Top 5 Innomotics Mky Gearbox Features You Should Know?

In the competitive landscape of industrial machinery, the Innomotics Mky Gearbox stands out for its innovation and efficiency. According to a recent market analysis from Research and Markets, the global gearbox market is poised to reach USD 45 billion by 2025, signaling a robust demand for well-engineered products like the Innomotics Mky Gearbox. This gearbox offers features that enhance performance and sustainability, appealing to industries focused on reducing operational costs.

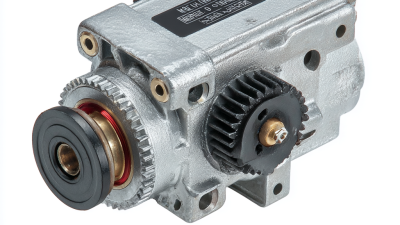

One key aspect of the Innomotics Mky Gearbox is its energy efficiency. Industry reports indicate that energy-efficient gearboxes can improve operational performance by up to 15%. However, some users report challenges in integrating new technologies, suggesting a need for comprehensive training. Another important feature is its modular design, allowing for flexibility in applications. Despite these advantages, users occasionally find the initial setup cumbersome, highlighting areas for improvement.

The Innomotics Mky Gearbox represents a significant advancement in gearbox technology. Yet, it is crucial to consider real-world challenges users face during deployment. As the gearbox market expands, understanding these features becomes essential for making informed decisions.

Key Characteristics of Innomotics Mky Gearbox Design

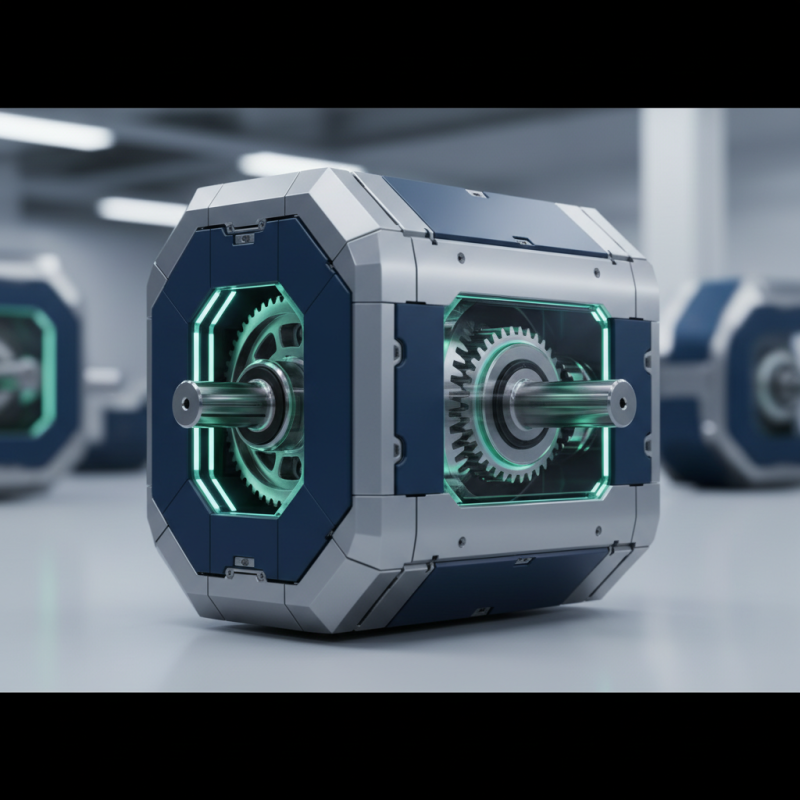

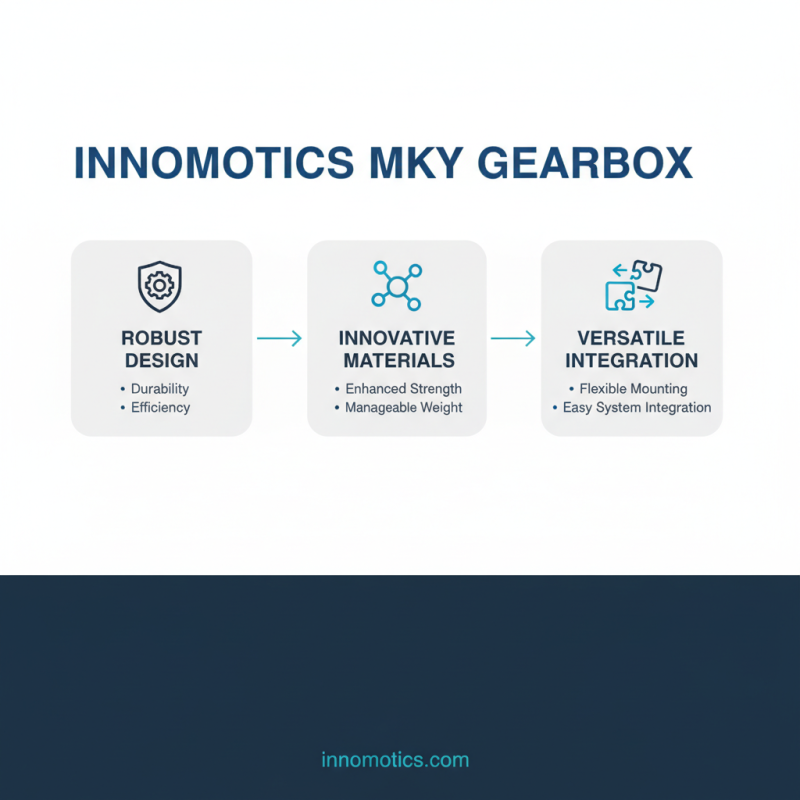

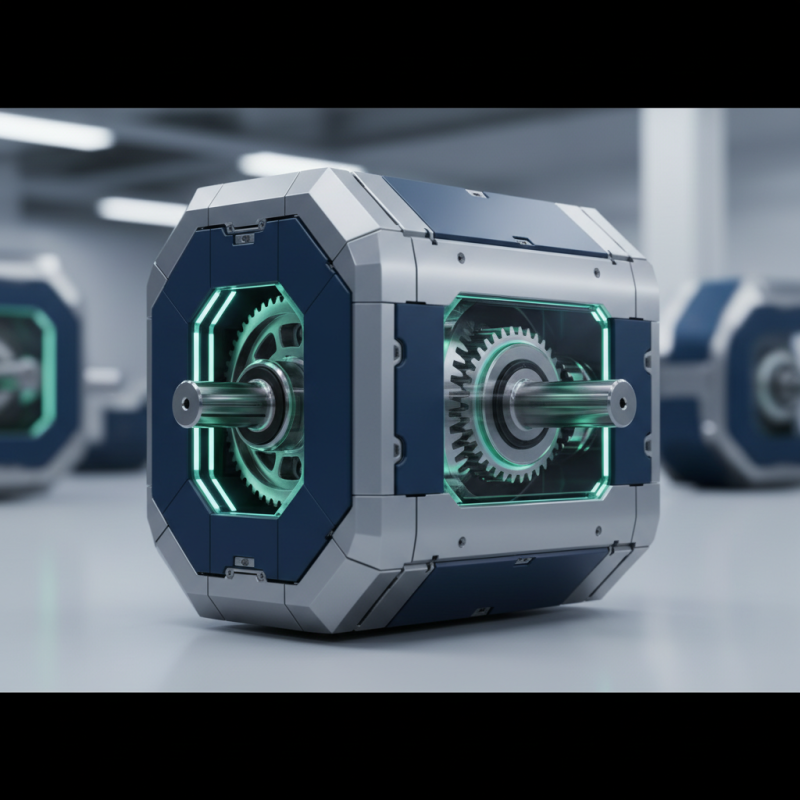

The Innomotics MKY gearbox features a robust design that stands out in various applications. Its construction combines durability with efficiency. The innovative materials used enhance strength while keeping the weight manageable. This design choice allows for versatile mounting options, making it easier to integrate into existing systems.

Another key characteristic is its superior thermal performance. The gearbox operates effectively under high temperatures. This is critical in industrial environments where overheating can lead to failures. Additionally, the compact size of the MKY gearbox allows for space-saving installations. However, users should monitor its heat management closely to avoid complications.

The lubrication system is noteworthy as well. It is designed for minimal maintenance, saving time and effort. Yet, users must remain vigilant about their lubrication schedules. A lapse could lead to increased wear. Overall, understanding these features can help users make informed decisions when considering gearbox options.

Durability and Reliability: Enhancing Performance Over Time

Durability and reliability are key factors in modern gearbox design. A robust gearbox can enhance overall performance and reduce maintenance costs. According to a 2022 industry report, high-quality gearboxes can lead to up to a 30% increase in operational efficiency. Understanding how these features work together is crucial for performance longevity.

One important aspect is material selection. Advanced materials can withstand extreme conditions better than standard options. This can significantly reduce wear and tear over time. Regular load testing can reveal how gearboxes respond under pressure. It's essential to consider this for long-term use.

Tips: Check the environment where the gearbox operates. High temperatures and heavy loads can accelerate deterioration. Implement a regular maintenance schedule. Early detection of issues can prevent major failures.

Sometimes, even with the best materials, challenges arise. Gearboxes can face issues like misalignment and lubrication failures. These problems may arise from oversight during installation. Addressing these concerns early ensures continuous performance and reliability. Always monitor performance metrics to catch any discrepancies quickly.

Top 5 Innomotics Mky Gearbox Features You Should Know

| Feature |

Description |

Benefit |

| High Durability |

Engineered to withstand harsh operating environments and high loads. |

Reduces the need for frequent replacements and maintenance. |

| Enhanced Efficiency |

Optimized gear design minimizes energy loss during operation. |

Increases overall system performance and lowers energy costs. |

| Low Noise Operation |

Advanced engineering reduces vibration and operational noise. |

Creates a more pleasant working environment and meets noise regulations. |

| Compact Design |

Space-saving layout allows for easy installation in tight spaces. |

Maximizes available space for machinery and enhances layout flexibility. |

| Modular Construction |

Interchangeable components simplify repairs and upgrades. |

Improves maintenance efficiency and reduces downtime. |

Versatile Application: Use Across Different Industries

In various industries, adaptability is crucial. The versatility of a good gearbox can be a game changer. Whether in manufacturing, energy, or transportation, these devices help streamline operations. Their ability to handle different loads sets them apart. This flexibility makes them suitable for many applications.

In manufacturing, for instance, gearboxes can drive conveyor systems. They transfer power efficiently, improving productivity. In the energy sector, they often connect turbines to generators. This ensures smooth energy conversion. However, challenges arise. Not all gearboxes perform optimally in all environments. Some may struggle with extreme temperatures or heavy loads.

Transportation also benefits from advanced gearbox technology. These components improve vehicle performance. They allow smoother gear shifts and better fuel efficiency. Yet, it's essential to regularly assess their condition. Wear and tear can impact their efficiency. Understanding real-world applications helps identify potential flaws. Continuous improvement in design and performance is necessary. Embracing versatility in design can lead to revolutionary changes in many industries.

Energy Efficiency: Cost-Effective Solutions for Operations

Energy efficiency plays a crucial role in modern operations, especially when it comes to industrial machinery. By optimizing energy use, organizations can significantly reduce their operational costs. These savings directly affect the bottom line. Every machine runs on energy, and wasted energy translates into wasted resources.

The gearbox features designed to enhance efficiency often come with additional benefits. Lower operating temperatures lead to less wear and tear. Consistently high efficiency minimizes the need for repairs. However, organizations must not overlook the potential downsides. Over time, the pursuit of energy efficiency can lead to complacency. Maintenance might be overlooked, resulting in unforeseen breakdowns.

Each gearbox’s design aims to provide better energy management. Precision engineering ensures that power is transferred smoothly. This results in lower energy consumption and improved output. However, implementing these advanced technologies requires a culture of continuous improvement. Teams must educate themselves about optimal operation practices to prevent lapses in performance.

Advanced Technology Integration: Smart Features for Modern Needs

The modern gearbox landscape is shifting dramatically. Advanced technology integration is crucial for enhancing efficiency. Smart features are no longer just perks; they’ve become necessities. For instance, gearboxes with predictive maintenance capabilities can reduce downtime by up to 25%. This data shows the importance of investing in technology that ensures reliability.

The integration of IoT in gearboxes allows real-time monitoring. Sensors collect data on performance metrics. This leads to quick adjustments and increased operational efficiency. A staggering 40% of machinery failures can be predicted through data analytics. Companies must adapt to these smart technologies rather than cling to old practices.

Tips: Regularly assess your gearbox’s technology to stay competitive. Consider updating outdated models. Embrace smart features and seek training on data analysis. Many users underutilize available data, leading to missed opportunities for improvement. Reflect on how you utilize technology. The fast-paced industry demands innovation and adaptability.

Top 5 Innomotics Mky Gearbox Features You Should Know

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor