Top 10 Gearmotor Manufacturers from China at the 137th Canton Fair

The 137th Canton Fair has proven to be a significant platform for international trade, showcasing the latest innovations and manufacturers from various sectors, including the gearmotor industry. With a record-breaking attendance of 288,938 overseas buyers from 219 countries, the fair highlighted the growing interest in gearmotors and their applications across multiple industries.

As we delve into the top gearmotor manufacturers from China featured at this event, we will explore how these companies are paving the way for advancements in technology and efficiency. The fair not only demonstrated the robust demand for gearmotors but also underscored the importance of global partnerships in driving innovation forward.

Join us as we dive into the standout manufacturers that are shaping the future of gearmotors in the ever-evolving market landscape.

The 137th Canton Fair has proven to be a significant platform for international trade, showcasing the latest innovations and manufacturers from various sectors, including the gearmotor industry. With a record-breaking attendance of 288,938 overseas buyers from 219 countries, the fair highlighted the growing interest in gearmotors and their applications across multiple industries.

As we delve into the top gearmotor manufacturers from China featured at this event, we will explore how these companies are paving the way for advancements in technology and efficiency. The fair not only demonstrated the robust demand for gearmotors but also underscored the importance of global partnerships in driving innovation forward.

Join us as we dive into the standout manufacturers that are shaping the future of gearmotors in the ever-evolving market landscape.

Top Manufacturers Leading the Gearmotor Industry at the 137th Canton Fair

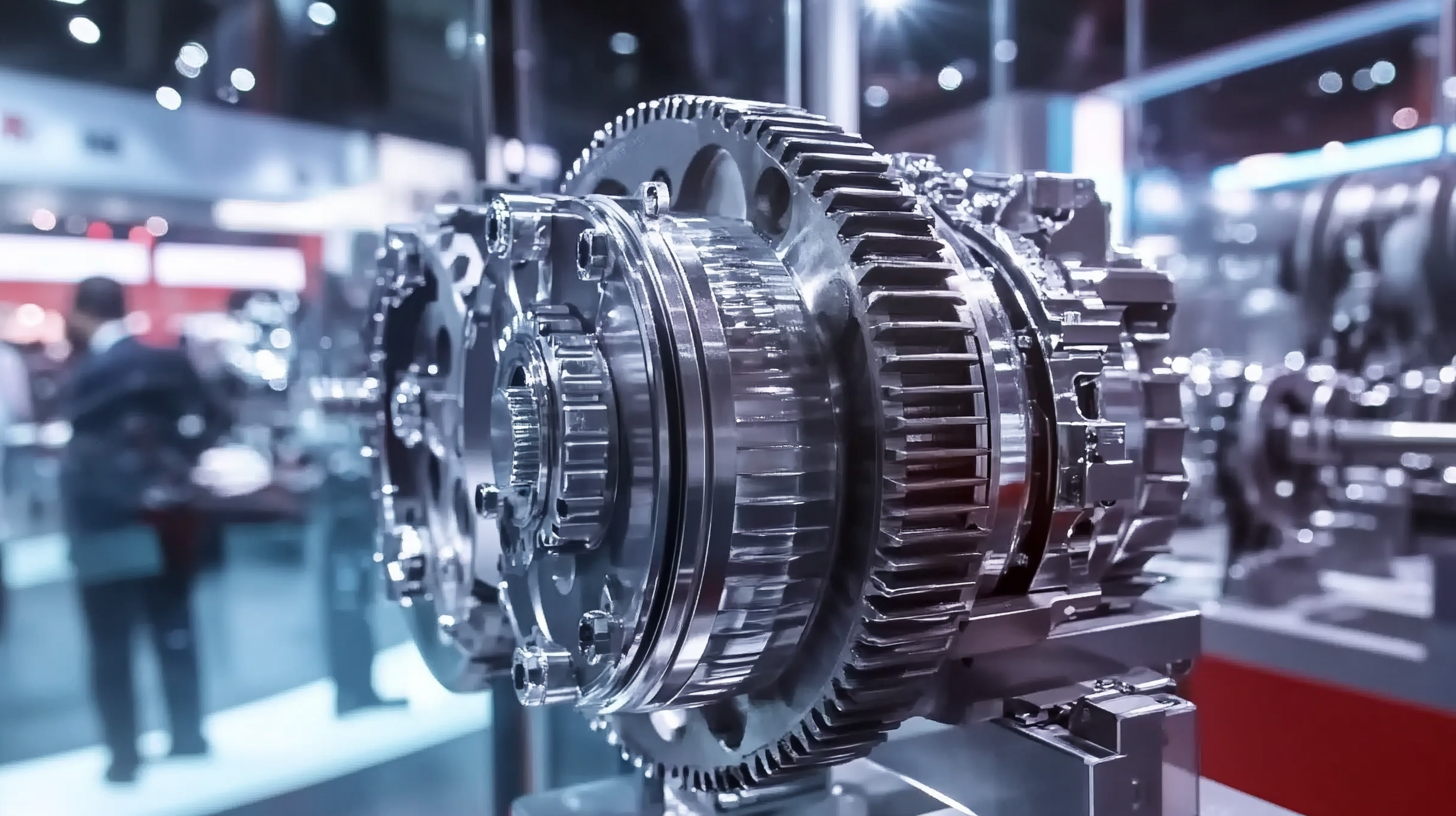

The 137th Canton Fair showcased a remarkable array of innovations in the gearmotor industry, highlighting the prowess of leading manufacturers from China. Among the exhibitors, companies like DONGYANG and NIDEC stood out with their cutting-edge technology and commitment to quality.

DONGYANG, recognized for its expertise in electric drives, introduced an advanced range of gearmotors that promise enhanced efficiency and durability, making them ideal for various industrial applications.

NIDEC, known globally for its precision and innovation, presented its latest solutions that integrate smart technology, positioning them as a frontrunner in the industry.

Furthermore, enterprises like JINAN RUIYI and HANGZHOU LAMDA showcased their unique offerings, including customized gearmotor solutions tailored to specific industry needs. Their strong emphasis on research and development has allowed these manufacturers to cater to the evolving demands of automation across sectors.

The presence of these top-tier manufacturers at the Canton Fair not only reflects the dynamic growth of the gearmotor sector in China but also underscores the global significance of their advancements, further solidifying China's position as a powerhouse in manufacturing.

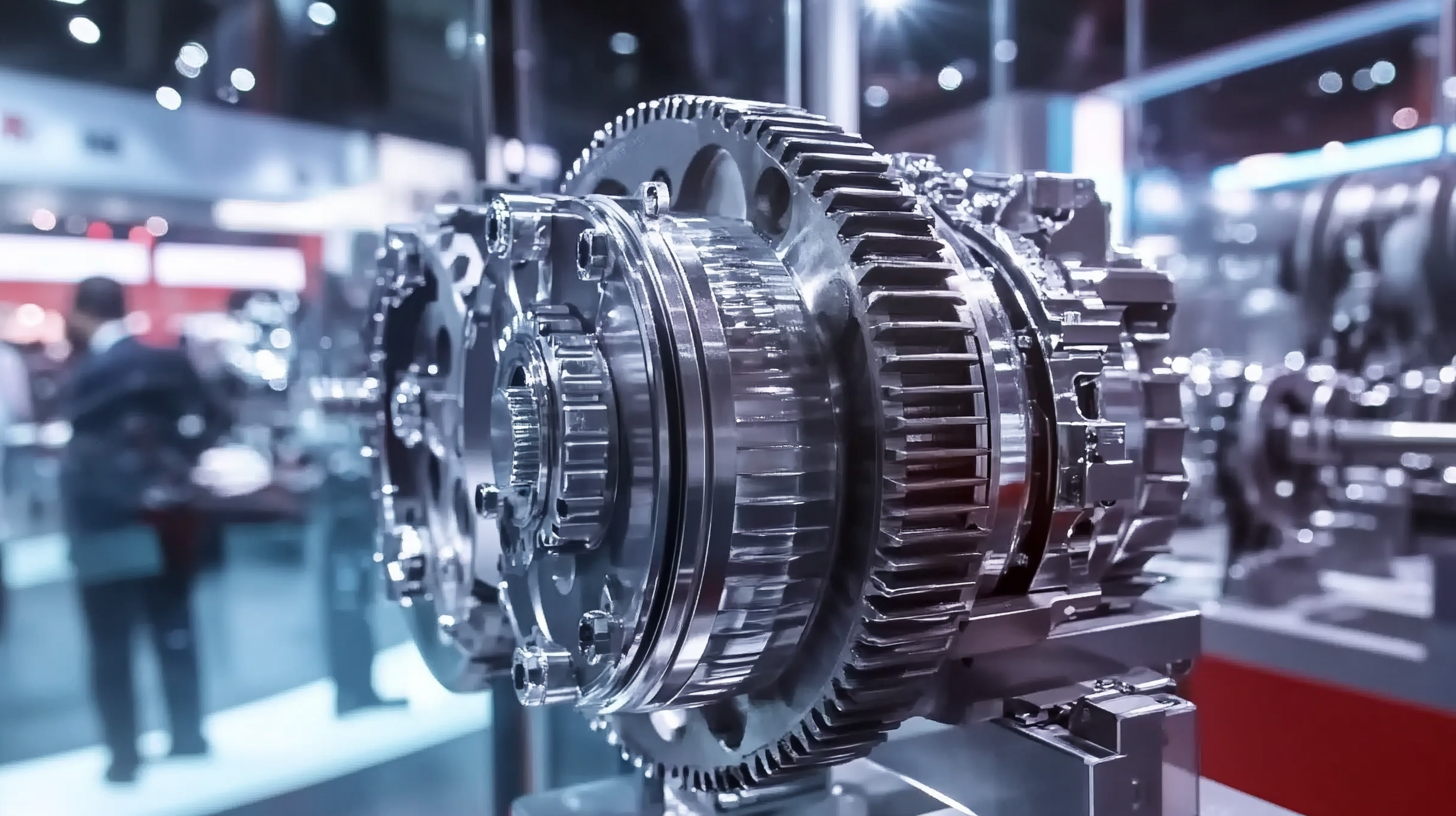

Record Participation of International Buyers: A Look at the 137th Canton Fair

The 137th Canton Fair has set new records in international participation, reflecting the growing global interest in Chinese manufacturing. According to industry reports, the fair attracted over 200,000 buyers from more than 200 countries, a significant increase compared to previous years. This participation not only underscores the importance of the Canton Fair as a key platform for international trade but also highlights China's pivotal role in the global supply chain. The fair's ability to connect manufacturers with international buyers demonstrates the increasing demand for high-quality products, especially in sectors like gearmotors, where innovation and reliability are crucial.

In recent years, the gearmotor industry has seen remarkable growth, with projected market values reaching $4 billion by 2025. Key factors driving this growth include automation and the push for energy-efficient solutions across various industries. The presence of top gearmotor manufacturers at the Canton Fair emphasizes the importance of networking and collaboration in this evolving market. Participants, including major Chinese players, showcased advanced technologies and diverse product offerings, reflecting their commitment to meet international standards and buyer expectations. This synergy between manufacturers and global buyers at the Canton Fair paves the way for enhanced trade relationships and technological exchanges.

Top 10 Gearmotor Manufacturers from China at the 137th Canton Fair

| Rank |

Manufacturer Type |

Main Products |

Annual Production (Units) |

Export Share (%) |

Years in Business |

| 1 |

Electric Gearmotor |

AC Motors, DC Motors |

250,000 |

70 |

15 |

| 2 |

Industrial Gearmotor |

Geared Motors, Speed Reducers |

200,000 |

60 |

20 |

| 3 |

Precision Gearmotor |

Servo Motors, Stepper Motors |

150,000 |

75 |

10 |

| 4 |

Torque Gearmotor |

High-Torque Motors, Gearbox |

180,000 |

65 |

18 |

| 5 |

High Efficiency Gearmotor |

Energy-Saving Motors |

220,000 |

80 |

12 |

| 6 |

Mini Gearmotor |

Compact Motors |

300,000 |

50 |

8 |

| 7 |

Variable Speed Gearmotor |

Adjustable Speed Motors |

130,000 |

55 |

16 |

| 8 |

Heavy Duty Gearmotor |

Robust Motors, Heavy Loads |

90,000 |

40 |

25 |

| 9 |

Robotic Gearmotor |

Robot Motors, Motion Systems |

110,000 |

68 |

9 |

| 10 |

Eco-Friendly Gearmotor |

Sustainable Motors |

85,000 |

85 |

7 |

Key Trends in Export Intentions: Insights from the 137th Canton Fair

The 137th Canton Fair has showcased an exciting shift in export intentions, revealing significant trends across various industries. Manufacturers are increasingly recognizing the importance of global sourcing, particularly in niches such as automotive solutions and furniture hardware. The fair highlighted innovative products like vehicle paint protection films and specialized furniture hinges, which are catering to burgeoning international demand driven by evolving consumer preferences.

Moreover, the event provided a platform for companies to present groundbreaking items, such as modern table lamps, which captured attention with their innovative designs and functionalities. This influx of novel products signifies a broader trend among exporters to leverage the Canton Fair for tapping into new markets and expanding their overseas presence. The overall atmosphere of the fair, marked by a palpable excitement for innovation and collaboration, strengthens the notion that Chinese manufacturers are not only meeting domestic needs but are also strategically positioning themselves on the global stage.

Anticipating Future Opportunities: The 138th Canton Fair's Export Focus

As the 138th Canton Fair approaches, industry experts are gearing up to explore new export opportunities, especially in the burgeoning gearmotor sector. With the increasing demand for automation across various industries, manufacturers are expected to showcase cutting-edge innovations and products that align with global sustainability trends. The focus on energy-efficient solutions will be a key highlight, as businesses look to minimize their carbon footprints while enhancing operational efficiency.

Furthermore, the Canton Fair provides an unparalleled platform for networking and collaboration. International buyers will have the chance to engage directly with Chinese gearmotor producers, fostering partnerships that can lead to mutually beneficial growth. As the fair continues to evolve, the emphasis on digital transformation and smart manufacturing stands out, promising a future where technology-driven solutions take center stage. With these upcoming opportunities in mind, attendees can anticipate a fruitful exploration of the latest advancements in gearmotor technology and its applications in various sectors.

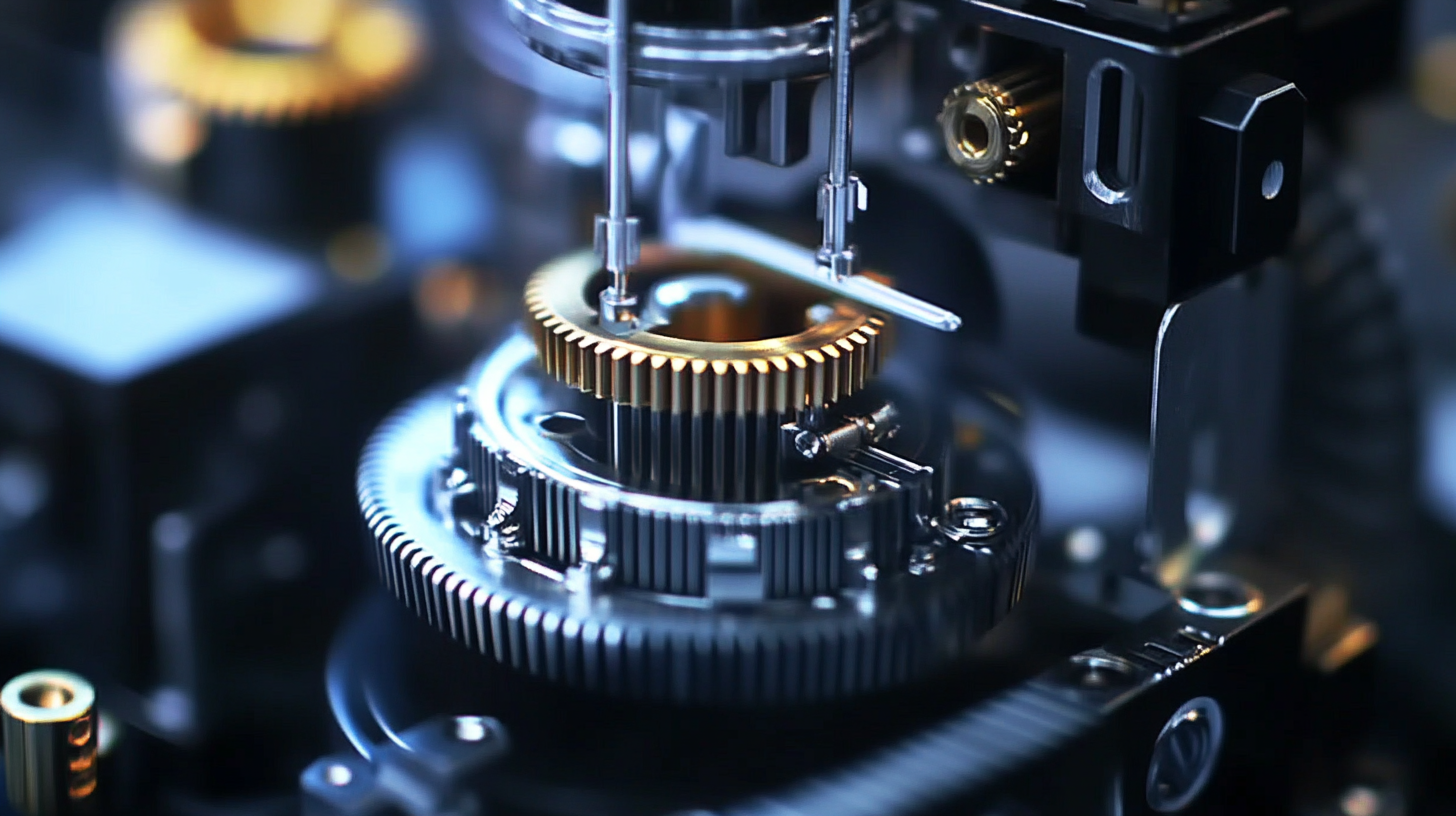

Gearmotor Innovations Highlighted at the 137th Canton Fair: Trends to Watch

The 137th Canton Fair recently showcased a myriad of innovations in the gearmotor industry, underscoring significant trends that are shaping the future of this crucial sector. As manufacturers focus on energy efficiency and compact designs, the market is projected to grow at a CAGR of 6.3% from 2023 to 2028, driven by the increasing demand across various applications from robotics to renewable energy solutions. This year, exhibitors highlighted breakthroughs in smart gearmotor technologies, which integrate IoT capabilities to enhance operational efficiency and facilitate predictive maintenance.

Tips for those considering a gearmotor purchase: always evaluate the energy rating and compatibility with existing systems. Opt for models that incorporate advanced features such as real-time monitoring and automated diagnostics. This not only ensures longevity but also optimizes performance.

Moreover, customization has emerged as a key trend, with manufacturers offering tailored solutions to meet the specific needs of their clients. This focus on bespoke designs can significantly reduce downtime and enhance productivity. As companies increasingly prioritize sustainability, the incorporation of eco-friendly materials in gearmotor production is another trend to watch, promising reduced environmental impact while maintaining performance reliability.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor The 137th Canton Fair has proven to be a significant platform for international trade, showcasing the latest innovations and manufacturers from various sectors, including the gearmotor industry. With a

The 137th Canton Fair has proven to be a significant platform for international trade, showcasing the latest innovations and manufacturers from various sectors, including the gearmotor industry. With a