The Future of Automation Powered by Servo Motor Technologies

As industries continue to evolve, the demand for automation powered by advanced technologies is on the rise, paving the way for innovations driven by servo motor solutions. According to a recent report by MarketsandMarkets, the global servo motor market size is expected to grow from USD 11.9 billion in 2021 to USD 17.3 billion by 2026, at a CAGR of 7.9%. This surge highlights the critical role servo motors play in enhancing precision, reliability, and efficiency in manufacturing processes. With their ability to provide high torque and excellent control, servo motors are increasingly becoming indispensable in sectors such as robotics, automotive, and aerospace. As companies strive to improve productivity while minimizing operational costs, adopting advanced servo motor technologies will be a top strategy for businesses looking to remain competitive in an automation-driven future.

The Role of Servo Motors in Modern Automation Systems and Their Impact on Efficiency

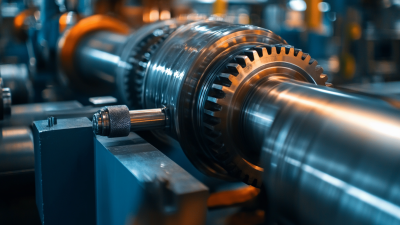

Servo motors play a pivotal role in modern automation systems, transforming industries with their precision and efficiency. According to a recent report by MarketsandMarkets, the global servo motor market is expected to reach $12.93 billion by 2026, growing at a CAGR of 6.5%. This growth is driven by the increasing demand for automated processes in manufacturing environments. Servo motors offer enhanced control over speed, position, and torque, making them essential for applications that require high accuracy, such as robotic arms and conveyor systems.

The impact of servo motors on efficiency cannot be overstated. Research by the International Energy Agency indicates that optimized servo systems can improve energy efficiency by up to 30% compared to traditional motors. This efficiency not only reduces operational costs but also contributes to sustainability goals, making servo technology a key player in the push towards environmentally friendly manufacturing practices. As industries continue to adopt automation, the integration of advanced servo motor technologies will undoubtedly lead to heightened productivity and lower energy consumption, ushering in a new era of intelligent automation.

Comparative Analysis of Servo Motor Alternatives: Benefits and Drawbacks

The comparative analysis of servo motor alternatives unveils a diverse landscape of technologies, each with its unique benefits and drawbacks.

Servo motors, known for their precision and efficiency, are essential in automation across various industries.

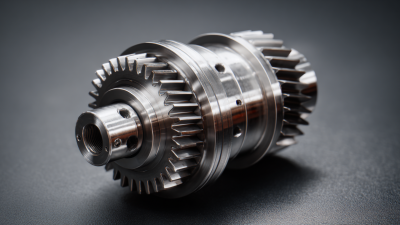

In recent studies, it has been noted that servo motors typically provide a higher torque-to-size ratio compared to traditional motors, making them ideal for applications requiring compactness without compromising performance

(Research Insights 2023). However, the investment in servo technology can be substantial, often requiring a higher initial cost and more complex integration processes.

On the other hand, alternatives such as stepper motors and AC motors present different advantages. Stepper motors, for instance, are praised for their simplicity and ease of use in open-loop control systems, making them a cost-effective option for basic applications. Yet, they often struggle with maintaining high torque at higher speeds, which can limit their effectiveness in more demanding tasks

(Automation Trends 2023). Conversely, AC motors tend to be more robust and suitable for high-power applications, but they may lack the precision and control that servo motors offer.

As such, the choice between these alternatives largely depends on specific automation needs, budget constraints, and performance requirements, highlighting the importance of thorough analysis before selection.

Market Trends of Servo Motor Technologies in Automation Industries

The automation industry is rapidly evolving, with servo motor technologies leading the way in enhancing efficiency and precision. These motors not only provide high-performance capabilities but also offer greater flexibility to adapt to various applications, from manufacturing to robotics. Recent market trends indicate a significant shift towards smart automation solutions that integrate advanced servo systems. Companies are investing heavily in these technologies to optimize production processes and reduce operational costs.

Tip: Consider leveraging data analytics alongside servo motor technologies to monitor performance in real-time. This approach not only improves the overall efficiency but also allows for predictive maintenance, minimizing downtime and extending the lifespan of equipment.

Additionally, the demand for energy-efficient solutions is driving the growth of servo motor technologies in the automation sector. As businesses strive to meet sustainability goals, servo motors are being recognized for their lower energy consumption compared to traditional systems. Integrating these technologies not only meets regulatory standards but also appeals to environmentally conscious consumers.

Tip: Explore partnerships with suppliers that focus on innovative servo motor solutions, ensuring you stay ahead of the competition. This collaboration can lead to customized applications that suit specific operational needs, ultimately enhancing productivity and market competitiveness.

The Future of Automation Powered by Servo Motor Technologies

This bar chart illustrates the projected market share of various applications of servo motor technologies in automation industries over the next five years. The data reflects the growing trend towards automation in sectors such as manufacturing, robotics, and materials handling.

Case Studies: Successful Implementations of Servo Motors Over Alternatives

Servo motors are revolutionizing automation across various industries, boasting superior precision and efficiency compared to traditional alternatives. One remarkable case study is the use of servo motors in the automotive assembly line at Ford. By integrating advanced servo technologies, Ford improved their robotic systems' response time and positional accuracy. This transition not only reduced production costs but also significantly minimized downtime, allowing for a more agile manufacturing process.

Another notable example can be seen in the food processing industry, where a major gelato manufacturer adopted servo-driven machines for their filling and packaging processes. The implementation of servo motors resulted in enhanced control over product consistency and increased throughput. The company reported a 30% rise in production speed while maintaining quality standards, showcasing how servo motor technology can lead to better operational outcomes. These case studies illustrate the tangible benefits of servo motors over traditional methods, highlighting their role as a key driver of innovation in automation.

Future Predictions: How Innovations in Servo Motor Technologies Will Shape Automation

The future of automation is undoubtedly tied to the advancements in servo motor technologies. As industries seek more efficient and precise solutions, innovations in servo motors are paving the way for enhanced automation processes. With the global industrial automation market expected to grow from $205.86 billion in 2022 to $395.09 billion by 2029, at a compound annual growth rate of 9.8%, it’s clear that this sector is on the rise. The integration of advanced servo motors will lead to significant improvements in manufacturing speed, quality, and adaptability, particularly in complex applications such as robotics and CNC machining.

Tips for businesses looking to leverage this trend include investing in training for staff on the latest servo motor technologies, which can enhance operational efficiency. Furthermore, companies should evaluate their existing equipment to identify opportunities for retrofitting with newer servo systems, ultimately improving performance and reducing long-term costs. Staying informed about industry developments and establishing partnerships with technology providers can also provide a competitive edge as automation continues to evolve.

The Future of Automation Powered by Servo Motor Technologies - Future Predictions

| Technology |

Predicted Impact |

Market Growth (%) |

Application Areas |

Challenges |

| Advanced Motion Control |

Enhanced precision in manufacturing |

12% CAGR |

Automotive, Aerospace |

High integration costs |

| Intelligent Servos |

Adaptive response to changing conditions |

15% CAGR |

Robotics, Packaging |

Software complexity |

| Energy-efficient Motors |

Reduced operational costs |

10% CAGR |

HVAC, Industrial Automation |

Technological transitions |

| Wireless Control Systems |

Improved flexibility in deployment |

20% CAGR |

Smart Manufacturing, IoT |

Security vulnerabilities |

| Multi-axis Servo Systems |

Higher operational efficiency |

18% CAGR |

CNC Machining, Textile |

Calibration difficulties |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor