Craftsmanship in Motion: Discover the World-Class Quality of China's Best Speed Reducers

In the realm of advanced manufacturing and machinery, the importance of

high-quality speed reducers is paramount. These critical components significantly

influence the efficiency and performance of various industrial applications, from robotics to conveyor systems.

According to a recent market report by Research and Markets, the global speed reducer market is projected

to grow at a CAGR of 5.9% from 2021 to 2028, driven by increasing automation

and demand for machinery across different sectors. China's commitment to enhancing its engineering and manufacturing

capabilities has positioned it as a leader in the production of world-class speed reducers, integrating

innovative designs and craftsmanship techniques that meet international standards.

As industries strive for precision and reliability, exploring the

intricacies of China's best speed reducers unveils a landscape of

unparalleled quality and engineering excellence that is shaping the

future of industrial automation solutions.

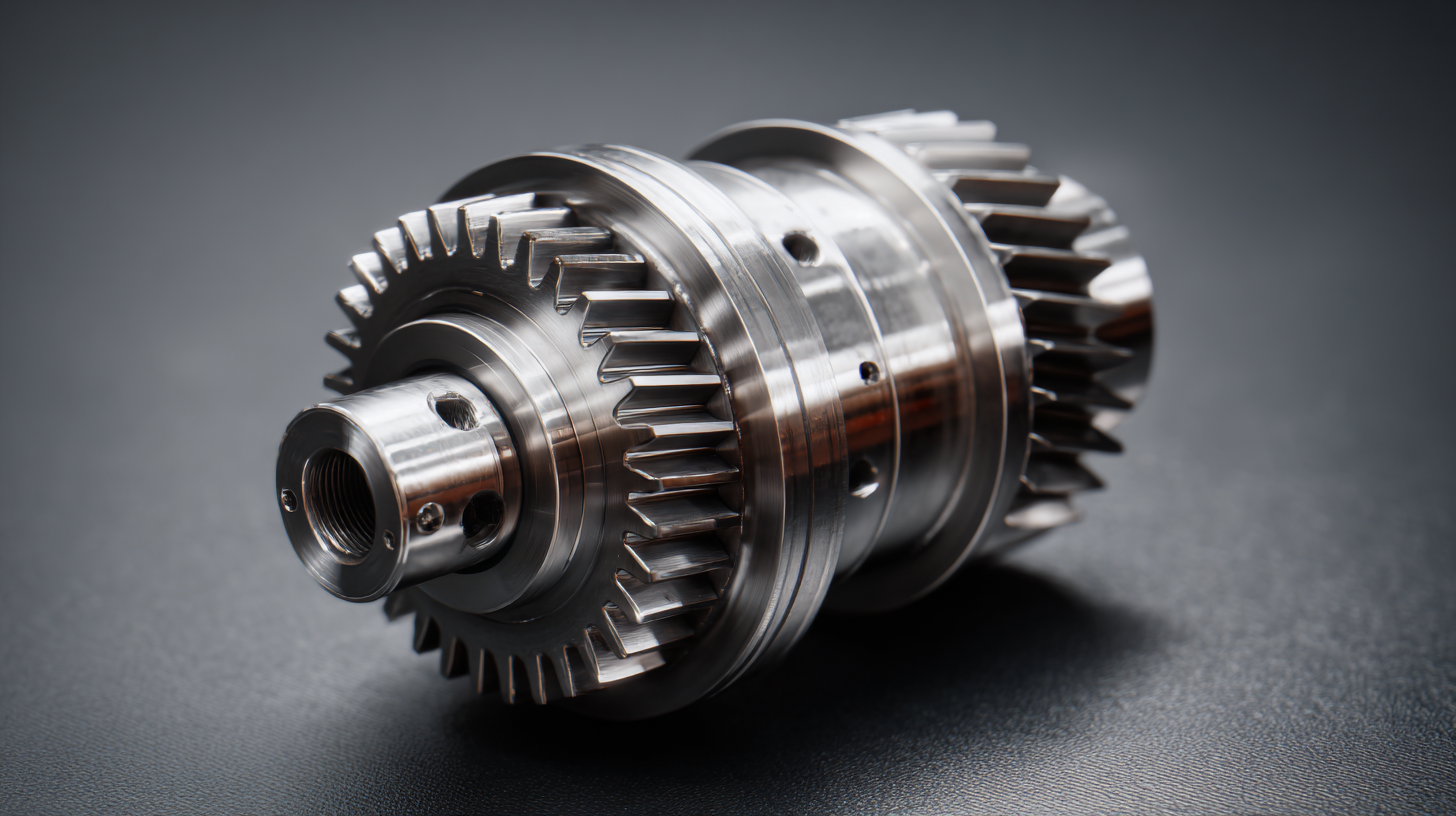

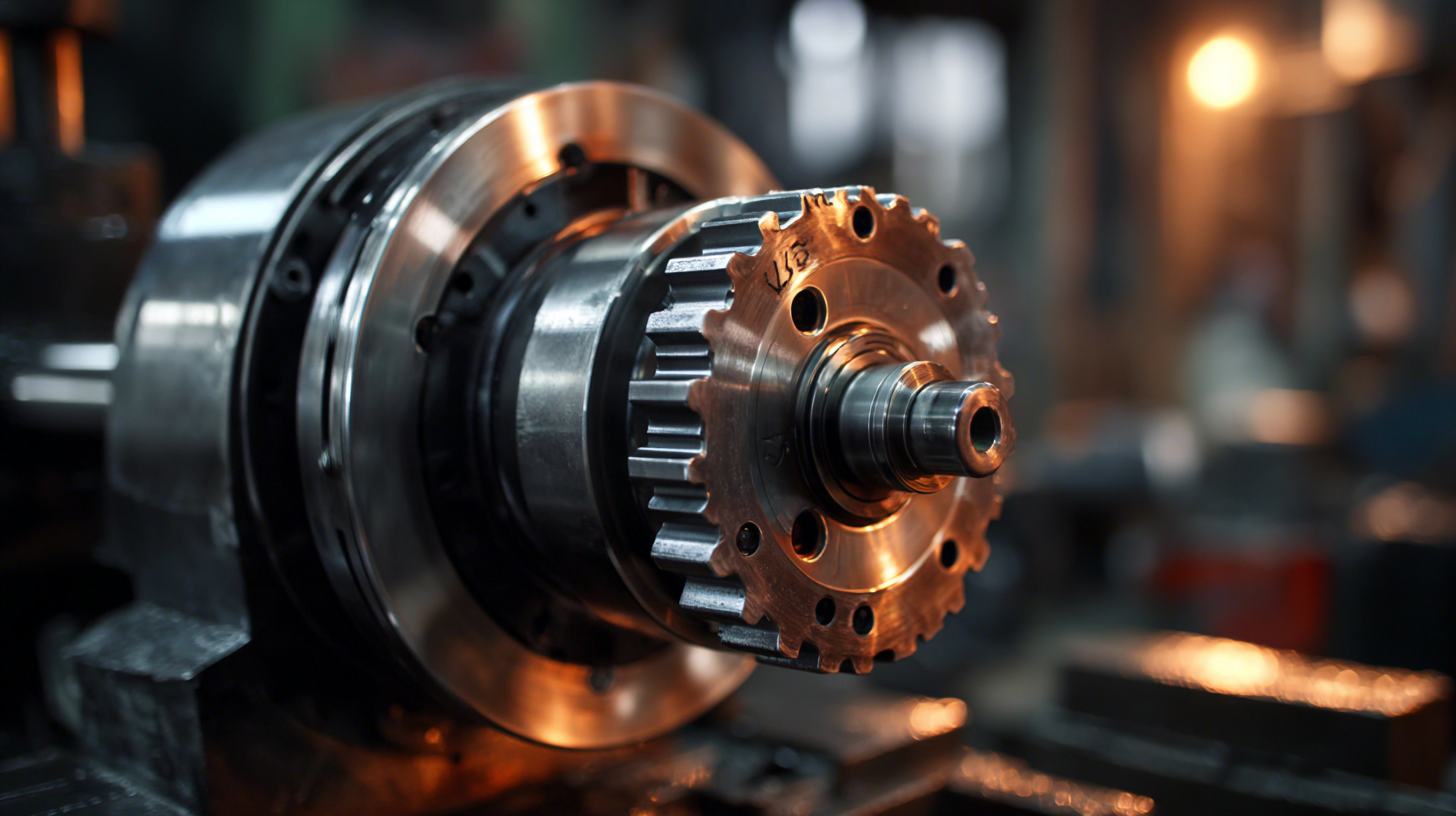

The Importance of Speed Reducers in Modern Machinery

In the realm of modern machinery, speed reducers play a pivotal role in enhancing performance and efficiency. These components are crucial for reducing motor speed while increasing torque, making them indispensable in various applications, from industrial equipment to robotics. As we step into an era where human-robot interaction becomes commonplace, the need for reliable and efficient speed reducers is more pronounced than ever. Their ability to precisely control motion not only improves the functionality of robotic devices but also ensures safety and effectiveness in operations.

As technology advances, particularly in the field of robotics, the design of speed reducers is evolving to meet new demands. Compact gearboxes, for instance, are gaining popularity for their ability to deliver high performance in a smaller form factor, essential for the intricate movements required in robots. As manufacturers focus on innovation, the quality and craftsmanship of speed reducers are increasingly highlighted, with China emerging as a leader in producing world-class products that meet international standards. This focus on quality not only enhances the capabilities of modern machinery but also paves the way for a future where robotics and automation reach new heights of sophistication and reliability.

Craftsmanship in Motion: Speed Reducer Efficiency in Modern Machinery

This chart represents the efficiency and performance of various types of speed reducers used in modern machinery. The data showcases the torque output vs. weight for worm, gear, and planetary speed reducers to highlight the importance of choosing the right type for specific applications.

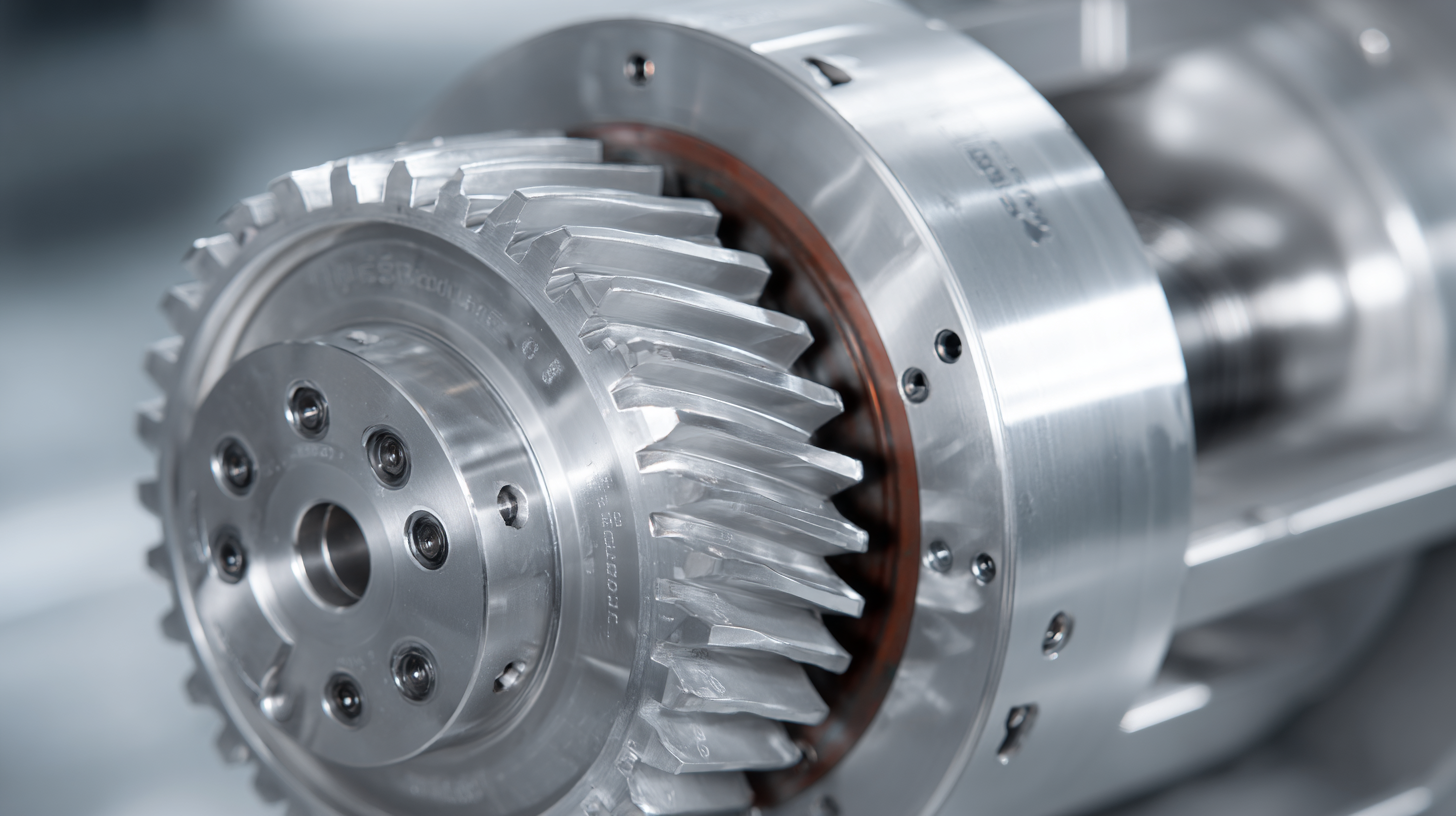

Types of Speed Reducers: Understanding Gear, Worm, and Planetary Variants

In the realm of mechanical engineering, speed reducers play a pivotal role in optimizing machinery performance. The three most common types—gear, worm, and planetary reducers—each offer unique advantages tailored to specific applications. Gear reducers are renowned for their efficiency and torque multiplication, making them the preferred choice for high-performance applications. According to a recent industry report by MarketsandMarkets, the global gear reducer market is expected to reach $9.35 billion by 2025, highlighting their critical role in various sectors, including automotive and industrial machinery.

Worm reducers, on the other hand, are favored for their compact design and ability to provide substantial speed reduction. They excel in low-speed, high-torque applications, which is crucial for industries like manufacturing and construction. The efficiency of worm gear systems can reach up to 90%, making them an effective solution for specific operational challenges. Additionally, a report published by Grand View Research indicates that the worm gear market is projected to grow at a CAGR of 4.5% through 2027, indicating robust demand.

When selecting a speed reducer for your project, consider these tips: firstly, evaluate the load and speed requirements meticulously; secondly, assess the space constraints of your installation; and finally, ensure that the chosen reducer aligns with your energy efficiency goals. Understanding the nuances of each type of speed reducer is essential for enhancing the durability and productivity of your machinery.

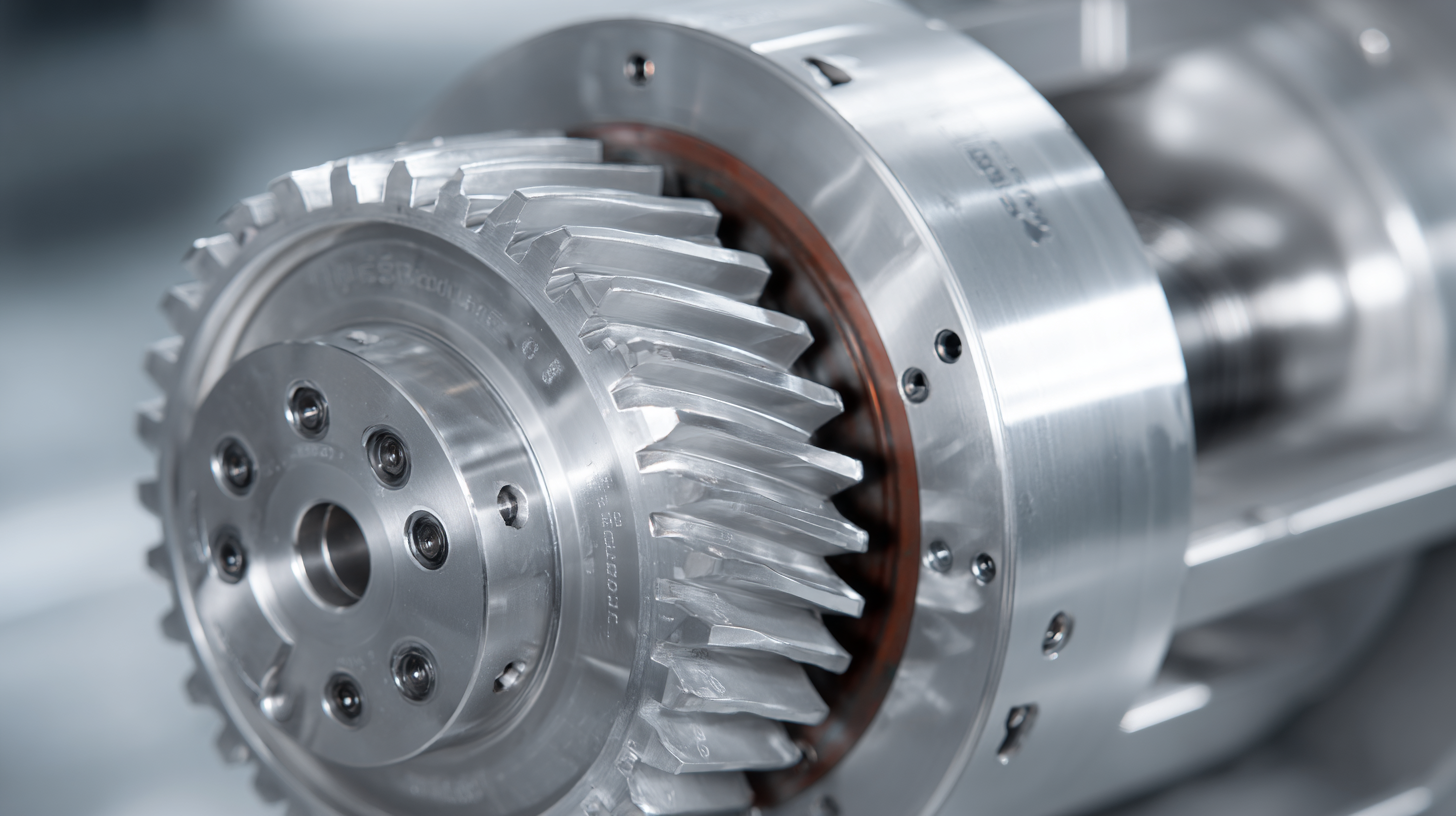

Key Features of High-Quality Speed Reducers for Industrial Applications

In the fast-evolving landscape of industrial applications, the quality of speed reducers can significantly impact operational efficiency and longevity. High-quality speed reducers are designed with key features that enhance their performance, such as precision gear profiles and advanced material compositions. These components are crucial in ensuring that motion transmission is accurate, which is especially important in robotics and automated production lines. Recent developments in manufacturing techniques, including tooth profile modification strategies, have led to improvements in the design of cycloidal gears, further contributing to the reliability and efficiency of these systems.

As China's industrial sector grows more innovative, its speed reducers are becoming increasingly recognized for their world-class quality. The emphasis on durability and performance means that these devices can withstand the rigors of modern production demands. In applications ranging from automotive to food processing, the integration of sophisticated drive systems highlights the importance of meticulous engineering and rigorous testing. This commitment to quality ensures that industries can leverage the advantages of advanced speed reducers, ultimately driving productivity and reinforcing China's position as a leader in advanced manufacturing technology.

Selecting the Right Speed Reducer: Factors to Consider for Optimal Performance

When selecting the right speed reducer, several key factors should be prioritized to ensure optimal performance. First and foremost, consider the power requirements. The speed reducer must match the motor's specifications, taking into account the torque and speed needed for your particular application. Additionally, it’s paramount to evaluate the efficiency of the speed reducer. Higher efficiency means less energy wasted, which directly impacts operating costs over time.

Another crucial aspect is the type of speed reducer that best fits your needs. Gear, belt, and chain options all offer unique benefits depending on the application, such as load handling and speed ratios. Maintenance requirements are also worth noting; some speed reducers require more upkeep than others, impacting long-term reliability. By focusing on these factors—power compatibility, efficiency, type, and maintenance—you can make an informed decision that enhances the productivity and longevity of your machinery.

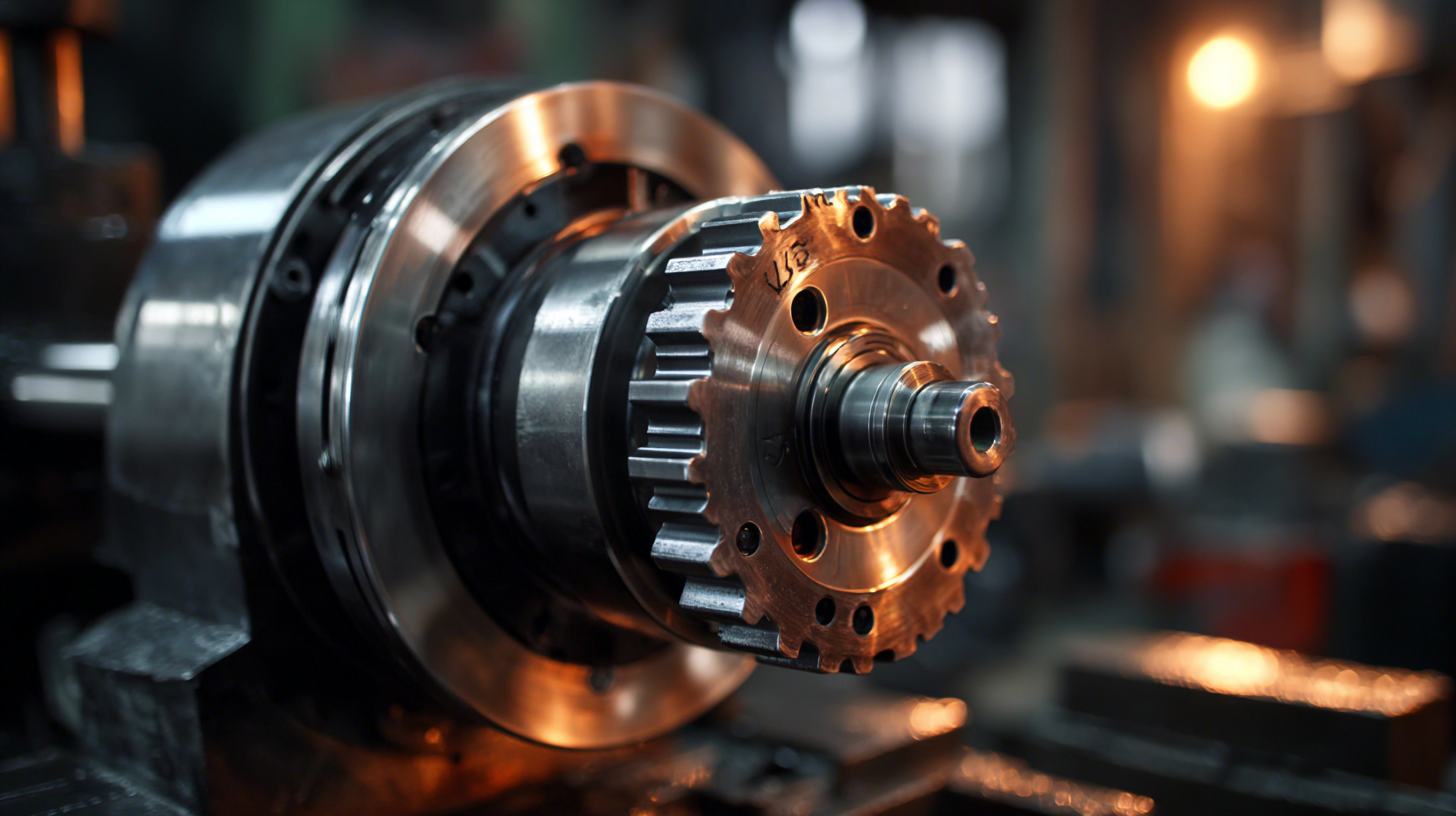

China's Leading Manufacturers: Innovations in Speed Reducer Technology

As the demand for precision and efficiency in mechanical applications grows, China's leading manufacturers are stepping up with groundbreaking innovations in speed reducer technology. According to a report by Research Institute of Industry Technology, the speed reducer market in China is projected to reach $12 billion by 2025, driven by advancements in automation and robotics. These manufacturers are increasingly focusing on developing high-performance gear units that not only reduce energy consumption but also enhance the durability and reliability of machinery.

One of the key innovations is the integration of IoT technology into speed reducers, allowing for real-time monitoring and predictive maintenance. This feature enables businesses to minimize downtime and optimize performance. Furthermore, manufacturers are leveraging advanced materials and precision engineering techniques to produce gear reducers that can handle heavier loads while maintaining compact sizes. A study by Global Market Insights highlights that companies investing in these cutting-edge technologies are witnessing efficiency improvements of up to 30%, positioning China at the forefront of the global speed reducer industry.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor