Exploring the Revolutionary Technology Behind Siemensmkygearbox Mechanics

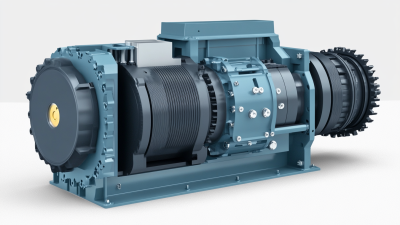

The Siemensmkygearbox represents a significant advancement in mechanical engineering, combining innovative technology with proven design principles to enhance operational efficiency and reliability. Recent industry reports indicate that the global gearbox market is projected to grow at a CAGR of 4.5%, reaching $35 billion by 2025, driven largely by the increasing demand for energy-efficient solutions in various sectors. The Siemensmkygearbox, with its unique design and advanced materials, offers superior performance that aligns with this trend, addressing challenges such as heat dissipation, load distribution, and noise reduction. By harnessing cutting-edge technology, Siemens is not only redefining mechanical functionality but also setting new standards in the gearbox sector, positioning themselves as leaders in a competitive market landscape.

The Siemensmkygearbox represents a significant advancement in mechanical engineering, combining innovative technology with proven design principles to enhance operational efficiency and reliability. Recent industry reports indicate that the global gearbox market is projected to grow at a CAGR of 4.5%, reaching $35 billion by 2025, driven largely by the increasing demand for energy-efficient solutions in various sectors. The Siemensmkygearbox, with its unique design and advanced materials, offers superior performance that aligns with this trend, addressing challenges such as heat dissipation, load distribution, and noise reduction. By harnessing cutting-edge technology, Siemens is not only redefining mechanical functionality but also setting new standards in the gearbox sector, positioning themselves as leaders in a competitive market landscape.

Understanding the Fundamental Principles of Siemensmkygearbox Mechanics

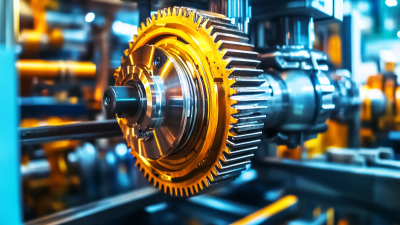

Siemensmkygearbox mechanics represent a significant advancement in engineering technology, merging efficiency with precision. At the core of this innovative design is the use of advanced materials and cutting-edge manufacturing techniques. Reports from the International Journal of Advanced Manufacturing Technology indicate that the incorporation of high-strength alloys can improve the lifespan of gearboxes by up to 30%. This durability is essential for industries that rely heavily on mechanical systems, such as automotive and aerospace.

One fundamental principle underpinning Siemensmkygearbox mechanics is the optimal gear design that minimizes friction loss, which can lead to significant energy savings. Research indicates that gearboxes utilizing helical gears, as seen in Siemensmky models, can achieve efficiencies exceeding 95% under optimal conditions. This is a critical statistic for industries eager to lower operational costs while maintaining performance.

**Tip:** When evaluating gearbox options, consider not only the efficiency ratings but also the maintenance requirements. Regular inspections and timely lubrication can further extend the lifespan and performance of mechanical systems. Additionally, investing in gearboxes with predictive maintenance features can preempt costly downtimes.

Comparative Analysis: Siemensmkygearbox vs. Traditional Gearbox Systems

The Siemensmkygearbox represents a significant advancement in gearbox technology compared to traditional gearbox systems. While traditional gearboxes typically rely on a simple gear mesh to transmit power, the Siemensmkygearbox incorporates advanced materials and innovative design principles. This results in reduced friction and improved efficiency, allowing for smoother operation and longer service life. Additionally, the Siemensmkygearbox is engineered to handle higher loads, making it suitable for demanding industrial applications where reliability is critical.

In a comparative analysis, the Siemensmkygearbox demonstrates superior performance metrics versus conventional gearboxes. For instance, its ability to operate at elevated temperatures without compromising efficiency significantly extends its lifespan. Furthermore, the integration of smart monitoring technologies within the Siemensmkygearbox enables real-time performance tracking, which is often absent in traditional designs. This data-driven approach not only enhances predictive maintenance but also optimizes energy consumption, further establishing the Siemensmkygearbox as a compelling alternative for industries seeking to modernize their mechanical systems.

The Role of Innovative Materials in Siemensmkygearbox Efficiency

In the realm of gearbox mechanics,

the Siemensmky gearbox stands out not only for its engineering ingenuity but also for its use of

innovative materials that significantly enhance efficiency. Recent data from a report by the

American Gear Manufacturers Association indicates that the

implementation of advanced composite materials can improve load-bearing capacity by up to

30% while simultaneously reducing weight.

This weight reduction is crucial in applications such as wind turbines, where lighter

components lead to improved energy efficiency and reduced mechanical stress.

Furthermore, the application of specialized coatings and lubricants has been shown to increase the life

span of gearboxes by as much as 40%. A study

published in the Journal of Mechanical Engineering highlighted

the impact of these materials on friction reduction, which is vital for decreasing wear and enhancing

the performance of machinery under load. By integrating these advanced materials,

the Siemensmky gearbox not only meets the rigorous demands of modern industries but also sets a

benchmark for sustainability and innovation in mechanical design.

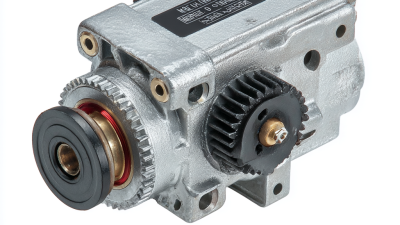

Examining the Impact of Advanced Technology on Mechanical Design

The advancement of technology has dramatically reshaped mechanical design, particularly in the realm of gearboxes. Siemensmkygearbox mechanics exemplifies how modern engineering techniques can enhance performance and efficiency in machinery. By integrating sophisticated computational models and high-quality materials, engineers can design gearboxes that not only meet rigorous industrial standards but also adapt to diverse operational environments. This evolution leads to decreased energy consumption and increased reliability, echoing a shift towards sustainability in engineering practices.

The advancement of technology has dramatically reshaped mechanical design, particularly in the realm of gearboxes. Siemensmkygearbox mechanics exemplifies how modern engineering techniques can enhance performance and efficiency in machinery. By integrating sophisticated computational models and high-quality materials, engineers can design gearboxes that not only meet rigorous industrial standards but also adapt to diverse operational environments. This evolution leads to decreased energy consumption and increased reliability, echoing a shift towards sustainability in engineering practices.

Tips: When considering the implementation of advanced technology in mechanical design, focus on understanding the specific operational requirements of your project. This involves analyzing the load conditions and expected performance metrics, which can guide the selection of materials and design features that optimize efficiency.

Moreover, the use of simulation tools allows designers to visualize the mechanics in action before physical prototypes are created. This strategy not only helps to identify potential issues early in the design stage but also enhances collaboration among engineers, as they can share insights and align on innovations. Embracing such technologies can lead to groundbreaking advancements in mechanical systems, ensuring that they are robust, versatile, and future-ready.

Future Trends: What’s Next for Siemensmkygearbox Development?

The future of Siemensmkygearbox technology is poised for significant advancements, driven by the increasing shift towards automation and efficiency across various industries, particularly automotive and renewable energy sectors. As manufacturers focus on developing intelligent transmission systems and hybrid solutions, the integration of advanced sensors and artificial intelligence will likely revolutionize gearbox mechanics. This evolution will not only enhance performance but also extend the lifespan of gearboxes, making them more reliable under extreme operating conditions.

Tips: When considering gear technology for your applications, prioritize systems that incorporate real-time monitoring to optimize performance and maintenance. Additionally, exploring direct-drive systems may offer significant advantages in reducing mechanical complexity and improving efficiency.

In the realm of wind energy, the trend towards gearless turbines is gaining traction. This shift is driven by the need for greater reliability and lower maintenance costs. Experts predict that as technology matures, wind turbine designs will increasingly adopt these innovative solutions, potentially reshaping the market landscape. Consequently, stakeholders in the industry should remain vigilant about emerging technologies and be prepared to adapt their strategies to stay competitive in a rapidly evolving market.

Exploring the Revolutionary Technology Behind Gearbox Mechanics - Future Trends: What’s Next for Gearbox Development?

| Technology Aspect |

Current Trends |

Future Developments |

Impact on Industry |

| Automation |

Increasing integration of AI and machine learning for predictive maintenance. |

Enhanced algorithms for real-time monitoring and diagnostics. |

Lower operational costs and improved uptime. |

| Material Science |

Use of advanced composites and lightweight materials for efficiency. |

Development of self-lubricating materials to reduce wear. |

Increased product lifespan and reduced maintenance needs. |

| Energy Efficiency |

Focus on reducing energy consumption in gearbox designs. |

Incorporation of regenerative braking technologies. |

Significant reductions in carbon footprint across applications. |

| Digitalization |

Deployment of IoT devices for enhanced data collection. |

Smart gearboxes that adapt to load conditions on-the-fly. |

Reduced downtime through proactive scheduling of maintenance. |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor The

The

The advancement of technology has dramatically reshaped mechanical design, particularly in the realm of gearboxes. Siemensmkygearbox mechanics exemplifies how modern engineering techniques can enhance performance and efficiency in machinery. By integrating

The advancement of technology has dramatically reshaped mechanical design, particularly in the realm of gearboxes. Siemensmkygearbox mechanics exemplifies how modern engineering techniques can enhance performance and efficiency in machinery. By integrating