Advantages of Using Custom Servo Motors in Your Applications

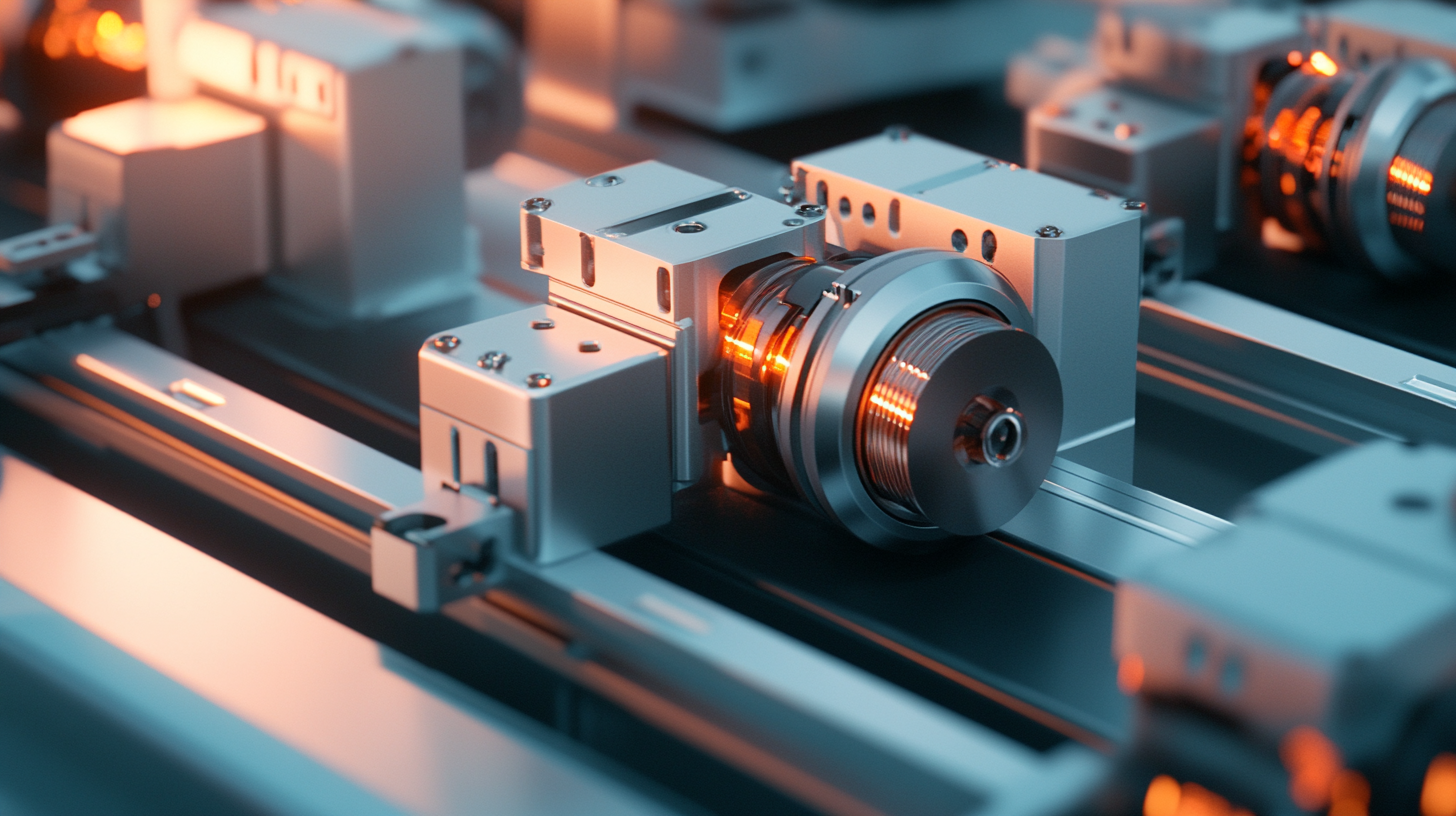

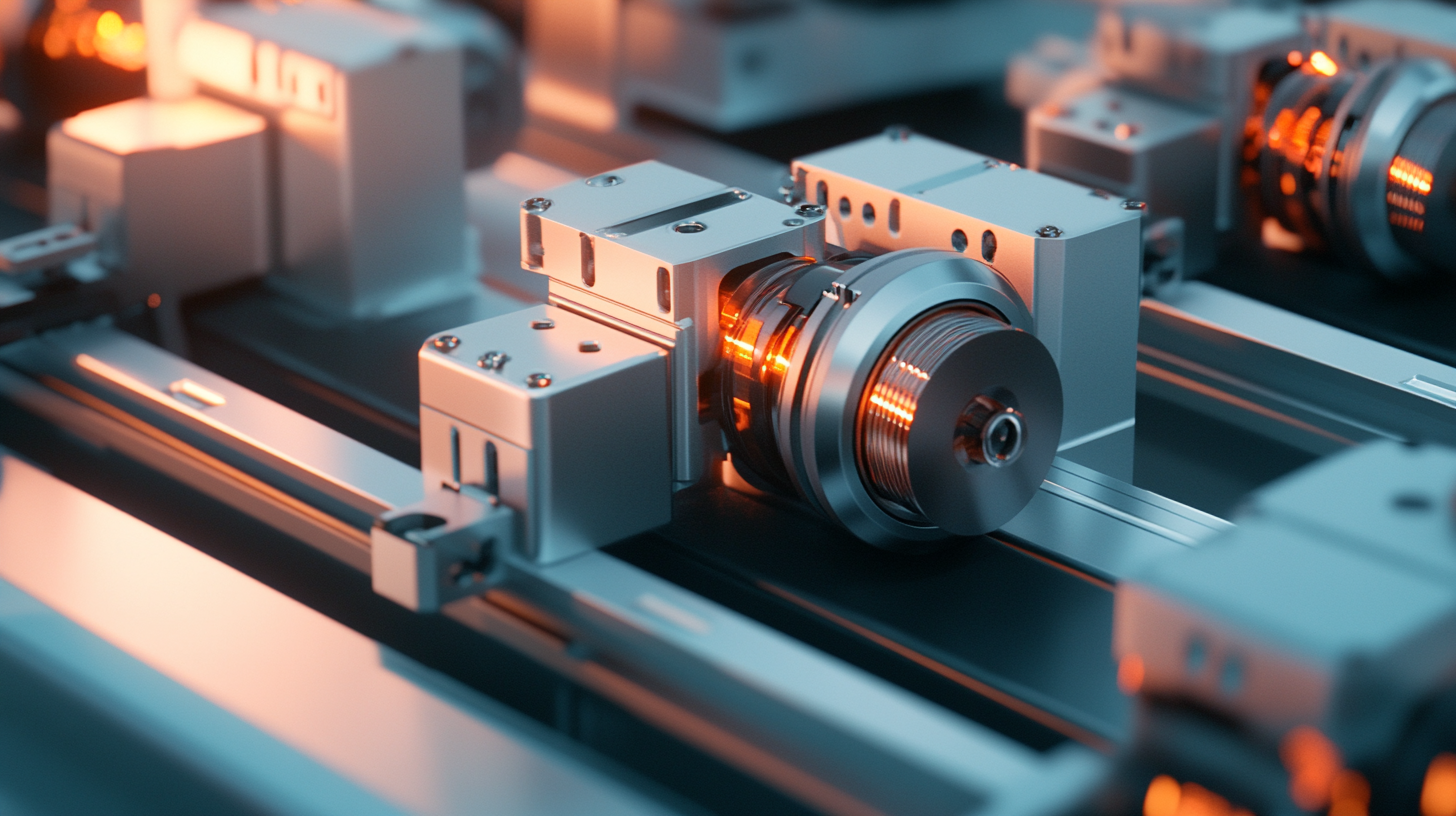

In today's rapidly advancing technological landscape, the demand for precision engineering and enhanced performance in various applications is greater than ever. One of the most effective solutions to meet these demands is the use of Custom Servo Motors. These tailored motors can be designed to provide the exact specifications required for specific projects, allowing engineers and designers to optimize their systems for efficiency, responsiveness, and reliability. By utilizing Custom Servo Motors, businesses can significantly enhance their operational capabilities, paving the way for innovations across multiple industries.

The advantages of integrating Custom Servo Motors into applications extend beyond mere performance improvements; they also offer cost-effectiveness and flexibility. Unlike standard motors, which may force designers to compromise on certain functionalities, custom solutions can be tailored to fit unique operational environments and requirements. This adaptability makes Custom Servo Motors an invaluable asset to industries such as robotics, automation, and automotive engineering, where precision and adaptability are paramount. In this blog, we will explore the various benefits offered by Custom Servo Motors and discuss how they can transform your engineering projects for the better.

Benefits of Tailoring Servo Motors for Specific Industry Needs

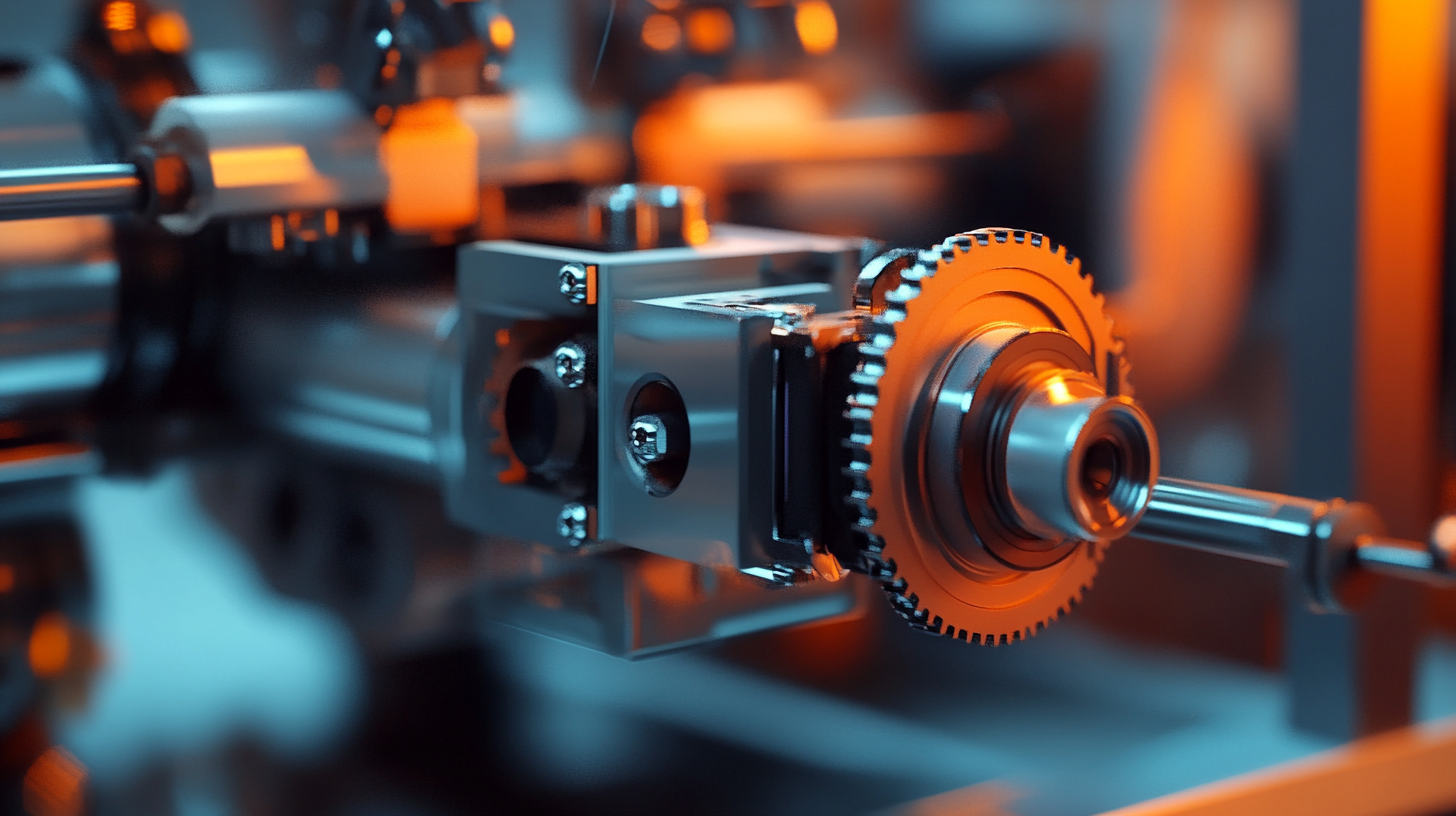

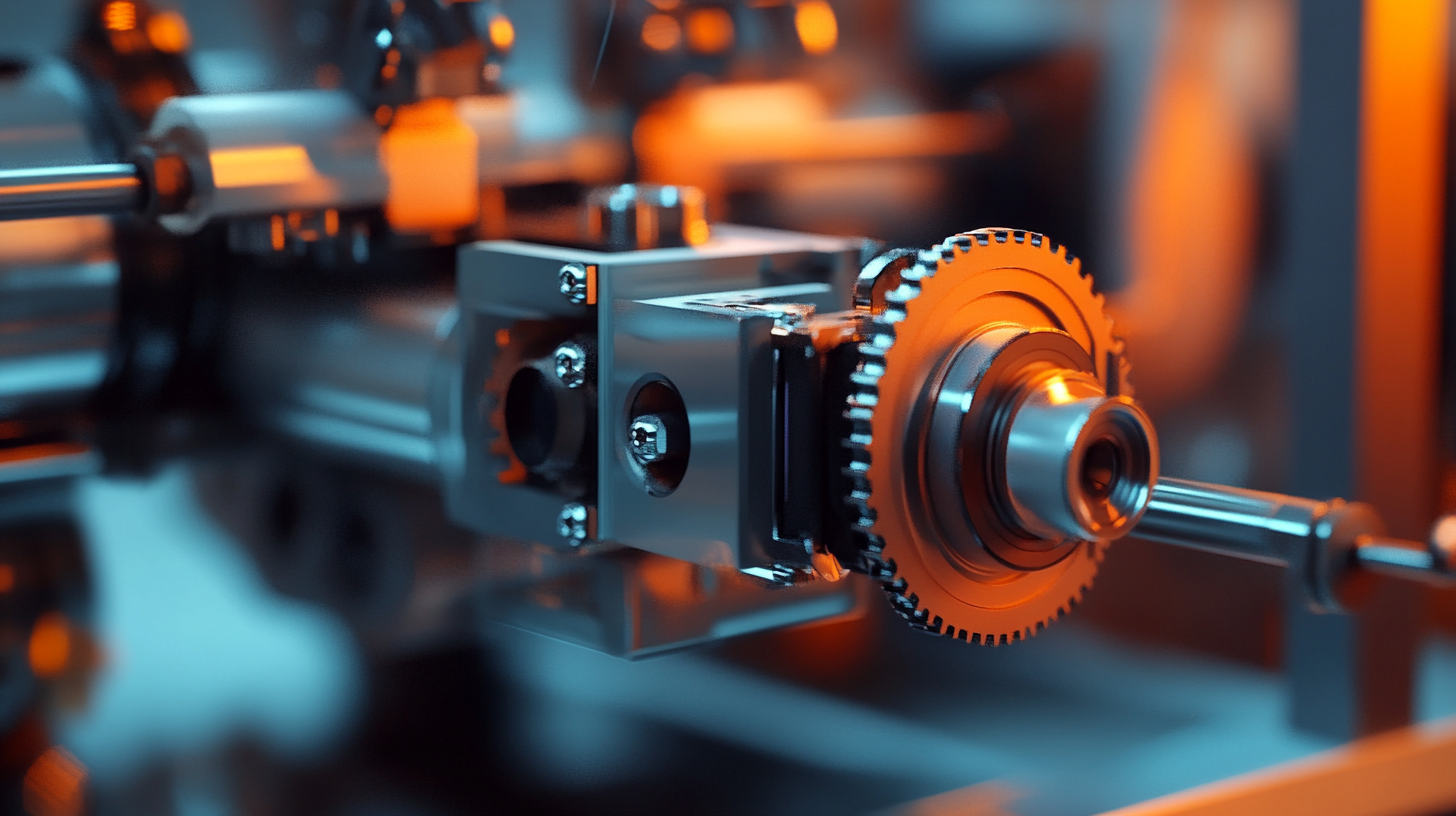

When it comes to optimizing the performance of industrial applications, custom servo motors are leading the way. Their design can be tailored to meet specific industry requirements, providing substantial benefits that standard motors simply cannot match. By customizing servo motors, manufacturers can enhance precision, efficiency, and overall functionality of machinery, aligning with unique operational demands that different sectors face.

For instance, in the textiles industry, the need for high-speed sewing with intricate patterns requires motors that can handle specific load conditions and speed variations. Custom servo motors, with their ability to respond swiftly and accurately, ensure that industrial sewing machines operate at peak performance with minimal downtime. This adaptability not only boosts productivity but also improves the quality of the finished products.

Furthermore, tailoring servo motors for specific applications facilitates energy savings and reduces maintenance costs. Companies can select motor components that are optimized for their unique processes, leading to less wear and tear, and ultimately extending the lifespan of their equipment. As industries continue to evolve, the capacity to implement customized solutions will remain a vital differentiator in maintaining competitive advantage and fostering innovation.

Enhanced Precision and Control in Custom Servo Motor Applications

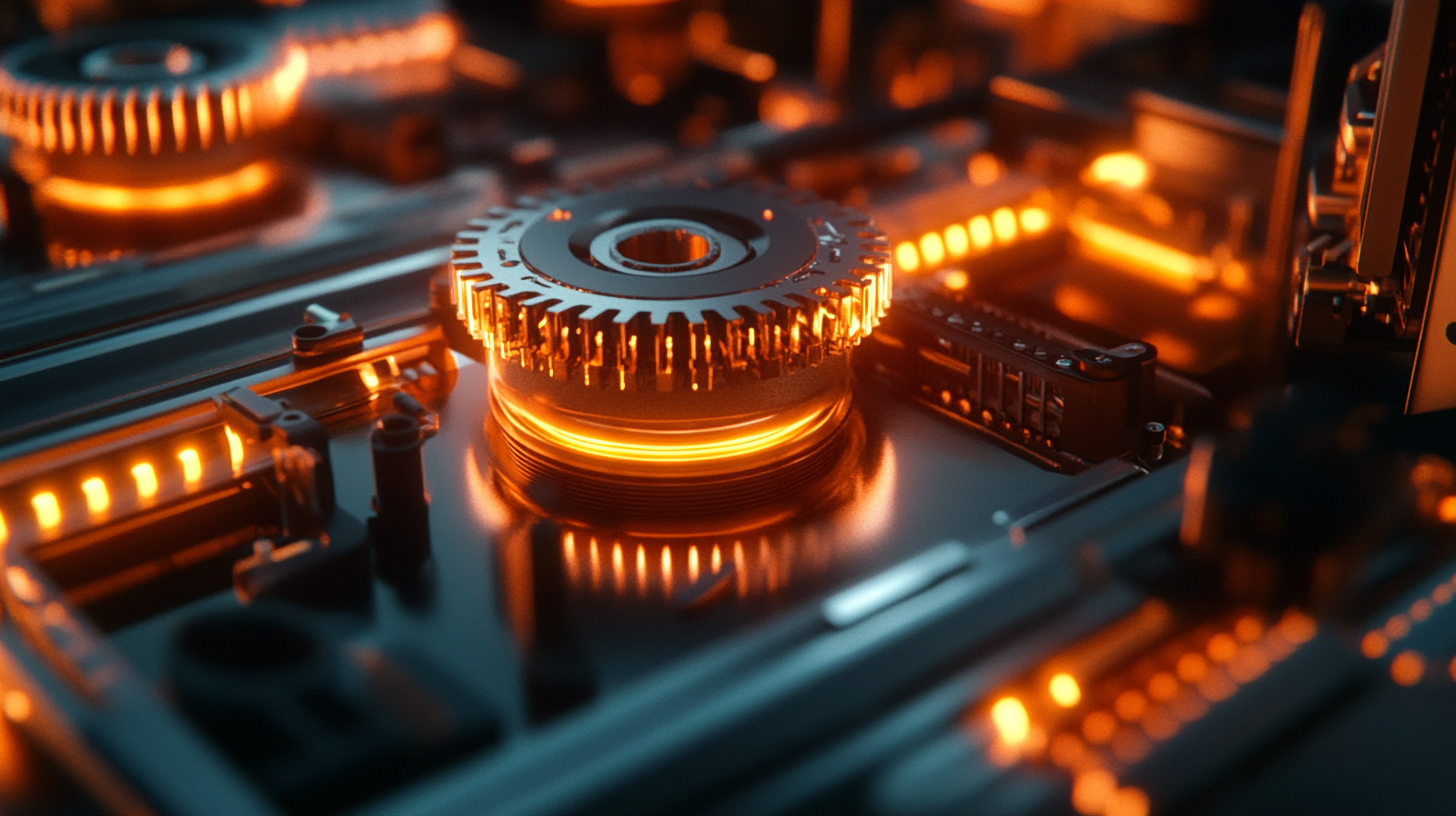

In today's rapidly evolving technological landscape, enhanced precision and control have become critical requirements across various applications, especially in manufacturing and robotics. Custom servo motors stand out as a key solution to meet these demands, offering tailored features that facilitate high-performance operations. According to a report by MarketsandMarkets, the global servo motor market is projected to reach $13.8 billion by 2027, demonstrating a compound annual growth rate (CAGR) of 6.5% from 2022. This growth underscores the significance of precision control as industries seek to optimize production processes.

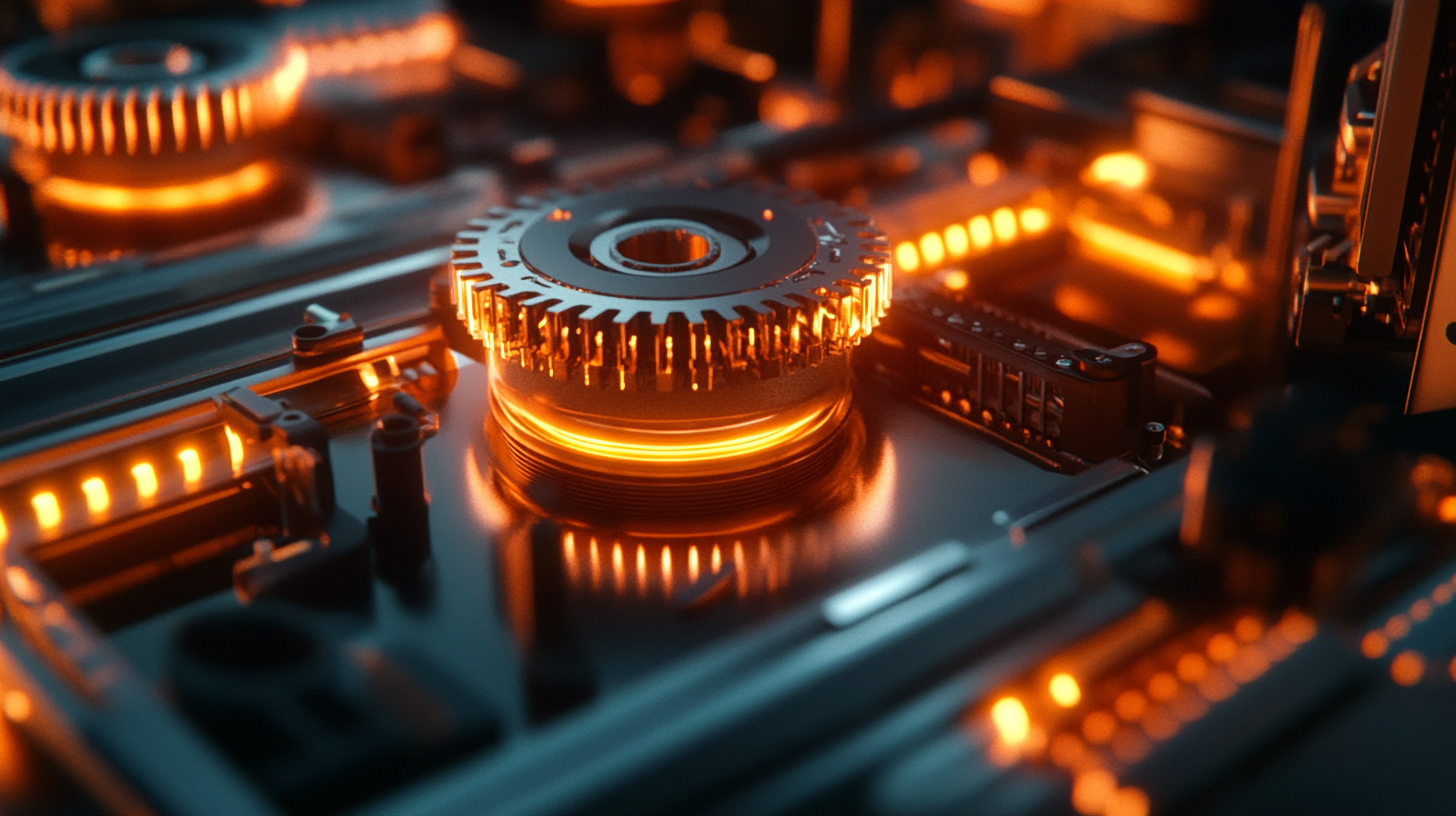

Custom servo motors allow for greater adaptability, enabling engineers to fine-tune specifications such as torque, speed, and response time to fit specific application needs. This customization enhances overall system accuracy, which is crucial in sectors like aerospace and electronics manufacturing, where even minor deviations can cause significant product failures. A case study by the International Journal of Advanced Manufacturing Technology noted that implementing custom servo systems improved manufacturing precision by up to 30%, significantly reducing waste and rework costs.

Moreover, advanced closed-loop control systems employed in custom servo motors provide real-time feedback, ensuring that the motor performance closely aligns with the operational parameters. Enhanced control dynamics lead to smoother motion profiles and eliminate issues like overshoot and hunting. The IEEE Robotics and Automation Society highlights that improved motion control technologies in servos contribute to a 25% increase in system efficiency, further aligning with the industry's push towards automation and precision engineering. As the demand for enhanced control systems continues to grow, custom servo motors will play a pivotal role in the future of automated applications.

Cost-Effectiveness: Long-Term Savings with Custom Servo Motors

When considering automation solutions, the cost-effectiveness of custom servo motors cannot be overstated. While the initial investment may appear higher than standard alternatives, the long-term savings these tailored systems provide can significantly outweigh the upfront costs. Custom servo motors are designed specifically for your application, optimizing performance and efficiency, which leads to reduced operational costs over time.

One of the primary advantages of custom servo motors is their ability to enhance energy efficiency. By ensuring that motors are tailored to meet the precise demands of a specific task, energy consumption can be minimized, leading to lower utility bills. Moreover, with improved performance comes decreased wear and tear on the equipment, resulting in fewer maintenance expenses and longer lifespans for both the motors and related machinery.

Additionally, these custom solutions often increase production speed and accuracy, which contributes further to overall cost savings. With optimized control and functionality, businesses can reduce downtime and improve throughput, translating into heightened productivity. Thus, while the initial cost of custom servo motors may be significant, their long-term benefits in terms of energy savings, reliability, and productivity create a compelling case for their adoption in various applications.

Increased Reliability and Performance in Challenging Environments

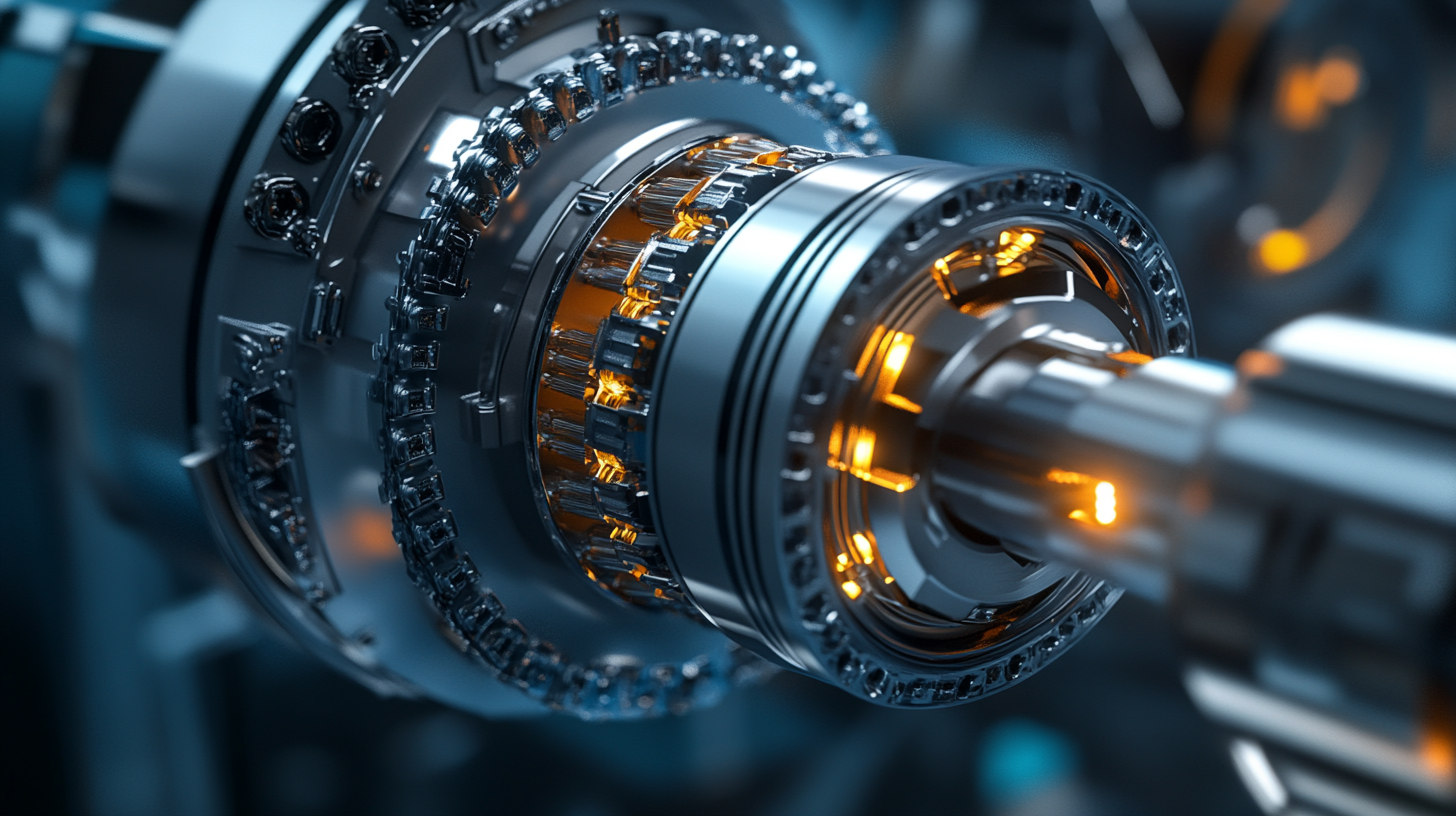

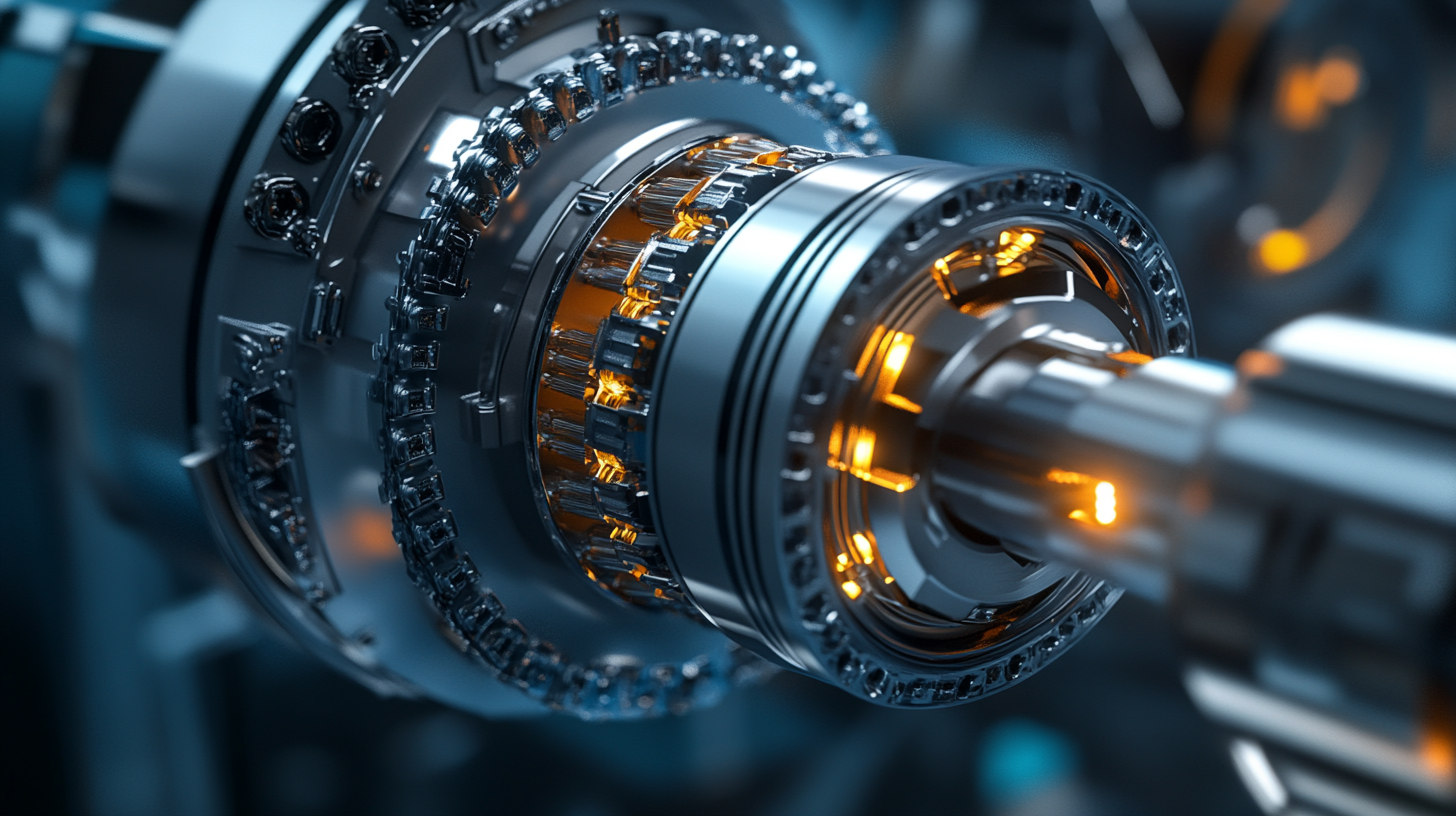

In the realm of advanced applications, the adoption of custom servo motors can significantly enhance reliability and performance in demanding environments. This becomes particularly critical when considering the challenges faced by next-generation power electronics, which require innovative materials and packaging solutions. Recent developments indicate that traditional manufacturing methods may struggle to maintain reliability under high-stress conditions, necessitating a more robust approach that custom servo motors can provide.

Custom servo motors are engineered to withstand extreme conditions and optimize performance in applications ranging from aerospace to automotive. For instance, the use of high-entropy alloys in servo motor construction can result in consistent mechanical behavior across a vast temperature range, from -196 °C to 600 °C. This advancement is crucial for applications that demand durability and reliability in challenging thermal environments, akin to the findings in the latest reliability research that highlights the importance of material science in enhancing electronic performance.

Furthermore, in critical fields such as drone technology, reliability is paramount. As the industry increasingly moves towards Beyond Visual Line of Sight (BVLOS) operations, reliable performance is essential for safety and regulatory compliance. Custom servo motors can play a vital role in ensuring that these systems operate without failure, supporting both performance metrics and safety requirements. The integration of reliable components not only drives operational excellence but also aligns with emerging trends in engineering that focus on maximizing system resilience and reliability.

Flexibility in Design: Adapting Servo Motors to Evolving Technologies

In today’s rapidly evolving technological landscape, the need for flexibility in design is more crucial than ever. Custom servo motors emerge as a powerful solution, enabling engineers to tailor their applications to meet specific requirements and adapt to new advancements. By modifying parameters such as size, torque, and control methods, businesses can create servo motors that are perfectly aligned with their operational demands, ensuring optimal performance.

This adaptability not only enhances the functionality of the servo motors but also allows for seamless integration into existing systems. As industries migrate towards automation and smart technologies, custom servo motors can be designed to interact with new sensors and software platforms. This ensures that businesses remain competitive and can quickly respond to emerging trends without overhauling entire systems.

Moreover, the ability to customize servo motors extends to their application environments. Whether in robotics, aerospace, or medical devices, specific requirements can dictate motor characteristics. Custom designs can accommodate unique conditions, such as extreme temperatures or space constraints, thereby maximizing efficiency and reliability. By embracing the flexibility offered by custom servo motors, companies can future-proof their technology, ensuring longevity and adaptability in a fast-paced world.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor