2026 Top AC Motor Types You Need to Know?

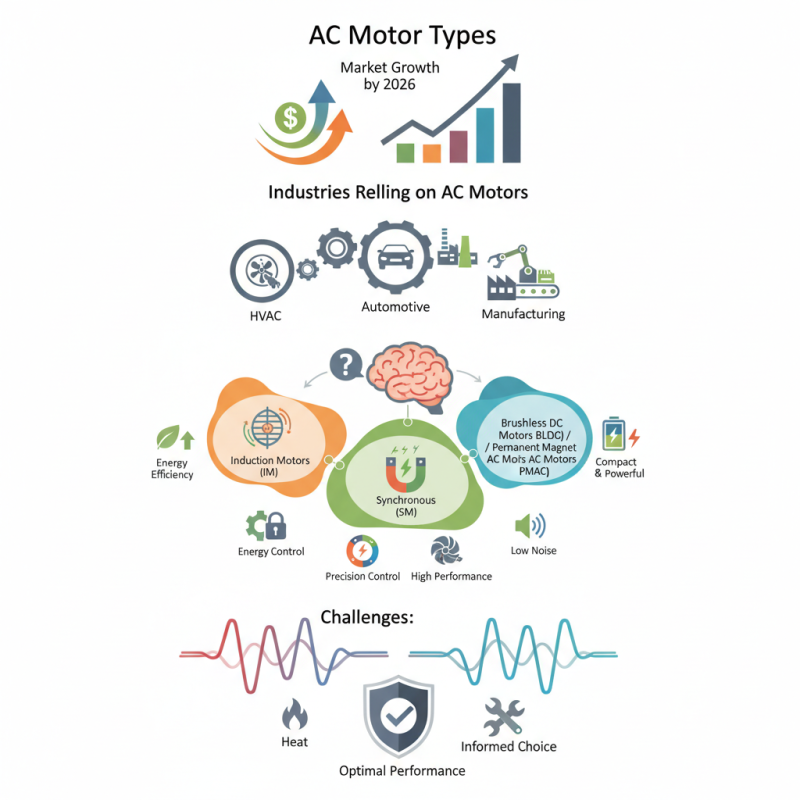

The global AC motor market is poised for significant growth by 2026. According to a recent report from MarketsandMarkets, the AC motor market is projected to reach $64.66 billion. This growth is fueled by increasing demand for energy-efficient solutions across various industries. Many sectors rely heavily on AC motors for their operations.

Consider the HVAC, automotive, and manufacturing industries. These sectors depend on reliable and efficient AC motors. The rise of automation also boosts AC motor demand. However, not all AC motors are created equal. Users must understand the different types to make informed choices.

Selecting the right AC motor is vital. The wrong choice can lead to inefficiencies and increased operational costs. Challenges such as noise levels and heat generation must also be evaluated. A clear understanding of these factors is essential for optimal performance. The journey to discover the top AC motor types begins now.

Types of AC Motors: An Overview of 2026 Trends

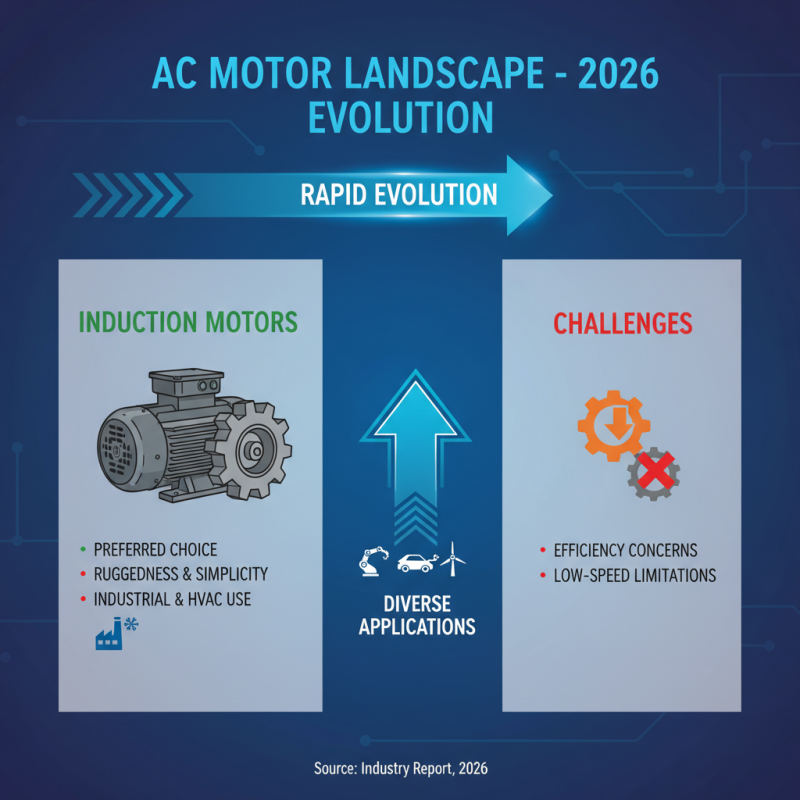

In 2026, the landscape of AC motors is evolving rapidly. Various types are becoming crucial in diverse applications. Induction motors remain a preferred choice due to their ruggedness and simplicity. They are widely used in industrial settings and HVAC systems. However, challenges arise from their efficiency, particularly at low speeds.

Permanent magnet synchronous motors (PMSMs) are gaining traction. These motors offer higher efficiency and performance in compact designs. Industries are exploring their potential in renewable energy systems. However, sourcing quality magnets can be a barrier, creating supply chain issues. The demand for energy-efficient solutions is pushing manufacturers to innovate.

The rise of smart technology impacts AC motors too. With IoT integration, motors can be monitored in real time. This increases performance but raises questions about cybersecurity risks. Balancing innovation with safety and reliability will be essential moving forward. The future of AC motors holds promise, yet uncertainty remains.

Applications of AC Motors in Various Industries

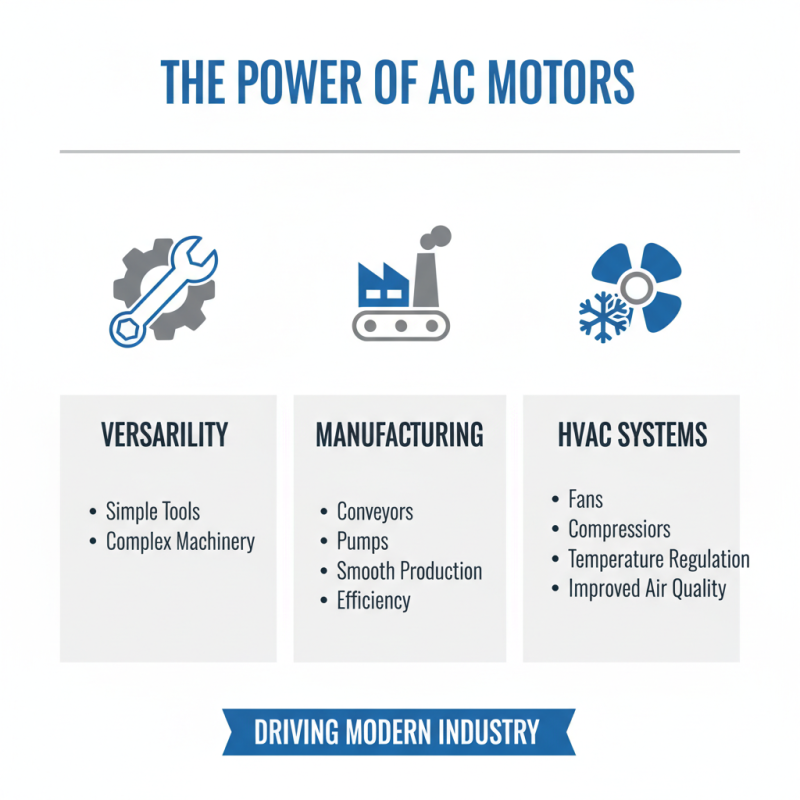

AC motors are vital in many industries today. They power everything from simple tools to complex machinery. In manufacturing, they drive conveyors and pumps. This ensures smooth production and efficiency. In HVAC systems, AC motors control fans and compressors. They help regulate temperature and improve air quality.

Tip: When selecting an AC motor, consider the specific application. Different environments may require different types of motors. For instance, motors in humid places need special coatings. This prevents rust and extends lifespan.

In the automotive sector, AC motors are used in electric vehicles. They provide propulsion and increase energy efficiency. This shift towards electric mobility is significant. However, the technology isn't perfect. There are challenges, like optimizing performance to maximize range.

Tip: Always test motors under real conditions. This provides insight into potential issues. For example, some motors may overheat when used continuously. Even small inefficiencies can lead to larger problems later.

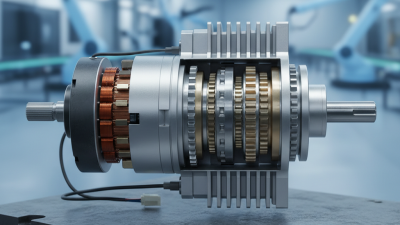

Key Features and Benefits of Each AC Motor Type

When exploring AC motors, understanding the key features and benefits is crucial. Synchronous AC motors, for instance, are known for their high efficiency and precision. According to industry reports, they maintain a constant speed regardless of load variations. This makes them suitable for applications like robotics and industrial automation, where precision is vital.

Induction motors are the most widely used type of AC motor. They account for about 90% of all AC motors in industrial applications. The simplicity of their design contributes to low maintenance costs. They operate using electromagnetic induction, and their durability makes them a popular choice for many manufacturing processes. However, they can suffer from efficiency losses at lower loads.

Permanent magnet synchronous motors (PMSMs) are gaining traction. They offer high torque and energy efficiency. Reports suggest that PMSMs can improve energy savings by over 20% compared to standard induction motors. However, they require more intricate control systems, raising installation costs. Balancing efficiency and complexity is an ongoing discussion in the industry. These insights highlight the diverse options available for different operational needs in 2026.

2026 Top AC Motor Types You Need to Know? - Key Features and Benefits of Each AC Motor Type

| AC Motor Type |

Key Features |

Benefits |

| Induction Motor |

Robust design, low maintenance |

Widely used, cost-effective |

| Synchronous Motor |

Constant speed, high efficiency |

Ideal for precise applications |

| Permanent Magnet Motor |

Compact, high torque density |

Improved energy efficiency |

| Torque Motor |

High starting torque, direct drive |

No need for a gearbox |

| Slip Ring Motor |

Variable speed, high starting current |

Better load adaptability |

| Dual-Shaft Motor |

Two output shafts, flexible design |

Versatile in applications requiring dual movement |

Comparative Analysis: Performance of Different AC Motor Types

When it comes to AC motors, understanding their performance characteristics is crucial. Among the various types, the two most prominent are induction and synchronous motors. According to a report from the International Electrotechnical Commission, induction motors account for nearly 90% of all AC motor use globally. Their simple design makes them affordable and reliable, yet they lack the efficiency of synchronous motors.

Synchronous motors maintain a constant speed regardless of load. This makes them ideal for applications requiring precise speed control. According to a study by the IEEE, these motors can achieve efficiencies exceeding 95%, significantly reducing energy costs over time. However, their complexity often leads to higher initial costs and maintenance requirements.

Another factor to consider is their operational capabilities. Induction motors can handle variable loads well, but they may struggle in applications that require a consistent output. On the other hand, synchronous motors can operate effectively but are often less flexible in load variations. The choice between them depends on specific applications and desired outcomes, leading to ongoing discussions among engineers about the most efficient options available.

2026 Top AC Motor Types Performance Comparison

This chart illustrates the efficiency of different types of AC motors in 2026. Induction motors display the highest efficiency, followed by synchronous motors, permanent magnet motors, and stepper motors.

Future Developments in AC Motor Technology and Design

The future of AC motor technology is promising. Innovations are crucial as industries demand more efficiency. According to a recent report by the International Electrotechnical Commission, electric motors accounted for about 45% of global electricity consumption in 2022. This figure is expected to rise, highlighting the need for improved designs.

One key area of development is smart motor technology. These systems integrate sensors and IoT capabilities. They offer real-time data, helping with predictive maintenance and energy management. A report from Markets and Markets notes that the smart electric motor market is projected to grow from $1.5 billion in 2023 to $3.5 billion by 2028. However, integrating these technologies poses challenges. Companies must adapt to new software and training for staff.

Another trend is the lightweight and compact design. The new materials can reduce weight while maintaining performance. Research shows that lighter motors can improve system efficiency. However, finding the right balance between durability and weight remains an issue. As the AC motor landscape evolves, addressing these challenges will be essential for manufacturers and users alike.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor