Essential Checklist for Global Buyers to Evaluate Gearbox Sew Gearmotor Performance and Reliability

When it comes to sourcing mechanical components for global operations, understanding the performance and reliability of the Gearbox Sew Gearmotor is paramount. This essential checklist aims to guide buyers through the critical aspects of evaluating the Gearbox Sew Gearmotor, ensuring that they can identify the most suitable alternatives that meet their operational needs. By considering factors such as efficiency, durability, and compatibility, buyers can make informed decisions that align with their benchmarks for quality and performance. This blog will delve into the various alternatives available in the market, providing insights into how to thoroughly assess these gearmotors, thereby enhancing operational efficiency and productivity in various applications across industries.

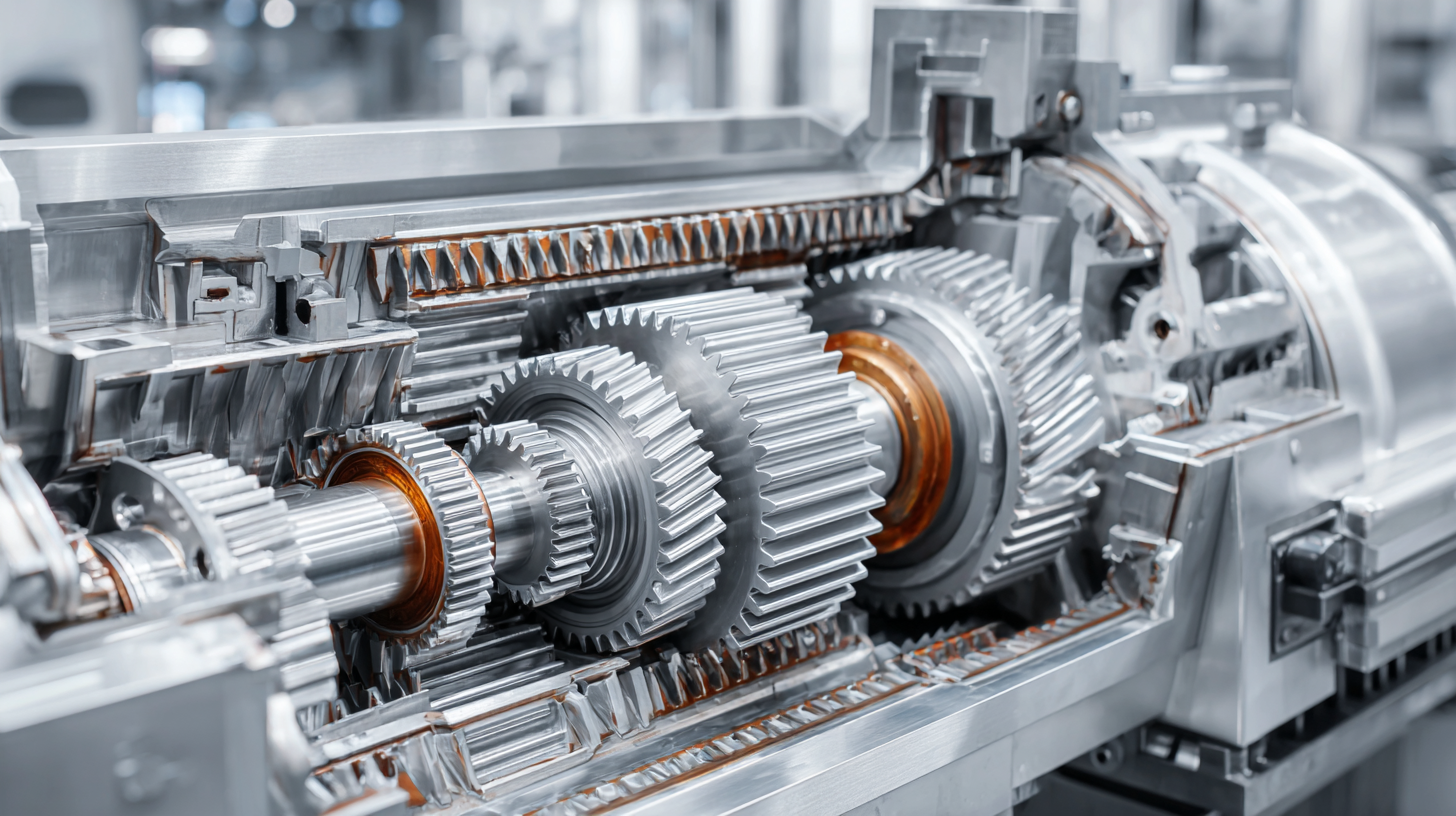

Key Performance Indicators for Gearbox Sew Gearmotor Evaluation

Evaluating the performance and reliability of Gearbox Sew Gearmotors is crucial for global buyers seeking durable and efficient solutions. Key Performance Indicators (KPIs) can significantly aid in assessing the effectiveness of these systems. Key among these indicators is the torque output, which ensures that the gearmotor meets the specific demands of various applications. Additionally, monitoring the efficiency ratings can provide insights into energy consumption, helping buyers choose products that align with sustainability goals.

When evaluating gearmotors, it is essential to examine the duty cycle, which indicates how long the gearmotor can operate effectively without overheating or experiencing wear. This vital data enables buyers to anticipate maintenance needs and ultimately prolong the lifespan of their equipment.

Another important KPI is the noise and vibration levels emitted during operation. Excessive noise and vibration can not only indicate potential mechanical issues but also affect workplace safety and comfort. Ensuring that selected gearmotors adhere to industry standards can lead to improved reliability and performance in the long run. By focusing on these KPIs, global buyers can make informed decisions that enhance operational efficiency.

Understanding Gearbox Efficiency: Metrics to Consider

When evaluating the performance and reliability of gearbox sew gearmotors, understanding gearbox efficiency is paramount. Efficiency metrics such as mechanical efficiency, volumetric efficiency, and overall efficiency provide critical insights into a gearbox's operational effectiveness.

According to a report by the American Gear Manufacturers Association (AGMA), mechanical efficiency can significantly affect the energy consumption of industrial applications, with typical efficiencies ranging from 85% to 98% depending on the gearbox design and load conditions.

In addition, volumetric efficiency, which measures the ratio of the actual output power to the theoretical output power, offers a deeper understanding of how effectively a gearmotor converts input energy into useful mechanical energy.

Industry studies indicate that volumetric inefficiencies can lead to performance losses upwards of 10%, underscoring the importance of selecting gearmotors with high volumetric efficiency ratings.

For global buyers, it is crucial to assess these metrics alongside reliability indicators, such as mean time between failures (MTBF) and maintenance intervals, to ensure that the chosen gearmotors meet the rigorous demands of their operational environments.

Reliability Factors: Ensuring Long-Term Performance in Gearmotors

When evaluating the performance and reliability of gearmotors, understanding the key reliability factors is crucial for global buyers.

First, one must consider the quality of materials used in the construction of the gearmotor.

High-grade metals and alloys can significantly enhance durability and resistance to wear, thus minimizing downtime and repair costs.

Additionally, the sealing technology employed in a gearmotor can affect its ability to withstand harsh operating conditions, such as moisture, dust, and extreme temperatures.

A well-sealed gearmotor ensures that internal components remain protected, leading to longer-lasting performance.

Another important aspect to assess is the manufacturer's reputation and history in the industry.

Established brands often provide detailed specifications and testing results that reflect the reliability of their products.

Buyers should also inquire about warranties and service agreements, as these can be indicative of the manufacturer's confidence in their gearmotor’s long-term performance.

Regular maintenance schedules and guidelines should also be highlighted, as they play a vital role in ensuring that the gearmotor continues to operate efficiently over the years.

By focusing on these reliability factors, global buyers can make informed decisions and choose gearmotors that will deliver steadfast performance throughout their operational lifespan.

Testing Methods for Gearmotor Durability and Performance Assessment

When evaluating the performance and reliability of gearbox sew gearmotors, thorough testing methods play a crucial role in determining their durability.

One of the primary approaches is fatigue testing, where gearmotors are subjected to repeated cycles of operation to simulate long-term use.

This method helps identify the point of failure and provides valuable data on how the gearmotor withstands stress over extended periods.

Additionally, thermal testing can be employed to measure how effectively the gearmotor can dissipate heat under various load conditions, ensuring that it operates within optimal temperature ranges.

Another essential testing method involves performance benchmarking against industry standards.

This includes measuring torque, speed, and efficiency metrics to ensure that the gearmotor not only meets but exceeds the expected performance criteria.

Vibration analysis is also critical, as excessive vibrations can indicate underlying issues, leading to premature wear or failure.

By applying these diverse testing methodologies, global buyers can confidently assess the durability and performance of gearbox sew gearmotors, ensuring they make informed decisions that align with their operational needs and longevity expectations.

Industry Trends: Future Innovations in Gearbox Sew Gearmotor Technology

As the industry moves toward increased automation and efficiency, the future of gearbox sew gearmotor technology brings several exciting innovations. One key trend is the integration of smart technology, enabling these devices to communicate with other systems in real time. This connectivity allows for predictive maintenance, reducing downtime and enhancing overall productivity. Manufacturers are increasingly focusing on developing gearmotors that can not only perform optimally under varying loads but also relay performance data for analysis.

Another promising innovation is the advancement in materials and design. Lightweight yet durable materials are being explored to create more compact and efficient gearmotors without compromising strength. Additionally, advancements in manufacturing techniques, such as additive manufacturing, are paving the way for more complex and efficient gearbox designs, ultimately optimizing performance while minimizing waste. These innovations not only enhance reliability but also contribute to sustainable practices within the industry. As these trends evolve, global buyers must stay informed to ensure they invest in technology that meets the future demands of the market.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor