Understanding the Features of Sewmkygearbox Technology

The advancement of gearbox technology has significantly transformed various sectors, particularly in automotive and industrial machinery. Among the latest innovations, Sewmkygearbox stands out for its remarkable efficiency and reliability.

According to a report by Markets and Markets, the global gearbox market is projected to grow from USD 23.4 billion in 2020 to USD 30.4 billion by 2025, at a CAGR of 5.8%. This growth is largely driven by the increasing demand for energy-efficient systems and the integration of automation in manufacturing processes.

As industries strive for operational excellence, understanding the features of Sewmkygearbox technology becomes essential for stakeholders aiming to enhance performance while minimizing costs.

In this guide, we will explore the key attributes of Sewmkygearbox, highlighting how its innovative design and functionality can provide a competitive edge in today’s dynamic market.

Key Advantages of Sewmkygearbox Technology in Modern Applications

Sewmkygearbox technology is becoming increasingly essential in modern applications due to its numerous key advantages. One of the primary benefits is its efficiency. The unique design of the Sewmkygearbox minimizes energy loss, enabling machines to operate using less power while achieving optimal performance. This efficiency is particularly vital in industries focusing on sustainability and energy conservation, aligning with global trends towards eco-friendly practices.

Another significant advantage is the technology's durability. Sewmkygearboxes are built with high-quality materials that withstand heavy use and extreme conditions. This resilience translates to less frequent replacements and repairs, ultimately saving businesses time and resources. In industries such as manufacturing and transportation, where downtime can be costly, the reliability of Sewmkygearbox technology plays a crucial role in maintaining operational continuity.

Tips: When considering the implementation of Sewmkygearbox technology, it's essential to evaluate the specific needs of your operation. This includes assessing the load requirements and environmental conditions that the gearbox will encounter. Additionally, investing in regular maintenance can extend the lifespan of the technology, ensuring it continues to deliver optimal performance even in demanding circumstances.

Innovative Features that Set Sewmkygearbox Apart from Traditional Gearboxes

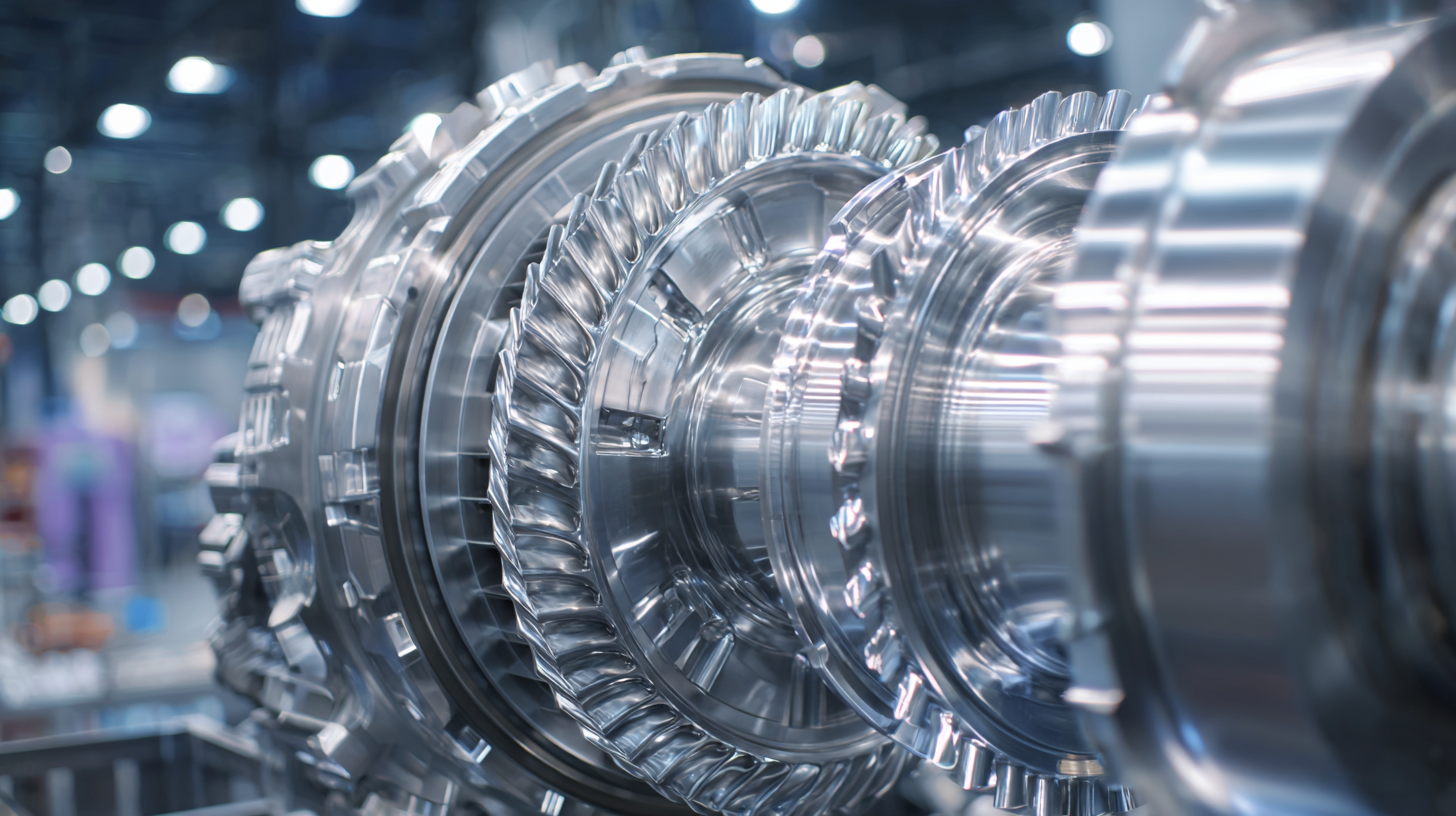

Sewmkygearbox technology represents a significant advancement in gearbox design, introducing innovative features that distinguish it from traditional gearboxes. One of the standout attributes is its adaptive efficiency, which optimizes power distribution based on real-time operational demands. Unlike conventional gear systems, which operate at a fixed efficiency level, Sewmkygearbox adjusts its parameters dynamically, leading to reduced energy consumption and improved overall performance.

Another notable feature is its compact and lightweight construction. Traditional gearboxes often suffer from bulkiness, making installation and maintenance cumbersome. In contrast, the streamlined design of Sewmkygearbox allows for easier integration into various applications, whether in industrial machinery or automotive systems. This innovation not only saves space but also enhances mobility and flexibility for manufacturers looking to maximize their equipment's utility. With these advancements, Sewmkygearbox technology is positioned to revolutionize the way gear systems function, paving the way for more sustainable and efficient industrial practices.

How Sewmkygearbox Technology Enhances Energy Efficiency in Machinery

Sewmkygearbox technology is revolutionizing the machinery industry by significantly enhancing energy efficiency. According to a report by the International Energy Agency (IEA), the manufacturing sector is responsible for approximately 30% of global energy consumption. Implementing advanced gearbox technologies can lead to a reduction of energy use by as much as 15-25%. This is achieved through improved gear design, which minimizes friction losses and optimizes mechanical performance, allowing machinery to operate more effectively.

The application of Sewmkygearbox technology not only reduces energy consumption but also contributes to lower operational costs. A study by the Gearbox Manufacturers Association revealed that companies adopting this technology saw an average decrease in energy expenses by 20%, resulting in a rapid return on investment. Additionally, as industries face increasing pressure to adhere to environmental regulations, energy-efficient solutions like Sewmkygearbox are becoming essential for sustainable operation. By embracing these advancements, manufacturers can enhance their productivity and reduce their carbon footprint, aligning with the global push for greener technologies.

Energy Efficiency Comparison of Machinery with and without Sewmkygearbox Technology

This chart illustrates the energy efficiency of machinery using Sewmkygearbox technology compared to traditional gear systems. The data showcases the percentage of energy savings achieved through the advanced technology.

Applications of Sewmkygearbox Technology Across Various Industries

Sewmkygearbox technology is making significant strides across various industries, driven by its unique features and capabilities. In automotive manufacturing, for instance, the technology enhances the efficiency of assembly lines, allowing for more precise movements and better synchronization of robotic systems. This leads to reduced cycle times and improved overall throughput, vital for meeting the growing demand for fast, high-quality vehicle production.

In the renewable energy sector, Sewmkygearbox technology is playing a pivotal role in wind turbine design. By providing lightweight and durable solutions, it enables turbines to operate at optimal efficiency, maximizing energy capture from wind sources. The adaptability of this technology also extends to automation in logistics, where it enhances the functionality of various robotic systems used for sorting and packaging, contributing to more streamlined supply chains. As industries continue to embrace innovative solutions, Sewmkygearbox technology is proving to be essential for driving operational improvements and boosting productivity.

Future Trends and Developments in Sewmkygearbox Technology

The future of technology is rapidly unfolding with significant trends shaping AI, quantum computing, and nuclear energy. A recent report highlights that AI adoption is projected to enhance productivity by up to 40% by 2025, with organizations increasingly leveraging machine learning algorithms to improve decision-making processes. The integration of generative AI is particularly notable, where applications in creative design and content generation are already transforming industries such as marketing and entertainment.

In the realm of quantum computing, advancements are accelerating, with the global market expected to exceed $65 billion by 2030. Real-world applications are emerging, particularly in sectors like pharmaceuticals, where quantum algorithms can significantly shorten drug discovery timelines. Furthermore, as countries strive for energy sustainability, nuclear technology is set to evolve, with investments in small modular reactors (SMRs) projected to grow, potentially reaching $5 billion annually by 2030. These developments are not only revolutionizing energy production but also addressing pressing global challenges such as climate change.

Transportation is also undergoing a technological renaissance, propelled by sustainability and digitalization trends. Innovations like electric and autonomous vehicles are reshaping how goods and people are moved, with the electric vehicle market alone expected to comprise 30% of total global vehicle sales by 2030. As these technologies converge, industries must adapt their strategies to leverage the transformational potential of these advancements.

Understanding the Features of Sewmkygearbox Technology - Future Trends and Developments

| Feature |

Current Trend |

Potential Development |

Impact on Industry |

| Compact Design |

Increased efficiency and space-saving solutions |

Integration with advanced materials |

Reduction in operational costs |

| Enhanced Durability |

Use of high-performance lubricants |

Development of self-lubricating systems |

Increased lifespan of machinery |

| Smart Features |

Integration of IoT sensors |

Predictive maintenance capabilities |

Reduction in downtime and repair costs |

| Energy Efficiency |

Focus on reducing energy consumption |

Adoption of energy recovery systems |

Environmental sustainability and cost savings |

| Modular Construction |

Flexibility in design and manufacturing |

Customization for specific applications |

Faster production times and reduced waste |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor