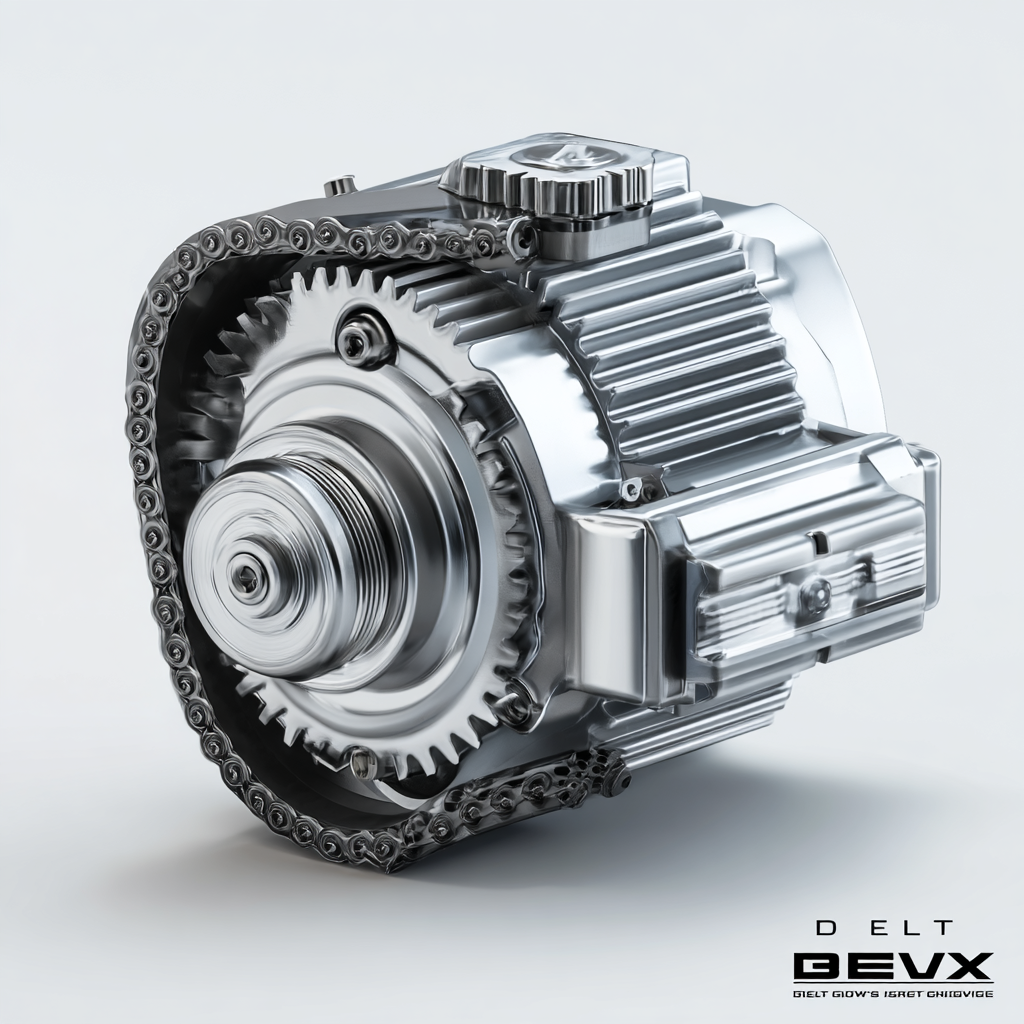

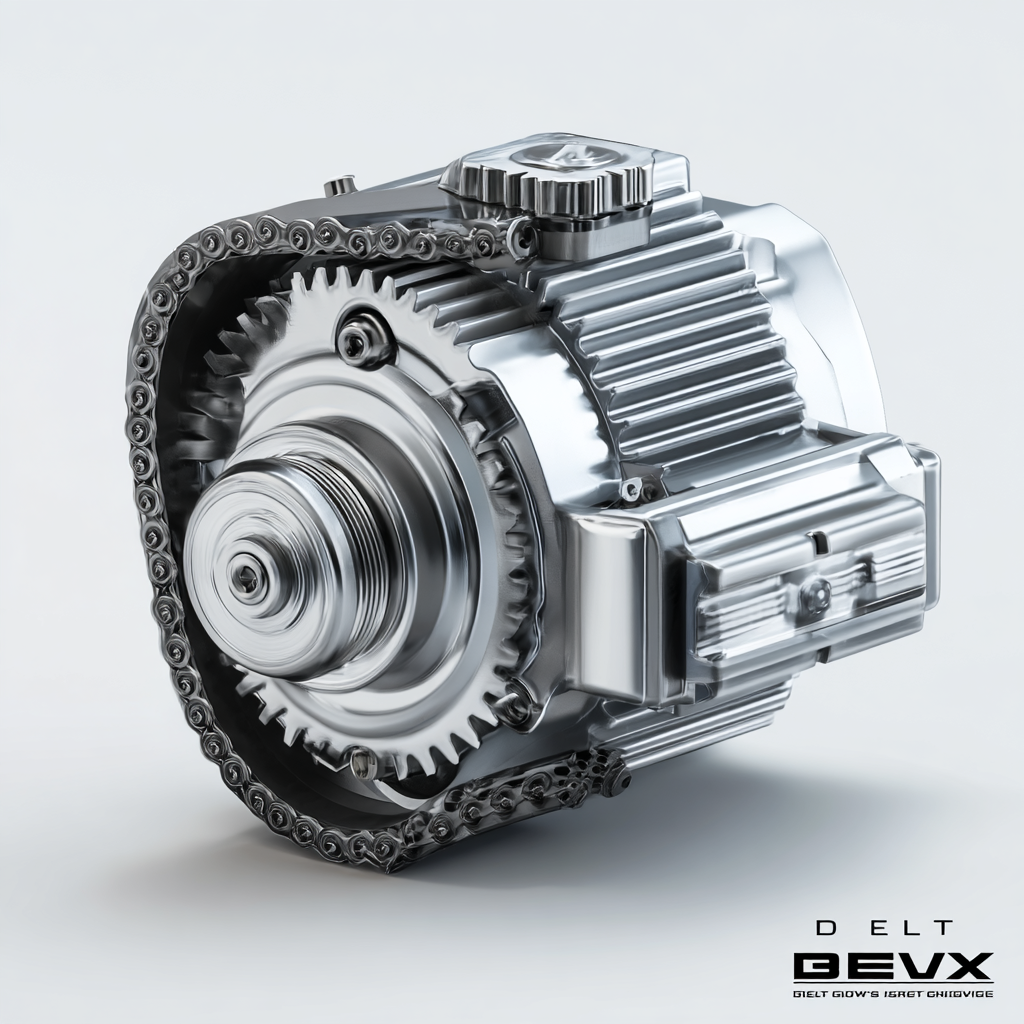

7 Reasons Why the Best Belt Drive Gearbox Stands Out from the Rest

As the manufacturing sector evolves towards Industry 4.0 and beyond,

the significance of efficient power transmission systems cannot be overstated.

Among these, the Belt Drive Gearbox has emerged as a crucial component in various applications,

from automotive to industrial machinery. According to a recent industry report by MarketsandMarkets,

the global belt drive market is projected to reach USD 15 billion by 2025,

reflecting a compound annual growth rate (CAGR) of 4.8%.

This growth is driven by the increasing demand for energy-efficient solutions and the ongoing advancements in gearbox technologies.

In light of these trends, it is essential to understand why the Belt Drive Gearbox stands out from the rest,

particularly in terms of performance, reliability, and adaptability to modern manufacturing needs.

This blog will delve into seven key reasons that highlight the competitive edge of

top-tier belt drive gearboxes.

Identifying Key Features of High-Quality Belt Drive Gearboxes

When it comes to belt drive gearboxes, distinguishing high-quality options from the average is essential for optimal performance and longevity. Key features that set the best models apart include

superior materials, precision engineering, and advanced thermal management systems. According to a recent report from the Global Transmission Market 2023, gearboxes made with high-grade alloys and advanced composites show a significant reduction in wear rates, which can extend operational lifetimes by 20% or more.

When selecting a belt drive gearbox, consider the design and build quality carefully. A well-crafted gearbox with precise tolerances ensures smooth operation and reduces vibration, leading to improved efficiency. Look for products that are backed by industry certifications, as these often indicate rigorous testing and adherence to quality standards.

Utilize tools such as vibration analysis to assess real-time performance—this proactive approach can help prevent costly downtime.

Tip: Always check the specifications for load ratings and temperature limits; this information is crucial in matching the gearbox to your operational requirements. Additionally, examining user reviews and real-world performance data can provide valuable insights into the reliability and effectiveness of different brands and models.

Evaluating Supplier Credentials for Optimal Gearbox Performance

When it comes to selecting a belt drive gearbox, evaluating the credentials of potential suppliers is crucial for ensuring optimal performance. A reputable supplier should have a solid history of manufacturing high-quality gearboxes that meet industry standards. Investigating their certifications, such as ISO accreditation, can provide insight into their commitment to quality and excellence. Additionally, reviewing their experience in the field can help gauge their ability to address specific application needs, ensuring that you invest in a product that meets your operational demands.

Furthermore, understanding a supplier's customer service and support capabilities is essential. A supplier that offers comprehensive technical support and responsive communication can make a significant difference in handling any issues that arise post-purchase. Look for testimonials or case studies that demonstrate their track record of reliability and customer satisfaction. By thoroughly evaluating supplier credentials, businesses can confidently choose a belt drive gearbox that not only stands out for its mechanical performance but also comes from a supplier dedicated to facilitating long-term success.

Gearbox Performance Evaluation

Top Strategies for Sourcing Reliable Belt Drive Gearbox Manufacturers

When sourcing reliable belt drive gearbox manufacturers, it’s crucial to adopt effective strategies that ensure quality and performance. One of the primary tips is to conduct thorough research on potential manufacturers. Check for industry certifications, customer reviews, and their track record in producing high-quality gearboxes. A strong reputation in the market often indicates reliability and attention to detail, essential for long-lasting equipment.

Another key strategy is to engage with manufacturers directly. Establishing open communication can help you assess their expertise and responsiveness. Ask questions about their production processes, materials used, and warranty policies. A manufacturer willing to provide detailed information demonstrates transparency and confidence in their products, which can give you peace of mind when making a purchase.

Finally, consider the importance of customization. The best manufacturers will work with you to tailor their products to your specific needs, ensuring optimal performance in your applications. Investing time in finding a manufacturer that offers customized solutions along with standard models can significantly enhance the efficiency and longevity of your belt drive gearboxes.

Understanding the Importance of Material Quality in Gearbox Selection

When selecting a gearbox, the material quality is paramount, significantly influencing durability, efficiency, and operational safety. According to a study by the American Gear Manufacturers Association (AGMA), nearly 60% of gearbox failures can be traced back to substandard materials. High-quality steel, for instance, exhibits superior tensile strength and fatigue resistance compared to lower-grade alternatives, allowing it to withstand larger loads and reduce the risk of mechanical failure.

When selecting a gearbox, the material quality is paramount, significantly influencing durability, efficiency, and operational safety. According to a study by the American Gear Manufacturers Association (AGMA), nearly 60% of gearbox failures can be traced back to substandard materials. High-quality steel, for instance, exhibits superior tensile strength and fatigue resistance compared to lower-grade alternatives, allowing it to withstand larger loads and reduce the risk of mechanical failure.

Moreover, utilizing advanced materials such as carbon fiber composites can enhance performance in various applications. The Composite Materials Handbook indicates that such materials can reduce weight by up to 30% while maintaining structural integrity, which is crucial in industries demanding high torque and low weight, like aerospace and automotive. Investing in gearboxes made with high-grade materials not only extends the lifespan of the equipment but also optimizes energy efficiency. Studies show that gearboxes built from premium materials can improve overall efficiency by up to 15%, highlighting the critical role of material selection in gearbox longevity and performance.

Maximizing Value: Cost vs. Quality in Belt Drive Gearbox Purchases

When it comes to purchasing a belt drive gearbox, the balance between cost and quality is critical. Opting for a low-cost option may save money initially, but it could lead to higher maintenance costs and reduced efficiency over time. Investing in a high-quality gearbox from reputable manufacturers ensures reliability, longevity, and superior performance. Remember, a well-constructed gearbox can enhance your machinery’s overall productivity, making it a cost-effective choice in the long run.

Tip: Always analyze the total cost of ownership rather than just the purchase price. Consider factors like maintenance intervals, warranty coverage, and energy consumption. Often, a slightly higher upfront cost can translate into significant savings over the product’s lifespan.

Moreover, when selecting a gearbox, don’t overlook the materials used in its design. High-quality materials such as steel and aluminum can withstand wear and tear better than cheaper alternatives. This not only increases durability but also maintains the gearbox's efficiency under heavy loads.

Tip: Check for certifications and user testimonials to gauge the quality of the gearbox. A trustworthy product typically comes with positive reviews and industry certifications, ensuring you are making a wise investment.

7 Reasons Why the Best Belt Drive Gearbox Stands Out from the Rest - Maximizing Value: Cost vs. Quality in Belt Drive Gearbox Purchases

| Feature |

Best Quality Gearbox |

Average Quality Gearbox |

Lower Quality Gearbox |

| Material Used |

High-grade Steel |

Standard Steel |

Low-grade Steel |

| Efficiency Rate |

95% |

85% |

75% |

| Noise Level (dB) |

50 |

60 |

70 |

| Lifespan (Years) |

15+ |

10 |

5 |

| Warranty Period |

5 Years |

3 Years |

1 Year |

| Maintenance Cost (Annually) |

$200 |

$400 |

$600 |

| Cost |

$1,500 |

$1,000 |

$600 |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor

When selecting a gearbox, the material quality is paramount, significantly influencing durability, efficiency, and operational safety. According to a study by the American Gear Manufacturers Association (AGMA), nearly 60% of gearbox failures can be traced back to substandard materials. High-quality steel, for instance, exhibits superior tensile strength and fatigue resistance compared to lower-grade alternatives, allowing it to withstand larger loads and reduce the risk of mechanical failure.

When selecting a gearbox, the material quality is paramount, significantly influencing durability, efficiency, and operational safety. According to a study by the American Gear Manufacturers Association (AGMA), nearly 60% of gearbox failures can be traced back to substandard materials. High-quality steel, for instance, exhibits superior tensile strength and fatigue resistance compared to lower-grade alternatives, allowing it to withstand larger loads and reduce the risk of mechanical failure.