Future Innovations in Gearbox Technology for Enhanced Gearmotors in 2025

The advancement of gearbox technology is set to revolutionize gearmotors in 2025, significantly enhancing performance and efficiency across various industries. According to a recent report by MarketsandMarkets, the global gear motor market is expected to reach USD 15.2 billion by 2025, with an annual growth rate of 6.8%. This surge is driven by the increasing demand for energy-efficient solutions, where innovations such as lightweight materials, smart sensors, and enhanced control algorithms play a pivotal role. As we delve into the future of "Gearboxinnomoticsgearmotor", it is essential to explore emerging trends, including the integration of Internet of Things (IoT) technologies, which promise to optimize operational efficiency and predictive maintenance. By embracing these advancements, manufacturers can not only improve the reliability and lifespan of gearmotors but also contribute to sustainability initiatives within their industries.

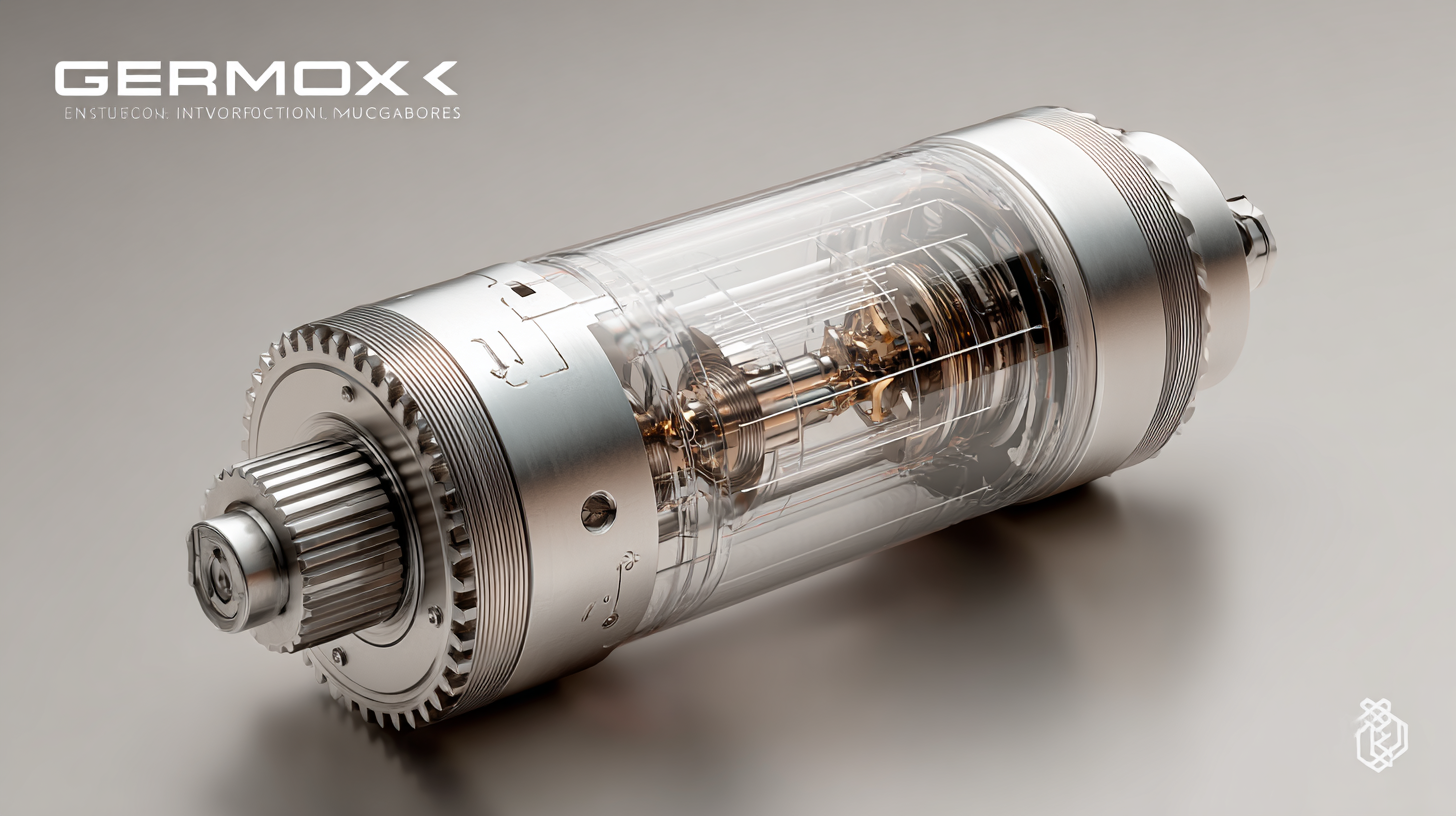

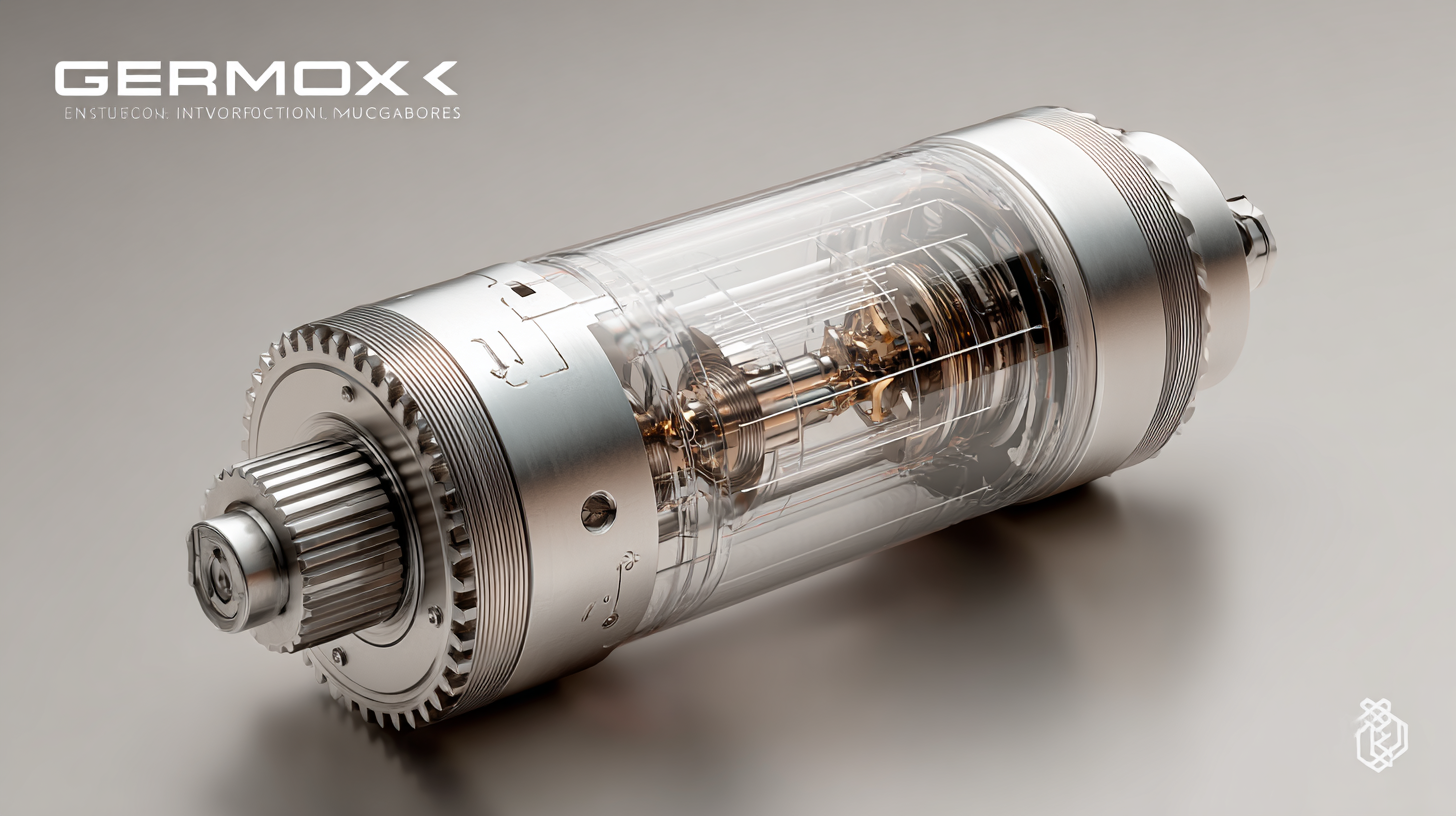

Future Trends in Gearbox Design and Functionality

As we look ahead to 2025, the landscape of gearbox design and functionality is poised for transformative changes driven by the rapid advancements in technology and increasing demand for efficiency. According to a recent industry report by MarketsandMarkets, the global market for gearboxes is expected to reach $20.6 billion by 2025, growing at a CAGR of 6.9% from 2020. This growth is largely fueled by the need for better energy management across various sectors, especially in renewable energy and electric vehicles, where optimized gearbox performance can lead to significant reductions in energy consumption.

In the quest for enhanced gearmotors, innovations such as smart gearboxes and additive manufacturing are set to redefine traditional design paradigms. Smart gearboxes, equipped with IoT capabilities, are anticipated to revolutionize performance monitoring and predictive maintenance, as noted in a report by ResearchAndMarkets. This is essential as the industry grapples with increasing demand for longevity and reliability. Moreover, the introduction of lightweight materials and advanced manufacturing processes will not only enhance the overall efficiency of gearmotors but also contribute to reduced production costs, increasing accessibility for various applications across different industries.

Innovative Materials and Their Impact on Gearmotors Efficiency

The advancement of gearbox technology is set to revolutionize gearmotors, particularly through the integration of innovative materials that enhance efficiency. According to a report by MarketsandMarkets, the global gearmotor market is expected to reach $13.1 billion by 2025, driven in large part by improvements in material science. New materials such as carbon fiber and advanced composites are gaining traction due to their lightweight properties and strength, which directly contribute to reduced energy consumption and enhanced performance in gearmotors.

A study from Research and Markets also highlights that gearmotors utilizing innovative materials can improve efficiency ratings by up to 20%. This increased efficiency not only minimizes operational costs but also aligns with global sustainability goals by reducing the carbon footprint of industrial operations. With ongoing research and development focusing on smarter material applications, the future of gearmotors looks promising, indicating a substantial shift in how industries approach their mechanical designs. As these innovations unfold, manufacturers will be positioned to create more reliable, efficient, and environmentally friendly gearmotors that meet the demands of the modern market.

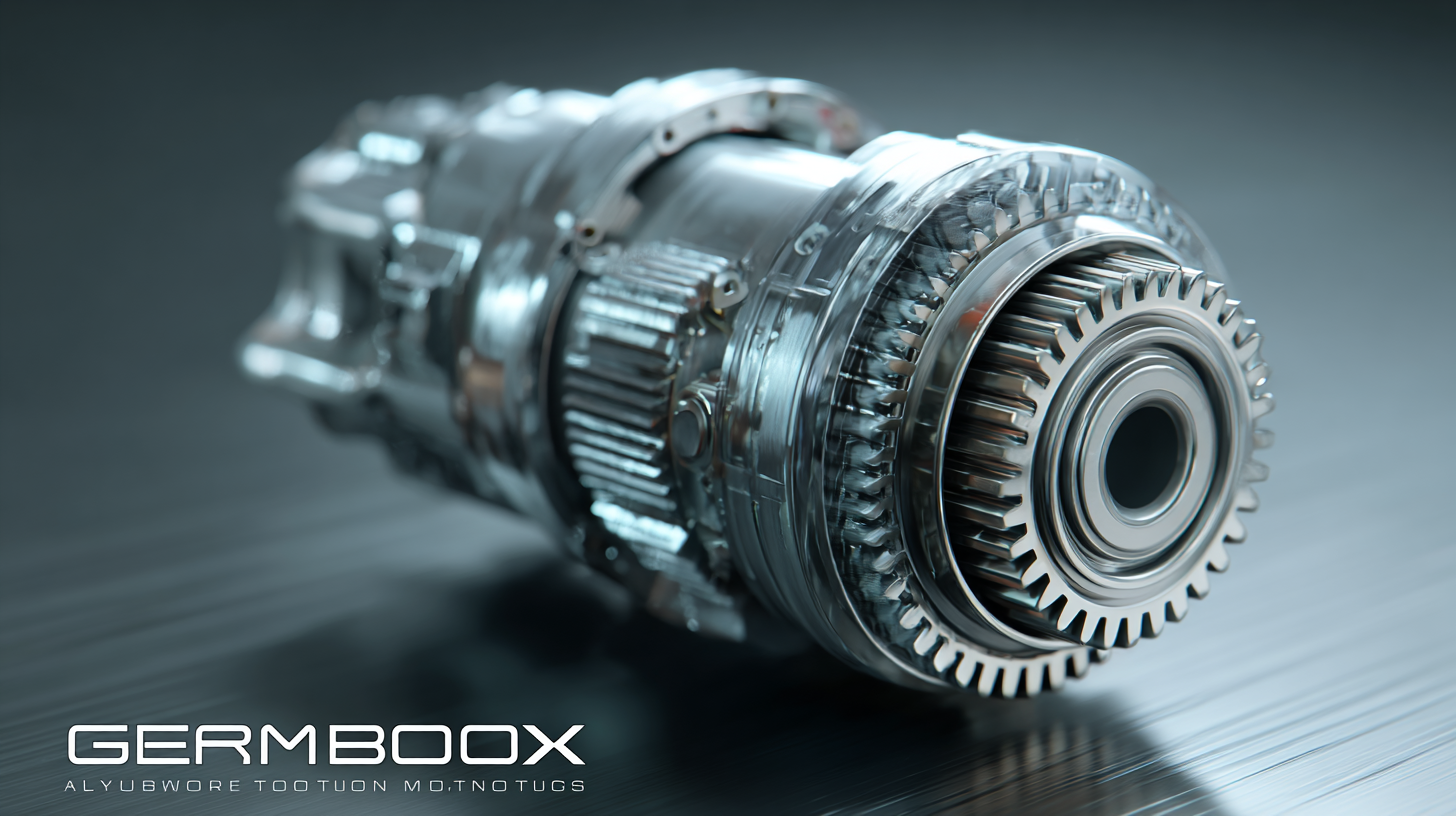

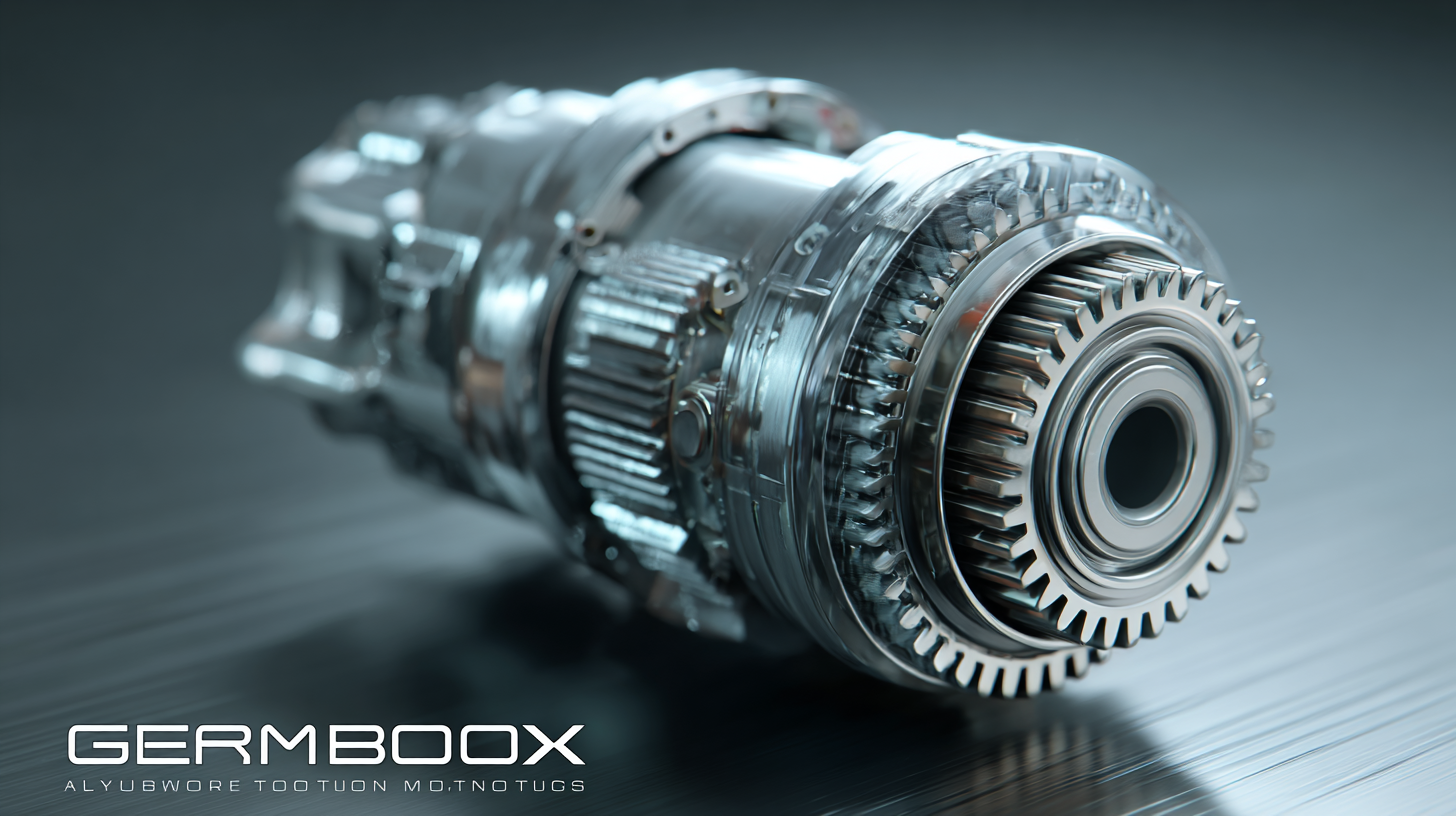

Smart Technologies Revolutionizing Gearbox Performance

The rapid evolution of smart technologies is set to redefine gearbox performance, particularly in the realm of gearmotors by 2025. Innovations such as real-time monitoring, predictive maintenance, and adaptive control systems are integrating with gearbox designs to enhance efficiency and reliability. By leveraging data analytics and IoT connectivity, manufacturers can achieve unprecedented levels of optimization, helping to mitigate wear and tear while maximizing operational lifespan.

Recent advancements in modular designs, exemplified by the launch of the first fully integrated transmission system for offshore wind turbines, illustrate the push towards flexibility and resilience in engineering. These developments not only showcase enhanced power capabilities but also emphasize the importance of robust design in harsh environments. As the demand for high-performance gearmotors increases across renewable energy sectors, the integration of smart technologies will be pivotal in driving future innovations, ensuring that equipment not only meets but exceeds operational expectations.

Sustainability and Eco-Friendly Practices in Gearbox Manufacturing

As the demand for sustainable and eco-friendly practices increases across industries, the gearbox manufacturing sector is stepping up to the challenge. According to a recent report by Research and Markets, the global gear motors market is projected to reach $39.9 billion by 2025, with a significant emphasis on environmentally responsible manufacturing processes. Companies are seeking to minimize their carbon footprint by adopting renewable energy sources in production, reducing waste through recycling initiatives, and utilizing biodegradable materials in their products.

In 2025, innovations in gearbox technology will likely incorporate advanced materials and manufacturing techniques, such as additive manufacturing and precision engineering. These technologies enable the production of lighter, more efficient gearbox designs that not only reduce energy consumption but also extend the life of gear motors. A study by McKinsey suggests that implementing sustainable practices in production could reduce operational costs by up to 25%, highlighting the dual benefits of economic efficiency and environmental responsibility. As manufacturers invest in greener technologies, the future of gearbox design will align with global sustainability goals, driving advancements that meet both performance demands and eco-friendly standards.

Global Market Perspectives: China's Role in Gearmotor Innovation

As we approach 2025, the landscape of gearmotor innovation is being significantly shaped by China’s burgeoning role in the global market. With its robust manufacturing capabilities, China is not just a consumer of gearbox technology but is becoming a key player in driving technological advancements. This shift is supported by substantial investment in research and development, aiming to enhance efficiency and performance in gearmotors, catering to a wide range of industries, from automotive to renewable energy.

Furthermore, Chinese companies are increasingly collaborating with international firms, leveraging global expertise and local insights to accelerate innovation. By focusing on smart manufacturing and automation, these partnerships aim to develop gearmotors that are not only more efficient but also adaptable to the rapid changes in market demands. The emphasis on sustainability and energy efficiency is particularly noticeable, as regulations tighten globally. As a result, China is positioning itself as a leader in producing innovative gearboxes that meet modern environmental standards, potentially redefining the future of gearmotors on a worldwide scale.

Future Innovations in Gearbox Technology for Enhanced Gearmotors in 2025 - Global Market Perspectives: China's Role in Gearmotor Innovation

| Region |

Market Size (Million USD) |

Growth Rate (2023-2025) |

Key Innovations |

China's Contribution (%) |

| North America |

1500 |

8% |

Smart Gear Systems |

10% |

| Europe |

1800 |

7% |

Eco-Friendly Materials |

15% |

| Asia-Pacific |

2000 |

10% |

AI-Driven Gear Optimization |

25% |

| Latin America |

600 |

5% |

Compact Gear Designs |

5% |

| Middle East & Africa |

400 |

6% |

Robust Gear Solutions |

3% |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor