Future Innovations in Helical Inline Geared Motors A Comprehensive Guide for Global Buyers

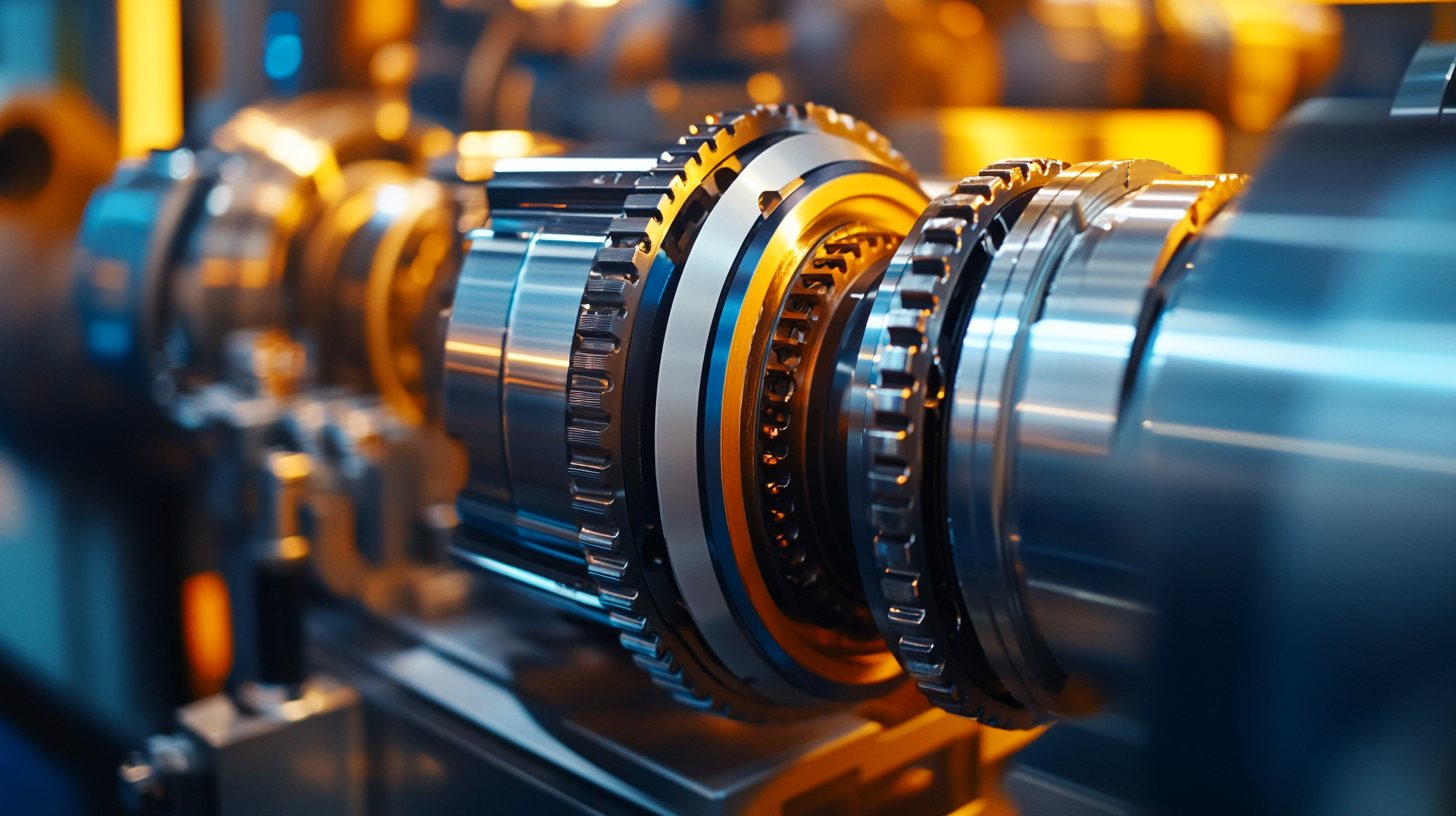

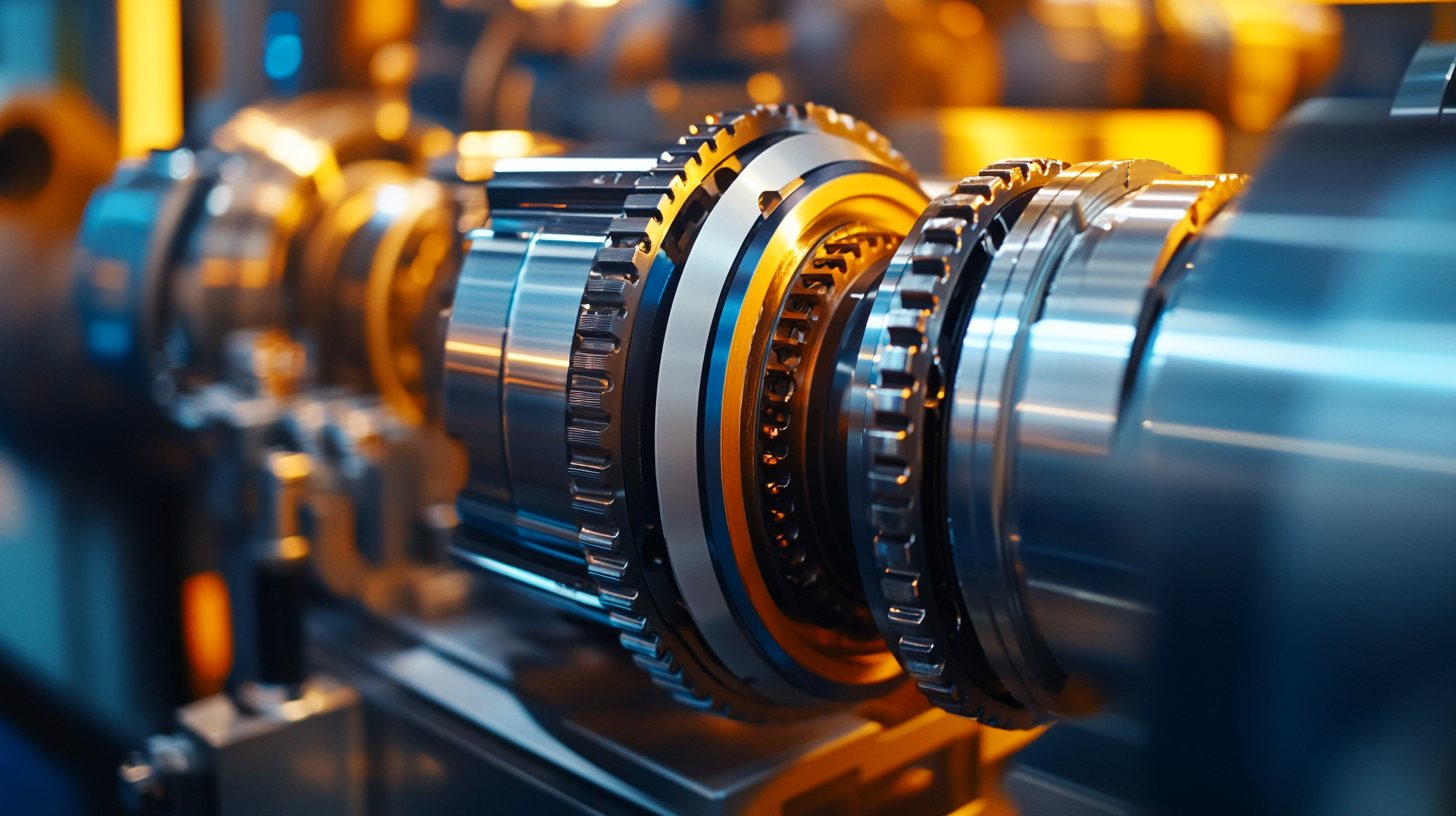

As the demand for efficient and reliable power transmission solutions continues to rise across various industries, the focus on innovative technologies like the Helical Inline Geared Motor has become increasingly vital. These advanced motors offer superior performance through a unique design that significantly enhances torque output and operational efficiency. In a world where precision and reliability are paramount, understanding the latest advancements in helical inline geared motors is essential for global buyers looking to invest in cutting-edge equipment that meets their operational needs.

This comprehensive guide aims to explore the future innovations surrounding helical inline geared motors, highlighting the technological advancements that are set to reshape the landscape. From improved materials and manufacturing processes to the integration of smart technologies and automation, this article will provide valuable insights for buyers interested in making informed purchasing decisions. By delving into the latest trends and innovations, we aim to equip stakeholders with the knowledge they need to harness the full potential of helical inline geared motors in their applications, ensuring a competitive edge in an ever-evolving market.

Emerging Trends in Helical Inline Geared Motors for Modern Applications

The landscape of helical inline geared motors is undergoing significant transformation, driven by emerging trends that cater to modern applications across various industries. As technology evolves, the demand for motors that offer not only efficiency but also compact design and enhanced performance is at an all-time high. One key trend is the integration of IoT capabilities into geared motor systems. This connectivity enables real-time monitoring and predictive maintenance, allowing companies to optimize their operations and mitigate downtime effectively.

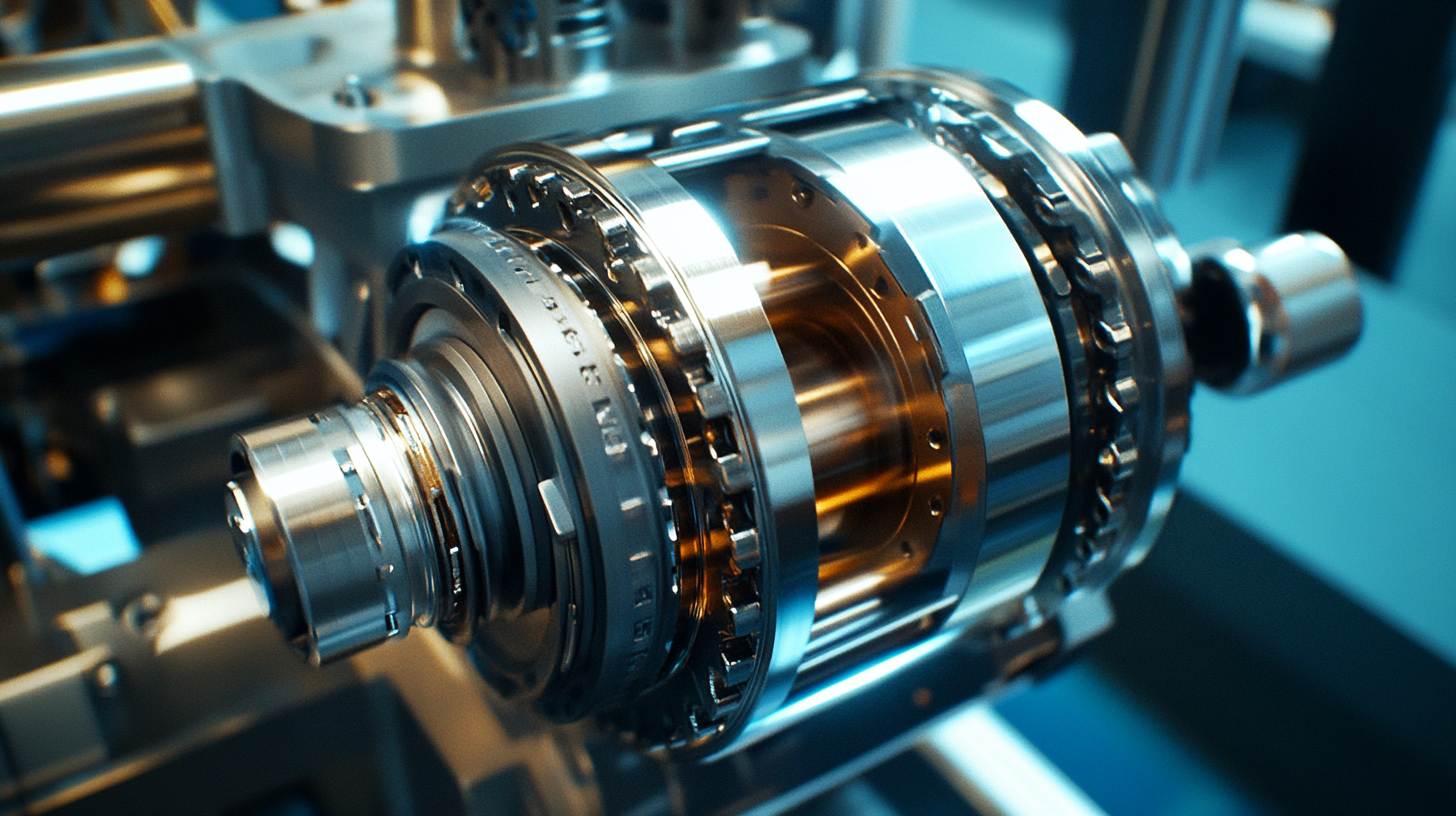

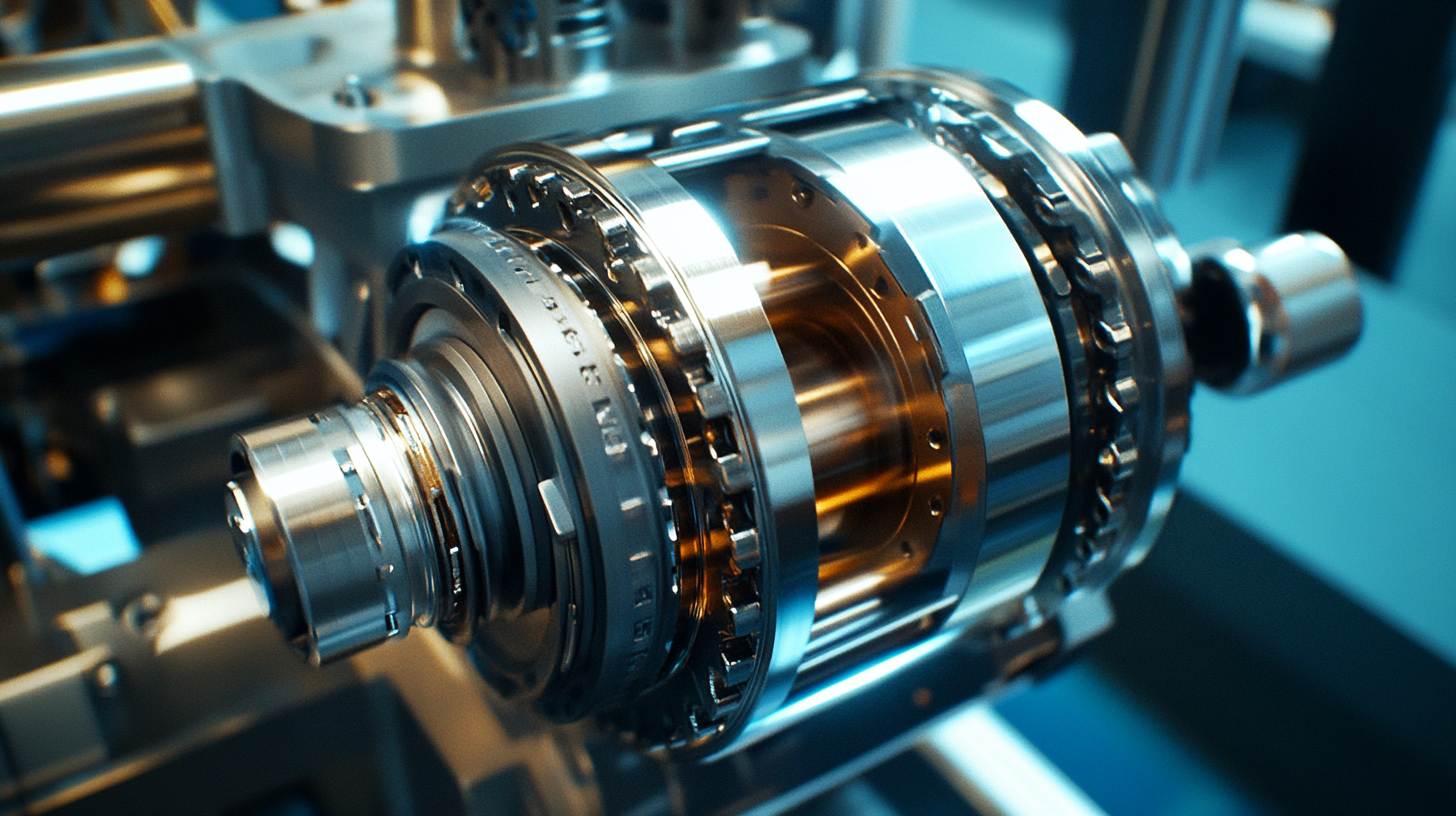

Moreover, advancements in materials and manufacturing processes are contributing to lighter and more durable helical inline geared motors. Innovations such as 3D printing and the use of advanced alloys are paving the way for motors that offer higher torque with reduced weight. These developments are particularly beneficial in sectors like automotive and aerospace, where weight savings can lead to significant performance improvements and energy efficiency.

Another noteworthy trend is the increasing focus on sustainability. Manufacturers are now prioritizing energy-efficient designs that minimize environmental impact while meeting stringent regulations. This shift not only aligns with the global movement towards greener practices but also presents buyers with options that can enhance their corporate social responsibility initiatives. The future of helical inline geared motors is poised to not only meet the demands of modern applications but also contribute positively to the world around us.

Key Technological Advances Shaping the Future of Gear Motors

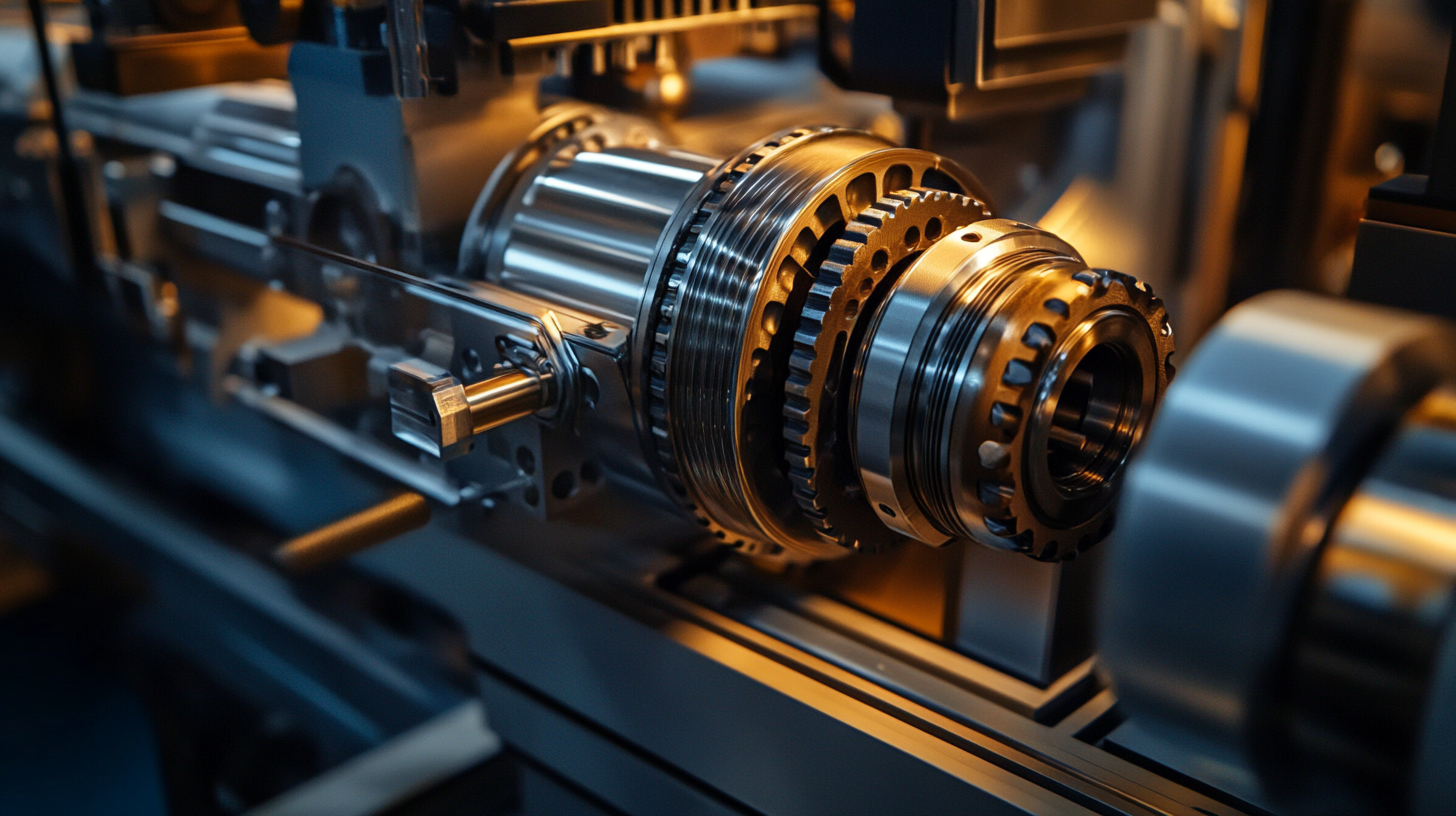

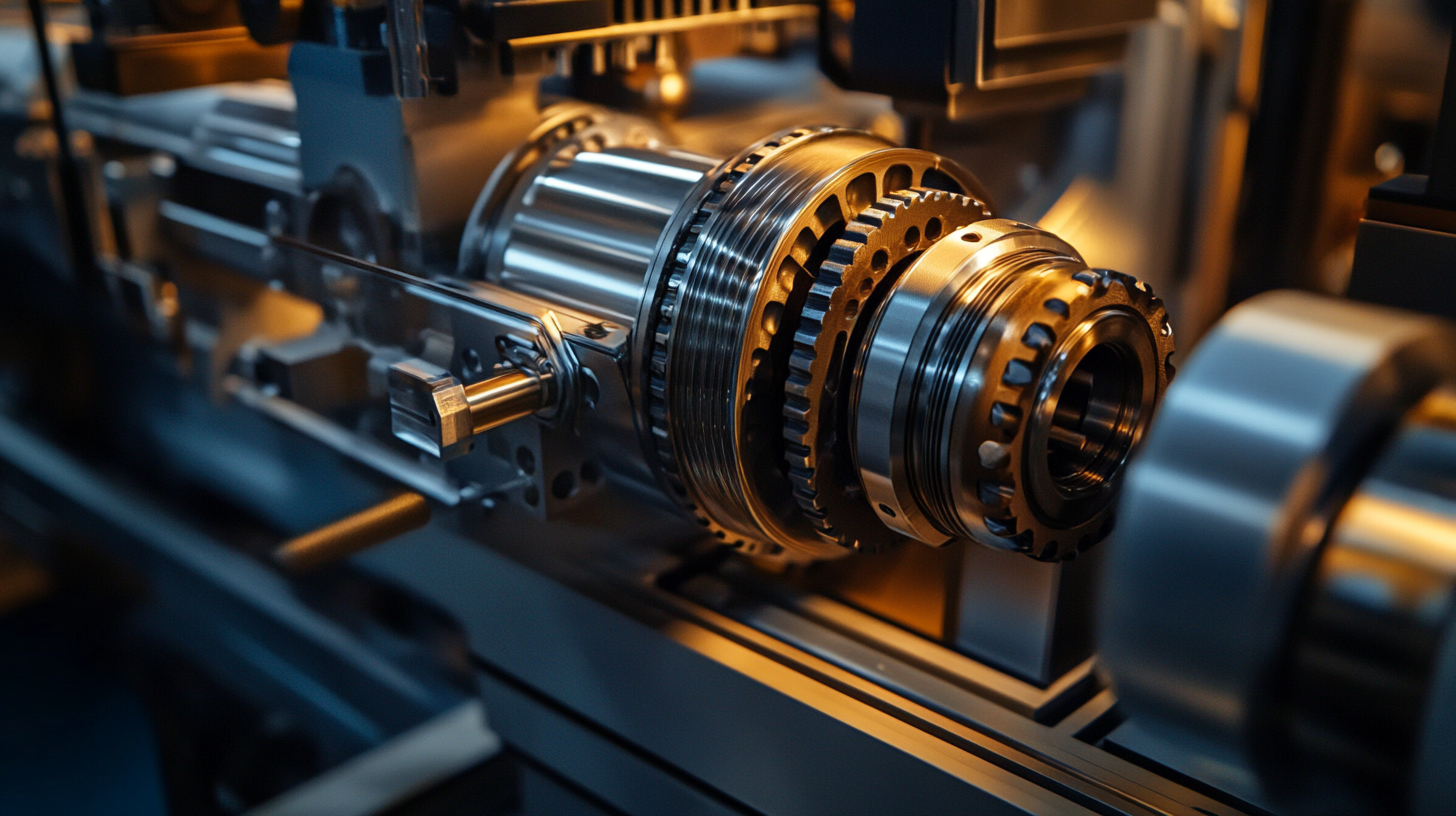

The landscape of helical inline geared motors is undergoing significant transformations, driven by advancements in technology that enhance performance, efficiency, and adaptability. One of the key technological innovations is the development of smarter control systems. These systems utilize advanced algorithms and real-time data to optimize motor performance, leading to improved energy efficiency and reduced operating costs. The integration of Internet of Things (IoT) technology also allows for remote monitoring and predictive maintenance, ensuring that potential issues are addressed before they escalate into costly downtimes.

Another important trend is the miniaturization of components without compromising on strength and reliability. Innovative materials, such as advanced alloys and composites, are being employed to create smaller and lighter gear motors. This allows for more versatile applications in tight spaces, making them ideal for industries ranging from robotics to aerospace. Furthermore, the trend towards sustainability is prompting manufacturers to focus on eco-friendly practices and recyclable materials, aligning with global environmental standards.

In tandem with these hardware advancements, software developments are enhancing the functionality of helical inline geared motors. Enhanced simulation software enables engineers to design and test motor systems virtually, streamlining product development cycles. The rise of artificial intelligence in optimization processes can analyze operational data and suggest improvements, paving the way for proactive enhancements in motor performance. These cutting-edge technologies collectively signify a promising future for helical inline geared motors, catering to the evolving needs of global buyers seeking innovative solutions.

Critical Factors to Consider When Sourcing Helical Inline Gear Motors

When sourcing helical inline geared motors, it's essential to consider several critical factors that can impact both performance and efficiency. These motors, recognized for their compact design and high reliability, play a pivotal role in various applications, from industrial machinery to renewable energy systems. As industries increasingly lean towards sustainability, the integration of helical inline geared motors in green technologies, such as wind turbines, has become more commonplace. For example, recent innovations in the design and fabrication of helical vertical axis wind turbines highlight the potential for these motors to contribute effectively to electricity supply while minimizing environmental footprints.

One of the foremost considerations when selecting helical inline geared motors is the torque and speed requirements specific to your project. Understanding the operational parameters is crucial, as this affects the motor’s efficiency and longevity. Additionally, the material and construction quality of the motor significantly influence its performance in demanding environments. Buyers should look for manufacturers that prioritize durability and offer products that can withstand extreme conditions, ensuring reliability over the long term. Compatibility with existing systems and ease of maintenance should also factor into sourcing decisions, as these aspects can lead to reduced downtime and operational costs.

Moreover, as technological advancements continue to drive innovation in geared motor design, it's vital to stay updated on the latest trends and features. Leveraging advancements in smart technology and automation can enhance the overall functionality of helical inline geared motors, offering improved performance analysis and predictive maintenance capabilities. By remaining informed about these innovations, global buyers can make more strategic sourcing decisions that align with their operational needs and sustainability goals.

Sustainability and Efficiency: The Future of Gear Motor Innovations

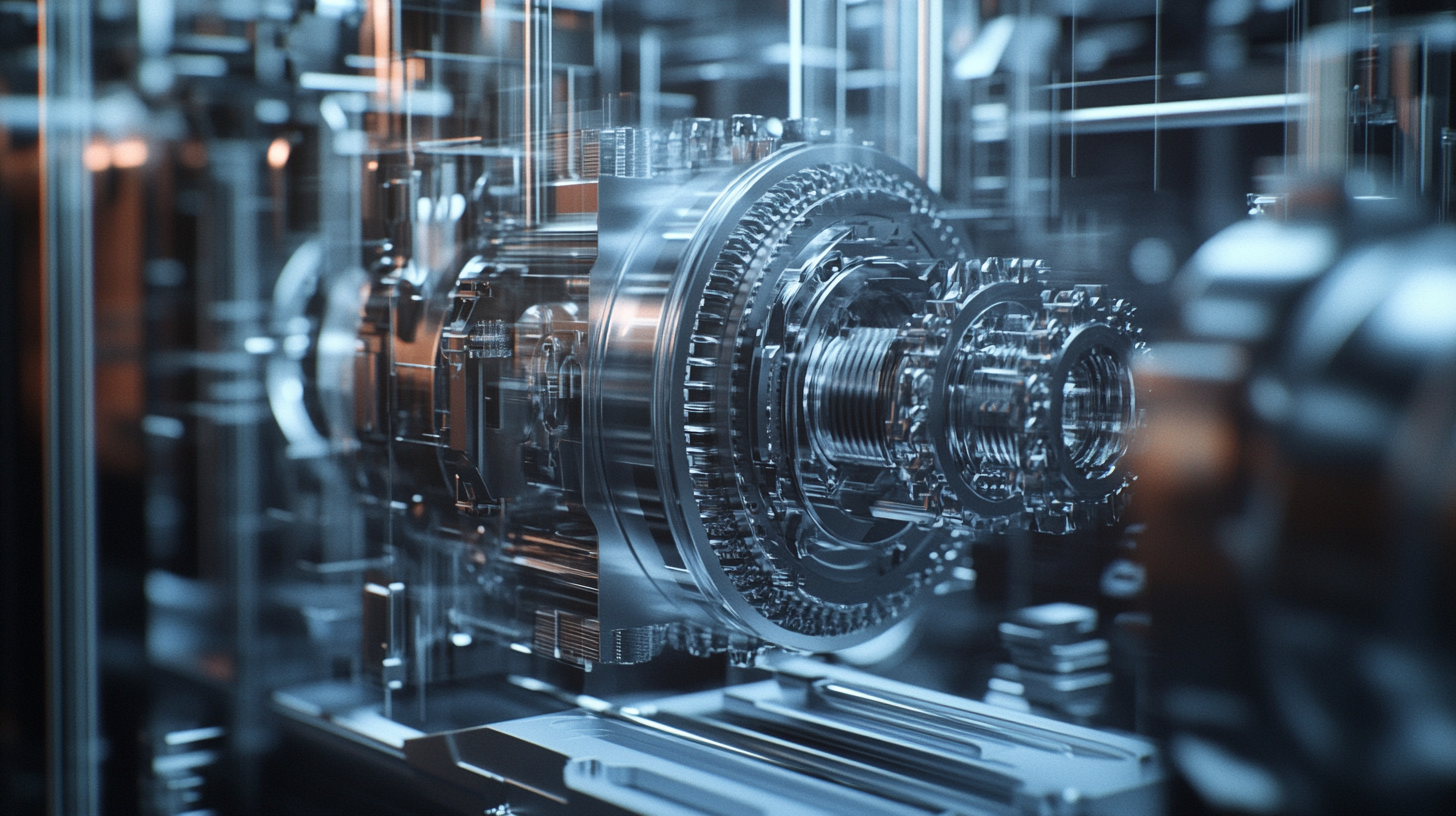

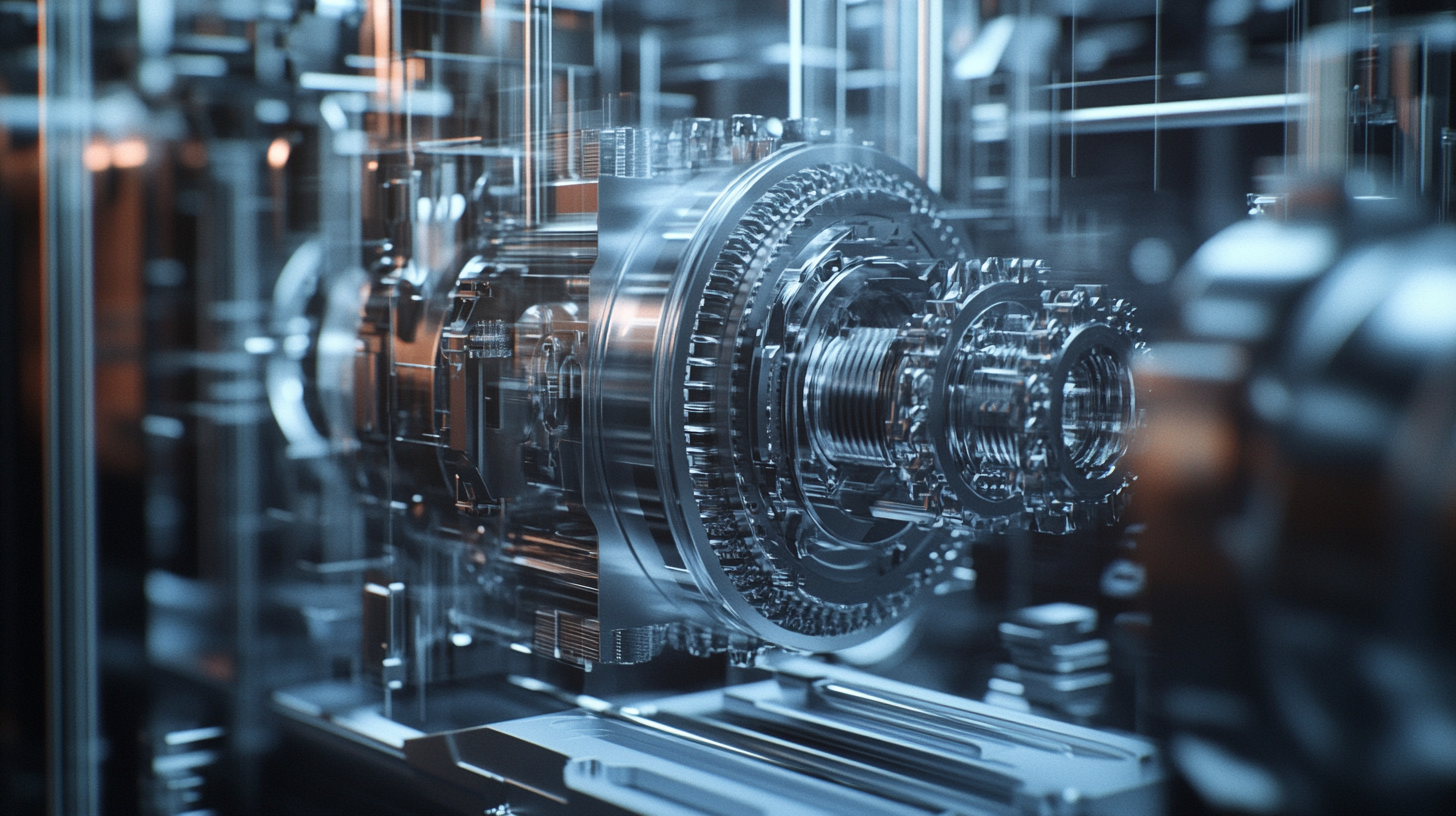

As industries worldwide strive to enhance their sustainability efforts, the future of helical inline geared motors is set against a backdrop of innovative designs that prioritize both efficiency and environmental responsibility. These motors are increasingly recognized for their ability to convert electrical energy into mechanical power with minimal energy loss, making them a vital component in reducing carbon footprints. By improving energy efficiency, manufacturers are able to create motors that not only perform better but also align with global efforts to combat climate change.

Emerging technologies play a crucial role in this evolution. The integration of smart sensors and IoT capabilities into helical inline geared motors enhances their performance monitoring, enabling real-time adjustments that optimize energy usage. This data-driven approach not only improves the operational efficiency of machinery but also allows for predictive maintenance, reducing waste and prolonging the lifespan of equipment. As a result, businesses can achieve significant cost savings while minimizing their environmental impact.

Moreover, advancements in materials and manufacturing processes are leading to lighter, more durable motors that consume less energy during operation. Innovations such as magnetic gearing and improved lubrication systems contribute to lower friction and reduced heat generation, further enhancing efficiency. As global buyers seek solutions that align with sustainability goals, these innovations in gear motors represent a promising frontier, offering both enhanced performance and a commitment to a greener future.

Global Market Insights: Demand and Growth Prospects for Gear Motors

The global market for gear motors, particularly helical inline geared motors, is witnessing a significant surge in demand driven by advancements in technology and an increasing need for precision in various applications. As industries continue to innovate, the flexibility and efficiency of helical inline geared motors position them as a preferred choice across sectors such as manufacturing, automotive, and robotics. This growing trend is underscored by the rising focus on energy efficiency and automation, which are pivotal in enhancing productivity and reducing operational costs.

In recent years, the growth prospects for gear motors have been largely influenced by the expansion of emerging markets and evolving consumer preferences. As economies develop, there is a marked increase in infrastructure projects and industrialization, fueling the need for reliable motion control systems. Furthermore, manufacturers are responding to this demand by investing in research and development, leading to the creation of more sophisticated and compact motor designs. This innovation not only improves performance but also opens up new applications that were previously unattainable with traditional motor designs.

Additionally, sustainability has become a cornerstone of growth in the gear motor industry. Companies are now prioritizing eco-friendly manufacturing practices and developing products that minimize energy consumption. With regulatory pressures and consumer awareness on the rise, manufacturers are tasked with providing solutions that not only meet performance standards but also contribute to environmental goals. As a result, the helical inline geared motor market is evolving rapidly, poised to play a crucial role in the machinery of the future.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor