Understanding the Benefits of Nordmkygearbox: Revolutionizing Gearbox Technology for Modern Applications

In an era where technological advancements dictate the efficiency and functionality of various applications,

the Nordmkygearbox emerges as a game-changer in gearbox technology.

This innovative system not only enhances performance but also addresses the unique challenges faced by modern machinery.

By integrating digital solutions with cutting-edge engineering, Nordmkygearbox provides a seamless blend of precision, durability,

and energy efficiency. As industries continue to pursue smarter, more sustainable solutions,

the advantages of Nordmkygearbox become increasingly clear, offering substantial benefits such as

reduced maintenance costs, improved power transmission, and a significant enhancement in operational reliability.

In this exploration, we will delve deeper into the transformative impact of Nordmkygearbox on contemporary applications,

showcasing how it stands at the forefront of a technological revolution in the gearbox domain.

Key Features of Nordmkygearbox: Enhancing Performance in Modern Machinery

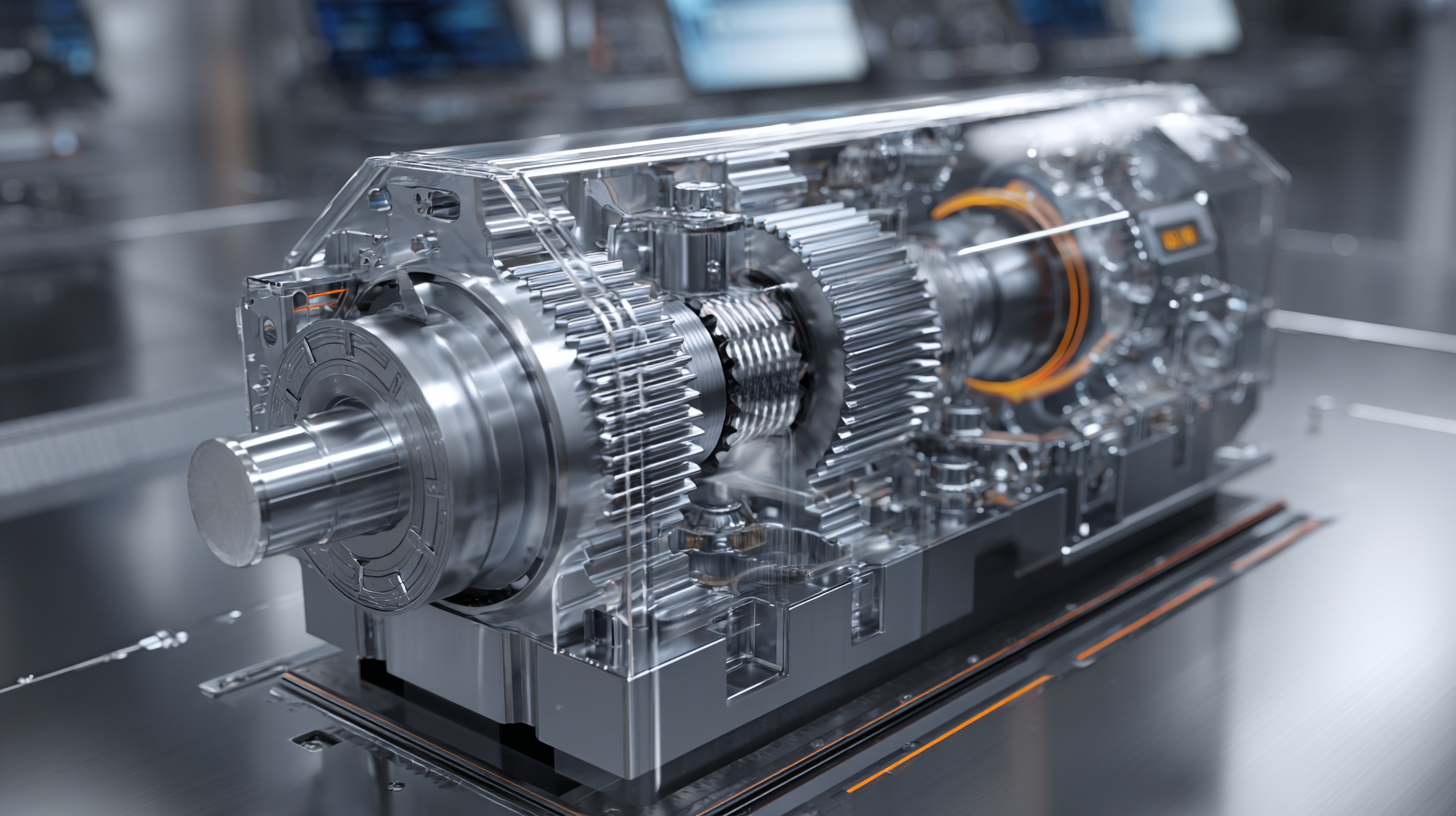

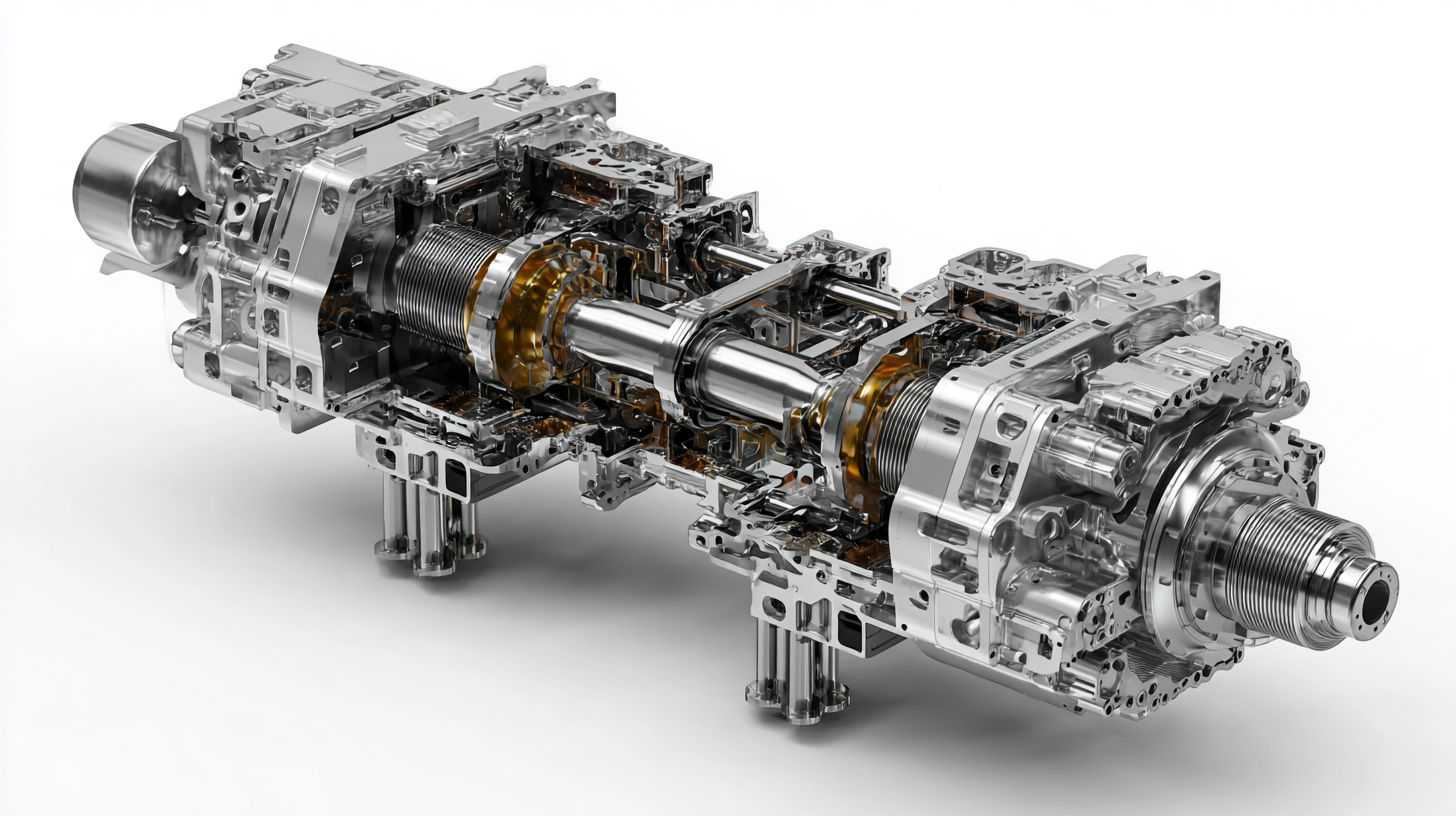

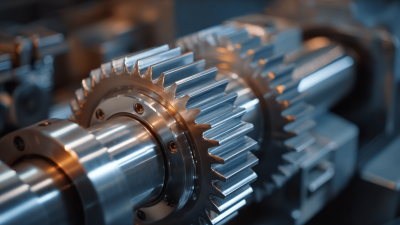

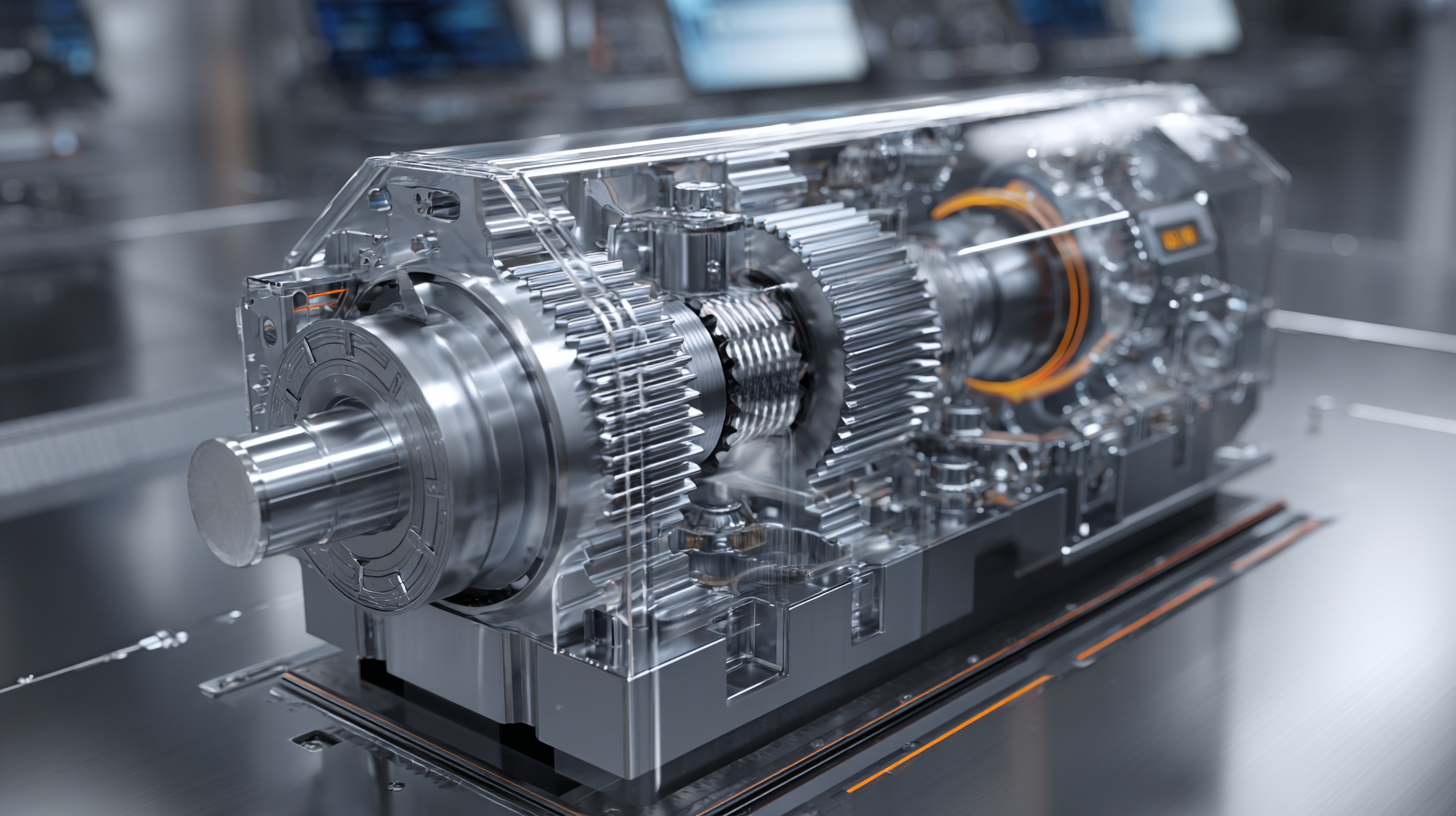

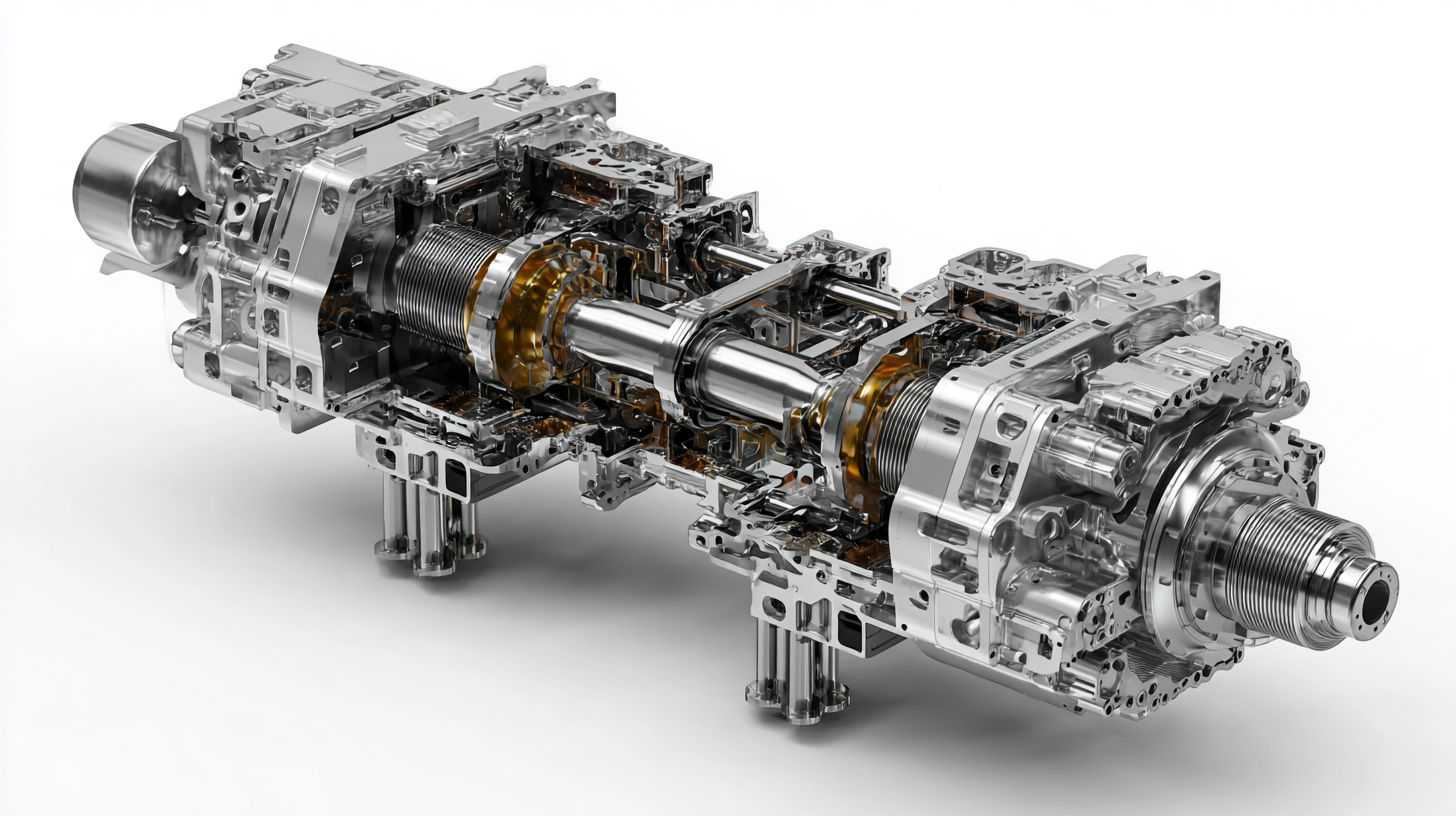

The Nordmkygearbox is a game-changer in gearbox technology, bringing significant advancements that cater to modern machinery needs. One of its key features is its superior efficiency, allowing for smoother operation and reduced energy consumption. This enhanced efficiency is particularly beneficial in industries where energy costs are a major concern, thus leading to significant savings over time. Engineers and operators can expect notably longer operational lifespans for their equipment due to this innovative design.

Another remarkable aspect of the Nordmkygearbox is its lightweight construction without compromising durability. This design feature facilitates easier installation and significantly reduces the overall weight of machinery, which is crucial for applications like robotics and automotive engineering. Additionally, the gearbox is engineered to handle high torque while maintaining consistent performance, making it suitable for demanding applications. With built-in adaptability, the Nordmkygearbox can seamlessly integrate into a variety of systems, enhancing overall effectiveness and productivity in diverse industrial scenarios.

Understanding the Benefits of Nordmkygearbox: Revolutionizing Gearbox Technology for Modern Applications

| Feature |

Description |

Benefit |

| High Efficiency |

Designed for minimal energy loss during operation |

Reduced operational costs and lower energy consumption |

| Compact Design |

Space-saving structure suitable for tight installations |

Easier integration into various machinery |

| Durability |

Robust materials designed to withstand high stress |

Longer service life and reduced maintenance needs |

| Advanced Technology |

Incorporates the latest innovations in gearbox design |

Increased performance and reliability in applications |

| Versatility |

Applicable across a wide range of industries and machines |

Greater adaptability for diverse operational needs |

Innovative Design Elements: How Nordmkygearbox Sets Itself Apart from Traditional Gearboxes

The Nordmkygearbox has emerged as a game changer in the gearbox technology sector, primarily due to its innovative design elements that distinguish it from traditional gearboxes. One of the standout features of the Nordmkygearbox is its modular construction, which allows for greater customization according to specific application needs. According to a recent report by Research and Markets, the global demand for customized gearbox solutions has driven the market growth, projecting a CAGR of 5.6% from 2023 to 2030. This adaptability is particularly advantageous in industries such as robotics and manufacturing, where precision and efficiency are paramount.

Moreover, the Nordmkygearbox incorporates advanced materials and manufacturing techniques, leading to significant reductions in weight and size while enhancing durability. The American Gear Manufacturers Association (AGMA) states that lightweight gear systems can improve overall machine efficiency by up to 20%, translating into lower energy consumption and operating costs. The innovative bearing arrangements and lubrication systems further reduce friction and wear, ensuring longer service life and reliability, critical factors for industries that rely on continuous operation. As companies continue to seek higher performance and cost-effective solutions, the Nordmkygearbox stands poised to lead the way in modern gearbox technology.

Applications of Nordmkygearbox: Meeting the Demands of Various Industries

The Nordmkygearbox is at the forefront of gearbox technology, meeting the diverse demands of modern industries such as automotive, aerospace, and renewable energy. In the automotive sector, gear efficiency directly influences fuel economy and emissions. According to a 2022 report from the Society of Automotive Engineers (SAE), advanced gearbox designs like the Nordmkygearbox can improve fuel efficiency by up to 10%, making vehicles not only more economical but also more environmentally friendly.

In aerospace, where performance and reliability are paramount, Nordmkygearbox technologies have shown to enhance power-to-weight ratios significantly. A 2023 study by the American Institute of Aeronautics and Astronautics (AIAA) indicated that utilizing cutting-edge gearbox solutions contributed to a weight reduction of up to 15% in aircraft, thereby improving overall operational efficiency and reducing fuel consumption for airlines.

The versatility of the Nordmkygearbox also extends to renewable energy applications, where its robust design can withstand harsh conditions while maximizing energy transfer efficiency. These advancements are crucial for the renewable sector, which aims to optimize performance as it scales to meet increasing global energy demands.

Installation and Maintenance Tips for Maximizing Nordmkygearbox Efficiency

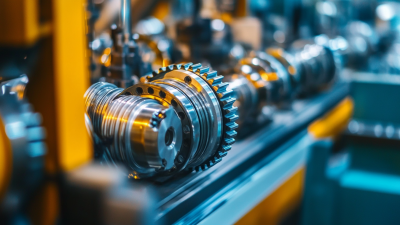

When it comes to maximizing the efficiency of the Nordmkygearbox, proper installation and maintenance are key factors that can significantly enhance its performance. First and foremost, users should ensure that the gearbox is installed in accordance with the manufacturer’s specifications. This includes checking alignment, securing the mounting bolts adequately, and ensuring that all electrical and hydraulic connections are properly made. Adequate lubrication is also crucial; selecting the right type of lubricant and replacing it regularly can prevent overheating and reduce wear and tear on the internal components.

Regular maintenance routines play an essential role in keeping the Nordmkygearbox running smoothly. Periodic inspections to detect any signs of wear, such as unusual noises or vibrations, can help identify potential issues before they escalate. Additionally, keeping the gearbox clean from contaminants will prevent damage and prolong its lifespan. Implementing a proactive maintenance schedule, which includes timely lubrication changes and the replacement of worn-out parts, will not only optimize efficiency but also minimize the risk of unexpected breakdowns, ensuring reliable performance in modern applications.

Cost-Benefit Analysis: Understanding the Value Proposition of Nordmkygearbox Technology

The Nordmkygearbox represents a significant advancement in gearbox technology, offering an array of benefits that enhance its appeal for modern industrial applications. A key aspect of its value proposition lies in its cost-efficiency. By integrating innovative design and advanced materials, Nordmkygearbox reduces energy losses and optimizes performance, leading to substantial savings in operational costs over time. This technology not only lowers initial investment requirements but also minimizes maintenance expenses, making it an attractive option for businesses aimed at long-term profitability.

Moreover, the durability and reliability of Nordmkygearbox contribute to its cost-benefit analysis. The advanced engineering reduces wear and tear, extending the lifespan of the gearbox and decreasing replacement frequency. Additionally, its lightweight design can improve overall system efficiency, allowing for enhanced productivity without the need for significant retrofitting of existing infrastructure. As organizations increasingly pursue cost-effective solutions, the Nordmkygearbox stands out as a transformative technology that offers both immediate and sustained economic advantages.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor