7 Key Advantages of Choosing Geared Motor Electric for Your Industrial Needs

In the rapidly evolving industrial landscape, the choice of machinery and equipment can significantly impact productivity and efficiency. One technology that has garnered attention for its reliability and performance is the Geared Motor Electric. These motors combine the capabilities of electric drives with the mechanical advantages of gear reduction, offering a perfect solution for a variety of industrial applications. Understanding the strengths of Geared Motor Electric systems can help businesses make informed decisions that lead to enhanced operational efficiency and reduced costs.

Industry leaders are increasingly recognizing the benefits of integrating Geared Motor Electric solutions into their workflows. From significantly improved torque output to compact designs that save space, the advantages are numerous. This blog will delve into seven key advantages of choosing Geared Motor Electric for your industrial needs, providing insights that can guide your investments towards more efficient and sustainable operations. Whether you are in manufacturing, logistics, or another sector requiring reliable power transmission, the merits of Geared Motor Electric systems are worth exploring.

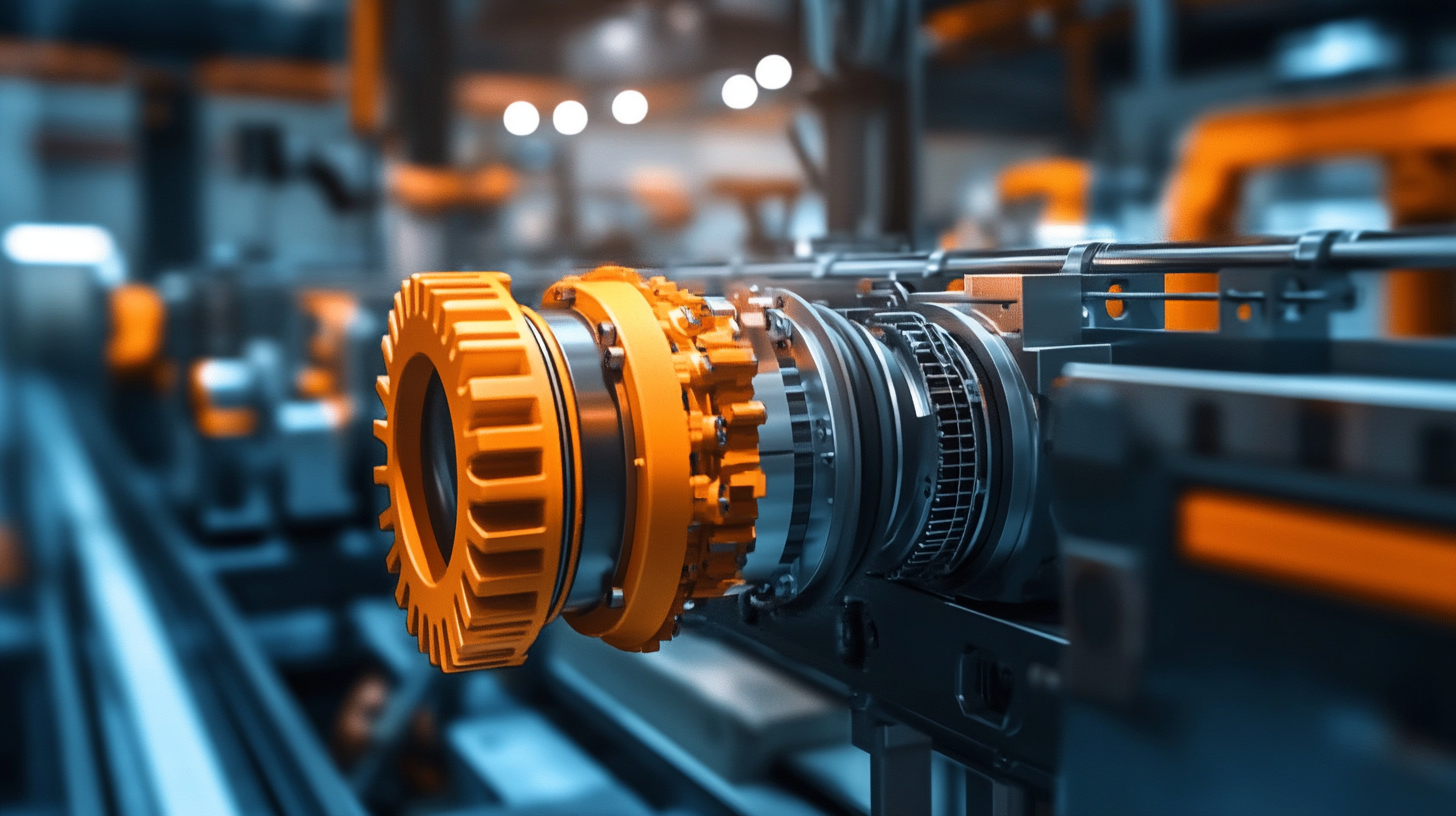

Advantages of Enhanced Efficiency in Geared Motor Electrics

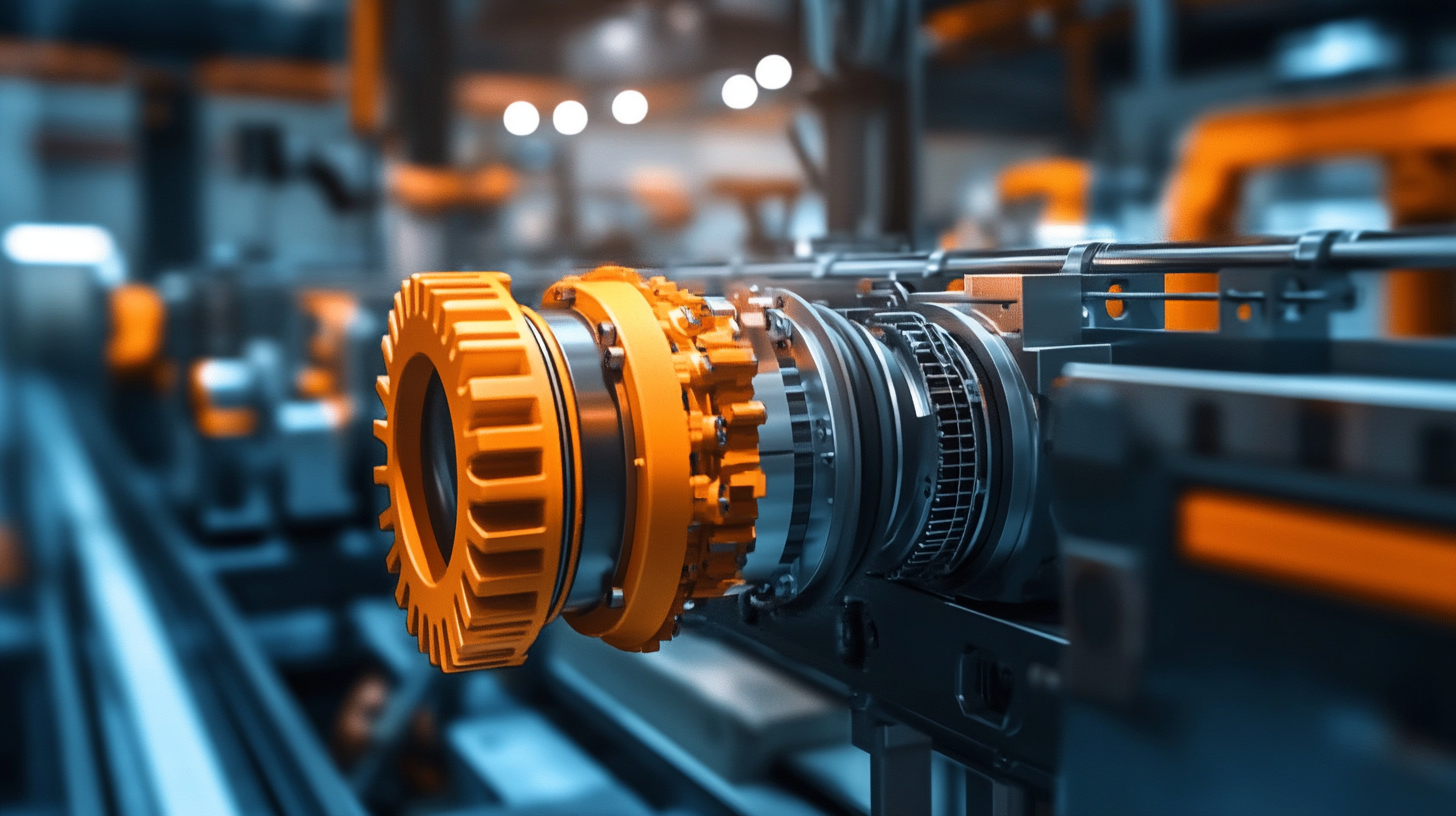

Geared motors have become a staple in various industrial applications due to their enhanced efficiency and reliable performance. According to a report by the International Electrotechnical Commission (IEC), geared motors can increase energy efficiency by up to 15%, making them a cost-effective choice for industries looking to optimize their operations. This significant improvement in efficiency leads to reduced energy consumption, which is not only beneficial for the environment but also results in considerable savings on utility bills over time.

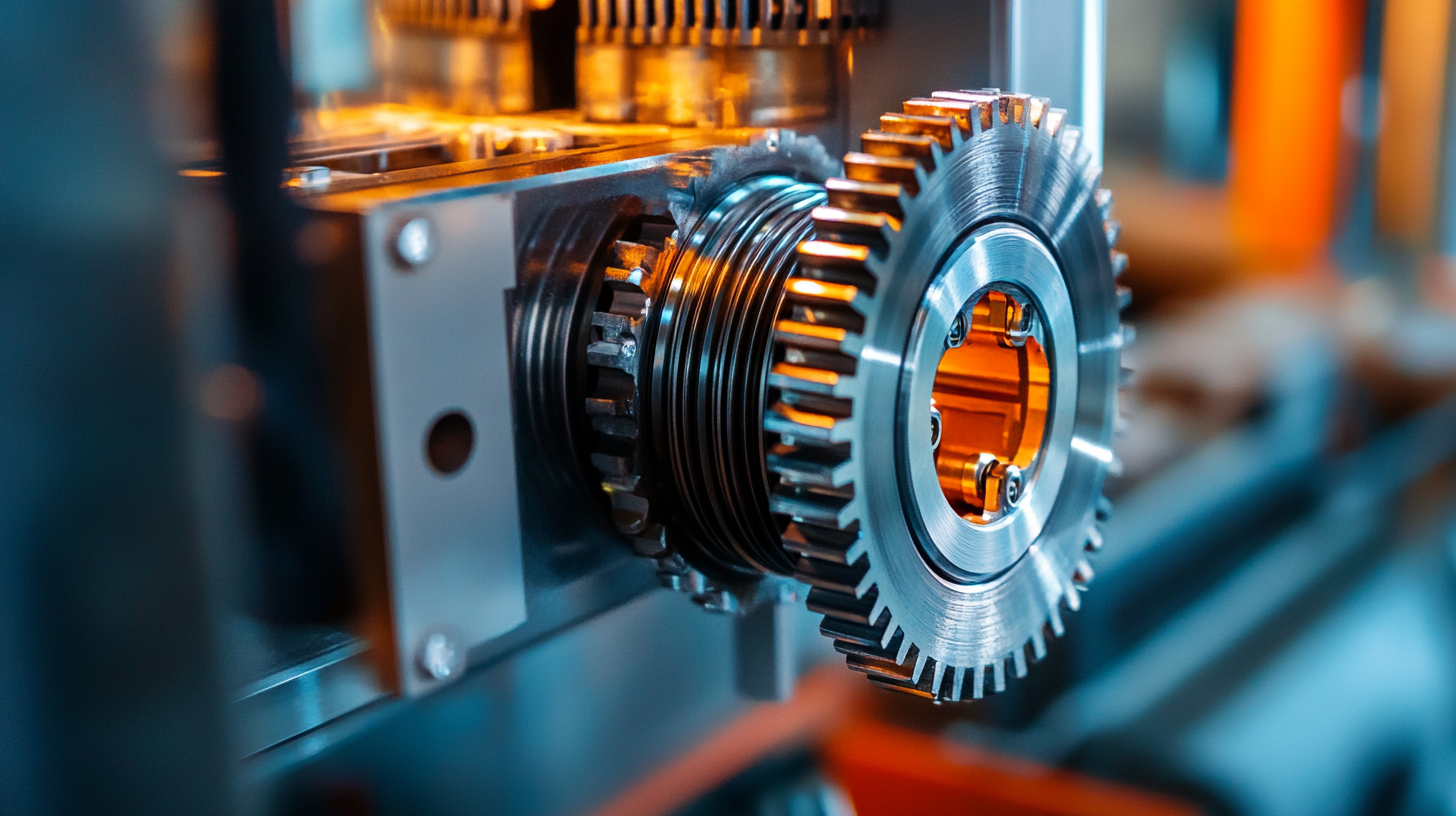

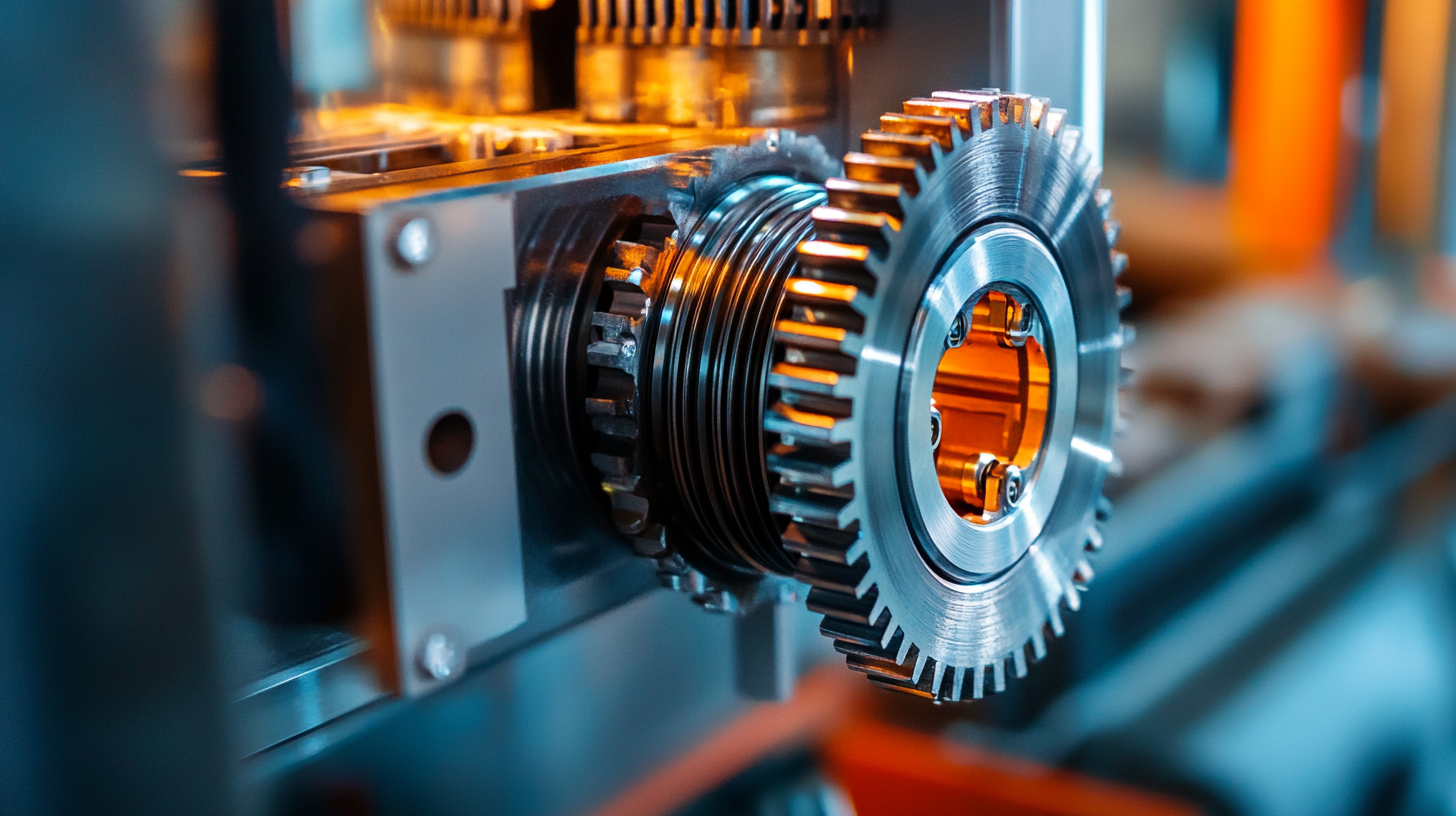

One of the key benefits of geared motor electrics is their ability to provide high torque while maintaining a compact design. A study from the Electric Power Research Institute (EPRI) underscores that compact geared motors can achieve torque increases of up to 300% compared to standard motors. This capability allows industries to use smaller, more efficient motors without sacrificing performance, thus freeing up valuable space in manufacturing facilities and reducing material costs.

Additionally, the integration of advanced technologies in geared motors, such as variable frequency drives (VFDs), enhances their operational efficiency. The Control Systems Report notes that employing VFDs in conjunction with geared motors can yield improvements in overall system efficiency by up to 20%. This synergy not only optimizes the performance of machinery but also extends their lifespan, ultimately contributing to lower maintenance costs and increased productivity in industrial settings.

Cost-Effective Solutions for Long-Term Industrial Operations

When considering long-term industrial operations, the efficiency and effectiveness of a geared motor electric drive system can significantly contribute to cost savings. These systems provide precise speed control and high torque output, which can enhance equipment performance and reduce operational expenses. Recent reports indicate that leveraging such technology can streamline processes, with some industries reporting a potential 20-30% reduction in energy consumption when transitioning to geared motors.

Moreover, the growing needs for sustainable practices in industries like water treatment underscore the importance of choosing energy-efficient machinery. Investments in projects, such as the recent seawater desalination plant designed in partnership with French firms, illustrate the trend towards modern, sustainable solutions. This facility, capable of producing 100,000 tons of freshwater daily, exemplifies how industrial setups demand consistent and reliable water sources, highlighting the critical role of efficient electric motor systems that support such operations.

In addition to operational efficiency, geared motors are increasingly seen as integral components in achieving green objectives. According to expert forecasts, the market for innovative water treatment solutions is expected to grow rapidly, with the magnetic pump market projected to expand from $700 million in 2024 to $960 million by 2033, reflecting a compound annual growth rate of approximately 3.6%. This growth signifies a shift towards adopting advanced technologies capable of mitigating environmental impacts while ensuring economic viability.

Investing in geared motor electric systems today not only promises immediate operational benefits but also aligns with the broader industrial strategy of sustainability and resource efficiency, paving the way for future advancements in various sectors. As industries adapt to both technological advancements and environmental considerations, the role of geared motors will undoubtedly become more pronounced.

Compact Design: Maximizing Space Utilization in Machinery

In the competitive landscape of industrial machinery, selecting the right components can significantly enhance operational efficiency. Among these, geared motor electric systems offer remarkable advantages, particularly in their compact design. This feature not only maximizes space utilization in machinery but also facilitates more streamlined layouts in workplaces where every square foot matters.

The compact design of geared motors allows manufacturers to integrate them into existing systems without extensive modifications. This efficiency of space becomes crucial in environments like agricultural machinery, where optimizing design can lead to better workflow and productivity. For instance, the newly launched mini-excavators illustrate how compact machinery can deliver powerful performance while occupying less physical space, highlighting the importance of innovation in design.

Moreover, the adaptability of geared motor electric systems in various applications ensures they remain a relevant choice for industries focused on growth and sustainability. As businesses increasingly look to minimize their environmental footprint, the compact nature of these motors plays a vital role in designing machines that are not only efficient but also eco-friendly. By investing in technologically advanced geared motors, companies can position themselves at the forefront of industrial advancement, leveraging space-saving designs to meet contemporary challenges.

Versatility Across Various Industrial Applications

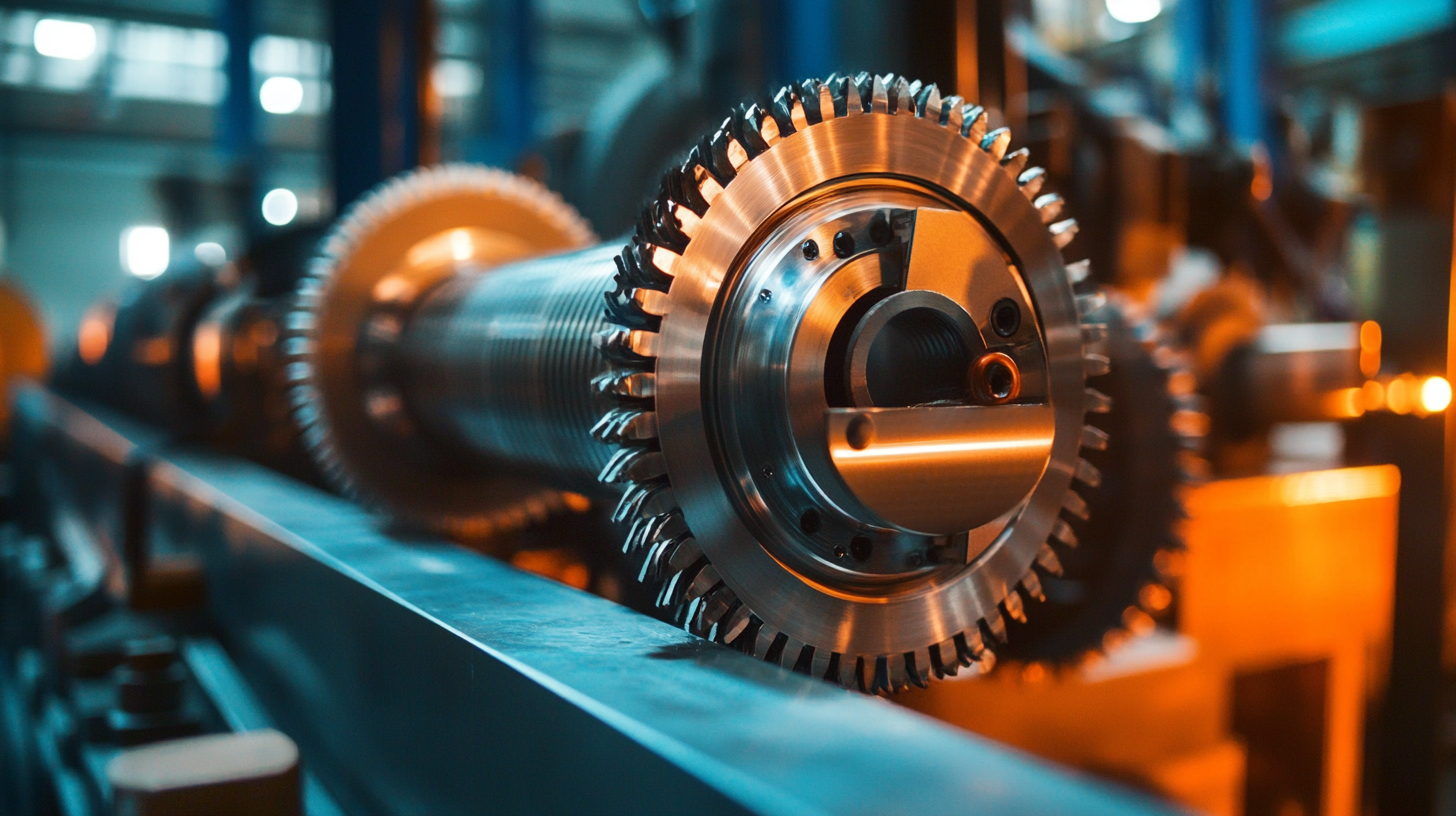

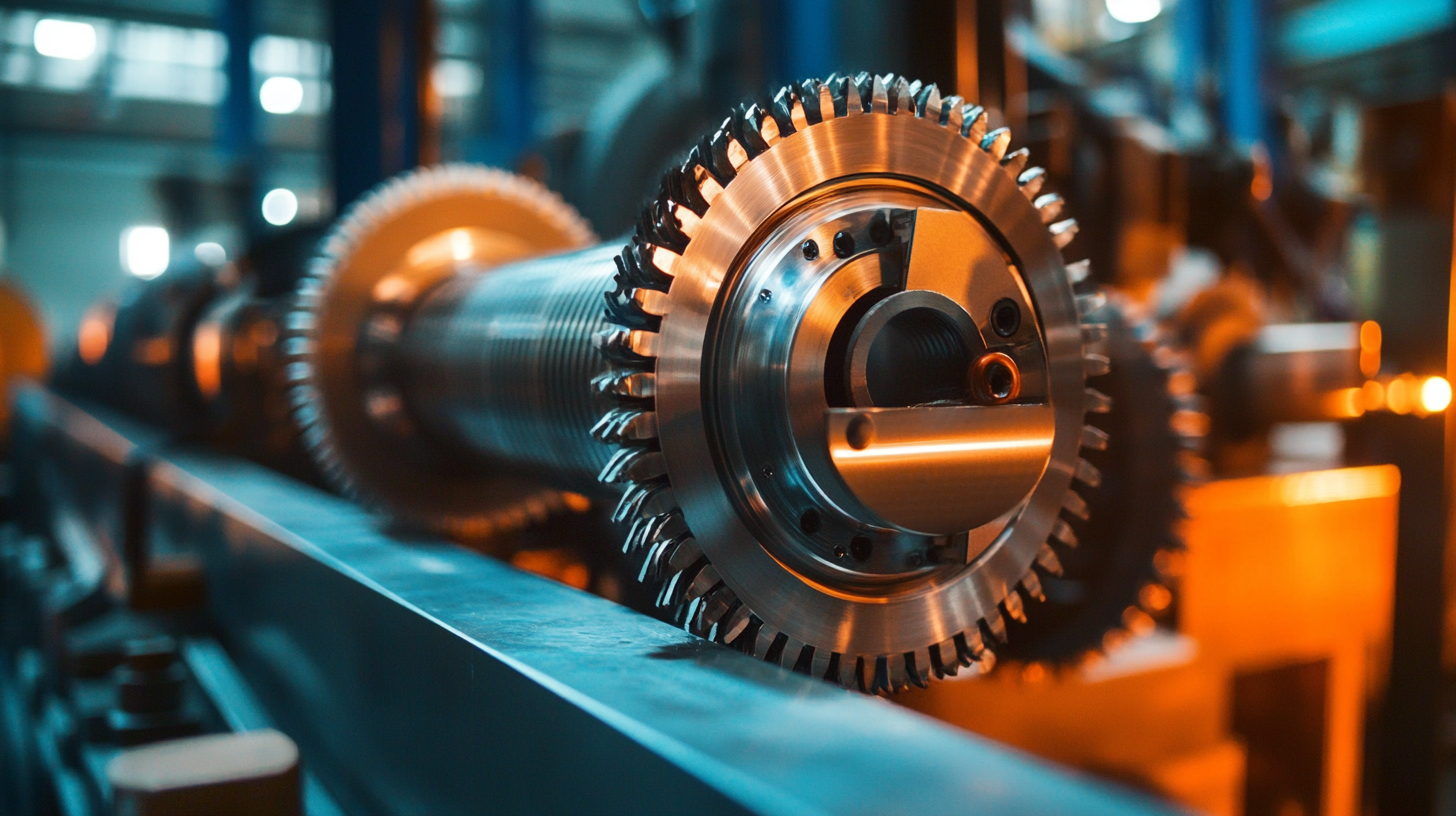

In today's rapidly evolving manufacturing landscape, the versatility of geared motor electrics plays a crucial role across various industrial applications. These compact yet powerful motors are designed to deliver efficient performance in multiple sectors, ranging from robotics to packaging and beyond. According to a report by Research and Markets, the global electric motor market, including geared motors, is expected to reach $185.9 billion by 2027, illustrating a steady growth trajectory driven by increasing automation and energy efficiency demands.

One of the significant advantages of geared motor electrics is their ability to provide high torque at low speeds, making them ideal for applications where precision and power are essential. Industries such as food processing and automotive manufacturing rely heavily on these motors for conveyor systems and automation equipment. A study by Technavio highlights that the growth in automation across the food and beverage sector is anticipated to propel the geared motor market, with a CAGR of over 6% from 2021 to 2025.

Furthermore, geared motor electrics are notable for their adaptability, which allows them to be integrated seamlessly into existing systems. This adaptability is particularly valuable in sectors such as textiles and pharmaceuticals, where machinery often requires custom specifications. Industry professionals have reported a decrease in downtime and maintenance costs due to the reliability and robustness of these motors. As businesses continue to focus on operational efficiency and sustainability, the demand for geared motor electrics will likely remain strong across diverse industrial applications.

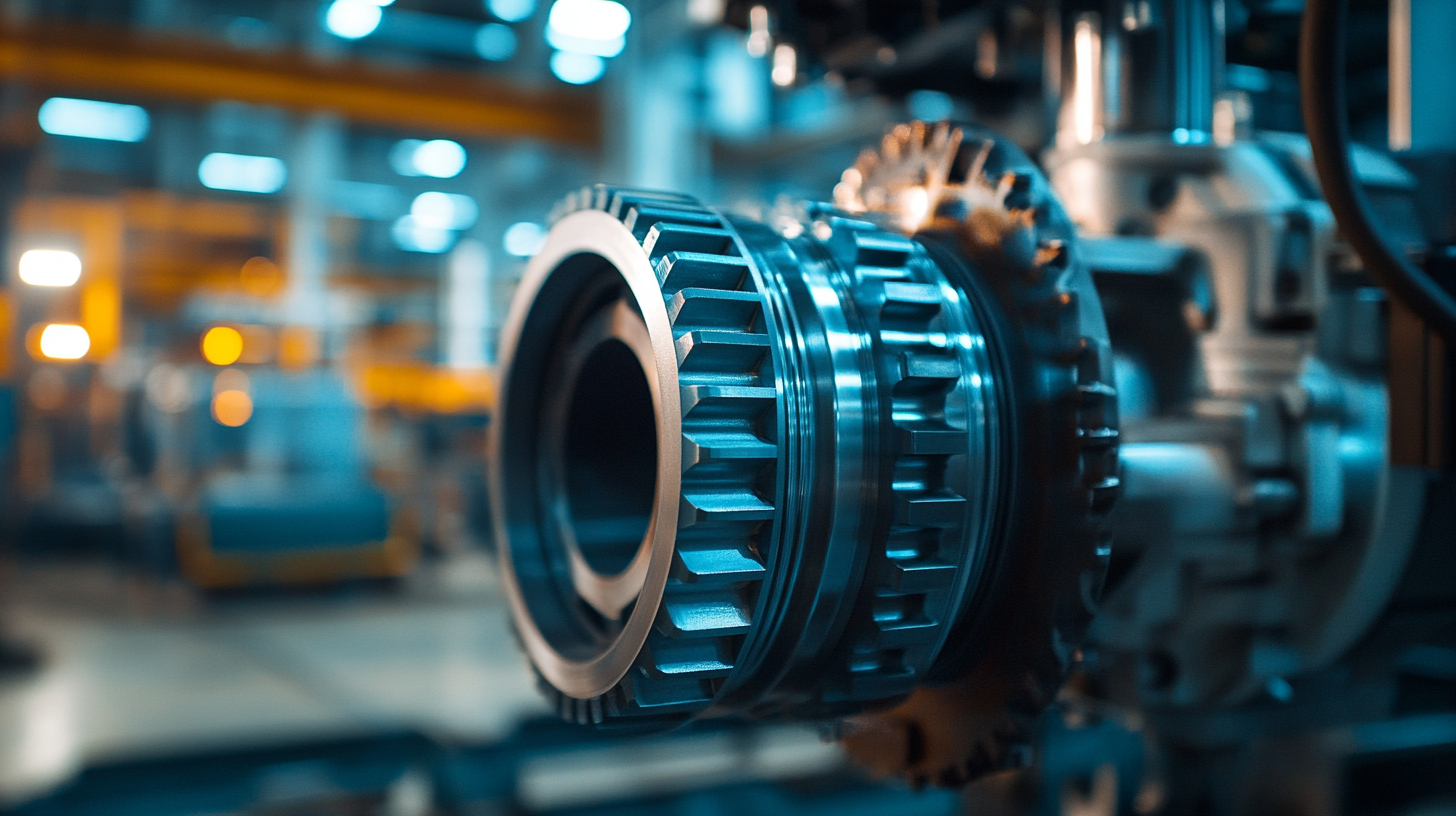

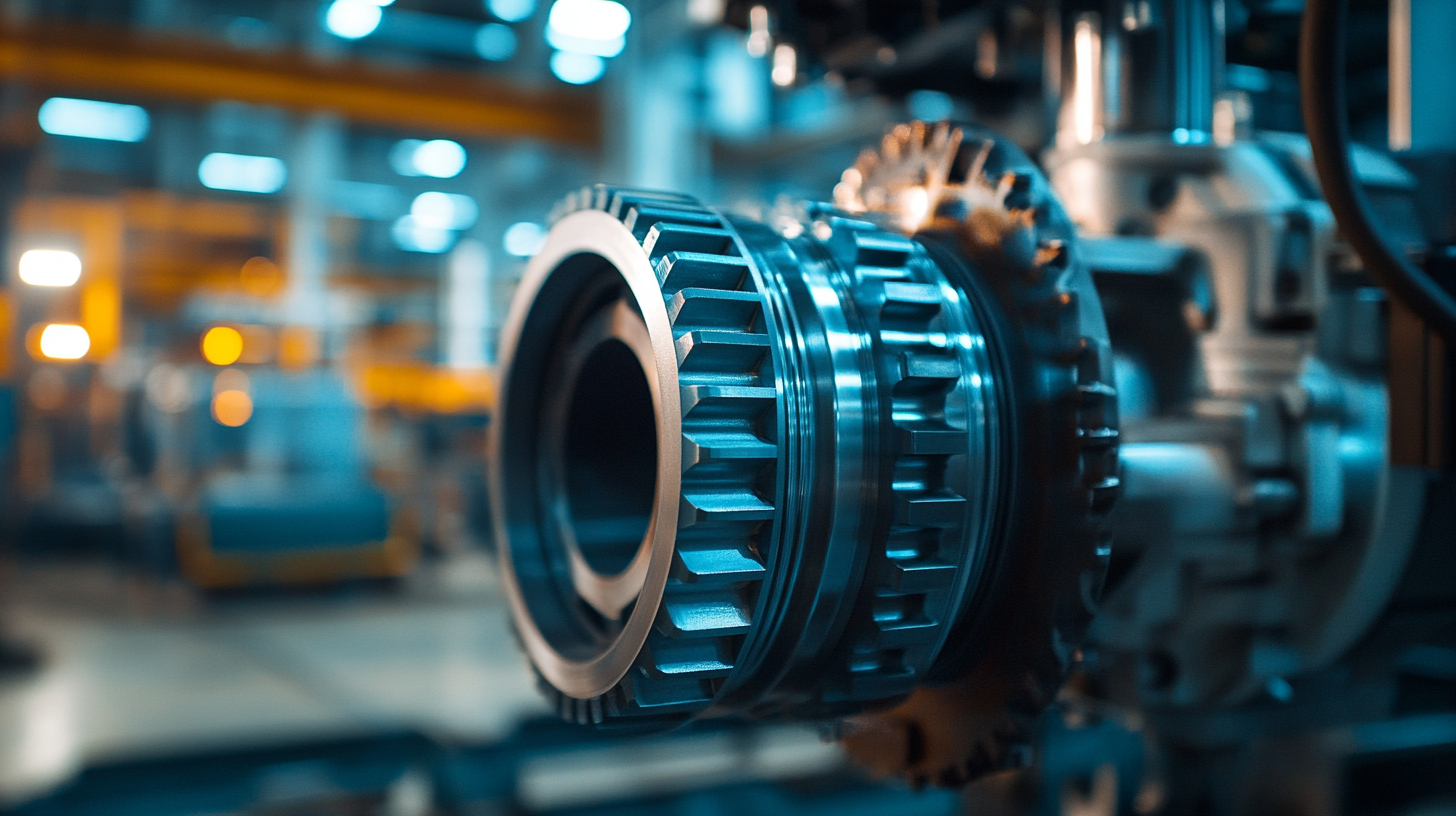

Improved Performance and Reliability in Challenging Environments

When it comes to enhancing performance and reliability in challenging industrial environments, geared motor electric systems stand out as a vital choice for many operations. These motors are designed to operate efficiently under demanding conditions, making them suitable for a wide range of applications, from manufacturing to mining. According to a report by MarketsandMarkets, the global geared motor market is projected to reach USD 12.18 billion by 2025, driven by the industrial automation sector's increasing reliance on these robust systems.

One of the key advantages of geared motors is their ability to provide high torque at low speeds. This capability is particularly essential in environments where heavy loads must be moved or controlled with precision. For example, the use of geared motor systems in conveyor belts has been shown to improve overall system efficiency, reducing energy consumption by up to 30%. Such enhancements translate not only to better performance but also to significant cost savings over time.

Moreover, geared motors feature enhanced durability, which is crucial for industrial applications that involve harsh conditions, such as fluctuating temperatures and exposure to dust and moisture. A report from Technavio indicates that the durability of geared motors contributes to a reduction in maintenance needs by 20% or more, allowing for uninterrupted operations and minimizing downtime. This reliability ensures that industries can meet production schedules without the frequent interruptions typical of less robust systems.

In conclusion, the integration of geared motor electric systems into industrial operations is pivotal for improving performance and reliability, particularly in challenging environments. Their ability to adapt and function efficiently under various conditions underscores their position as a preferred choice in the evolving landscape of industrial technology.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor