Understanding the Applications and Benefits of Geared Servomotors in Modern Automation

In the realm of modern automation, the demand for efficient and precise motion control has surged, making Geared Servomotors an integral component across various industries. According to a report by MarketsandMarkets, the global servomotor market is projected to reach USD 8.9 billion by 2025, growing at a CAGR of 5.5% from 2020. This growth is fueled by the increasing adoption of automation in manufacturing, robotics, and aerospace applications, where high torque and accurate positioning are paramount.

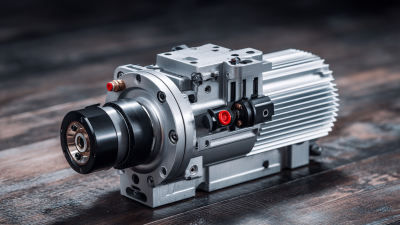

Geared Servomotors, characterized by their ability to convert electrical energy into mechanical motion with improved torque output, play a crucial role in this dynamic landscape. As highlighted in a 2023 research report by Research and Markets, the incorporation of geared servomotors enhances efficiency by up to 30% compared to traditional motor systems, enabling businesses to achieve higher productivity levels while minimizing energy consumption. With their ability to provide reliable performance in demanding environments, these motors are pivotal in driving innovations across sectors, thereby underscoring their significance in the future of automation technologies.

Applications of Geared Servomotors in Different Industries

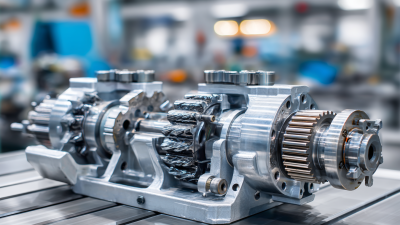

Geared servomotors are becoming increasingly vital across various industries due to their precision and efficiency in motion control applications. In the automotive sector, these servomotors are deployed in robotic assembly lines, where they ensure precise positioning of components during manufacturing. Their ability to provide high torque at low speeds makes them perfect for tasks such as welding, painting, and material handling, where accuracy significantly impacts quality and productivity.

In the robotics and automation fields, geared servomotors are indispensable for creating fluid movements in robotic arms and mobile platforms. They facilitate complex motion profiles that are essential in applications ranging from surgical robots to automated guided vehicles (AGVs). Additionally, in the packaging industry, these servomotors enhance speed and efficiency in processes like filling, sealing, and labeling, thereby minimizing downtime and maximizing throughput, ultimately leading to better inventory management and reduced operational costs.

Understanding the Applications and Benefits of Geared Servomotors in Modern Automation - Applications of Geared Servomotors in Different Industries

| Industry |

Application |

Benefits |

| Manufacturing |

Robotic Arms |

High precision and repeatability |

| Automotive |

Assembly Line Automation |

Enhanced speed and efficiency |

| Aerospace |

Control Systems |

Reliable performance in critical applications |

| Food Processing |

Packaging Machines |

Improved hygiene and safety standards |

| Healthcare |

Medical Equipment |

Accurate dosage and control |

| Robotics |

Automated Guided Vehicles (AGVs) |

Flexible transportation solutions |

| Textile |

Sewing Machines |

Increased productivity and automation |

Key Advantages of Using Geared Servomotors in Automation Processes

Geared servomotors play a pivotal role in modern automation by enhancing the precision and efficiency of motion control systems. One of the primary advantages of using geared servomotors is their ability to provide high torque at low speeds. This characteristic is crucial in applications that require heavy lifting or handling of loads that require careful manipulation. By gearing down the motor's output, operators can achieve better control over speed and position, allowing for more intricate automation tasks to be executed with greater accuracy.

Another significant benefit of geared servomotors is their improved energy efficiency. Compared to traditional motors, geared servomotors can deliver the same output with less input power, which leads to reduced energy costs and an overall lower carbon footprint for manufacturing operations. Additionally, the integration of geared servomotors in automation processes helps in minimizing wear and tear on mechanical components. The smoother operation and consistent torque delivery extend the life of the machinery, making them a cost-effective investment for industries looking to enhance their automation capabilities.

How to Select the Right Geared Servomotor for Your Project

When selecting the right geared servomotor for your project, it's essential to consider several key factors that will ensure optimal performance and efficiency. Start by assessing the torque requirements of your application. Higher torque ratings generally provide better load handling, but always ensure that the motor aligns with the specific needs of your system without unnecessary over-specification.

Tip: Calculate the torque needed not just for static loads, but also for dynamic conditions, accounting for inertia and potential external forces. This will help in finding a motor that meets your application’s demands without the risk of stalling or excessive wear.

Next, focus on the gear ratio. A well-chosen gear ratio can dramatically influence the output speed and torque, which are vital for your automation processes. Identify if high speed or high torque is more critical for your application to inform your gear ratio selection.

Tip: Experiment with simulation tools to visualize how different gear ratios impact your application before finalizing your choice. This can save time and prevent costly errors during implementation, ensuring you select the most suitable geared servomotor for your needs.

Maintaining and Troubleshooting Geared Servomotors for Optimal Performance

Maintaining and troubleshooting geared servomotors is crucial for ensuring optimal performance in modern automation systems. According to a report by the International Society of Automation, proper maintenance can lead to a reduction of downtime by up to 30%, significantly impacting overall productivity. Frequent checks on the motor’s lubrication, alignment, and wear can preemptively address issues that may arise from prolonged use, thus enhancing operational efficiency. Additionally, implementing a predictive maintenance strategy based on data analytics allows for timely interventions, preventing costly repairs and extending the lifespan of the equipment.

Troubleshooting geared servomotors involves a systematic approach to diagnosing issues such as abnormal noises, overheating, or erratic performance. A study published by the Automation Research Institute indicates that approximately 25% of motor failures can be traced back to electrical issues, while mechanical failures account for an additional 40%. Utilizing advanced diagnostic tools and maintaining a well-documented history of motor performance can greatly aid in identifying patterns leading to failures. Regular training for maintenance personnel on the latest troubleshooting techniques also empowers teams to handle problems swiftly, ensuring that production processes continue uninterrupted.

Future Trends in Geared Servomotor Technology and Automation Solutions

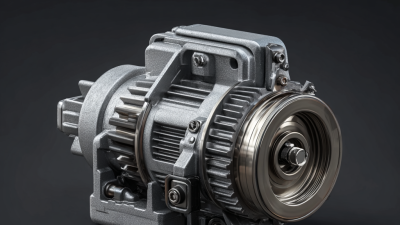

Geared servomotors are at the forefront of modern automation, driving significant advancements in various sectors. With the growing integration of artificial intelligence and continuous support from policies, the utilization of these motors in humanoid robots presents an exciting frontier. Research indicates that the global servomotor market is anticipated to reach USD 8.54 billion by 2026, emphasizing an urgent need for high precision and reliability in automation solutions. As industries pivot towards smarter applications, geared servomotors offer unmatched torque, efficiency, and precision, essential for meeting the demands of innovative robotic technologies.

Tips: When selecting geared servomotors for your projects, consider factors such as torque requirements, speed, and control capabilities to ensure optimal performance. Investing in high-quality servomotor systems can lead to enhanced operational efficiency and reduced maintenance costs.

Future trends indicate a shift towards more compact and energy-efficient geared servomotors, as designers aim to integrate these components into smaller robotic platforms. The demand for automation across sectors, fueled by advancements in AI, will likely accelerate the development of geared servomotors with superior functionalities. With anticipated growth in the humanoid robot industry, companies focusing on R&D of these technologies are positioned to capitalize on emerging opportunities, driving innovation and further enhancing the automation landscape.

Applications and Benefits of Geared Servomotors in Modern Automation

This chart illustrates the key benefits of geared servomotors in modern automation, highlighting their advantages such as precision, torque density, energy efficiency, speed control, and cost-effectiveness. Each benefit is rated on a scale of 100.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor