What is Nordmkygearbox and How it Benefits Your Machinery Performance

In the realm of industrial machinery, the efficiency and performance of equipment are paramount. One innovative solution that has been gaining traction is the Nordmkygearbox. This advanced gearbox technology plays a crucial role in optimizing the performance of various machinery applications. Renowned industry expert, Dr. Emily Carter, highlights its significance by stating, "The Nordmkygearbox not only enhances torque transfer but also significantly reduces energy consumption, leading to overall operational efficiency."

The Nordmkygearbox is designed to deliver superior performance and reliability, essential for modern manufacturing and equipment operations. By streamlining power transmission and minimizing wear and tear, it enables machinery to function at its best, reducing downtime and maintenance costs. Furthermore, as industries increasingly focus on sustainability, the Nordmkygearbox stands out by offering a solution that aligns with energy-saving goals while maintaining high output levels.

As we delve into the intricacies of the Nordmkygearbox, it becomes evident that this innovation is more than just a mechanical component; it is a critical element that contributes to the success of machinery performance. Understanding its benefits offers valuable insights for manufacturers seeking to enhance their operational capabilities.

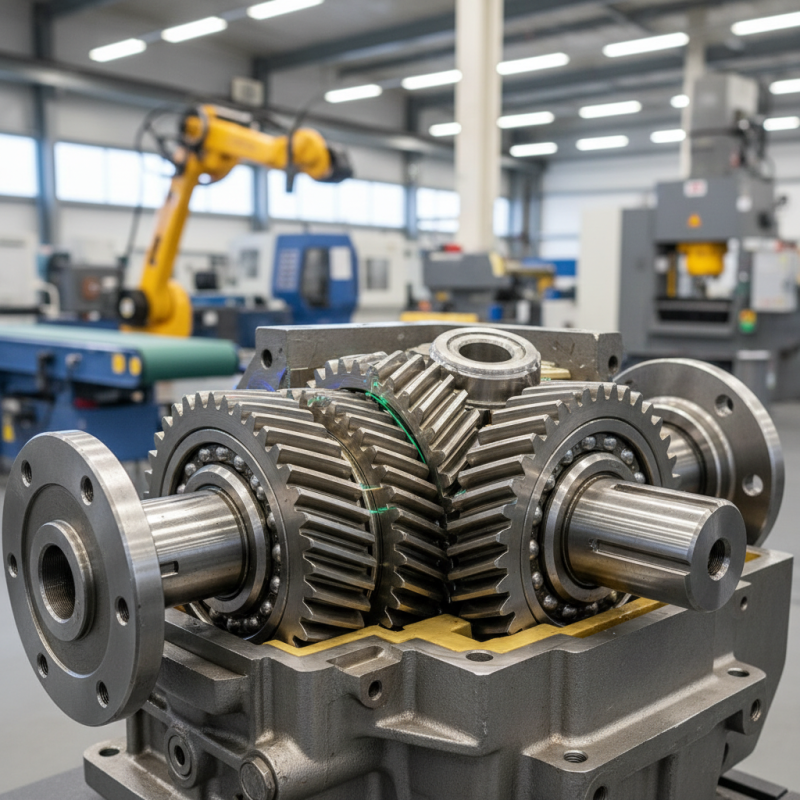

What is Nordmkygearbox and Its Role in Machinery

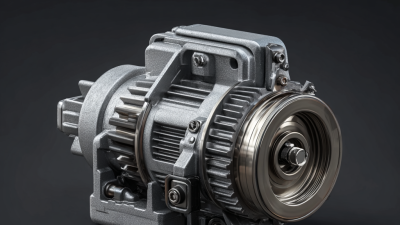

Nordmkygearbox is a critical component in the machinery sector, designed to enhance the efficiency and reliability of various operational processes. Its primary function is to convert the speed and torque generated by motors into more usable power for machinery systems. By optimizing these elements, Nordmkygearbox ensures that equipment runs smoothly, ultimately reducing wear and tear on components, which can lead to significant maintenance costs.

The role of Nordmkygearbox in machinery extends beyond simple power conversion. It also contributes to precision in machinery operations, enabling tasks to be performed at optimal speeds. This is particularly important in high-performance environments where timing and precision can impact overall productivity.

Furthermore, the gearbox acts as a buffer against overload, providing essential protection to motors and other components within the mechanical system. This not only extends the lifespan of machinery but also ensures consistent operational performance, making it a valuable asset in any industrial setup.

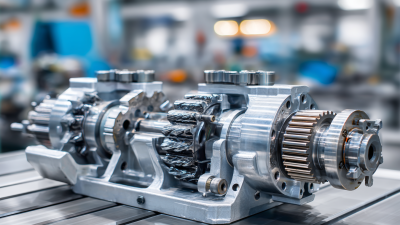

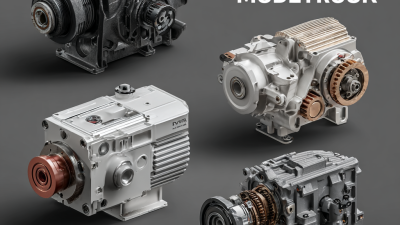

Key Features of Nordmkygearbox Explained

The Nordmkygearbox is revolutionizing machinery performance across various industrial sectors. One of its standout features is its high torque capacity, which can significantly enhance operational efficiency. According to a recent industry report by the International Mechanical Engineering Society, gearboxes that feature advanced torque capabilities can improve power transmission by up to 30%, optimizing the functionality of machinery and reducing energy consumption. This efficiency not only leads to lowered operational costs but also extends the lifespan of reliance on heavy machinery.

Another key feature that sets Nordmkygearbox apart is its compact design. This design allows for easier installation in tight spaces, a critical factor in industries where equipment needs are continuously evolving. The reduced footprint also enables better thermal management, which can prevent overheating—a common issue in traditional gearbox systems. As highlighted in the Journal of Manufacturing Processes, implementing compact gearbox solutions has led to a reduction in equipment overheating incidents by nearly 25%, thereby increasing overall productivity.

**Tips:** To maximize the benefits of a Nordmkygearbox, ensure regular maintenance checks that can help in identifying wear and preventing unexpected failures. Additionally, aligning your machinery properly with the gearbox can improve operational efficiency and reduce strain on components. Regularly updating lubrication can also enhance performance and durability, ensuring that your machinery continues to operate at peak condition.

What is Nordmkygearbox and How it Benefits Your Machinery Performance - Key Features of Nordmkygearbox Explained

| Feature |

Description |

Benefits |

| High Efficiency |

Designed to minimize energy loss, resulting in improved overall performance. |

Lower operational costs and reduced carbon footprint. |

| Compact Design |

Space-saving construction suitable for tight spaces in machinery. |

Easier integration into existing systems and machinery. |

| Durability |

Constructed from high-quality materials to withstand heavy use. |

Longer lifespan and reduced maintenance requirements. |

| Quiet Operation |

Engineered for low noise levels during operation. |

Enhanced working environment, reducing noise pollution. |

| Versatility |

Compatible with a wide range of machinery applications. |

Suitable for various industries, enhancing operational flexibility. |

Benefits of Using Nordmkygearbox for Machinery Performance

The Nordmkygearbox is an essential component for enhancing machinery performance across various industrial applications. One of the primary benefits of using this gearbox is its ability to increase torque efficiency. By optimizing the power transmission between the motor and the machine, the Nordmkygearbox ensures that energy is used effectively, reducing wastage and improving the overall output. This efficiency can lead to lower operational costs and extended machinery lifespan, making it an attractive choice for manufacturers aiming for sustainability and productivity.

Another significant advantage of the Nordmkygearbox is its reliability in different operating conditions. Designed to withstand high loads and adverse environments, this gearbox minimizes downtime caused by mechanical failures. This reliability fosters a consistent performance in industrial operations, allowing businesses to maintain their production schedules without unexpected interruptions. Furthermore, the ease of maintenance and installation associated with the Nordmkygearbox provides additional convenience, enabling quicker adjustments and repairs that keep the machinery running smoothly. Overall, these benefits highlight the value of incorporating the Nordmkygearbox into machinery systems, contributing to enhanced performance and efficiency.

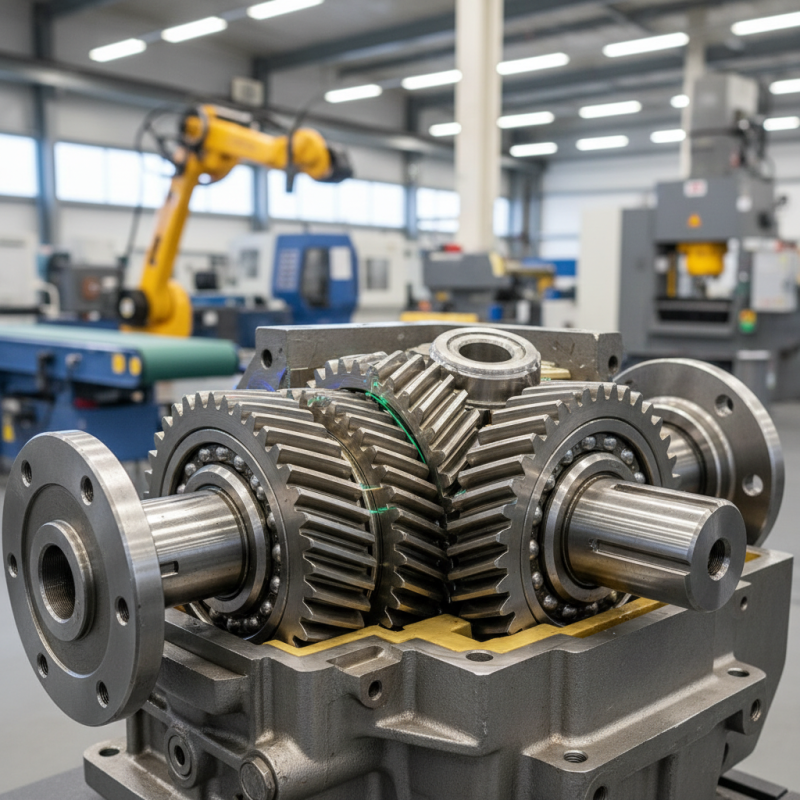

How Nordmkygearbox Enhances Efficiency and Durability

When it comes to enhancing machinery performance, the efficiency and durability of components are paramount. A well-engineered gearbox can significantly influence these factors, ensuring that machinery operates under optimal conditions. By utilizing innovative design techniques and high-quality materials, modern gearboxes can effectively reduce energy losses and improve transmission performance. This means that machinery can achieve higher outputs while consuming less energy, ultimately lowering operational costs.

Moreover, the durability of a gearbox is critical for the longevity of machinery. Advanced materials and protective coatings can resist wear and tear, even in the most demanding environments. By minimizing maintenance requirements and preventing unexpected breakdowns, these gearboxes contribute to smoother operations and increased uptime. Furthermore, their ability to operate at higher torque levels without compromising performance leads to more reliable and robust machinery, making them an essential component in various industrial applications. The integration of such gearboxes not only boosts efficiency but also ensures that machines are built to last, providing substantial benefits to operations over time.

Applications of Nordmkygearbox in Various Industries

Nordmkygearbox is becoming increasingly important in various industrial applications due to its enhanced efficiency and performance. In the manufacturing sector, for instance, the integration of Nordmkygearboxes has led to a reported 15% improvement in energy consumption efficiency. This is crucial in industries that rely on high-performance machinery, such as automotive assembly and food processing, where precise torque and speed control directly impact production quality and operational costs.

In the renewable energy sector, the use of Nordmkygearboxes in wind turbine systems has allowed for a more reliable and effective conversion of kinetic energy into electrical energy. According to a recent industry report, the implementation of advanced gearing systems, including the Nordmkygearbox, has increased turbine efficiency by up to 20%. These improvements significantly contribute to achieving sustainability goals by maximizing energy output while minimizing operational downtime.

Moreover, in the robotics and automation field, Nordmkygearboxes facilitate enhanced movement precision, which is vital for complex assembly tasks. Reports indicate that robotic systems equipped with advanced gearbox technology can operate with an accuracy rate exceeding 98%, thereby reducing errors and increasing productivity in high-stakes environments like electronics manufacturing and pharmaceuticals. Such advancements underscore the transformative role that Nordmkygearbox technology plays across various sectors, driving performance and operational excellence.

Benefits of Nordmkygearbox in Various Industries

This bar chart illustrates the percentage increase in machinery performance across different industries when utilizing Nordmkygearbox. The data shows significant improvements in efficiency and output in various applications.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor