- SIEMENS Gearmotor

- NORD Industrial Gear Unit

- LENZE Gearmotor

- NORD Gearmotor

- SEW Planetary Gear Unit

- SEW Industrial Gear Unit

- SEW Gearmotor

- BONFIGLIOLI Precision Planetary Gearbox and Gearmotor

- BONFIGLIOLI Inverters and Servo drives

- BONFIGLIOLI Industrial Gear Unit

- BONFIGLIOLI Gearmotor

- FLENDER Coupling

- FLENDER Gear Unit

01

BIPEX S Backlash free Coupling high performance

Benefits

BIPEX-S couplings are suitable for mounting horizontally, vertically or in any desired position. The coupling parts can be arranged as required on the shaft ends to be connected.

The coupling can be axially plugged in.

The cam ring is pretensioned and is therefore assembled without backlash. The cams attached to the cam ring allow the coupling to compensate shaft misalignment and also provide electrical isolation since they prevent contact between the two hub parts.

BIPEX-S couplings are fail-safe. When the cam ring is worn, the claws of the coupling hubs provide for fail-safe operation.

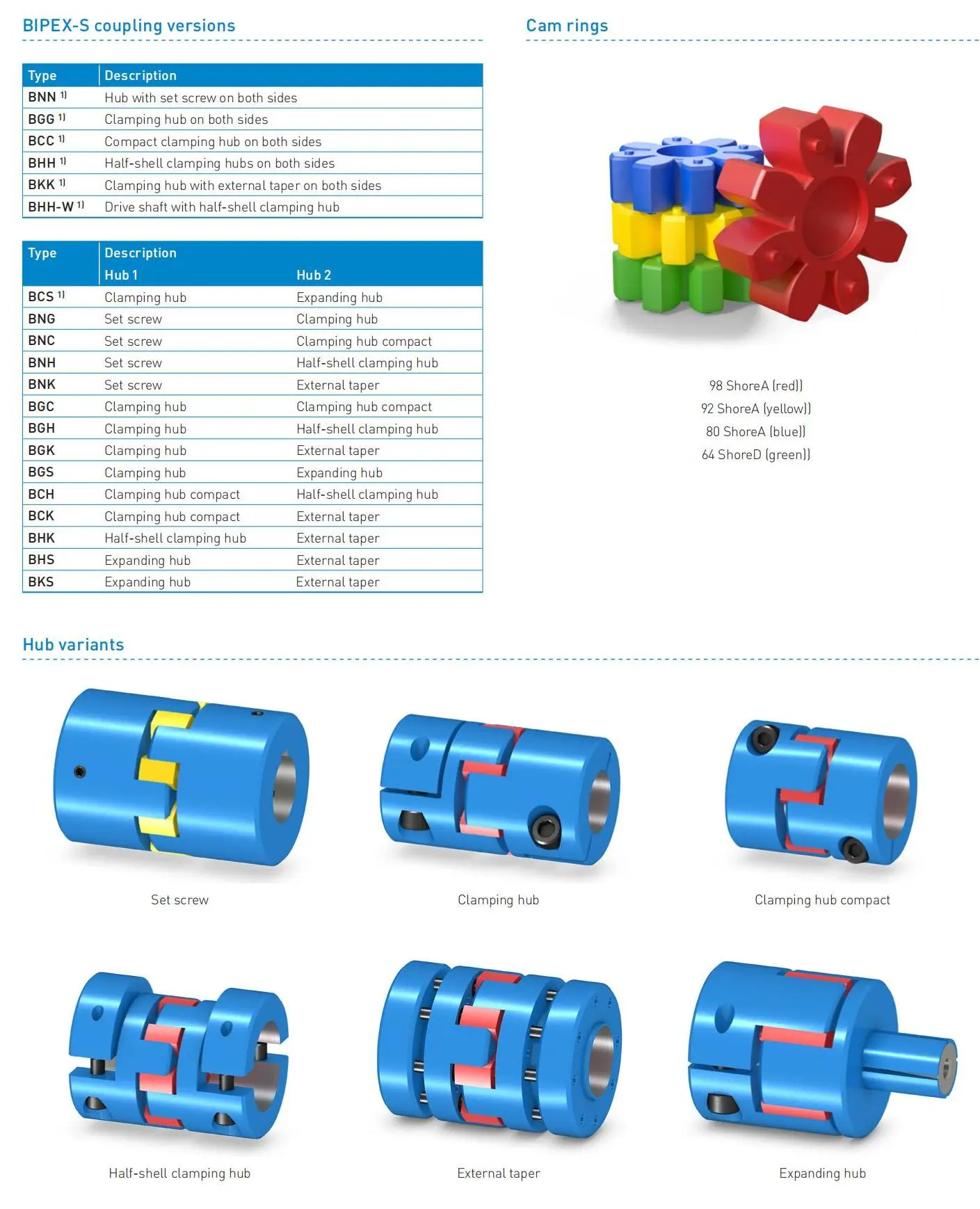

Available in 4 different Shore hardness grades, the cam rings allow to select the optimum degree of rigidity for any application.

Application

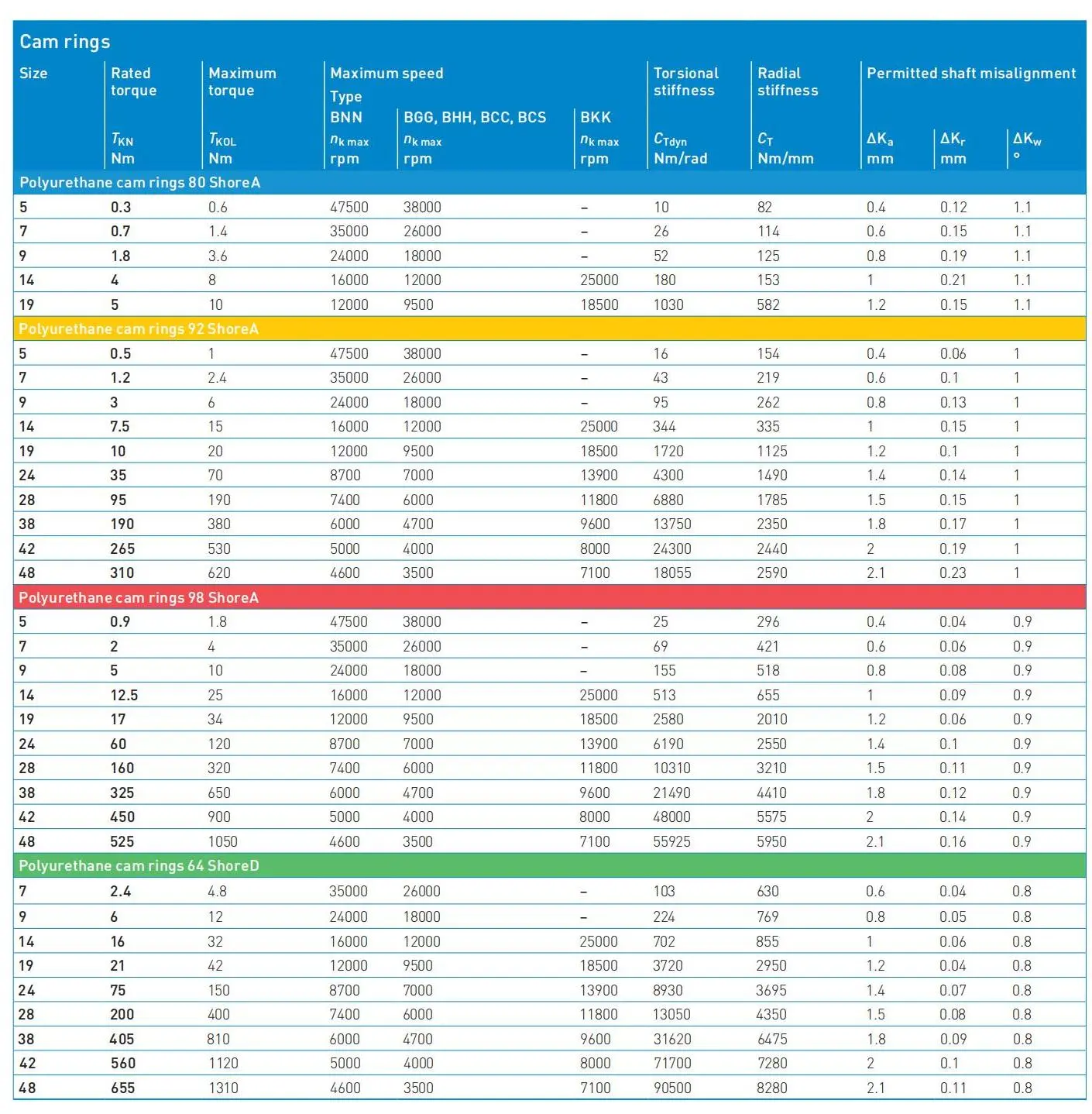

BIPEX-S couplings within the standard catalog range are available in 10 sizes with torque ratings ranging from 0.5 to 655 Nm. The coupling is suitable for ambient temperatures of between -30 °C and +90 °C. Cam rings with alternative hardness grades can be supplied for ambient temperatures down to -50 °C or up to +120 °C.

BIPEX-S couplings are ideal for use in servo drives, linear axes or rotary encoders of the type typically deployed in machine tools, packaging machines or printing presses.

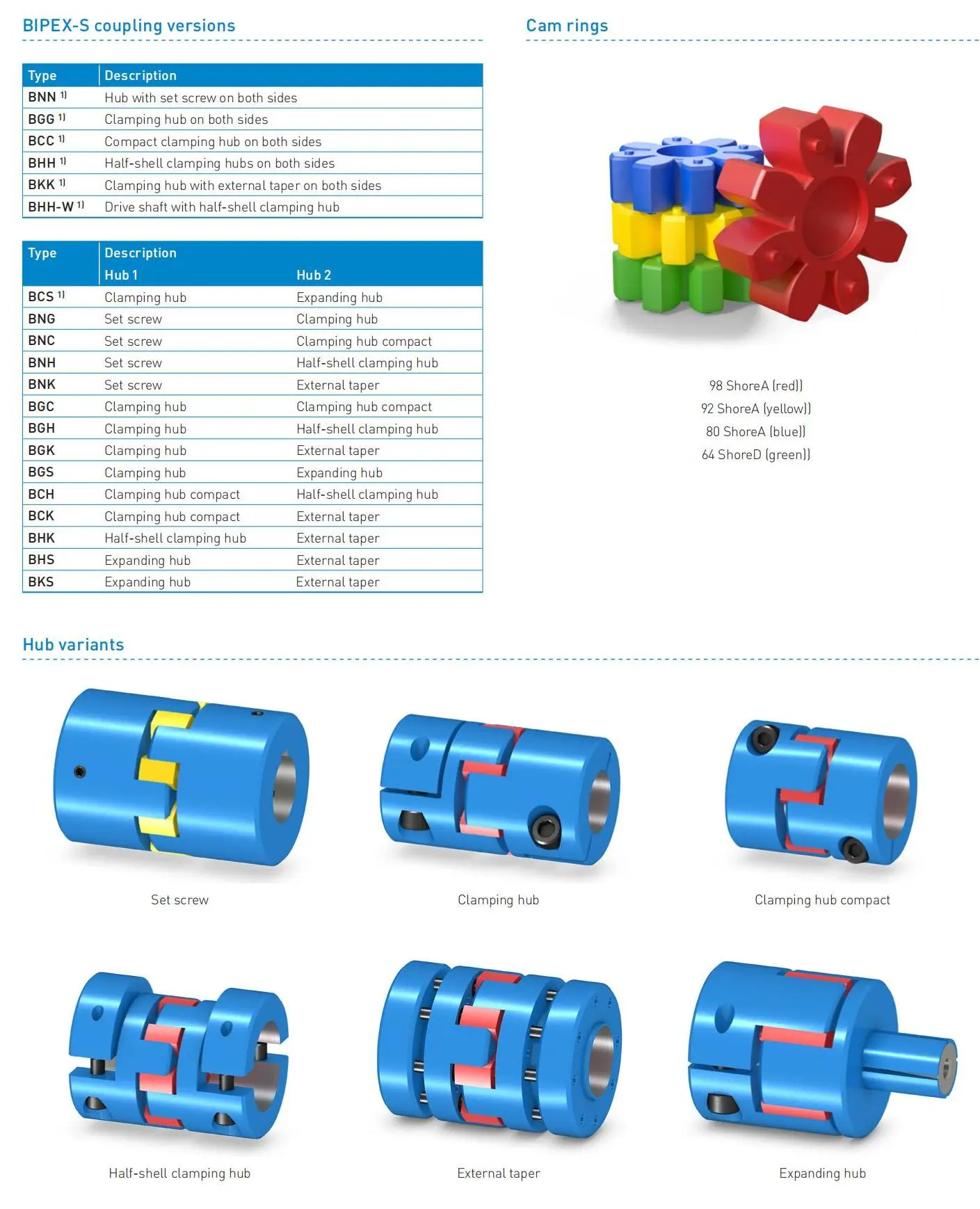

Design and configurations

BIPEX-S couplings each comprise two hub parts connected by a cam ring made of polyurethane (PU).

The couplings can be axially plugged in during assembly.

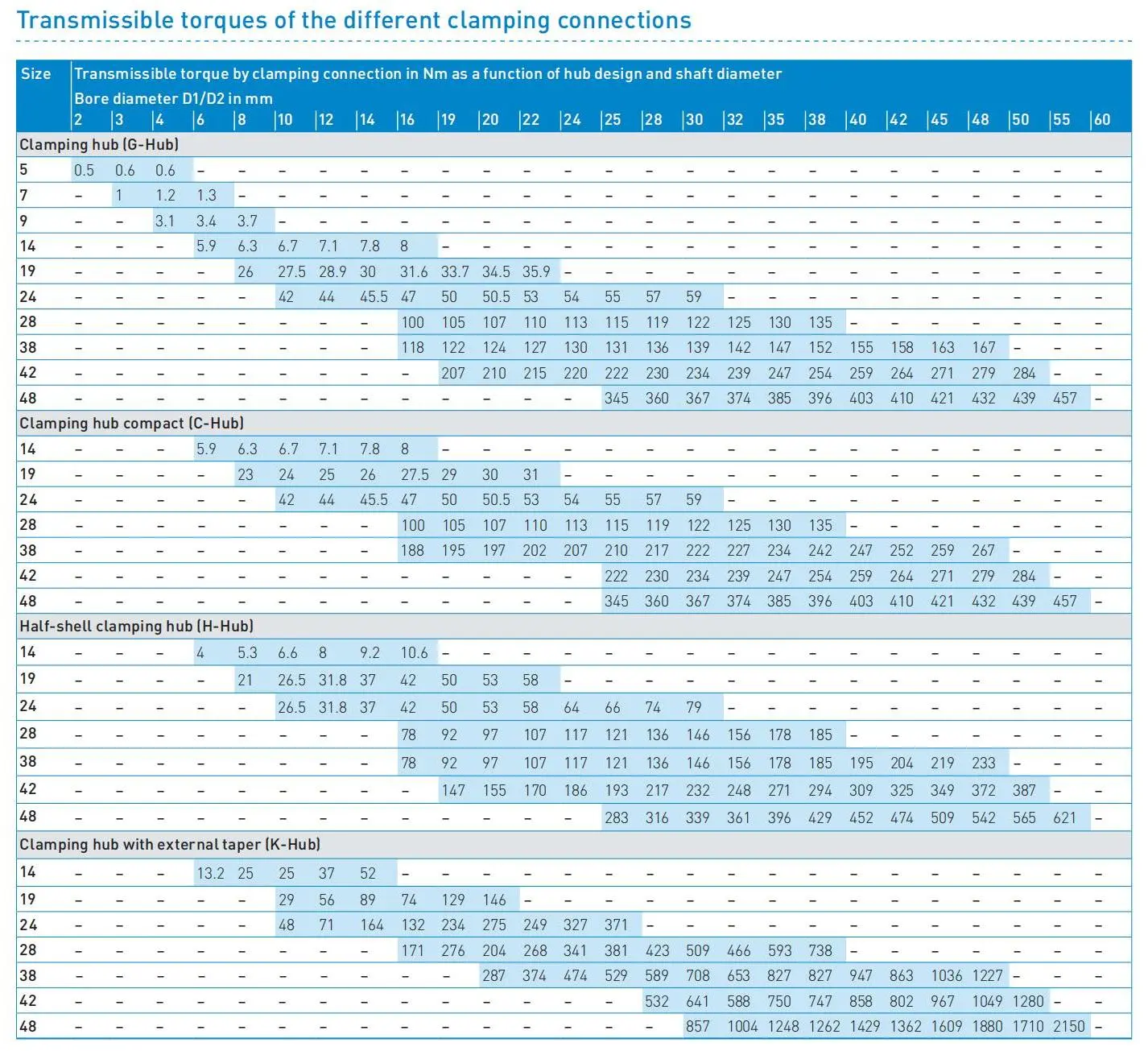

The hubs can be coupled to the shafts by many different methods including set screws, key joint, slotted clamping hubs, half-shell hubs, clamping hubs or expanding hubs.

BIPEX-S couplings are positive-locking and torsionally flexible thanks to the polyurethane cam ring. Misalignment between the connected shafts deforms the cam ring.

Coupling materials

Hubs Up to size 38 aluminum

Sizes 42 and 48 steel

Cam ring PU 80 ShoreA -50 °C to +80 °C

PU 92 ShoreA -40 °C to +90 °C

PU 98 ShoreA -30 °C to +90 °C

(standard ring)

PU 64 ShoreD -50 °C to +120 °C

The coupling types can be combined from the available range of hub versions and different elastomer grades.

Hub versions

Hub Description

N Hub with set screw

G Slotted clamping hub

C Slotted clamping hub, compact

H Half-shell clamping hub

K Clamping hub with external taper

S Expanding hub

The N version has a keyway as standard. Versions G, C and H are optionally available with keyway.

The fitting tolerance of the coupled shaft ends should be g6 or h7.

Preliminary dimensioning

Dimensioning according to torque

The coupling must be dimensioned such that the rated torque of the drive including service factors does not exceed the rated torque of the coupling:

TKN ≥ TN ⋅ FB ⋅ FT

Torque characteristic Service factor FB

Uniform 1.25

Non uniform 1.5

Rough 2

In order to increase the torsional rigidity and therefore minimize the torsional backlash, it is possible to apply significantly higher service factors for main spindle or positioning drives.

Temperature range Temperature factor FT

-30 °C to +30 °C 1

to +60 °C 1.4

to +80 °C 1.8

to +100 °C 2

to +120 °C 2.8

Note:

Please note the permissible temperature ranges of different cam rings.

Starts per hour Startup factor FA

< 125 1

125 to 250 1.3

250 to 500 1.6

500 to 1000 1.8

> 1000 2

Preliminary dimensioningChecking the peak torques

The coupling size selected during the preliminary dimensioning process must also be suitable with respect to peak torques at the drive and load ends:

Checking the maximum speed

For all load situations nKmax > nmax

Checking the permitted shaft misalignment

The actual shaft misalignment must be less than the permitted shaft misalignment for all load situations.

Checking the shaft-hub connection

In the case of clamping connections without feather key, it must be ensured that the transmissible torque of the hub connection is greater than the peak torque at the coupling.

Technical information

Torsional stiffness and damping

The values stated in the table apply to a capacity utilization of 50 %, an excitation amplitude of 10 % TKN with a frequency of 10 Hz and an ambient temperature of 20 °C.

The dynamic torsional stiffness is load-dependent and increases in proportion to capacity utilization.

The relative damping coefficient is

ψ = 0,8 for 98, 92 and 80 ShoreA

ψ = 0,75 for 64 ShoreD.

TKOL is the torque which can be transmitted very rarely as maximum torque by the coupling.

Zulässiger Wellenversatz

The permitted shaft misalignments ΔKa, ΔKr and ΔKware maximum values and must not occur simultaneously.

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150 SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage SIEMENS SINAMICS V90

SIEMENS SINAMICS V90 SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage FLENDER Gear Unit

FLENDER Gear Unit FLENDER Helical Gear Unit

FLENDER Helical Gear Unit Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox Playmaker In The Premium League

Playmaker In The Premium League Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200 Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships Reliable Power Generation on board

Reliable Power Generation on board Maximum performance level, fast deliverable

Maximum performance level, fast deliverable Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable. FLENDER Coupling

FLENDER Coupling ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance SEW Gearmotor

SEW Gearmotor R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor