The Ultimate Guide to Choosing the Best Servo Motor for Your Industrial Needs

In the competitive landscape of modern industry, choosing the right Servo Motor is paramount for optimizing performance and enhancing productivity. According to a report by Markets and Markets, the global servo motor market is projected to grow from USD 8.18 billion in 2020 to USD 13.12 billion by 2025, reflecting a CAGR of 10.3%. This growth is largely driven by increased automation in manufacturing processes, particularly in sectors such as automotive and electronics, where precision control is essential. As industries strive for "精工细造,中国制造,服务世界," the selection of an appropriate servo motor can directly impact operational efficiency and product quality.

In this ultimate guide, we will explore key factors to consider when selecting a servo motor to meet specific industrial needs, ensuring that your investment yields maximum returns in a rapidly evolving market.

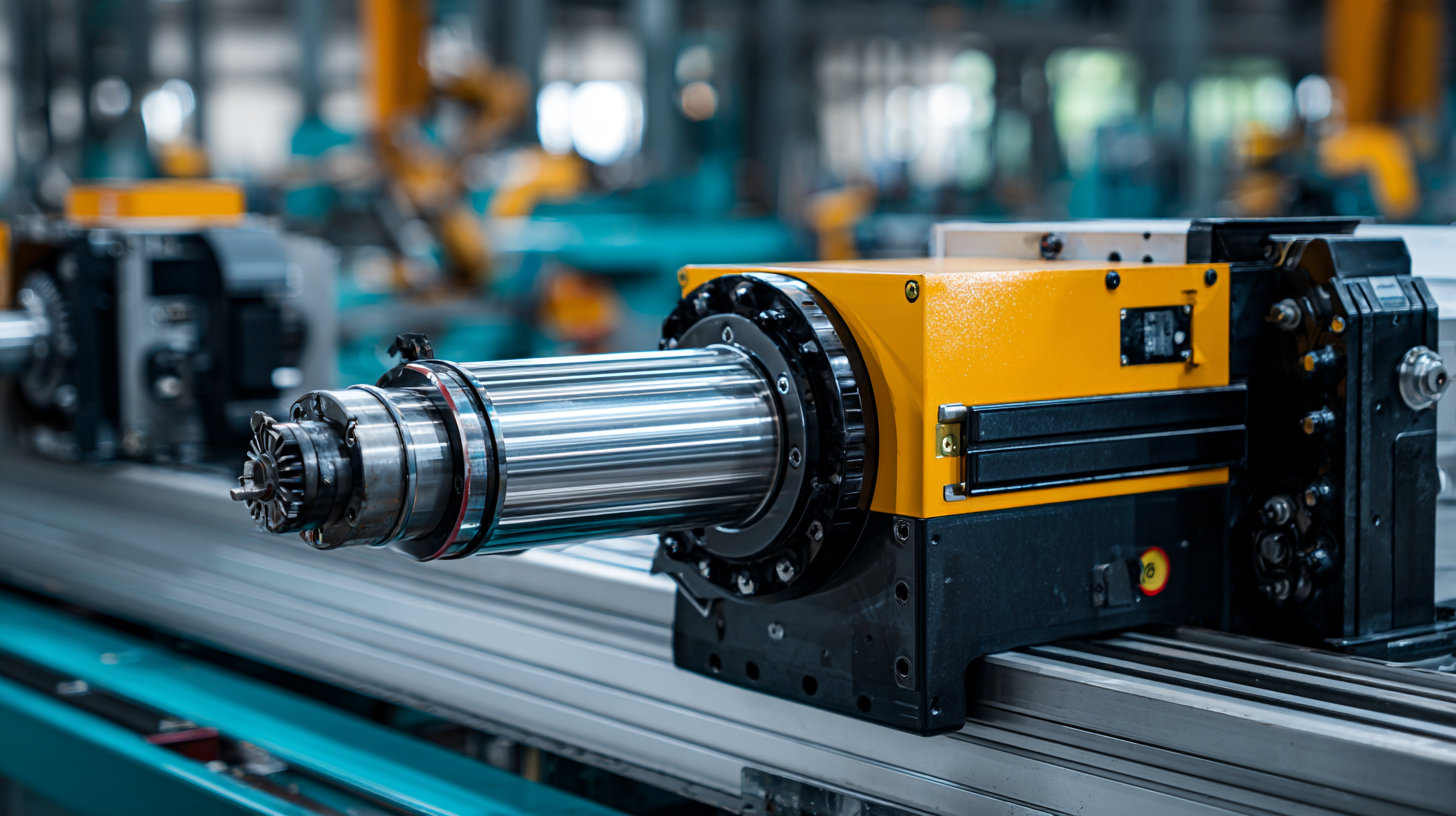

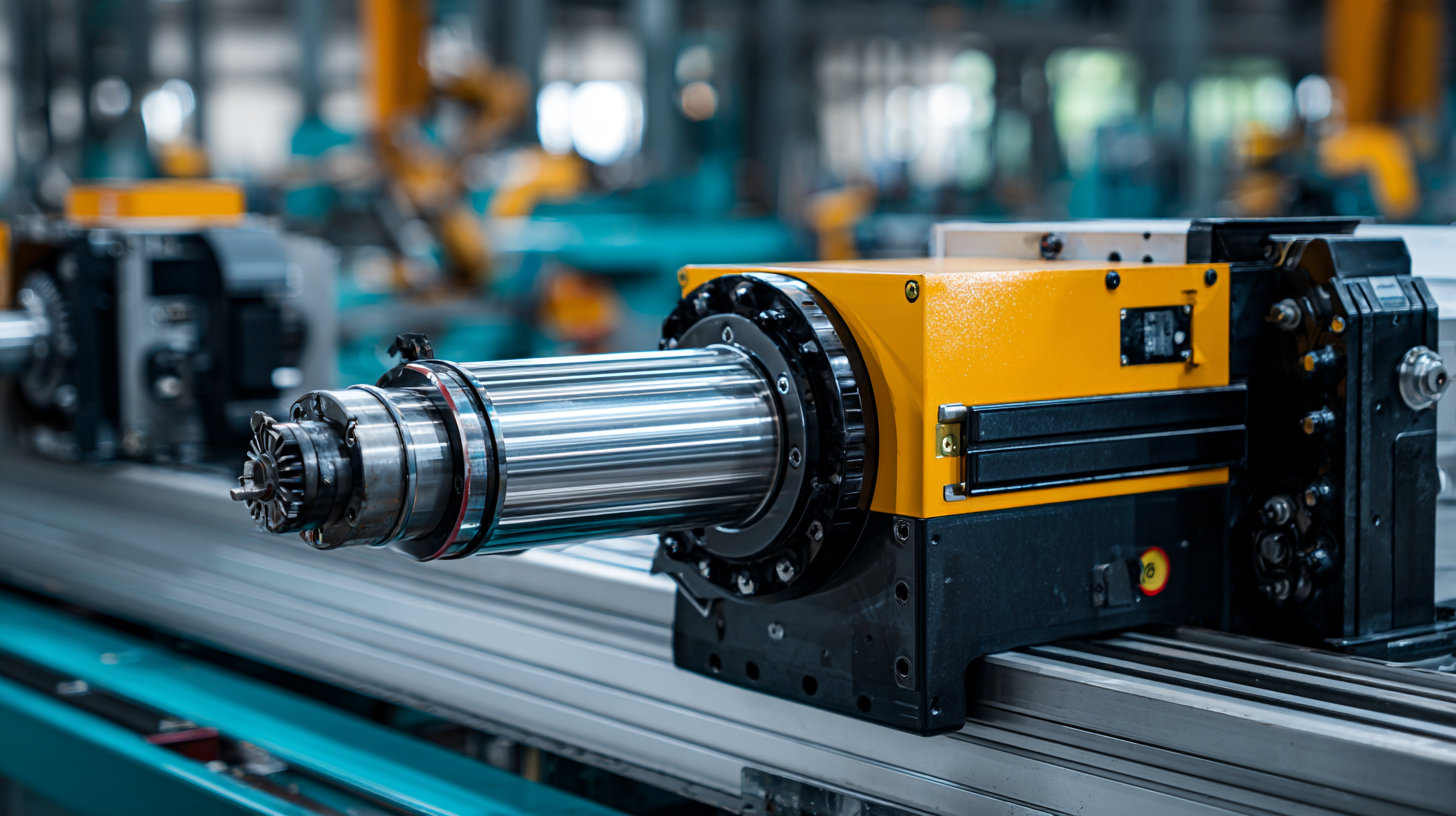

Understanding Servo Motor Types and Their Applications in Industry

When selecting a servo motor for industrial applications, understanding the various types and their respective functionalities is crucial. Servo motors, renowned for their precision in controlling angular or linear position, speed, and acceleration, are integral to automation processes across multiple sectors. Recent trends show that industries are increasingly adopting these motors, evidenced by the expected growth of the variable frequency drive market, projected to reach USD 32.00 billion by 2030. This growth indicates a rising demand for high-performance motors like servo motors that facilitate energy efficiency and reliability.

When selecting a servo motor for industrial applications, understanding the various types and their respective functionalities is crucial. Servo motors, renowned for their precision in controlling angular or linear position, speed, and acceleration, are integral to automation processes across multiple sectors. Recent trends show that industries are increasingly adopting these motors, evidenced by the expected growth of the variable frequency drive market, projected to reach USD 32.00 billion by 2030. This growth indicates a rising demand for high-performance motors like servo motors that facilitate energy efficiency and reliability.

Different types of servo motors, including brushless DC and stepper motors, provide specialized benefits tailored to specific industrial needs. For instance, brushless DC motors are celebrated for their efficiency and low maintenance, making them suitable for continuous operational scenarios. Meanwhile, the stepper motor market is predicted to grow substantially, driven by the automation surge in manufacturing, emphasizing the importance of selecting the right motor type based on application requirements. With advancements in motor control solutions, industries are better equipped to meet their operational challenges while enhancing productivity.

Key Factors to Consider When Selecting a Servo Motor for Your Facility

When selecting a servo motor for industrial applications, there are several key factors that demand careful consideration to ensure optimal performance and efficiency. Firstly, understanding the required torque and speed is crucial. According to a 2022 report by Research and Markets, the servo motor market is projected to reach $7.6 billion by 2026, highlighting the growing demand for high-performance applications. A precise calculation of the torque required for your specific tasks can prevent underperformance or over-engineering, which can lead to increased operational costs.

Another significant factor is the motor's compatibility with the existing control systems and feedback devices. Servo motors necessitate a reliable feedback loop to maintain accuracy, and selecting models with appropriate communication protocols can enhance overall system integration. The same report notes that advancements in connectivity, particularly with Ethernet-based protocols, are transforming the way servo systems operate, allowing for real-time monitoring and adjustments. Thus, choosing a servo motor that aligns with both the operational needs and technological infrastructure of your facility is essential for maximizing productivity and minimizing downtime.

Comparative Analysis of AC vs. DC Servo Motors in Industrial Settings

When it comes to selecting the right

servo motor

for industrial applications, understanding the

differences

between AC and DC servo motors is crucial. AC servo motors are generally preferred for their high efficiency

and excellent performance in applications requiring precise control and speed variation. These motors tend to offer

smoother operation and better heat dissipation, making them ideal for

high-speed machinery

and environments requiring continuous use. Their ability to maintain

torque at high speeds is particularly beneficial in applications such as

robotic arms

and CNC machines.

On the other hand, DC servo motors

have their own set of advantages that may suit specific industrial needs. They are

simpler

and often more cost-effective, making them a popular choice for small-scale or less complex applications.

DC motors excel in situations where rapid acceleration and deceleration are needed, as they

can respond more quickly to input signals. This makes them a good fit for automated systems

where speed and responsiveness are paramount, albeit at the cost of some efficiency compared to their AC counterparts.

Ultimately, the choice between AC and DC servo motors

will depend on the specific requirements of the application, balancing factors like performance, cost, and complexity.

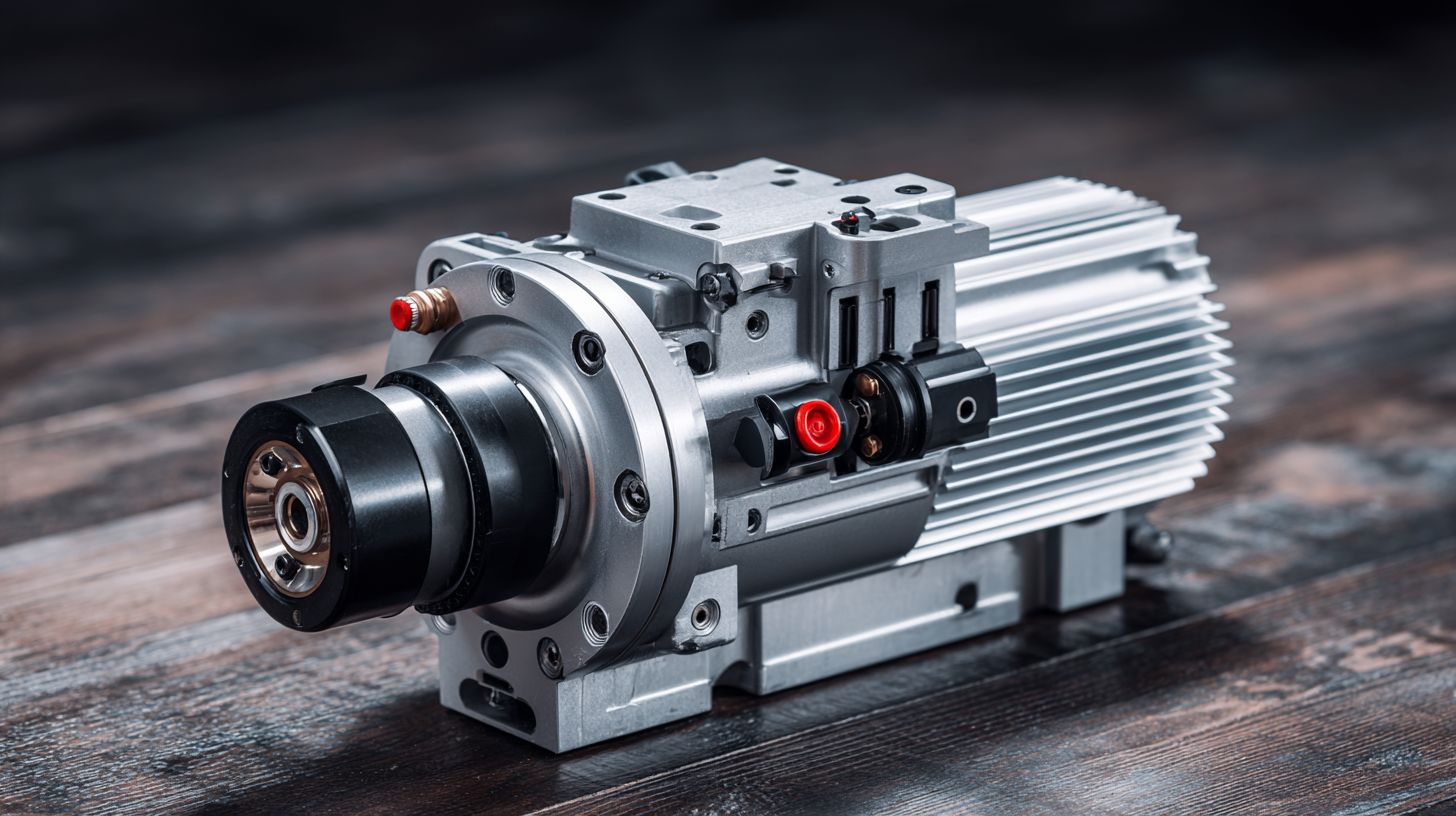

Evaluating Torque, Speed, and Feedback Systems for Optimal Performance

When selecting the ideal servo motor for industrial applications, evaluating key performance factors such as torque, speed, and feedback systems is crucial. Torque is a primary consideration, as it determines the motor's ability to perform work and handle load variations. High torque is essential for applications requiring precise control over heavy loads, while lower torque might suffice for lighter tasks. Additionally, understanding the relationship between the motor's torque and the operational speed is vital, as it impacts the overall efficiency and responsiveness of the system.

Speed is another critical parameter, affecting the motor's responsiveness and capability in dynamic environments. It's important to choose a servo motor that can achieve the desired speed without compromising on torque. Variables like acceleration and deceleration rates also come into play, influencing the motor's performance in real-time applications. Finally, an effective feedback system—such as encoders or resolvers—ensures accurate position and speed control, enabling the servo motor to adapt to varying operational conditions seamlessly. By carefully analyzing these factors, you can ensure optimal performance and longevity for your industrial processes.

The Ultimate Guide to Choosing the Best Servo Motor for Your Industrial Needs

| Motor Type |

Torque (Nm) |

Speed (RPM) |

Feedback System |

Application |

| AC Servo Motor |

1.5 |

3000 |

Incremental Encoder |

Robotics |

| DC Servo Motor |

2.0 |

2500 |

Hall Effect Sensor |

Conveying Systems |

| Stepper Motor |

1.0 |

1500 |

Open Loop Control |

3D Printing |

| Coreless Motor |

0.8 |

5000 |

Optical Encoder |

Medical Devices |

Latest Industry Trends in Servo Motor Technology and Future Innovations

The landscape of servo motor technology is rapidly evolving, driven by advancements in automation and control systems. One of the latest trends is the integration of AI and machine learning algorithms into servo motor systems, enabling real-time adjustments and improved precision. This allows for enhanced performance in applications that require high responsiveness, such as robotics and CNC machinery. As these technologies become more prevalent, manufacturers are likely to see increased efficiency and reduced operational costs.

Another significant innovation is the shift towards more compact and energy-efficient servo motors. Designers are now focusing on minimizing size without compromising power output, which is particularly beneficial for industries with limited space. Additionally, innovations such as direct drive systems are eliminating the need for gearboxes, thus reducing mechanical losses and increasing reliability. With these advancements, the future of servo motors looks promising, offering enhanced capabilities that align with the ever-growing demands of industrial applications.

The Ultimate Guide to Choosing the Best Servo Motor for Your Industrial Needs

This bar chart represents key specifications to consider when choosing a servo motor for industrial applications, highlighting Torque, Speed, Efficiency, and Cost. Understanding these metrics can help optimize your operational needs.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor

When selecting a servo motor for industrial applications, understanding the various types and their respective functionalities is crucial. Servo motors, renowned for their precision in controlling angular or linear position, speed, and acceleration, are integral to automation processes across multiple sectors. Recent trends show that industries are increasingly adopting these motors, evidenced by the expected growth of the variable frequency drive market, projected to reach USD 32.00 billion by 2030. This growth indicates a rising demand for high-performance motors like servo motors that facilitate energy efficiency and reliability.

When selecting a servo motor for industrial applications, understanding the various types and their respective functionalities is crucial. Servo motors, renowned for their precision in controlling angular or linear position, speed, and acceleration, are integral to automation processes across multiple sectors. Recent trends show that industries are increasingly adopting these motors, evidenced by the expected growth of the variable frequency drive market, projected to reach USD 32.00 billion by 2030. This growth indicates a rising demand for high-performance motors like servo motors that facilitate energy efficiency and reliability.