How to Choose the Right Fluid Coupling for Your Industrial Application

In the realm of industrial applications, the selection of the appropriate fluid coupling can significantly enhance performance and operational efficiency. As emphasized by industry expert Dr. Jane Smith, a leading specialist in mechanical transmission systems, "Choosing the right fluid coupling is crucial for optimizing torque transfer and minimizing wear in machinery." This statement resonates with many engineers and technicians who face the challenge of integrating fluid couplings into their systems.

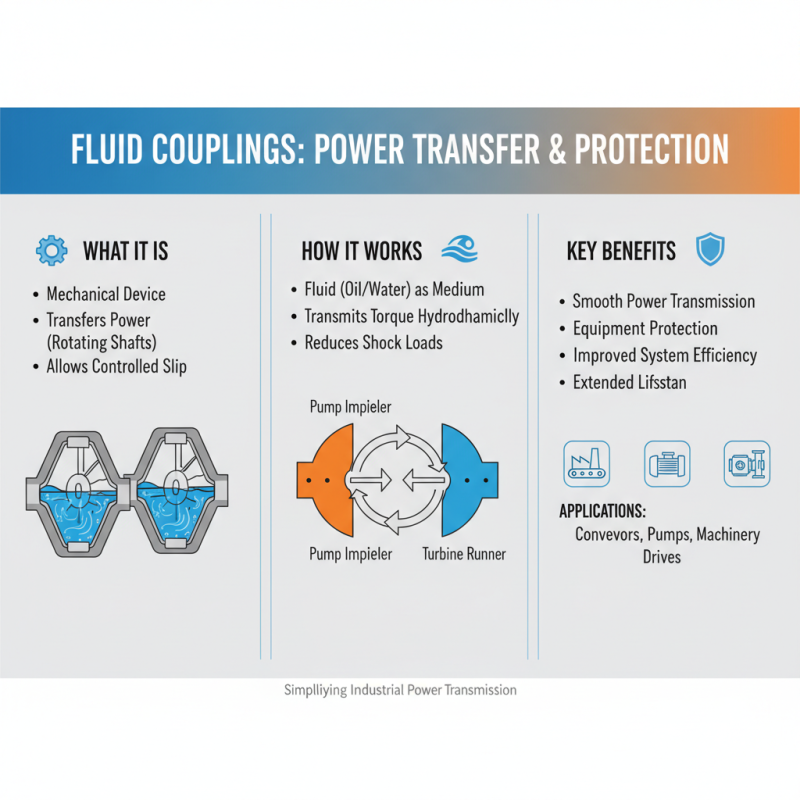

Fluid couplings serve as essential components that facilitate smooth power transmission while allowing for some degree of slip, which can protect equipment during sudden load changes. However, with various types and specifications available in the market, the decision-making process can be overwhelming. Therefore, understanding the operational parameters, application requirements, and the benefits of different fluid couplings is vital for ensuring reliability and performance in industrial settings.

By delving into the fundamental principles of fluid couplings and their specific applications, this guide aims to assist professionals in making informed choices that cater to their unique operational needs. Whether it is for manufacturing, mining, or any other sector requiring robust energy transfer solutions, selecting the right fluid coupling can lead to enhanced productivity and prolonged equipment lifespan.

Understanding Fluid Couplings and Their Applications

Fluid couplings are essential mechanical devices that transfer power between rotating shafts while allowing for some degree of slip, primarily in industrial applications. They work by using a fluid as a medium to transmit torque, which helps in reducing shock loads and improving the efficiency of the system. Understanding the fundamental principles of how fluid couplings operate can significantly impact the selection process for various industrial settings, including conveyors, pumps, and machinery drives.

When choosing the right fluid coupling for an application, factors such as the required torque output, operating speed, and environmental conditions must be considered. Different designs of fluid couplings are available, each offering specific performance characteristics tailored to distinct operational needs. For instance, some couplings provide higher slip for smoother starting and acceleration in applications with heavy loads, while others may be optimized for maximum efficiency at constant speed. Additionally, the fluid medium's temperature and viscosity can affect performance; thus, proper specification is crucial to enhance durability and maintain optimal functionality in demanding industrial environments.

Key Factors to Consider When Selecting a Fluid Coupling

When selecting a fluid coupling for industrial applications, several key factors must be considered to ensure optimal performance and efficiency. One primary factor is the operating conditions, including temperature, viscosity of the fluid, and environmental influences. According to industry reports, operating temperatures can significantly impact the efficiency and lifespan of fluid couplings. For instance, couplings designed for high-temperature environments often utilize specialized materials that resist thermal degradation, ensuring reliability under extreme conditions.

Another crucial aspect is the power transmission requirements of the application. It is essential to evaluate the load and torque characteristics of the machinery involved. Research studies indicate that selecting a coupling with the appropriate torque capacity can prevent excessive slippage and energy loss, ultimately enhancing productivity. Careful analysis of the operational load curves and dynamic behavior helps in choosing a coupling that maintains consistent performance under varying load conditions.

Tips: Always consult technical specifications and seek expert advice when in doubt about the power transmission needs. Additionally, ensure that the selected fluid coupling is compatible with the application’s hydraulic requirements to prevent issues related to energy dissipation. Regular maintenance and monitoring of the fluid levels can also prolong the lifespan of the coupling, improving overall operational efficiency.

Different Types of Fluid Couplings and Their Functions

Fluid couplings are essential components in various industrial applications, offering a method for transmitting power while providing benefits such as protection against overloads and enhancing the operational efficiency of machinery. There are several types of fluid couplings, each designed with specific functions in mind.

The most common types include the simple centrifugal coupling, which utilizes a vaned impeller to transmit torque via hydraulic fluid. This type is ideal for applications requiring smooth start-ups and the ability to absorb shock loads. Another type is the retarder fluid coupling, which serves as a braking mechanism to control speed and provide deceleration without relying solely on mechanical brakes. Lastly, the adjustable fluid coupling allows operators to regulate the energy transfer and adjust torque output based on real-time operational needs, making it versatile for varying workload requirements. Each type of fluid coupling has its unique advantages, making it essential for industries to choose the correct type based on their specific operational demands and the characteristics of the machinery involved.

Evaluating Performance Characteristics of Fluid Couplings

When selecting a fluid coupling for industrial applications, understanding the performance characteristics is crucial for ensuring efficiency and reliability. Fluid couplings are essential components in various industries, serving to transmit power between machinery while providing shock absorption and reducing wear. Factors such as torque capacity, fluid type, and temperature range exert significant influence on the performance profile. A study published in the Journal of Mechanical Engineering highlights that employing the correct fluid coupling can reduce energy consumption by as much as 15%, which emphasizes the importance of tailored selections based on application specifics.

Tips for evaluating performance characteristics include analyzing the operational environment carefully. For instance, if the application involves high-temperature operations, it is vital to choose couplings designed to withstand elevated temperatures without degrading the fluid properties. Furthermore, understanding the load torque requirements of the driven machinery can prevent premature wear and ensure optimal performance. A report from the International Society of Automation notes that improperly sized couplings can lead to a 20% increase in maintenance costs over the lifespan of the equipment.

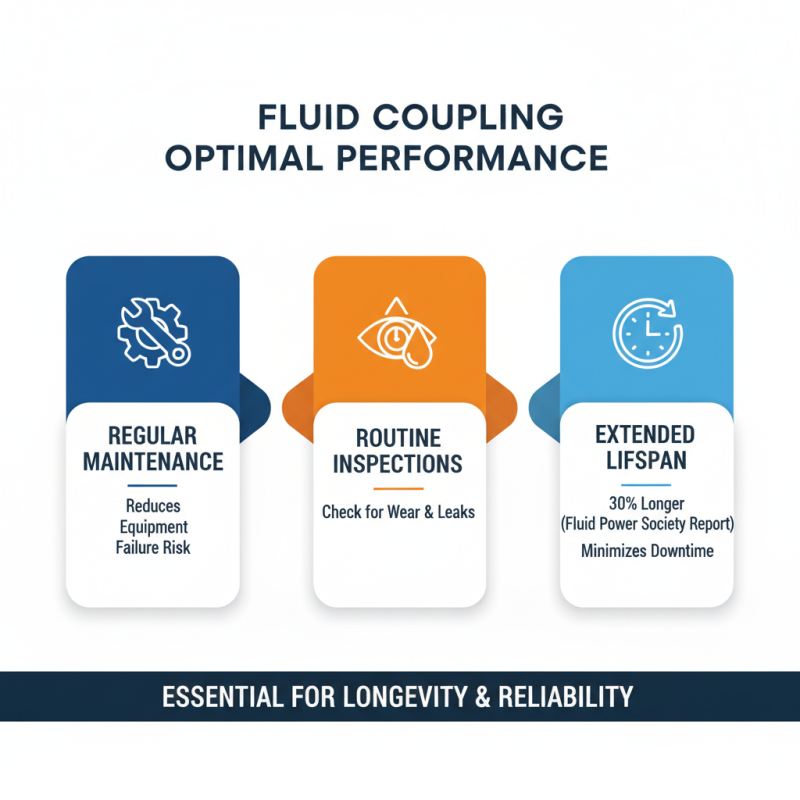

Another critical aspect to consider is the maintenance requirements of the fluid coupling. Regular monitoring and fluid replacement can extend the lifespan of the coupling and maintain efficiency. According to industry guidelines, routine checks should be performed every 3 to 6 months, particularly in high-demand environments. By prioritizing performance characteristics and aligning them with application needs, industries can achieve significant operational gains.

Performance Characteristics of Fluid Couplings

This chart illustrates the performance characteristics of fluid couplings based on various key parameters such as torque rating, efficiency, starting torque, speed range, and temperature range. Analyzing these metrics is essential for selecting the right fluid coupling for industrial applications.

Maintenance and Operating Considerations for Fluid Couplings

When selecting a fluid coupling for your industrial application, understanding maintenance and operational considerations is essential for ensuring optimal performance and longevity. Regular maintenance of fluid couplings can significantly reduce the risk of equipment failure. It is recommended that operators conduct routine inspections to check for signs of wear or fluid leaks. According to a report from the Fluid Power Society, scheduled maintenance can extend the lifespan of fluid couplings by as much as 30%, minimizing unexpected downtimes that can disrupt production.

Operating conditions also play a critical role in the performance of fluid couplings. Parameters such as temperature, pressure, and load need to be carefully monitored. For instance, studies indicate that fluid couplings operating at temperatures above 100°C can experience substantial reductions in fluid viscosity, adversely affecting torque transmission. Furthermore, coupling selection should consider the application’s environmental conditions, as contaminants can adversely affect coupling functionality. By adhering to best practices for maintenance and being attentive to operational conditions, industries can significantly enhance both efficiency and reliability in their applications.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor