-

Home

-

Products

-

SIEMENS Gearmotor

-

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage -

SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor -

SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor -

SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage -

SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor -

SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage -

SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage -

SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage -

SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage -

SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage -

SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage -

SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage -

SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150 -

SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage -

SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage -

SIEMENS SINAMICS V90

SIEMENS SINAMICS V90 -

SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage

-

-

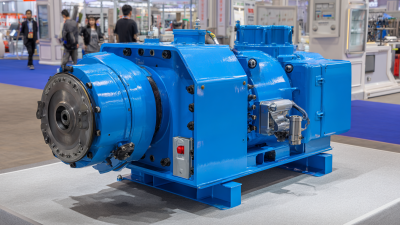

FLENDER Gear Unit

FLENDER Gear Unit -

FLENDER Helical Gear Unit

FLENDER Helical Gear Unit -

Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears -

FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox -

Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance -

Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents -

SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox -

Playmaker In The Premium League

Playmaker In The Premium League -

Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox -

Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections -

Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces -

Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200 -

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill -

The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox -

Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox -

Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox -

The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships -

Reliable Power Generation on board

Reliable Power Generation on board -

Maximum performance level, fast deliverable

Maximum performance level, fast deliverable -

Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills -

Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.

-

-

FLENDER Coupling

FLENDER Coupling -

ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling -

ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling -

N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling -

N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling -

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts -

N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling -

RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling -

N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling -

ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling -

ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance -

ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance -

FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance -

SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance -

BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance -

FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance

-

-

SEW Gearmotor

SEW Gearmotor

-

-

Our Company

-

News

-

Case

-

Contact Us

Leave Your Message

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor

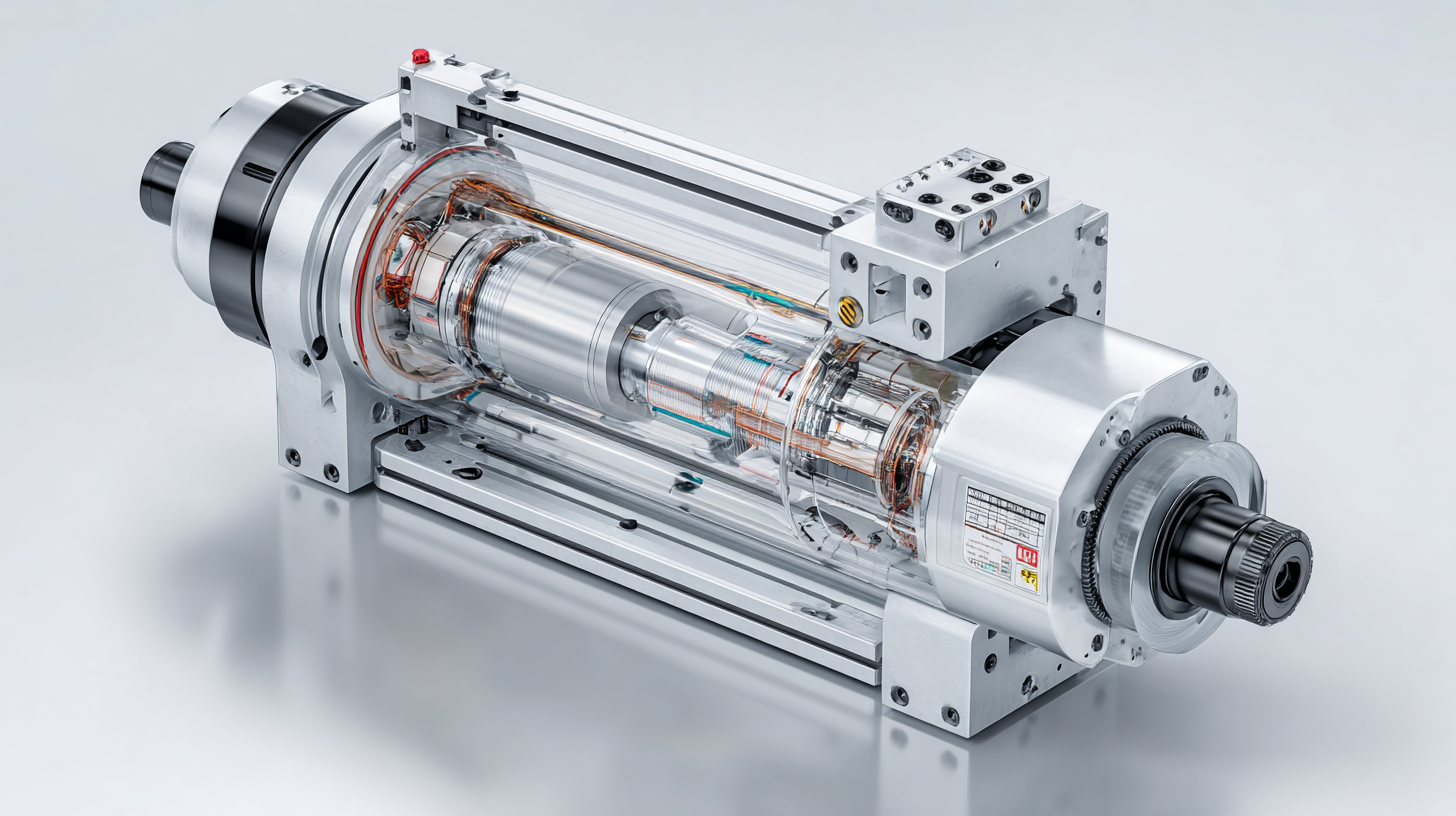

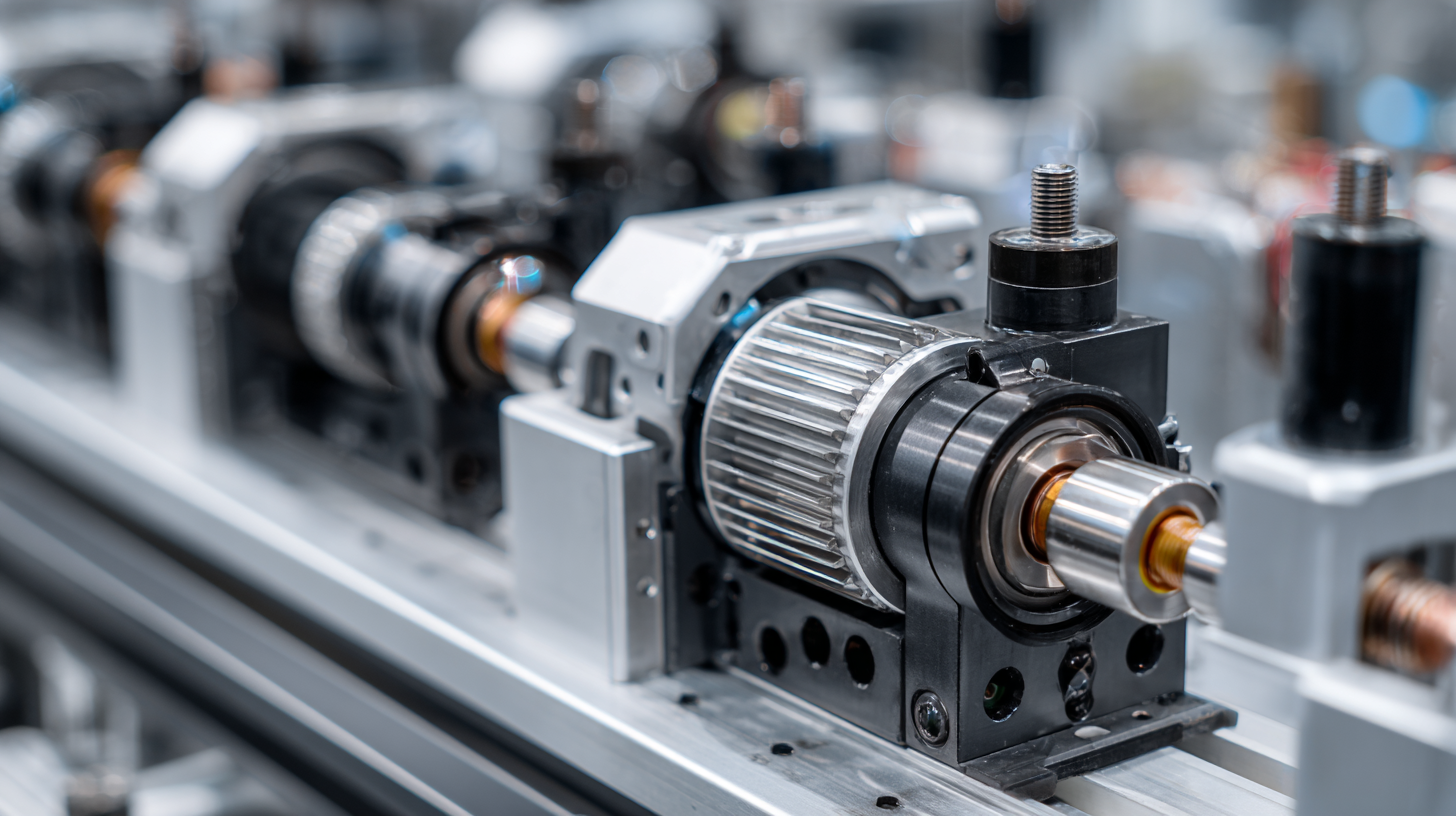

Servo motors are integral components in modern robotics and automation systems, providing precise control of angular position, velocity, and acceleration. These motors operate based on a closed-loop feedback system, allowing them to respond dynamically to input commands. According to a report by Markets and Markets, the global servo motor market is projected to reach USD 11.5 billion by 2026, reflecting their increasing adoption in various applications, including manufacturing, automotive, and consumer electronics.

Servo motors are integral components in modern robotics and automation systems, providing precise control of angular position, velocity, and acceleration. These motors operate based on a closed-loop feedback system, allowing them to respond dynamically to input commands. According to a report by Markets and Markets, the global servo motor market is projected to reach USD 11.5 billion by 2026, reflecting their increasing adoption in various applications, including manufacturing, automotive, and consumer electronics. Servo motors are revolutionizing the landscape of modern robotics and automation systems due to their high precision and reliability. In recent years, the demand for servo motors has surged, with the global market projected to reach

Servo motors are revolutionizing the landscape of modern robotics and automation systems due to their high precision and reliability. In recent years, the demand for servo motors has surged, with the global market projected to reach