Exploring the Technical Specifications of the Best Ac Motor for Optimal Performance

In the realm of industrial machinery, the significance of selecting the

right AC motor cannot be overstated, as it directly influences

operational efficiency and performance. As we explore the technical specifications of the best

AC motors available in the market, it's essential to recognize the

unparalleled craftsmanship and innovation that factories in China are bringing to the global stage.

These manufacturers are dedicated to producing top-tier products that meet diverse

industrial needs while adhering to stringent quality standards.

Through this blog, we will delve into the intricate details of AC motor design,

including factors like power ratings, efficiency levels, and durability, ensuring you make

informed decisions that enhance productivity and reliability.

Join us on this journey as we uncover how the right AC motor can

transform your operations and deliver optimal performance

in various applications.

Understanding AC Motor Basics: Types and Functions

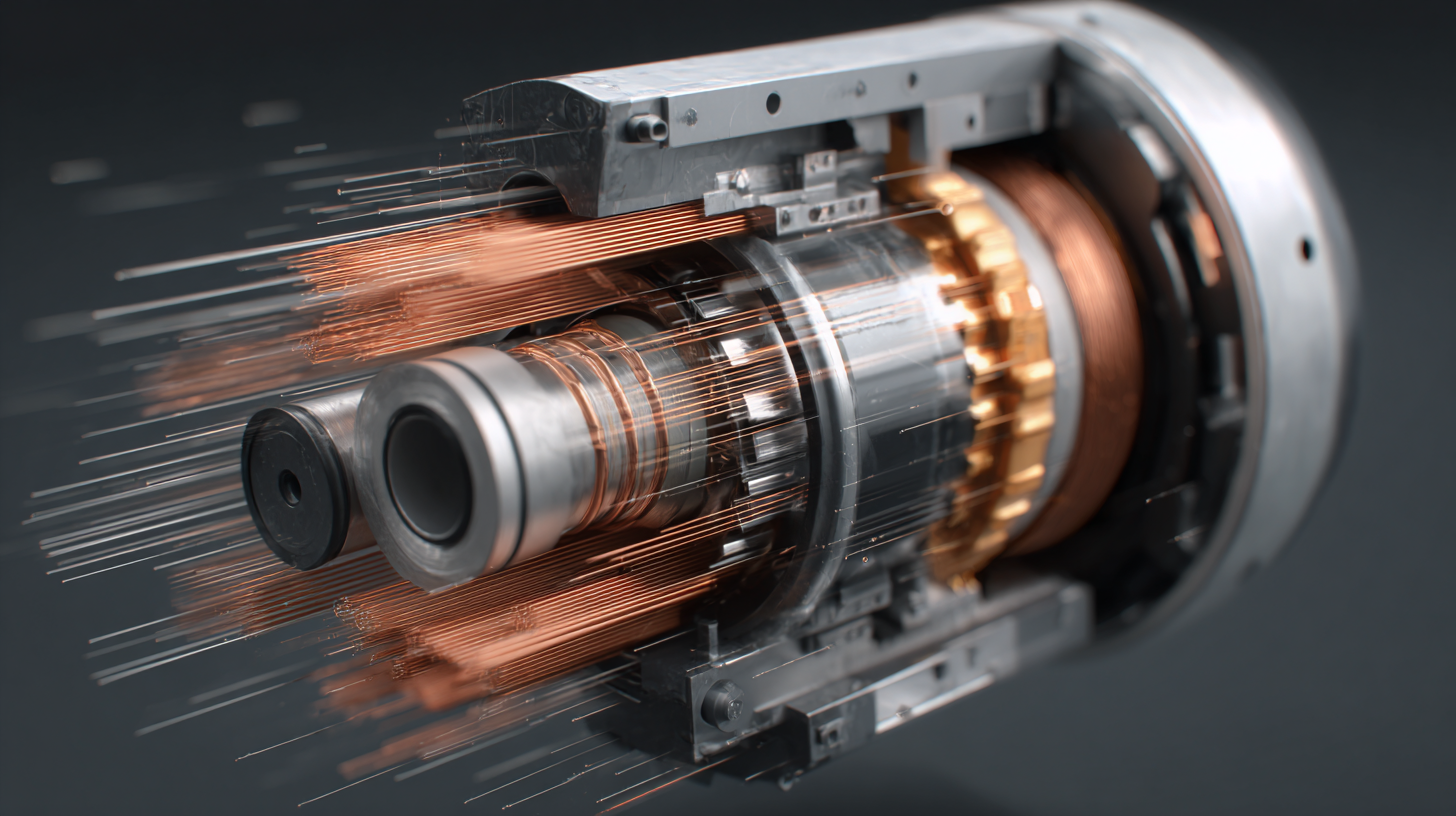

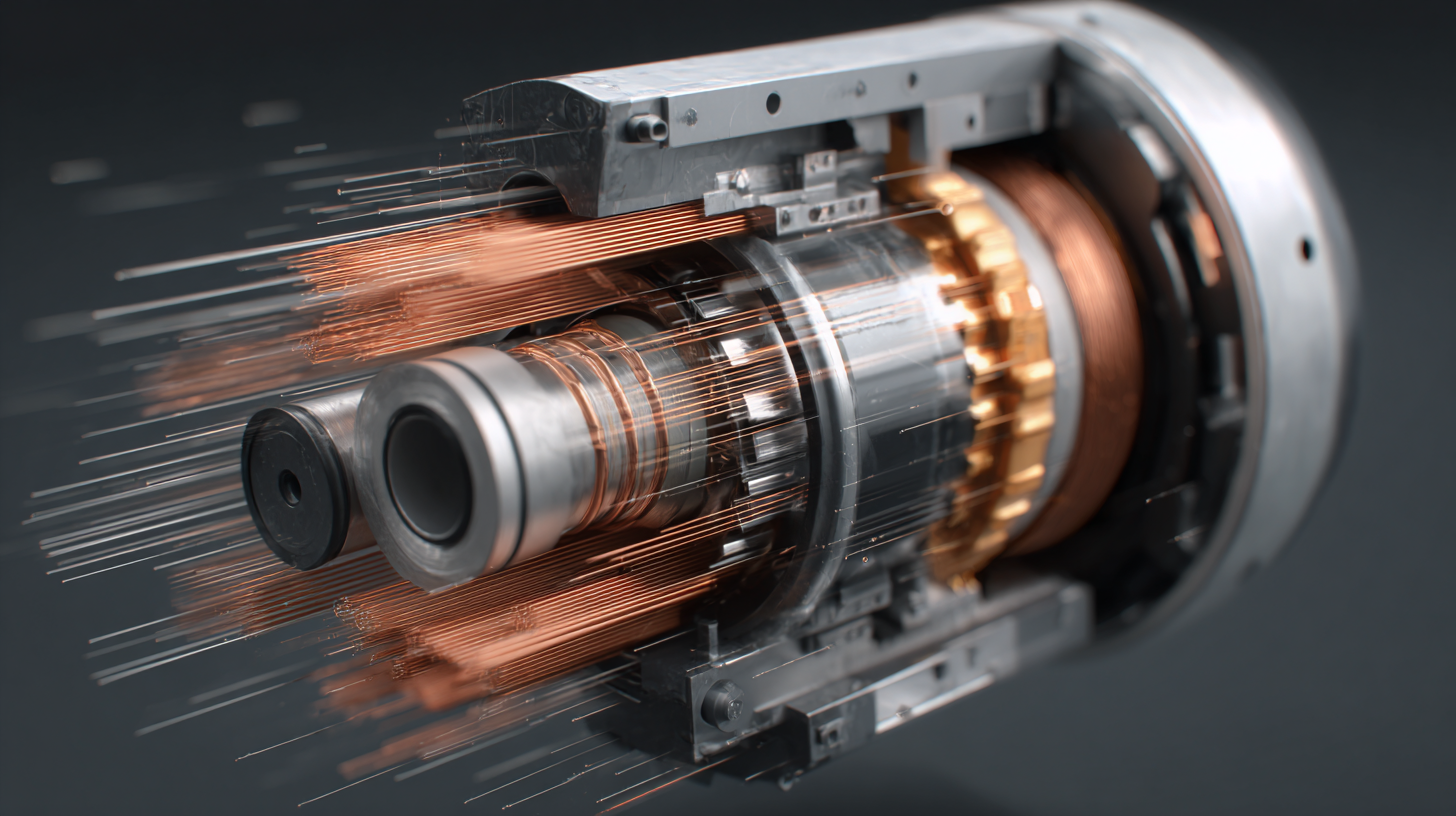

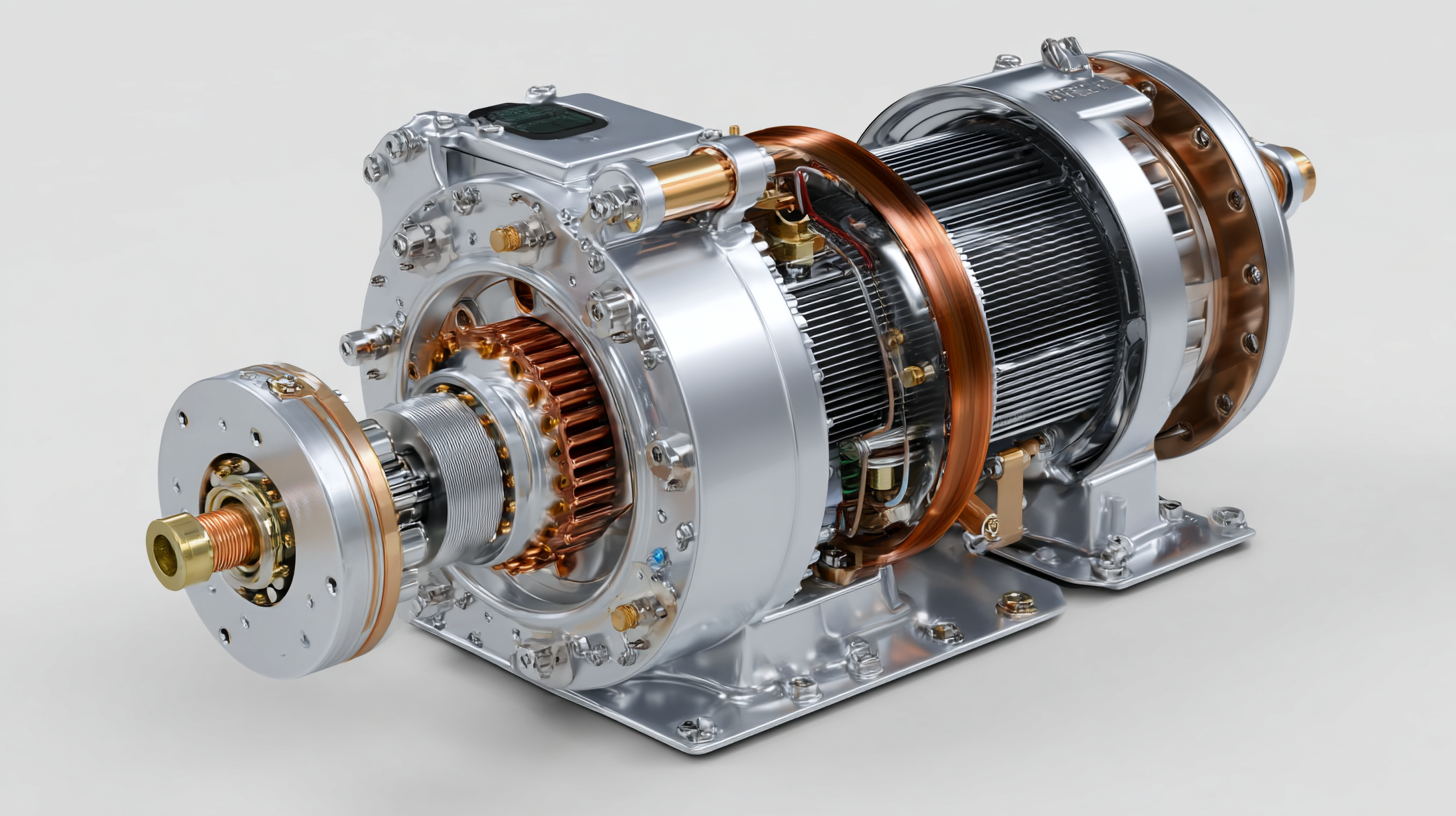

When exploring the fundamentals of AC motors, it's essential to understand the variety of types and their functions that cater to specific applications. AC motors can be broadly categorized into two main types: synchronous and induction motors. Synchronous motors operate at a constant speed determined by the supply frequency, making them ideal for applications requiring precise speed control. In contrast, induction motors are widely used due to their robustness and simpler construction, functioning efficiently in various industrial settings.

The performance of these motors can be significantly impacted by their specifications, such as torque, speed, and operating efficiency. Recent studies indicate that advancements in variable frequency drives have enhanced the control over AC motors, resulting in improved energy consumption and operational efficiency. It's estimated that implementing such drives can lead to energy savings of 20-50% in industrial applications. Additionally, engineers are increasingly being tasked with optimizing motor selection based on specific operational needs, such as size and accuracy, to achieve maximum performance and efficiency in diverse applications, including those seen in modern treadmill designs and electric vehicle systems.

Key Technical Specifications to Consider in AC Motors

When selecting an AC motor for optimal performance, understanding key technical specifications is crucial. Factors like power rating, efficiency, and torque characteristics play significant roles. According to a recent report by the International Electrotechnical Commission, electric motors consume about 45% of global electricity, highlighting the importance of choosing efficient models. The efficiency ratings often range from 80% to 96%, with higher ratings leading to reduced operational costs and lower environmental impact.

Tip: Always check the efficiency class of an AC motor before purchase. Motors classified as IE3 or higher can significantly reduce energy consumption, contributing to lower bills and a smaller carbon footprint.

Aside from efficiency, another vital specification is the motor's operational speed. Most AC motors operate at constant speeds, which are typically categorized into synchronous and asynchronous types. The choice between these two often depends on the application's specific requirements. For instance, synchronous motors are ideal for applications requiring precise speed, while asynchronous motors are more common due to their simplicity and cost-effectiveness.

Tip: For variable speed applications, consider investing in a variable frequency drive (VFD) to enhance motor performance and flexibility. This not only optimizes motor speed but also improves energy efficiency.

Comparative Analysis: Top AC Motors for Industrial Applications

When exploring the best AC motors for industrial applications, it's essential to consider various performance metrics, including efficiency, torque, and power output. The comparative analysis of advanced motor technologies reveals significant differences between traditional induction motors and newer options like synchronous reluctance motors. While three-phase induction motors dominate industrial environments due to their robustness, the increasing interest in electric motor technologies reflects the industry's shift toward sustainability and enhanced performance.

Tips for selecting the right motor include evaluating the specific application requirements and considering the operational environment. High-efficiency motors can lead to reduced energy consumption and lower operational costs, making them an attractive option for industries seeking to improve their bottom line while reducing their environmental footprint. Additionally, assessing long-term reliability and maintenance needs can guide users towards a motor that minimizes downtime and maximizes productivity.

When comparing AC motors, pay close attention to the cooling systems and starting mechanisms, as these factors can significantly impact performance in demanding industrial settings. A collaborative approach, involving consultation with motor specialists, can further ensure that the selected motor aligns with both current and future operational needs, paving the way for optimal performance and innovation in industrial applications.

Maximizing Efficiency: Choosing the Right AC Motor for Your Needs

When it comes to selecting an AC motor for optimal performance, the efficiency of the motor should be at the forefront of your decision-making process. AC motors are widely used across various applications, and choosing the right one can significantly affect operational costs and productivity. Factors such as the motor's power rating, efficiency class, and operational environment need careful consideration. A higher efficiency motor not only reduces energy consumption but can also lead to lower heat generation, less wear over time, and extended lifespan, ultimately saving you money in the long term.

Additionally, understanding the specific needs of your project is essential. Different applications may demand various motor types—synchronous or asynchronous motors, for example, each have their strengths. It's crucial to match the motor's characteristics with the application's requirements, including load conditions and speed control. By prioritizing efficiency and aligning the motor's specifications with your operational needs, you can optimize performance and foster a sustainable approach to energy consumption in your facility.

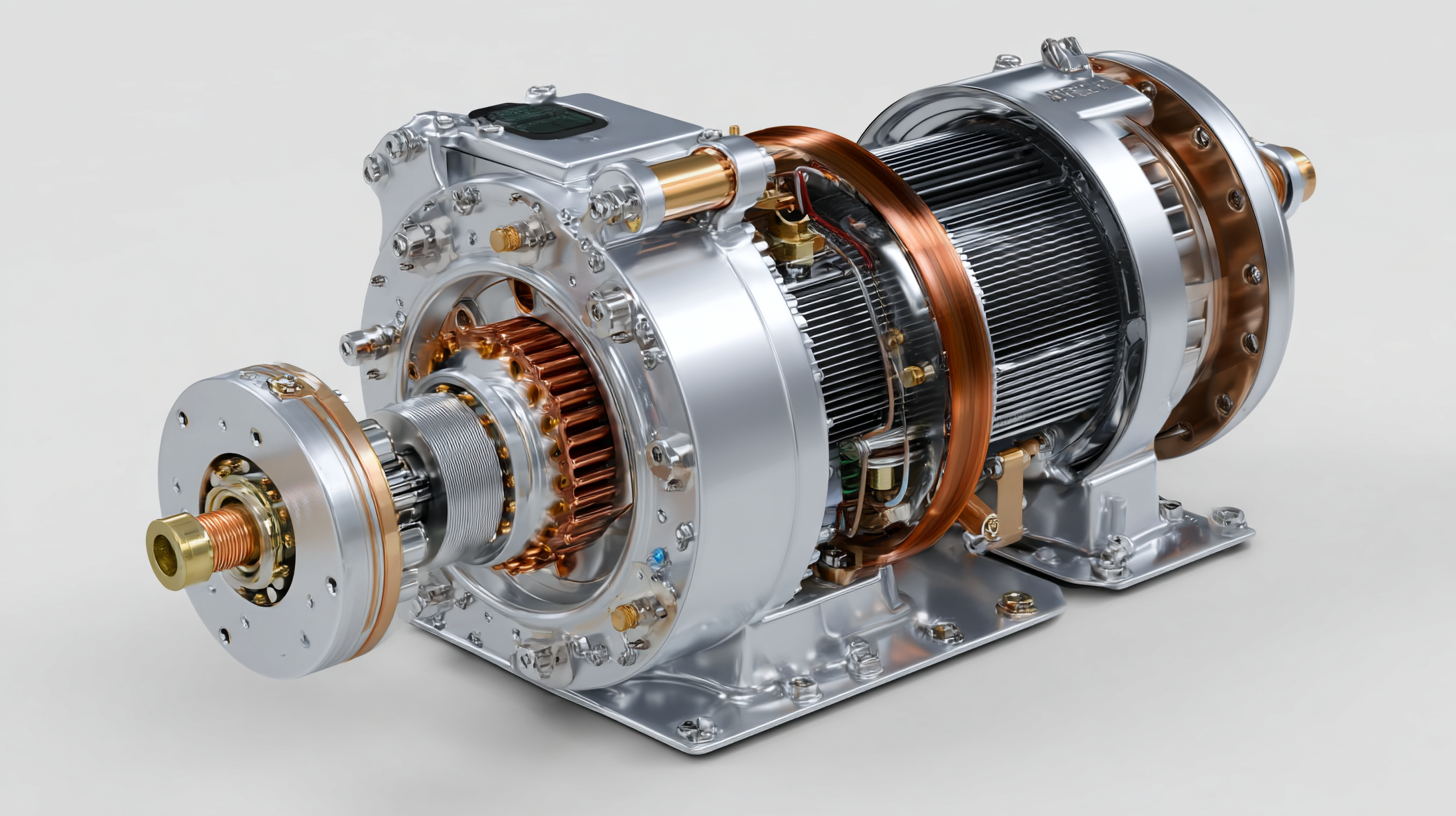

Exploring the Technical Specifications of the Best Ac Motor for Optimal Performance

| Motor Type |

Power Output (HP) |

Efficiency Rating (%) |

Voltage (V) |

Frequency (Hz) |

Frame Size (inches) |

Weight (lbs) |

| Induction Motor |

5 |

90 |

230 |

60 |

5.5 |

150 |

| Synchronous Motor |

10 |

92 |

480 |

60 |

7 |

210 |

| Permanent Magnet Motor |

1.5 |

95 |

230 |

50 |

3.5 |

75 |

| Split-phase Motor |

3 |

85 |

115 |

60 |

6 |

110 |

| Capacitor Start Motor |

2 |

88 |

230 |

60 |

5 |

90 |

Innovative Technologies in AC Motors for Enhanced Performance

The enhancement of performance in AC motors is increasingly reliant on innovative technologies that push the boundaries of efficiency and reliability. Among these advancements, the integration of smart sensors and IoT connectivity stands out. According to a report by MarketsandMarkets, the global smart motor market is projected to grow from USD 6.38 billion in 2020 to USD 12.06 billion by 2025, highlighting the rising demand for intelligent manufacturing solutions. Smart sensors enable real-time monitoring of motor conditions, allowing for predictive maintenance that can reduce downtime by up to 30%.

Another significant innovation is the development of advanced materials such as high-efficiency rotor designs and permanent magnet synchronous motors (PMSMs). A study by the International Energy Agency indicates that PMSMs can achieve efficiencies exceeding 95%, making them ideal for applications requiring high performance with minimal energy loss. This efficiency not only contributes to lower operational costs but also aligns with sustainability goals, as lower energy consumption translates to reduced carbon footprints. As industries continue to embrace these innovative technologies, the future of AC motors promises even greater strides in performance and environmental responsibility.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor