2025 Top 5 Gearbox Innovations That Will Transform Your Transportation Industry

As the transportation industry evolves rapidly, the advancements in gearbox technology are set to play a pivotal role in reshaping how we move goods and people. Leading experts in the field, such as Dr. Emily Carter, a renowned gearbox innovator, emphasize the significance of these innovations. Dr. Carter states, "The future of transportation hinges on the efficiency and reliability of gearboxes, which are the unsung heroes of modern vehicles."

In 2025, we anticipate groundbreaking developments in gearbox technology that will not only enhance performance but also advance sustainability within the sector. The integration of smart materials, improved manufacturing techniques, and advanced software algorithms are just a few areas where innovation is making strides. These enhancements promise to increase efficiency, reduce caloric waste, and improve overall vehicle dynamics, making transportation safer, faster, and more eco-friendly.

As we explore the top five gearbox innovations set to transform the transportation industry in 2025, it becomes clear that these advancements are crucial for overcoming the challenges posed by global logistics, energy consumption, and urban congestion. The road ahead is paved with opportunities for efficiency and innovation, and the gearbox remains at the heart of this transformation.

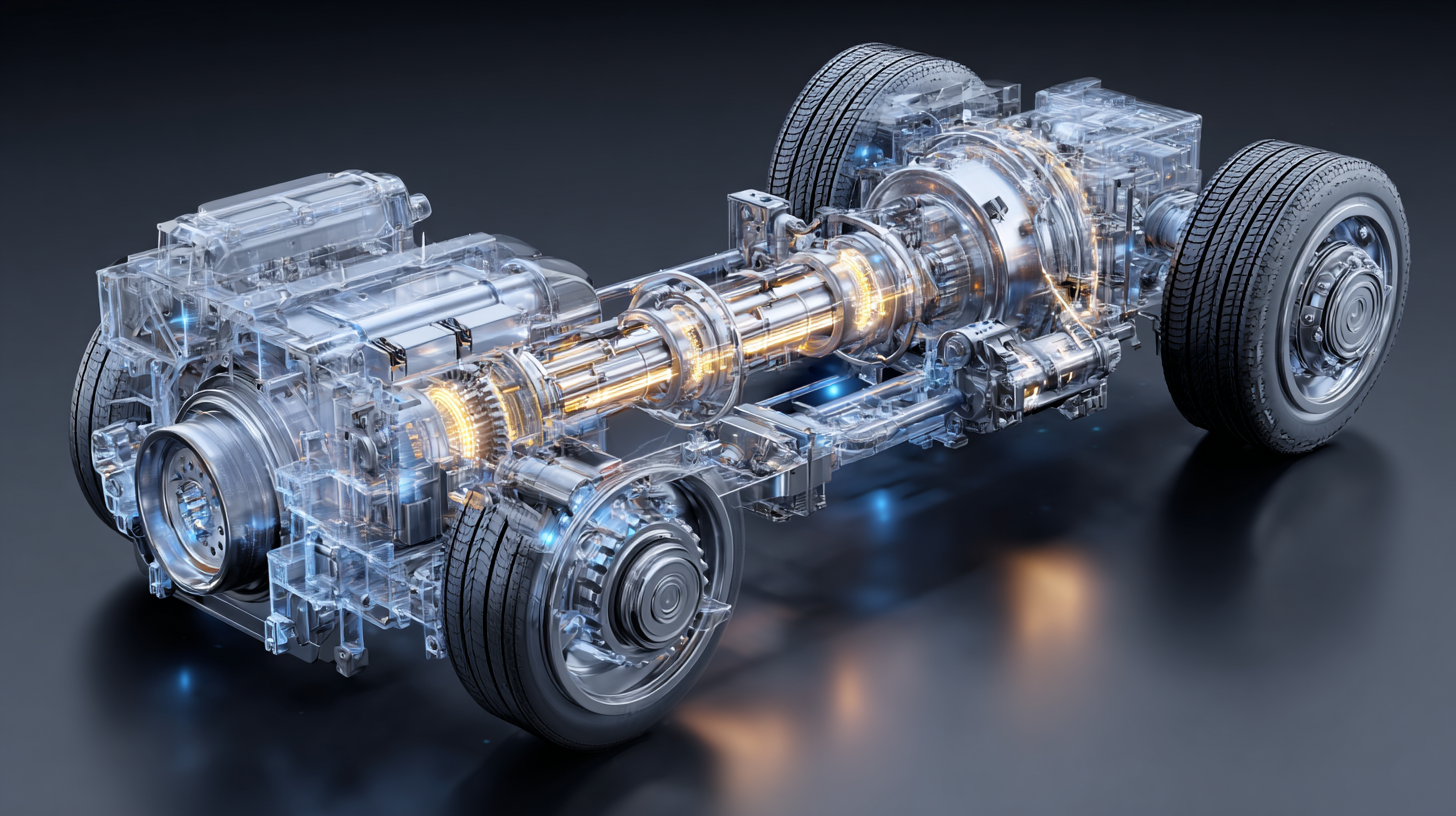

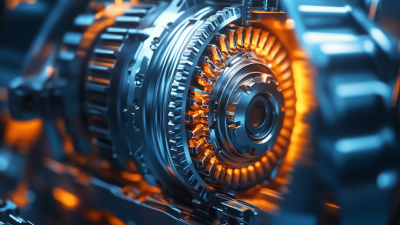

Revolutionizing Efficiency: The Rise of Electric Gearbox Systems in 2025

In 2025, the transportation industry is set to experience a paradigm shift with the rise of electric gearbox systems. These advanced systems promise not only to enhance efficiency but also to dramatically reduce the carbon footprint associated with conventional gearboxes. As electric vehicles (EVs) proliferate globally, the integration of electric gearbox technology is poised to revolutionize how power is transmitted within vehicles, optimizing performance and energy consumption.

The design of electric gearboxes allows for greater precision in power delivery, resulting in smoother acceleration and improved overall drivability. This innovation not only caters to the demands of a more environmentally conscious market but also aligns with regulatory pushes towards greener transportation solutions. In urban settings, electric gearbox systems can facilitate rapid response times, making vehicles more agile and responsive to traffic conditions. The combination of these innovations is set to transform the transportation landscape, leading to a more efficient and sustainable future.

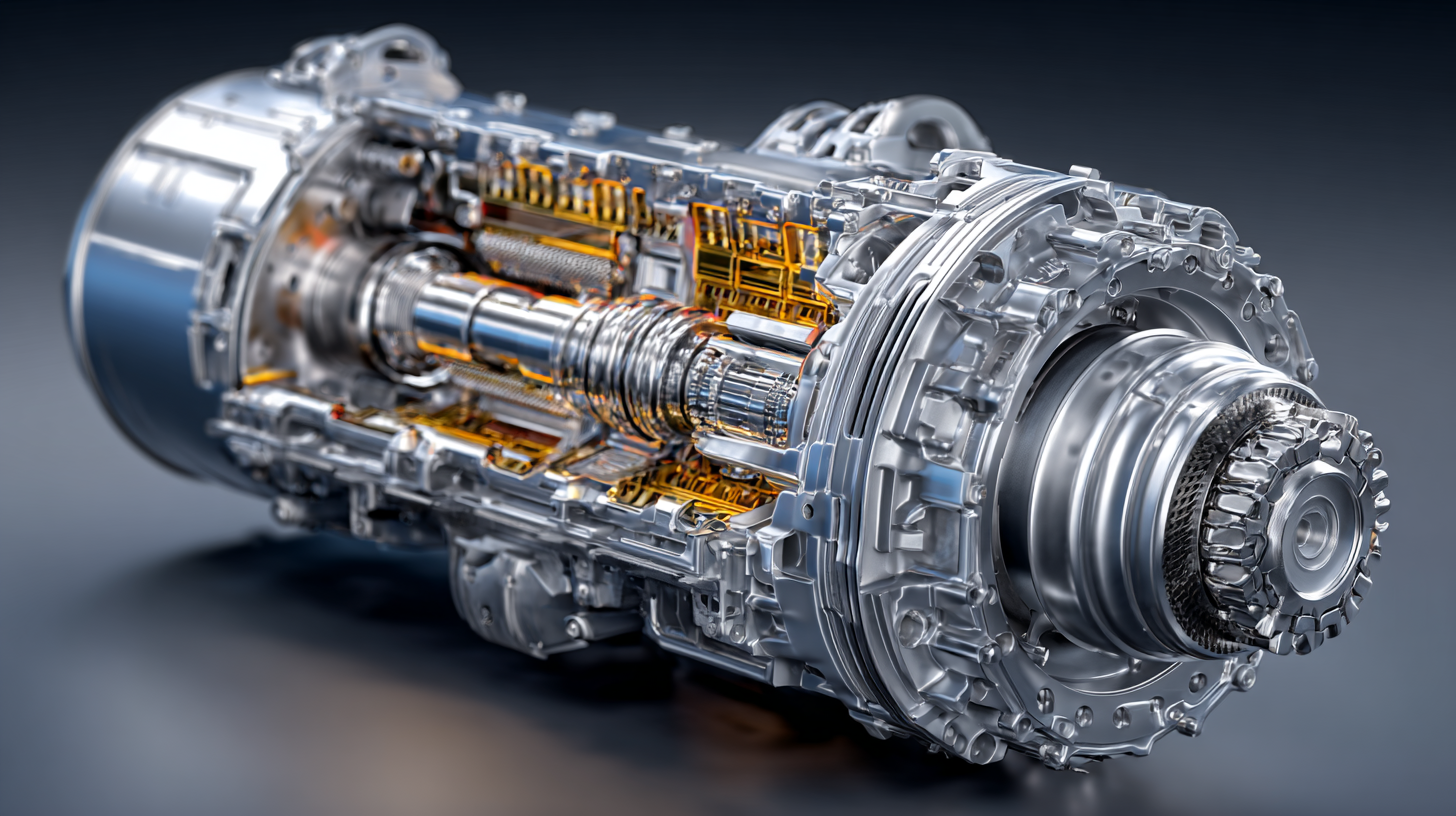

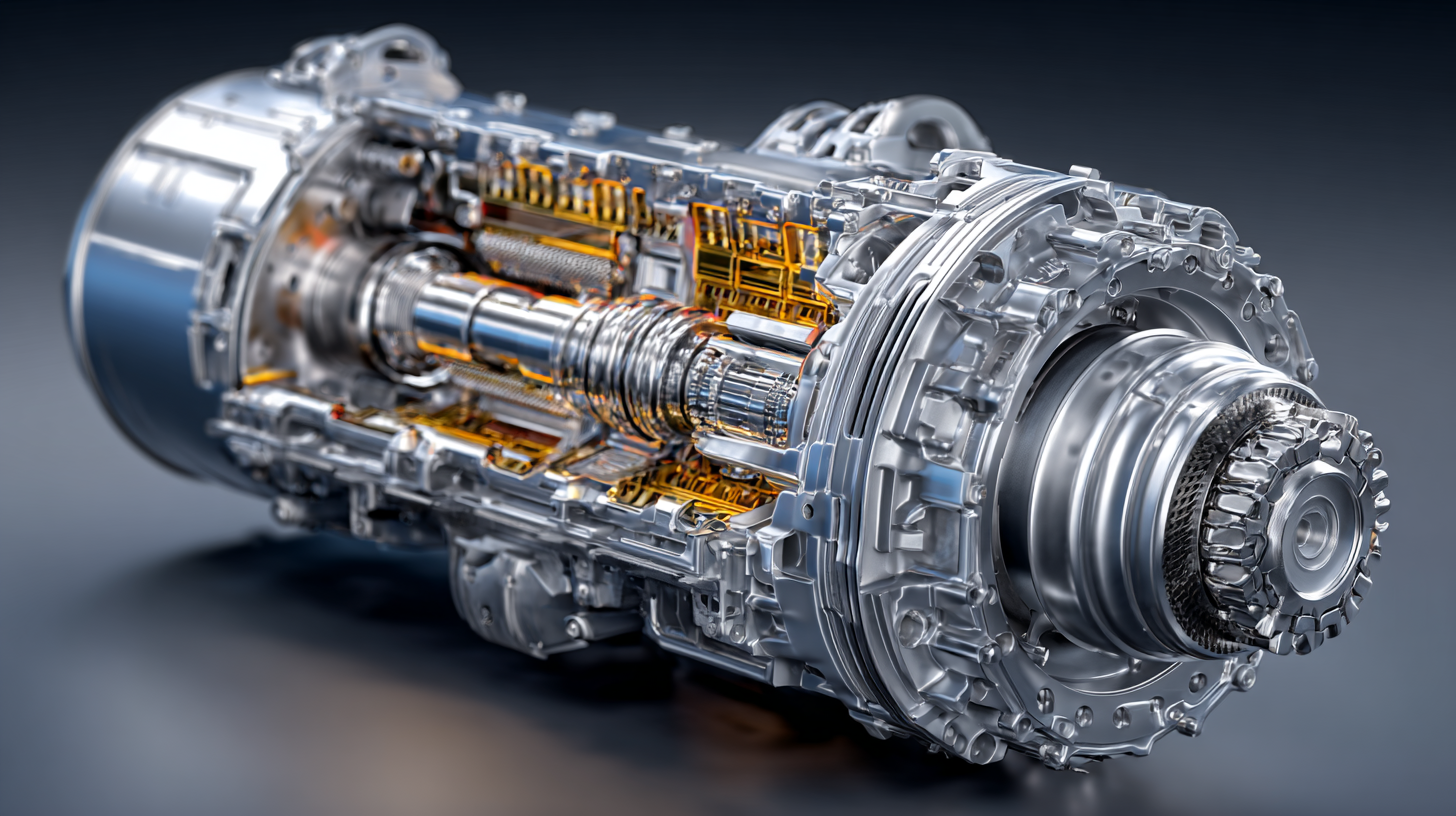

Unlocking Performance: How Advanced Gearbox Designs Enhance Fuel Economy

As the transportation industry strives for greater efficiency and sustainability,

advanced gearbox designs are playing a pivotal role in enhancing fuel economy. Modern gearboxes have moved

beyond traditional mechanical systems, integrating innovative technologies like dual-clutch and

continuously variable transmissions (CVTs). These designs allow for seamless power delivery and optimized

engine performance, reducing fuel consumption while maintaining high levels of power output.

Additionally, the advent of smart gearbox systems equipped with

predictive algorithms is transforming vehicle dynamics. By analyzing driving

patterns and conditions in real-time, these systems can adjust gear ratios instantaneously. This adaptability not

only contributes to a smoother driving experience but also maximizes fuel efficiency by ensuring that vehicles

operate in the most energy-efficient manner possible, regardless of terrain or load. As these innovations emerge,

they certainly signify a new era in transportation, where efficiency and performance coalesce to meet the

environmental challenges ahead.

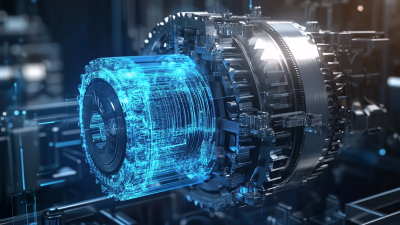

Smart Gearbox Technologies: Implementing IoT for Real-Time Monitoring and Predictive Maintenance

The transportation industry stands on the brink of revolutionary change with the implementation of smart gearbox technologies, which leverage the Internet of Things (IoT) for real-time monitoring and predictive maintenance. According to recent market data, the global IoT in manufacturing market, valued at $116.52 billion in 2024, is projected to reach $141.18 billion by 2025. This growth signifies a significant shift toward integrating advanced technologies that enhance efficiency and performance in transportation systems. Smart gearboxes equipped with IoT capabilities enable continuous monitoring, reducing unforeseen breakdowns and maintenance costs—a crucial factor in maintaining operational agility.

Implementing smart grid sensors plays a pivotal role as well. These sensors help mitigate challenges such as energy losses and improve demand-response capabilities in transportation systems, leading to more sustainable operations. The integration of renewable energy sources becomes seamless, aligning with global sustainability goals.

Tips for optimizing the use of smart gearboxes include routine data analysis from IoT devices to predict maintenance needs accurately and investing in scalable technology that allows for future upgrades. Engaging in staff training on interpreting sensor data can also maximize the benefits derived from these innovations, ensuring transportation industries remain competitive in an increasingly digital landscape.

Sustainable Solutions: The Role of Lightweight Materials in Future Gearbox Innovations

The transportation industry is on the brink of a revolution, and lightweight materials are poised to play a crucial role in the development of the next generation of gearboxes. Traditional gearbox designs often rely on heavy metals that, while providing strength, significantly increase the overall weight of vehicles. By integrating advanced lightweight materials such as carbon fiber composites and aluminum alloys, manufacturers can reduce the weight of gearboxes, leading to improved fuel efficiency and reduced carbon emissions.

Moreover, the use of lightweight materials not only enhances performance but also contributes to greater durability and longevity of gearbox systems. These materials can withstand high loads and harsh environmental conditions, ensuring that gearboxes remain reliable over time. As the industry shifts towards more sustainable practices, the adoption of lightweight materials in gearbox innovations represents a key strategy in creating transportation solutions that meet the demands of both efficiency and environmental responsibility. As designers and engineers focus on integrating these materials, the potential for cost savings and improved vehicle performance will undoubtedly transform the landscape of the transportation industry.

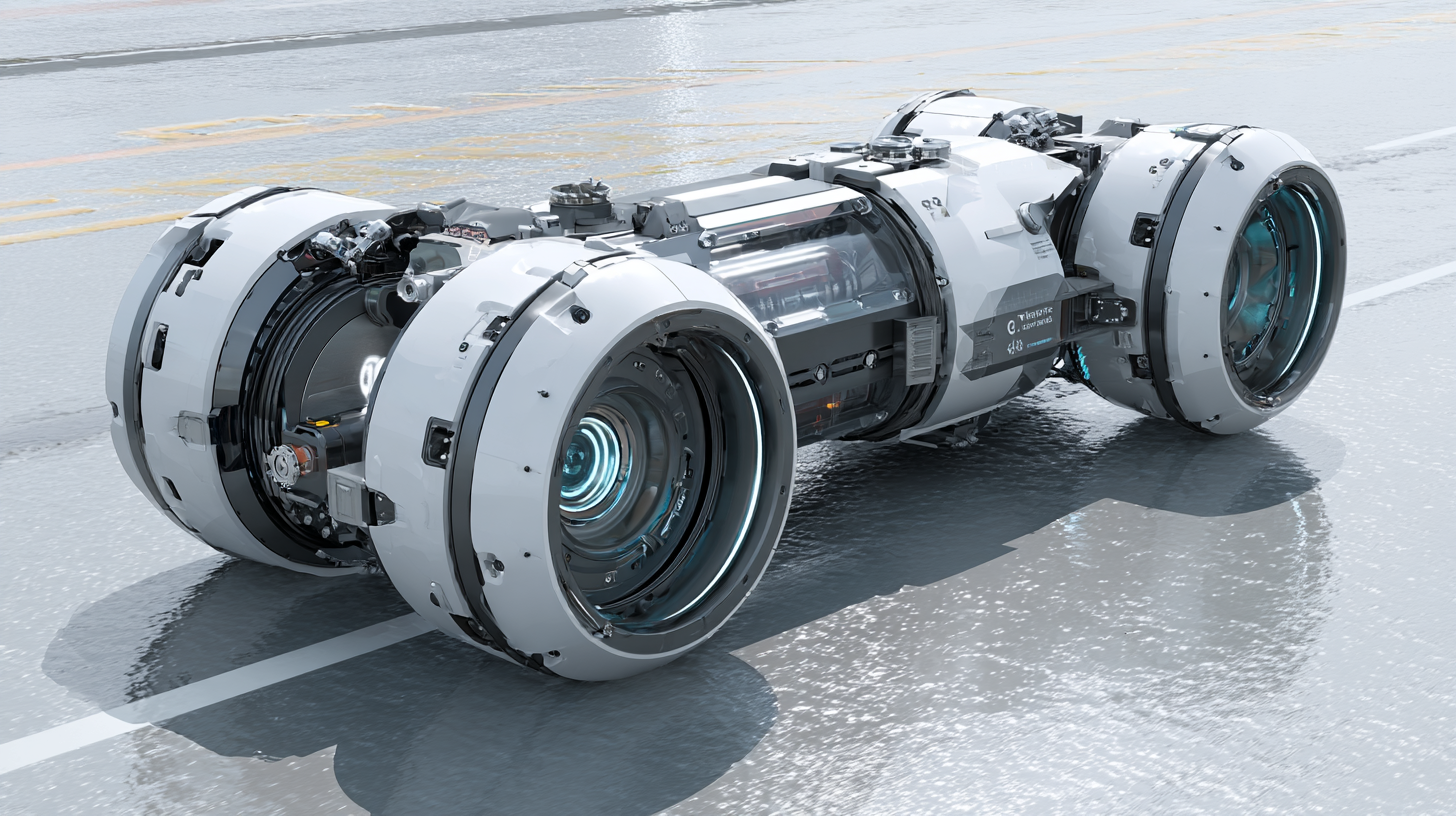

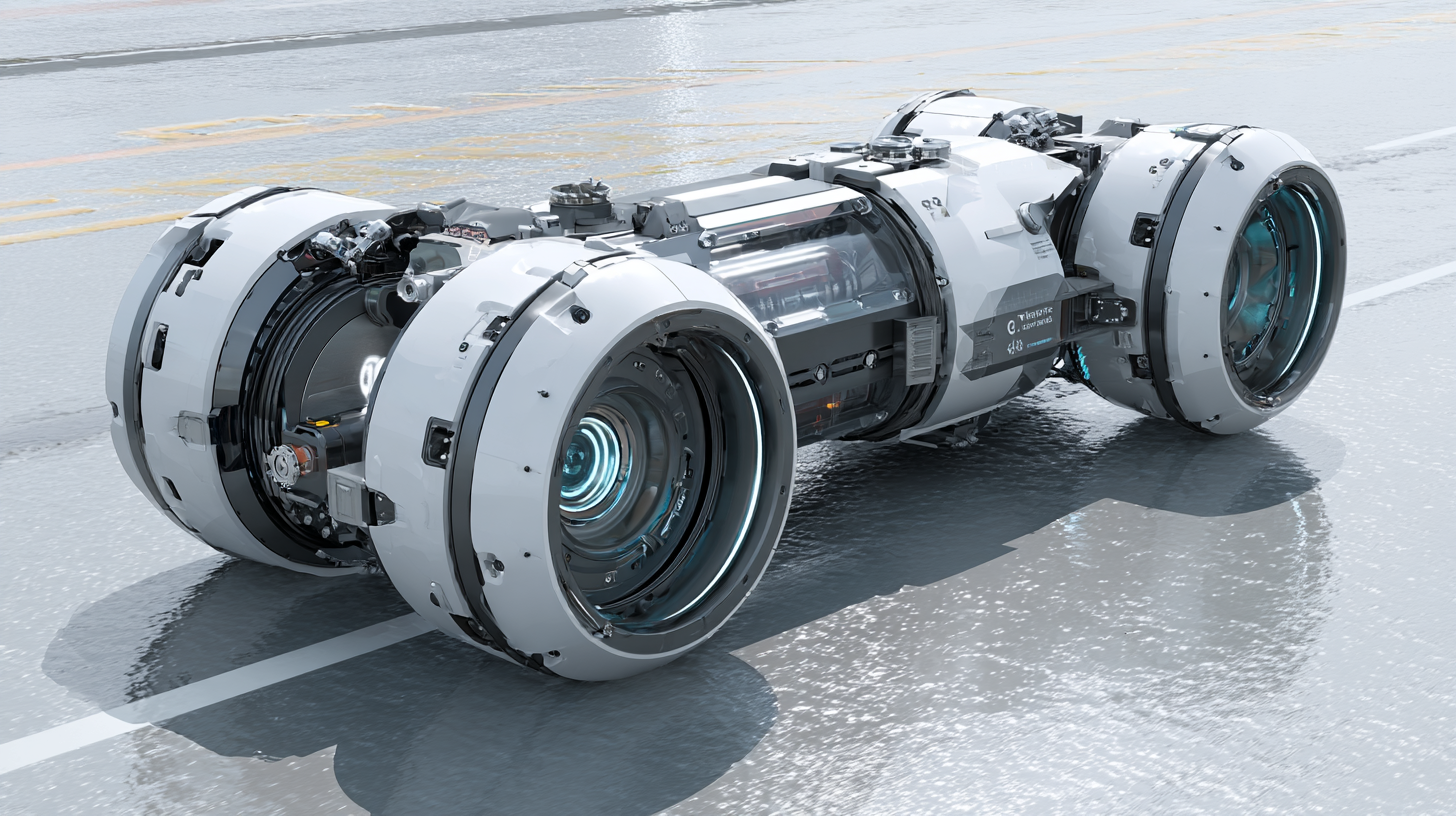

Integration of Automation: Impact of Gearbox Innovations on Autonomous Vehicle Development

The integration of automation in gearbox innovations is set to play a pivotal role in the evolution of autonomous vehicles. Modern gearboxes are becoming increasingly sophisticated, offering seamless transitions and predictive capabilities that enhance vehicle performance. These advancements allow for smoother acceleration and deceleration, which is essential for the safety and reliability of autonomous systems. With smart gearbox technologies, vehicles are now able to analyze driving conditions in real-time, optimizing their operations and adapting to environmental changes effectively.

Moreover, the interplay between automation and gearbox design significantly impacts the overall architecture of autonomous vehicles. As manufacturers focus on creating lighter, more efficient gear systems, the weight reduction contributes not only to improved fuel efficiency but also to advanced control algorithms. This synergy enables autonomous vehicles to execute precise maneuvers, navigate complex urban environments, and respond to potential hazards with greater agility.

The ability of innovative gearboxes to integrate with artificial intelligence systems ensures that autonomous vehicles can make informed decisions, emphasizing the critical role of gearbox technologies in shaping the future of transportation.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor