Discover the Superior Quality of Best Servo Motors from Leading Chinese Manufacturers

In the rapidly evolving landscape of automation and robotics, the demand for

high-performance Servo Motors has surged significantly.

According to the International Federation of Robotics, the global market for

industrial robots is projected to reach over $20 billion by

2025, with Servo Motors playing a crucial role in driving these advancements.

Engineered for precision and responsiveness, the best Servo Motors from leading

Chinese manufacturers are at the forefront of innovation, offering superior quality

that meets the rigorous standards of various industries, from manufacturing to automotive.

As the competition intensifies and the need for efficiency increases, understanding how to

select and integrate these high-quality Servo Motors can

greatly enhance operational productivity and performance.

This blog will guide you through key considerations in choosing the best

Servo Motors, ensuring that you harness their full

potential for your applications.

Understanding the Importance of Industry Production Standards in Servo Motors

When it comes to servo motors, understanding production standards is crucial for ensuring optimal performance and reliability. According to a report by the International Electrotechnical Commission (IEC), industry standards such as IEC 60730, which governs the safety and performance of motor-driven appliances, significantly influence manufacturing practices. These standards not only specify the essential safety features but also outline the testing procedures that manufacturers must adhere to, ensuring that the products meet international safety and reliability benchmarks.

Notably, Chinese manufacturers are increasingly aligning their production processes with these international standards. A recent study by the China Electronics Standardization Institute indicated that over 70% of leading servo motor manufacturers in China have implemented ISO 9001 quality management systems, which enhance efficiency and product quality. By adhering to these rigorous industry standards, they are not only improving their competitiveness in the global market but also ensuring that their servo motors are reliable and effective for various industrial applications. This commitment to quality and compliance is reshaping the perception of Chinese manufactured products on the world stage, highlighting the unmatched potential of their servo motors.

Performance Comparison of Servo Motors from Leading Chinese Manufacturers

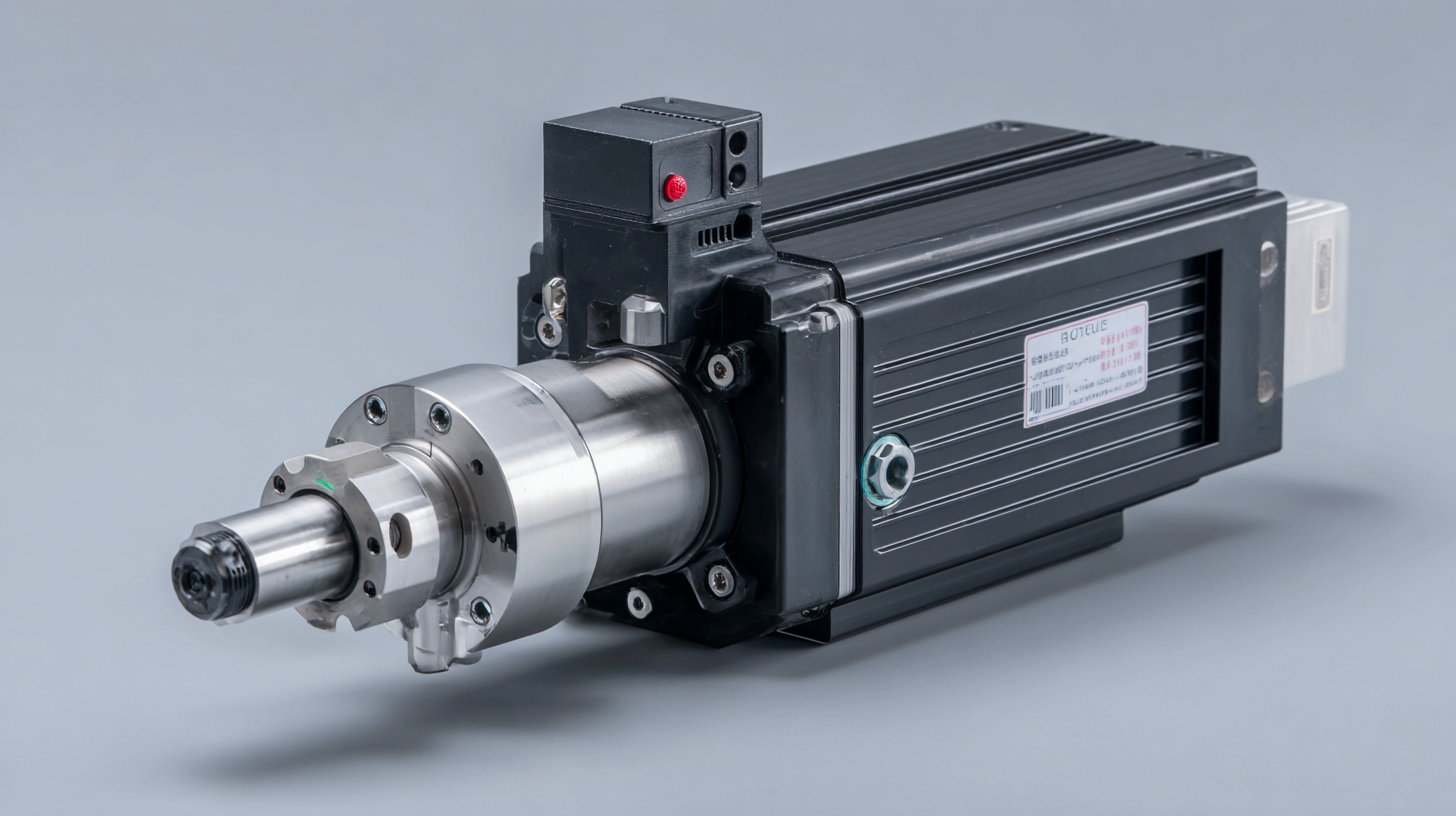

Top Features to Look for in High-Quality Servo Motors from Chinese Manufacturers

When it comes to selecting high-quality servo motors, understanding the top features from leading Chinese manufacturers is crucial. One key aspect to consider is the type of motor—AC and DC servo motors serve different applications and environments. According to industry analysis, the integrated servo motor market is projected to experience significant growth, with AC motors dominating due to their versatility and efficiency.

Additionally, manufacturers are increasingly producing energy-efficient models that comply with green development initiatives, making them appealing to environmentally conscious businesses.

Another vital feature to look for is the voltage range of servo motors. Low, medium, and high voltage options cater to various needs across sectors, including automotive and industrial applications. It’s important to select a motor that matches your system requirements to ensure optimal performance. Furthermore, advanced functionalities such as integrated control systems can enhance precision and responsiveness, thus improving overall operational efficiency.

Tips: Always verify the technological innovations incorporated into the servo motors you are considering. Being aware of the latest developments can significantly impact performance and reliability. Additionally, consider the support and service options provided by manufacturers, as strong after-sales support can be indicative of product quality and company reputation.

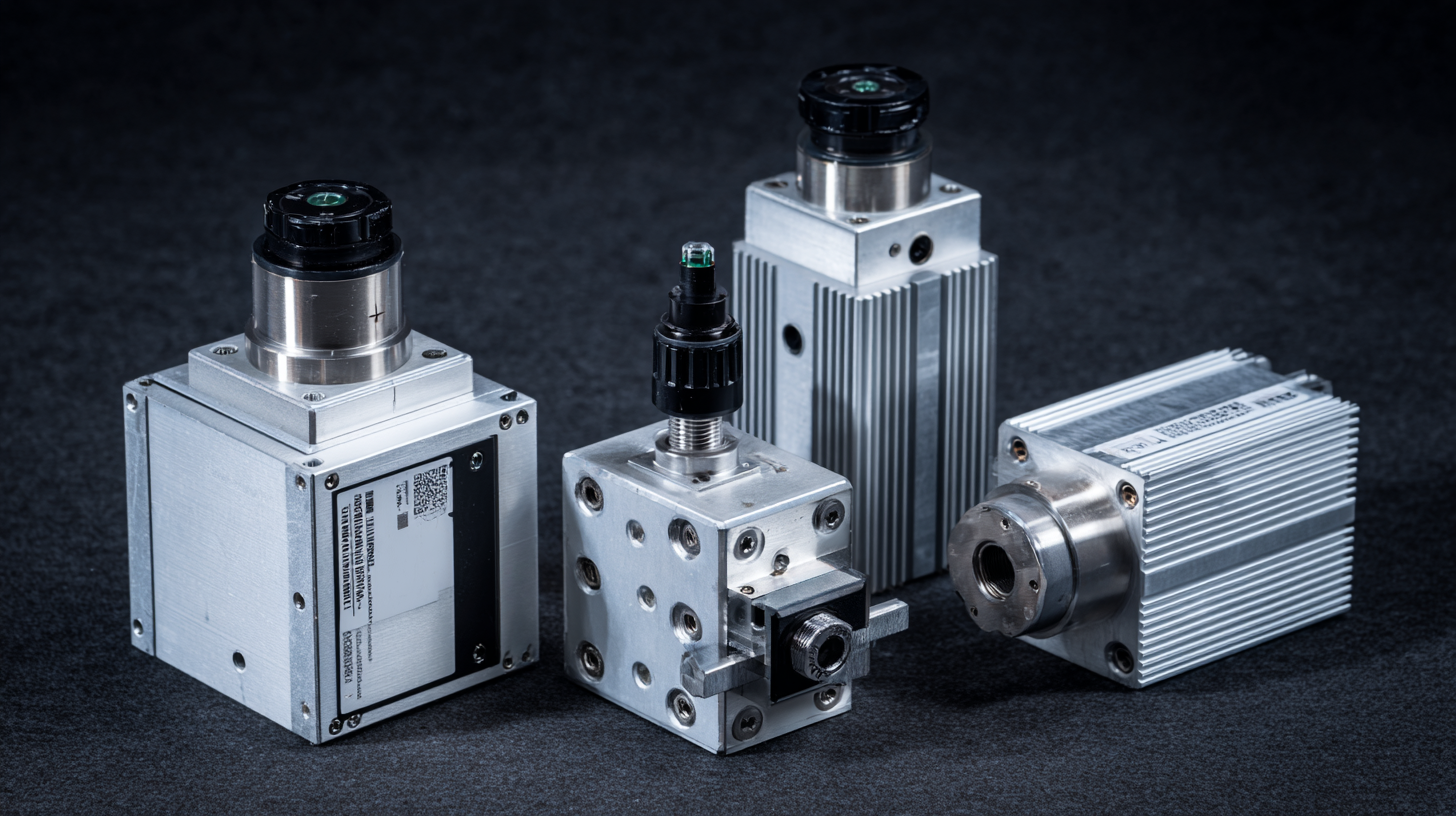

Comparative Analysis of Leading Servo Motor Brands in China

When considering the performance and reliability of servo motors, a comparative analysis of leading brands from Chinese manufacturers reveals significant insights. Brands like Hauneng, SANY, and Delta stand out due to their innovative technologies and robust quality control measures. Hauneng, for instance, leverages advanced AI algorithms to enhance precision and efficiency, making its servo motors ideal for complex automation tasks. Meanwhile, SANY’s motors excel in durability and energy conservation, suitable for heavy-duty industrial applications.

In addition to performance aspects, pricing and customer support also influence brand choice. Delta offers competitive pricing without compromising on quality, appealing to budget-conscious businesses. Their comprehensive after-sales support further solidifies their position in the market. Evaluating these factors not only helps in selecting the right servo motor but also showcases the growing prominence of Chinese manufacturers in the global arena. Ultimately, investing in quality servo motors from these leading brands promises significant improvements in automation and productivity across various industries.

Discover the Superior Quality of Best Servo Motors from Leading Chinese Manufacturers

| Parameter |

Brand A |

Brand B |

Brand C |

Brand D |

| Rated Power (kW) |

0.5 |

1.0 |

1.5 |

2.0 |

| Torque (Nm) |

1.2 |

2.5 |

3.8 |

4.0 |

| Max Speed (RPM) |

3000 |

4000 |

5000 |

6000 |

| Feedback Type |

Incremental |

Absolute |

Absolute |

Incremental |

| Price (USD) |

150 |

200 |

250 |

300 |

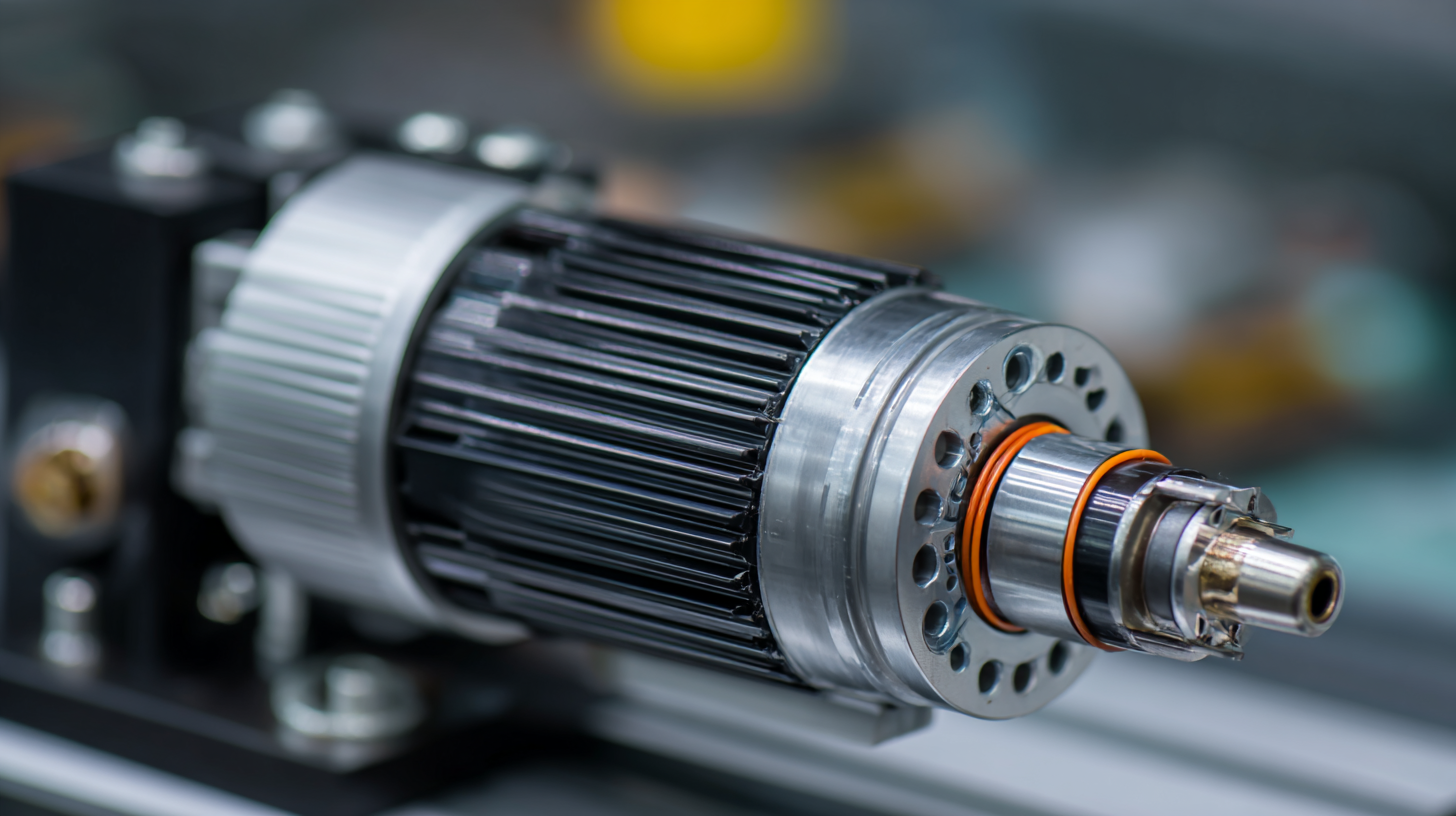

The Role of Technology and Innovation in Enhancing Servo Motor Quality

In recent years, the competitive landscape of servo motors has witnessed significant transformation, predominantly driven by technological advancements and innovative practices. Leading Chinese manufacturers have leveraged cutting-edge technologies such as artificial intelligence and machine learning to enhance the precision and reliability of their servo motors. This has not only optimized performance but also increased energy efficiency, thereby meeting the growing demands of various industrial applications.

Moreover, these manufacturers are investing heavily in research and development to pioneer new materials and design techniques. By integrating smart manufacturing processes, they ensure that each servo motor produced adheres to stringent quality standards while accommodating customization for specific client needs.

The continuous focus on innovation enables these companies to keep pace with global trends, positioning themselves as trusted suppliers in the international market. As they push the boundaries of traditional manufacturing, the evolution of servo motor technology in China exemplifies the pivotal role of innovation in driving quality and performance.

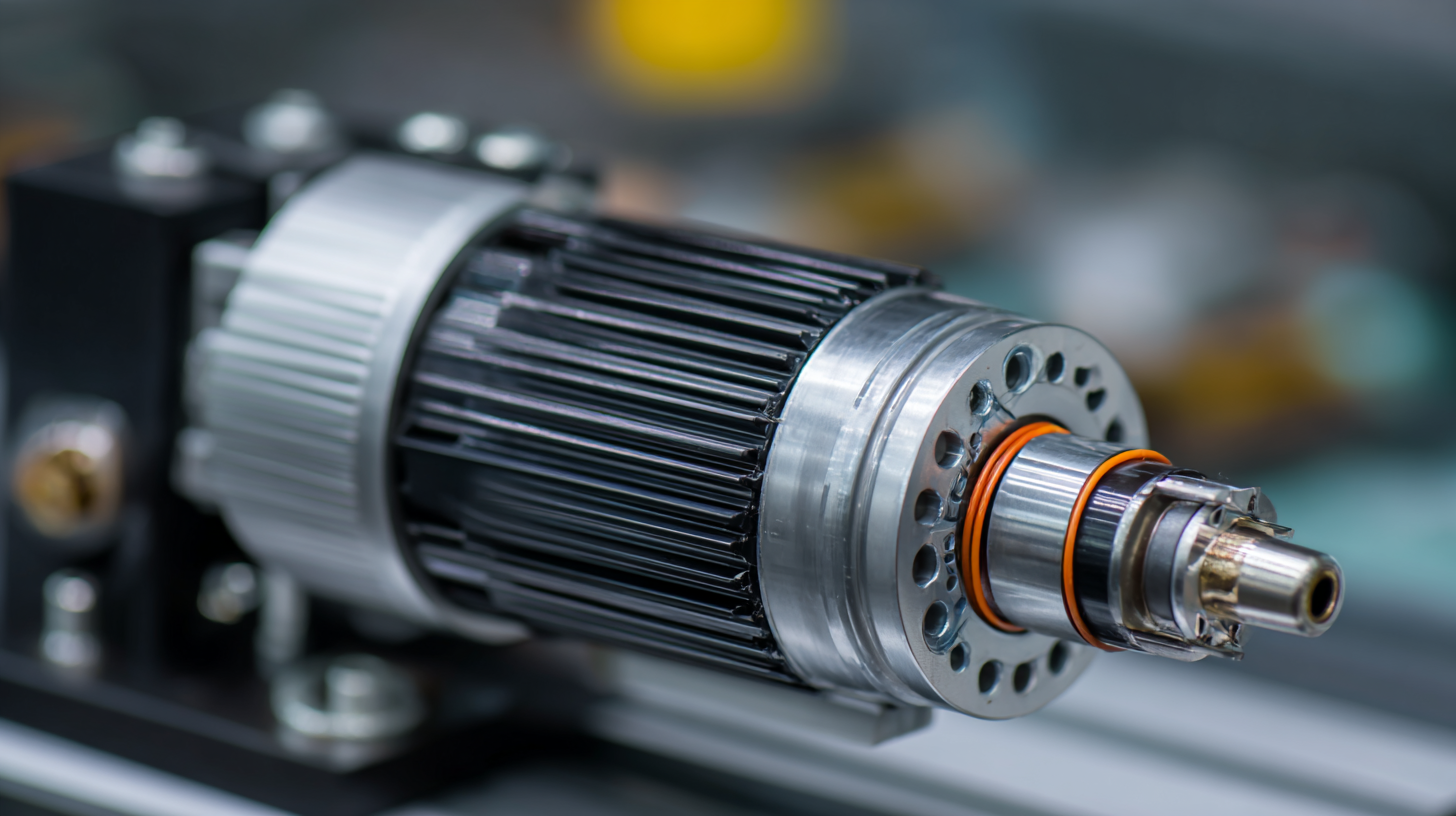

How Quality Assurance Practices Shape the Future of Servo Motor Manufacturing

The future of servo motor manufacturing is being shaped by robust

quality assurance practices, which are integral for maintaining competitiveness

in the evolving market. Leading Chinese manufacturers are adopting advanced quality management systems that ensure precision

and reliability in their servo motors. This commitment to quality not only enhances product performance but fosters trust

among customers who increasingly seek value and durability in their equipment.

To enhance your understanding of quality practices, consider implementing these tips:

- First, regularly assess your suppliers

to ensure they uphold stringent quality standards.

- Next, incorporate testing protocols

that simulate real-world conditions to verify the performance and longevity of your servo motors.

- Lastly, invest in employee training programs

focused on quality management practices, which can significantly improve the manufacturing process.

The introduction of innovative systems, such as the latest servo-drive packages,

demonstrates the industry’s shift towards integrating quality with technology. These advancements not only optimize manufacturing processes

but also reflect the commitment of manufacturers to produce high-caliber servo motors

that meet the demands of future applications.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor