Mastering Bevel Helical Gearboxes: A Comprehensive Guide to Installation and Maintenance

In the world of mechanical engineering, the Bevel Helical Gearbox stands out as a crucial component for enhancing power transmission and improving efficiency in various applications. This sophisticated gearing mechanism combines the strengths of both bevel and helical gear designs, allowing for seamless operation even in challenging industrial environments. As industries continue to seek higher performance levels and greater reliability from their machinery, understanding the installation and maintenance of Bevel Helical Gearboxes has become essential for engineers and technicians alike. This comprehensive guide aims to provide a deep dive into the intricacies of these gearboxes, detailing the best practices for installation and key maintenance strategies to ensure optimal performance and longevity. Whether you're new to the field or an experienced professional, mastering the nuances of Bevel Helical Gearboxes will empower you to make informed decisions that enhance operational effectiveness.

Understanding Bevel Helical Gearboxes: Design and Functionality

Bevel helical gearboxes represent a sophisticated blend of design and functionality, making them vital components in mechanical systems requiring efficient power transfer and space optimization. At their core, these gearboxes utilize conical involute gears, commonly known as beveloid gears, which derive their geometry from the foundational design of cylindrical involute gears. This unique construction enables them to effectively manage power transmission at various angles, making them ideal for applications in 4WD gear units where robust and reliable performance is crucial.

The effective design of bevel helical gearboxes hinges on their ability to combine both rotational motions while minimizing backlash and enhancing load-bearing capacities. The three-stage spur gear drive, in conjunction with a bevel gear stage, exemplifies this synergy, resulting in finely tuned systems that maintain efficiency even under heavy loads. Additionally, advancements in automated design synthesis utilizing graph-based techniques allow for more innovative and precise gear configurations, streamlining the installation and maintenance processes. Such developments not only improve gear performance but also extend their longevity, lessening the frequency of repairs and ensuring consistent output in demanding environments.

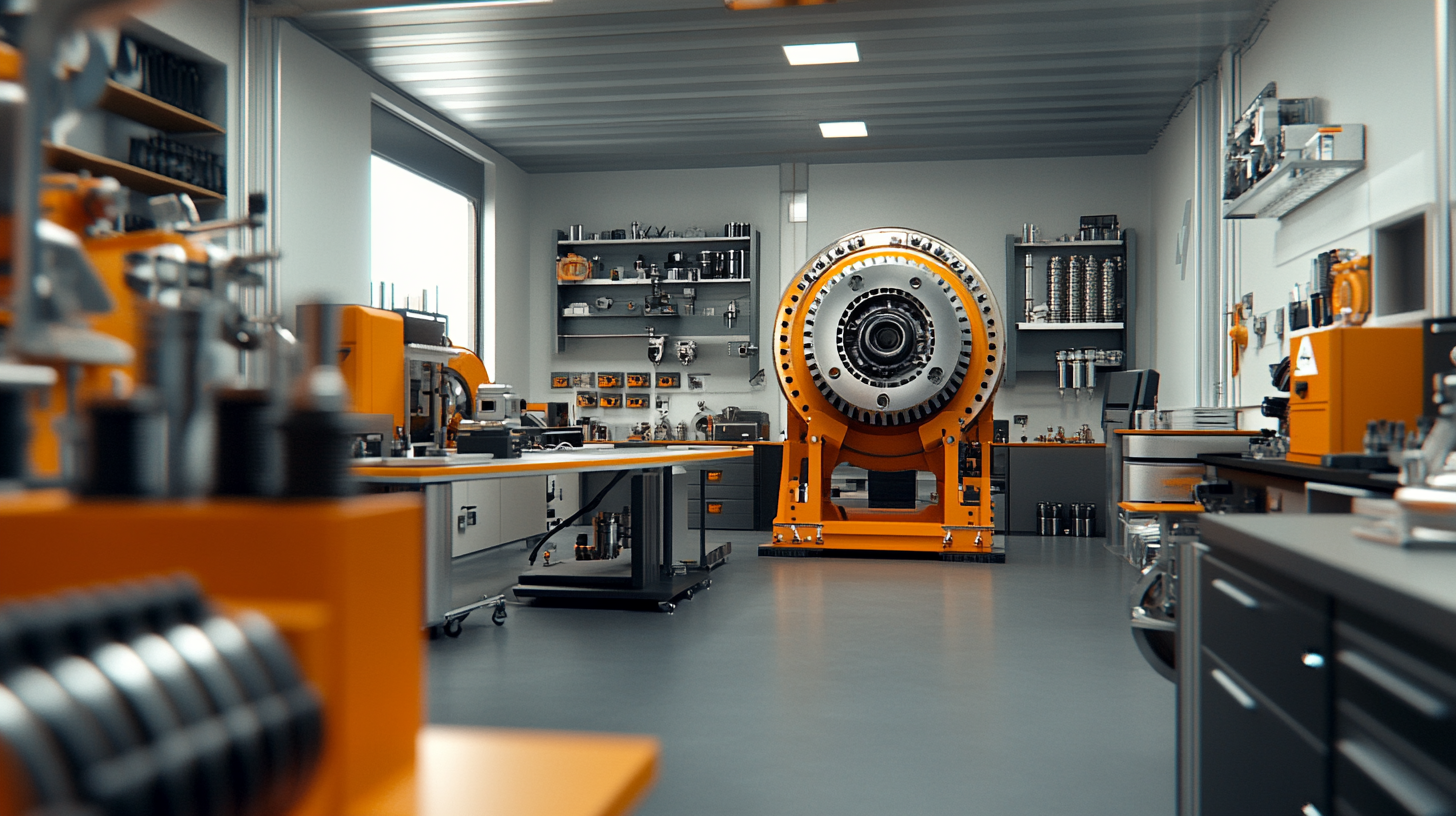

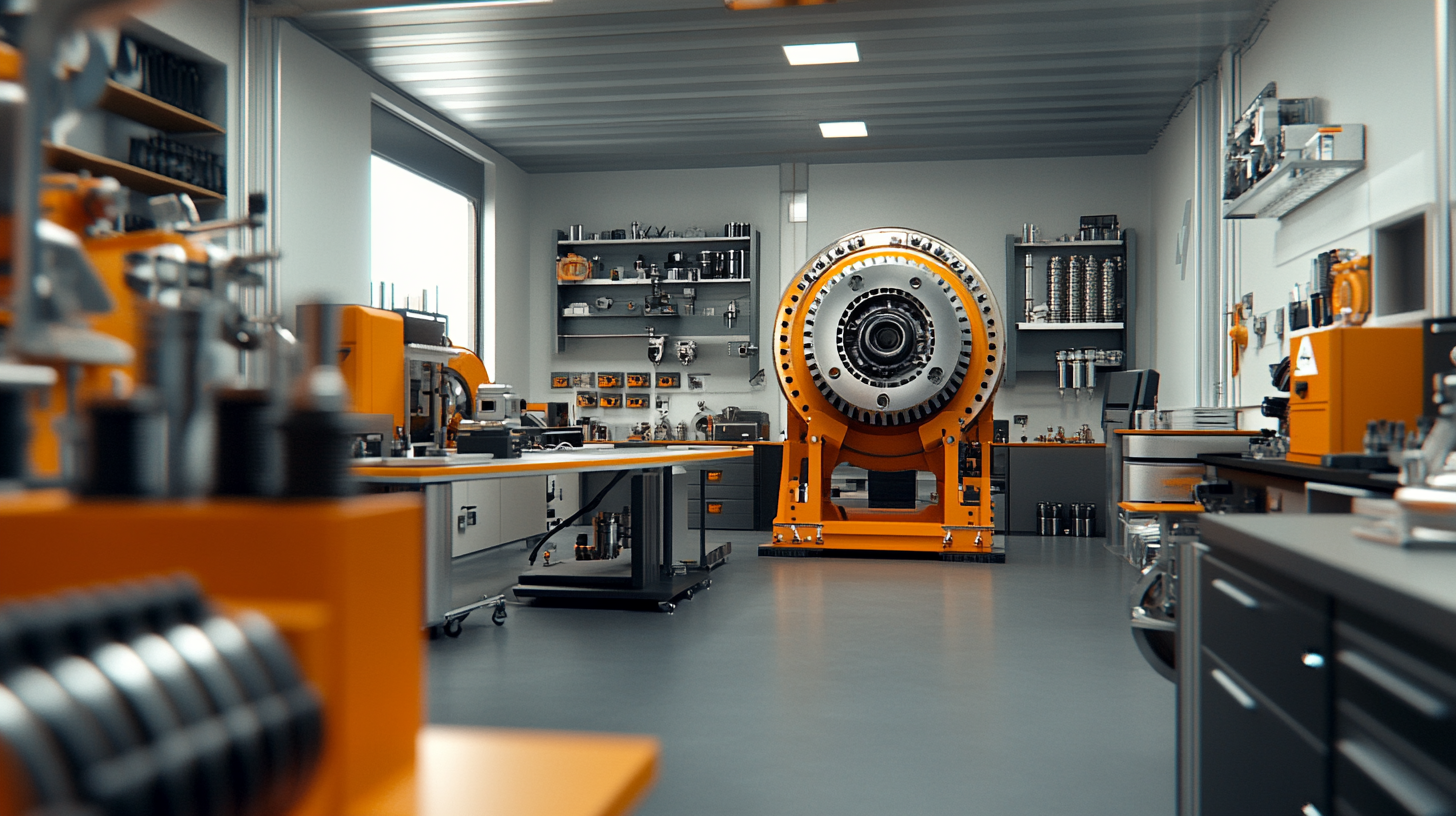

Essential Tools and Equipment for Installing Bevel Helical Gearboxes

When it comes to the installation of bevel helical gearboxes, having the right tools and equipment is paramount to achieving optimal performance and longevity. Essential tools include precision measuring instruments, such as calipers and micrometers, which help ensure accurate alignment and fit of gear components. Additionally, a robust set of wrenches, screwdrivers, and torque tools are critical for securing fasteners to the manufacturer's specifications, as improper torque can lead to premature wear or failure of the gearbox.

Beyond traditional hand tools, specialized equipment is often required for the installation process. For instance, gear alignment tools are invaluable for achieving the correct setup, as misalignment can result in increased friction and energy loss. Moreover, a hydraulic lifting device can assist in maneuvering large and heavy gearboxes safely into position. Investing in quality tools not only facilitates a smoother installation process but also enhances maintenance practices, thereby ensuring the gearbox operates efficiently over its lifespan.

Step-by-Step Guide to Installing Bevel Helical Gearboxes

Installing bevel helical gearboxes can seem daunting, but with the right approach, it becomes a manageable task. Begin by ensuring that you have all necessary tools and equipment at hand. Gather the gearbox, mounting hardware, and any required lubrication. It's essential to inspect the gearbox before installation to check for any shipping damage or defects. Make sure to consult the manufacturer's specifications for dimensions and mounting requirements to ensure a proper fit.

Next, prepare the mounting surface to ensure it is clean and level. This will help prevent misalignment, which can lead to premature wear or failure of the gearbox. Position the gearbox carefully on the mount, aligning the input and output shafts as per the outlined specifications. Using the correct torque settings as recommended, secure the gearbox with the appropriate fasteners, ensuring that each bolt is tightened uniformly to maintain balance.

Finally, once the gearbox is installed, it is crucial to perform a thorough check of the installation. Verify that all connections are tight and that the gearbox operates smoothly without any unusual noise. Implementing these steps will not only ensure a successful installation but will also set the foundation for effective maintenance of the bevel helical gearbox in the future.

Routine Maintenance Practices for Optimal Performance

Routine maintenance practices are crucial for ensuring the optimal performance of bevel helical gearboxes. According to a report from the American Gear Manufacturers Association, improper maintenance can reduce the lifespan of gearboxes by up to 50%. Regular inspection of gear alignment, lubrication levels, and wear patterns can significantly mitigate the risk of mechanical failure. Specifically, an effective lubrication strategy that adheres to manufacturer specifications is vital, as it helps to minimize friction and heat generation during operation.

Furthermore, periodic analysis of vibration and noise levels can serve as early indicators of potential issues. The International Organization for Standardization (ISO) suggests that equipment experiencing vibrations exceeding acceptable limits should undergo immediate servicing to avoid catastrophic failures. Implementing a routine schedule for these maintenance tasks can enhance both reliability and efficiency, which are key considerations in high-demand industries. A well-maintained bevel helical gearbox not only improves productivity but also optimizes energy consumption, aligning with findings from recent industry studies that emphasize maintenance as a critical component of operational excellence.

Common Issues and Troubleshooting Techniques for Bevel Helical Gearboxes

Bevel helical gearboxes are essential components in many mechanical systems, but like any machine, they can encounter issues that disrupt performance. Common problems include abnormal noise, overheating, and difficulty in engagement. Noise, often caused by misalignment or worn gears, can be particularly telling. Regular troubleshooting should involve checking the alignment of the input and output shafts and inspecting gear teeth for signs of wear. Addressing these issues promptly can help maintain the integrity of the gearbox and extend its lifespan.

Another prevalent issue is overheating, which can stem from excessive load, insufficient lubrication, or ventilation problems. It’s crucial to monitor operating temperatures and ensure that the gearbox is adequately cooled and lubricated. Regular maintenance checks should include verifying lubricant levels and the condition of cooling systems. If overheating occurs, reducing the load and allowing the gearbox to cool down before further operation is advisable.

Finally, difficulties in gear engagement may arise due to incorrect input speed or wear on the gear teeth. This can lead to reduced efficiency or even system failure. Troubleshooting this issue involves inspecting the gearbox for any signs of damage and ensuring that the input speed and torque ratings are within the manufacturer’s recommendations. Applying these troubleshooting techniques can significantly improve the performance and reliability of bevel helical gearboxes.

Mastering Bevel Helical Gearboxes: Common Issues Distribution

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor