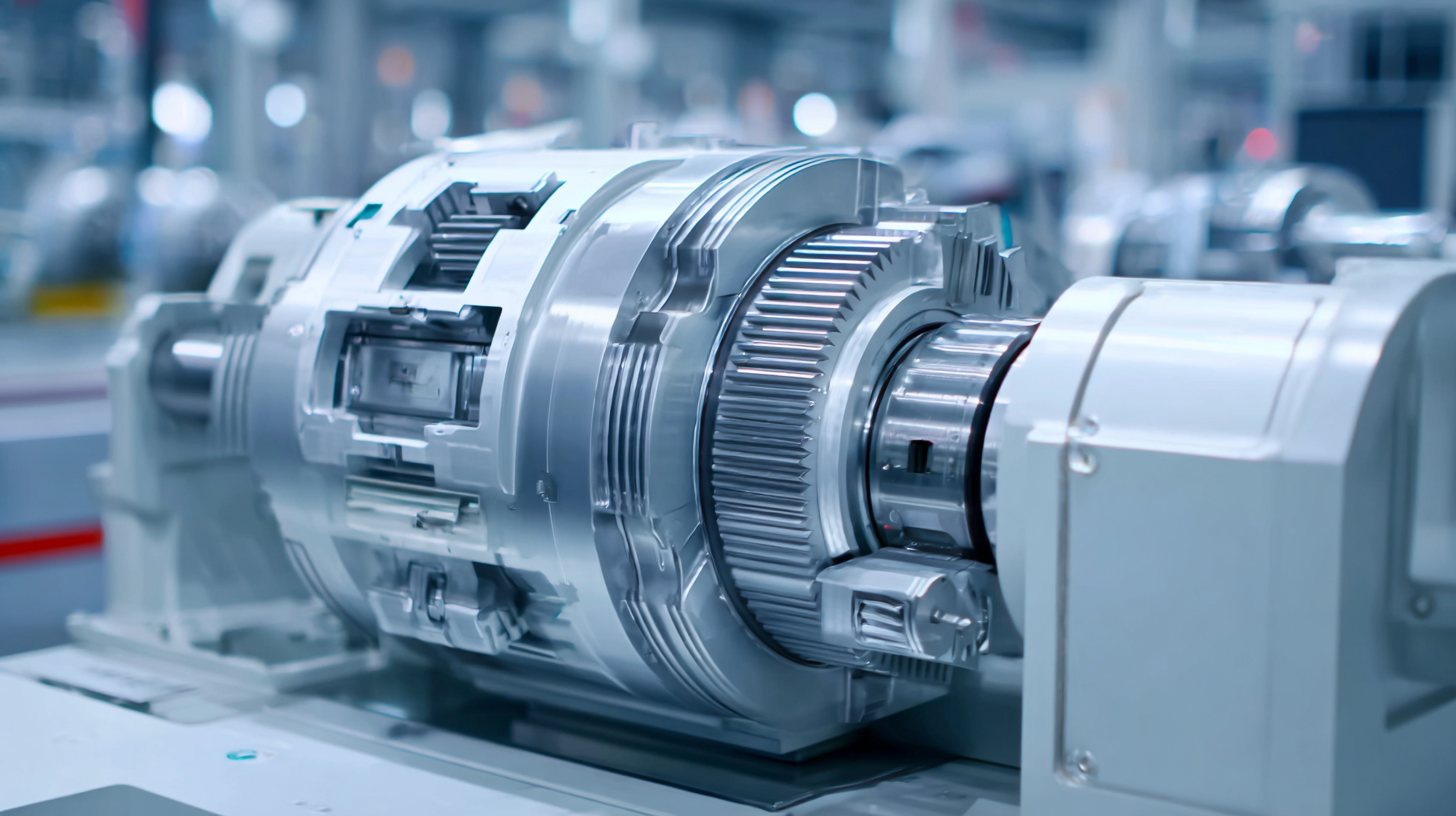

Moreover, the durability and reliability of Siemens gearmotors contribute to uninterrupted operations, which is crucial for maintaining high productivity levels. These gearmotors are engineered for reliability, often featuring enhanced protection against environmental factors such as dust and moisture. This robustness reduces downtime and maintenance needs, allowing industries to focus on their core processes without worrying about equipment failure. Ultimately, the integration of Siemens gearmotors into industrial applications not only streamlines operations but also helps businesses remain competitive in a rapidly evolving market.

Key Performance Metrics: How Siemens Gearmotors Reduce Energy Consumption

In today's competitive industrial landscape, energy efficiency has become a crucial element for success. Companies are increasingly turning to advanced gearmotors to optimize their operations and reduce energy consumption. Siemens gearmotors exemplify this trend, offering innovative solutions that help global industry leaders achieve significant energy savings. For instance, recent initiatives in the UAE demonstrate the potential of advanced technology to drive efficiencies, with an impressive target of 27% energy savings in government buildings.

To maximize the benefits of gearmotors in your operations, consider these tips: First, assess your energy usage and identify areas where gearmotors can enhance performance, such as in conveyor systems or vertical motion applications. Second, leverage smart infrastructure solutions to integrate gearmotors with other energy management systems, facilitating real-time monitoring and adjustments. Lastly, invest in regular maintenance to ensure optimal performance and longevity of your gearmotors.

By focusing on energy-efficient solutions like Siemens gearmotors, industries can not only reduce costs but also contribute positively to sustainability efforts. Embracing innovations in motion control is essential for those aiming to stay ahead in a rapidly evolving marketplace.

Integrating Siemens Gearmotors for Improved Automation in Manufacturing Processes

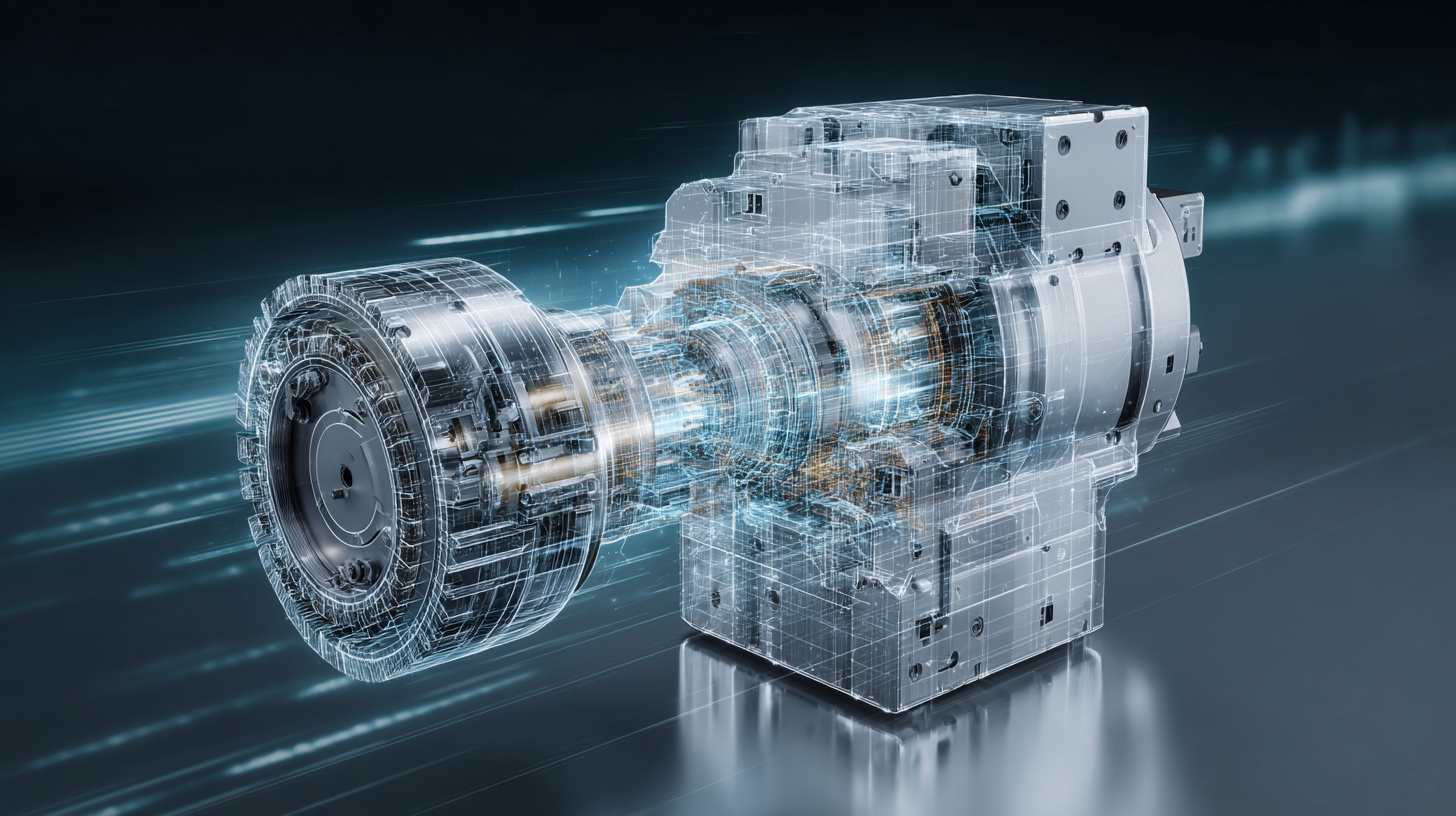

In today's fast-paced manufacturing environment, automation is pivotal for enhancing productivity and efficiency. Integrating Siemens gearmotors can significantly improve automation processes across various industries. According to a report by the International Federation of Robotics, global sales of industrial robots reached 384,000 units in 2020, reflecting the increasing reliance on automated systems. Siemens gearmotors, known for their robustness and precision, ensure seamless operation of automated machinery, minimizing downtime and maximizing output.

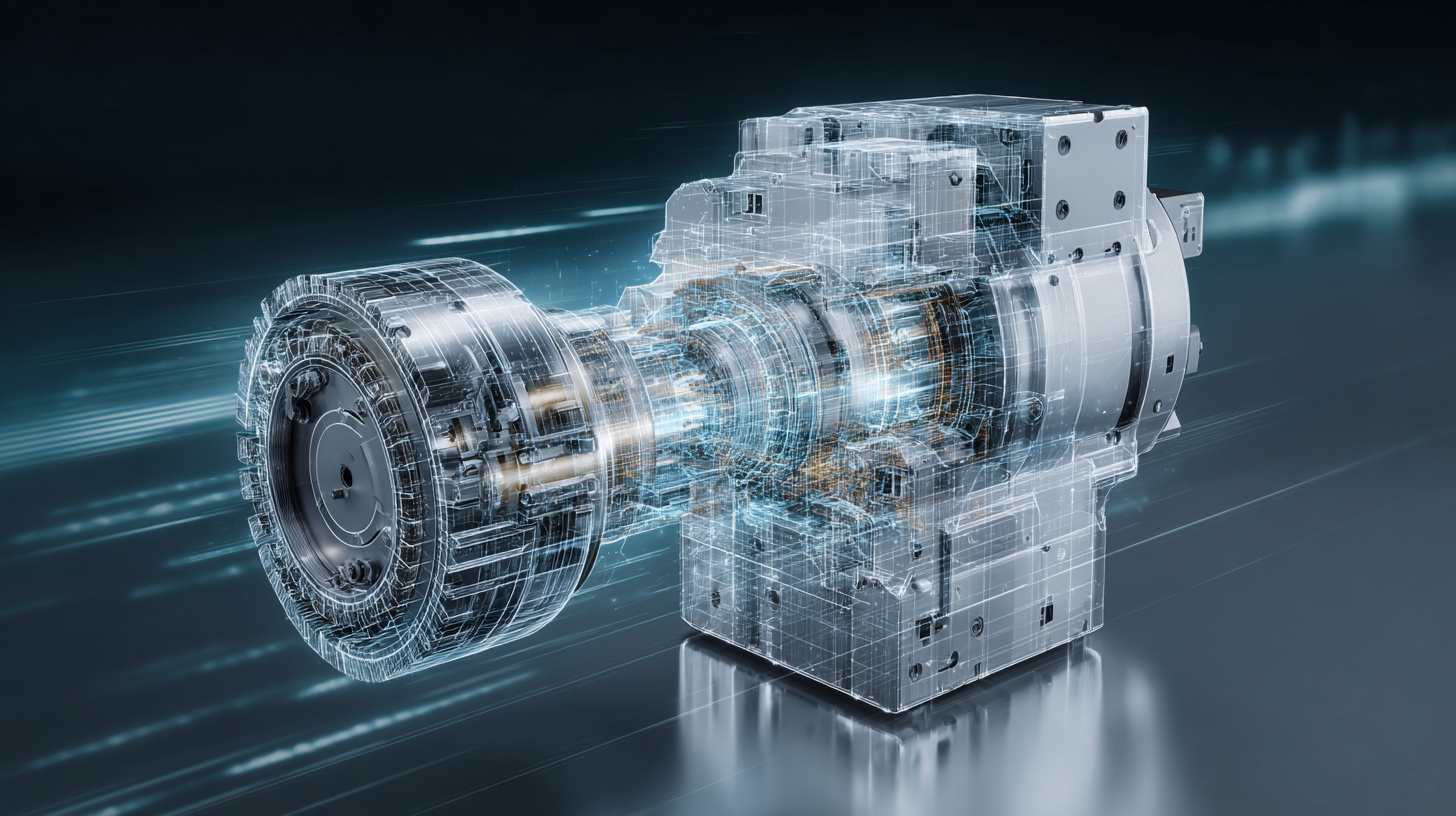

Tips to consider when integrating Siemens gearmotors include assessing the specific requirements of your production line. Ensure that the gearmotor specifications match the load and speed requirements of your application. Additionally, leveraging Siemens' digital twin technology can streamline the design and testing phases, reducing the risk of costly errors. Implementing smart sensors alongside gearmotors can also provide real-time data, facilitating proactive maintenance and further enhancing automation efficiency.

Furthermore, a study conducted by McKinsey & Company indicates that automation can boost productivity by up to 25% in manufacturing sectors. By harnessing the capabilities of Siemens gearmotors, companies can capitalize on this potential, ensuring that their operations are not only effective but also agile enough to adapt to changing market demands.

Unlocking Efficiency: The Advantages of Gearmotors in Manufacturing

Real-World Case Studies: Industry Leaders Achieving Success with Siemens Gearmotors

In the rapidly evolving landscape of modern manufacturing and industrial processes, Siemens gearmotors stand out as a pivotal asset for global leaders seeking efficiency and innovation. Real-world case studies illustrate how companies are leveraging Siemens products to achieve remarkable success. For instance, NWI Aerostructures has partnered with Fives Group to integrate Siemens' digital-native solution, enhancing their machining capabilities. This collaboration helps operators maximize their productivity through advanced technology.

Tip: Embracing digital solutions not only streamlines operations but also reduces downtime. Companies that invest in innovative technologies position themselves for a competitive edge in their respective markets.

Moreover, the synergy between Siemens and other industry players, as seen in recent collaborations with major aerospace and energy firms, highlights the versatility of Siemens gearmotors across various sectors. By utilizing these cutting-edge solutions, businesses can implement smart manufacturing practices that facilitate real-time monitoring and optimization of processes.

Tip: Company leaders should continuously explore partnerships that focus on innovation and technology integration, as these collaborations can lead to groundbreaking advancements and operational excellence.

Future Trends: The Role of Siemens Gearmotors in Sustainable Industrial Practices

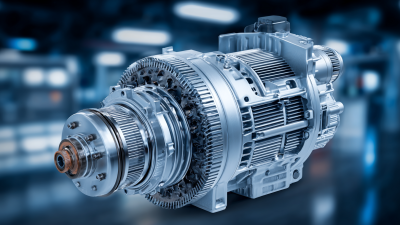

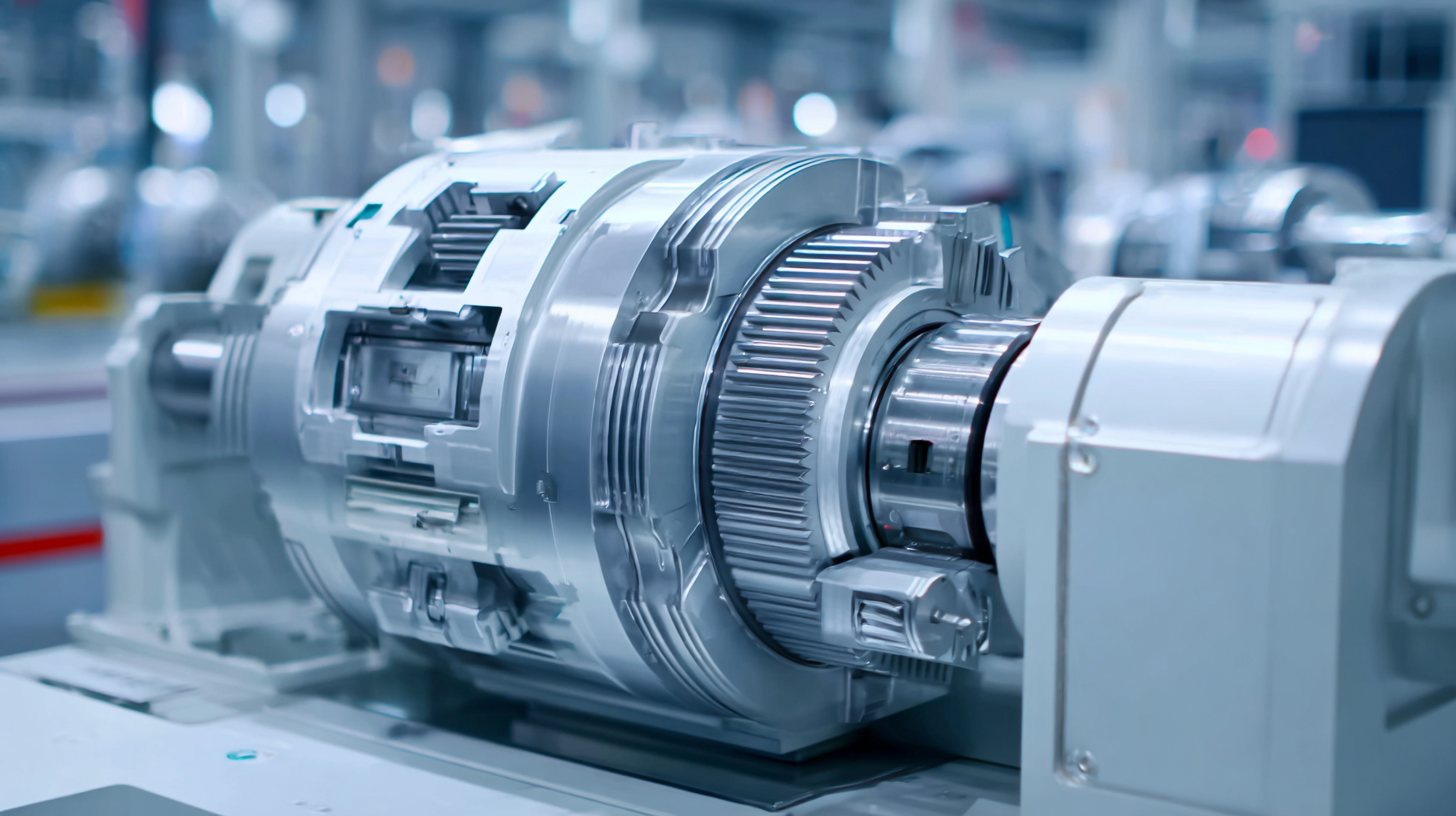

In today's rapidly evolving industrial landscape, sustainability has become more than just a buzzword; it is imperative for long-term success. Siemens gearmotors are positioned at the forefront of this transformation, showcasing their vital role in adopting sustainable practices across various sectors. Designed for efficiency and longevity, these gearmotors contribute significantly to reducing energy consumption, thereby lowering carbon footprints for global industry leaders seeking environmentally friendly solutions.

As industries strive to meet stringent regulatory requirements and consumer demands for greener products, Siemens gearmotors offer advanced technologies that facilitate energy savings and waste reduction. By integrating intelligent automation and predictive maintenance capabilities, these gearmotors not only optimize performance but also extend the lifespan of equipment. This alignment with sustainability goals enables companies to implement cleaner manufacturing processes, reinforcing their commitment to a more sustainable future while maintaining operational excellence.

Unlocking Efficiency: The Advantages of Siemens Gearmotors for Global Industry Leaders - Future Trends: The Role of Siemens Gearmotors in Sustainable Industrial Practices

| Aspect |

Description |

Benefit |

Future Trend |

| Energy Efficiency |

Optimized power consumption through advanced design. |

Reduced operational costs and CO2 emissions. |

Increasing focus on renewable energy integration. |

| Compact Design |

Space-saving designs suitable for modern factory layouts. |

Maximized production space and improved workflow. |

Growing demand for modular and flexible manufacturing systems. |

| Durability |

Robust construction for rigorous industrial applications. |

Lower maintenance costs and longer service life. |

Trend towards more sustainable product lifecycles. |

| Smart Technology |

Integration with IoT for predictive maintenance and monitoring. |

Enhanced operational efficiency and reduced downtime. |

Increasing adoption of Industry 4.0 technologies. |

| Versatility |

Applicable in various industries from food processing to robotics. |

Flexibility in applications leads to broader market reach. |

Rising trend towards automation and customization. |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor Specifically, the

Specifically, the