Exploring the Advantages of Gearbox Bonfiglioli Planetary Gear Systems in Modern Engineering

The growing complexity and demands of modern engineering necessitate innovations that enhance efficiency and performance. One key player in this arena is the Gearbox Bonfiglioli Planetary Gear, renowned for its compact size and superior torque output. According to a recent industry report by Research and Markets, the planetary gear market is expected to reach USD 4.3 billion by 2027, demonstrating an annual growth rate of 6.5%. This remarkable growth is largely driven by the increasing adoption of automation and mechatronics in various sectors, such as automotive, aerospace, and robotics. The Gearbox Bonfiglioli Planetary Gear Systems stand out due to their robust design and adaptability, offering engineers a reliable solution to meet the relentless pursuit of efficiency and precision. As we explore the advantages of these systems, we will delve into their applications, benefits, and how they are shaping the future of engineering.

Understanding the Basics of Bonfiglioli Planetary Gear Systems in Engineering Applications

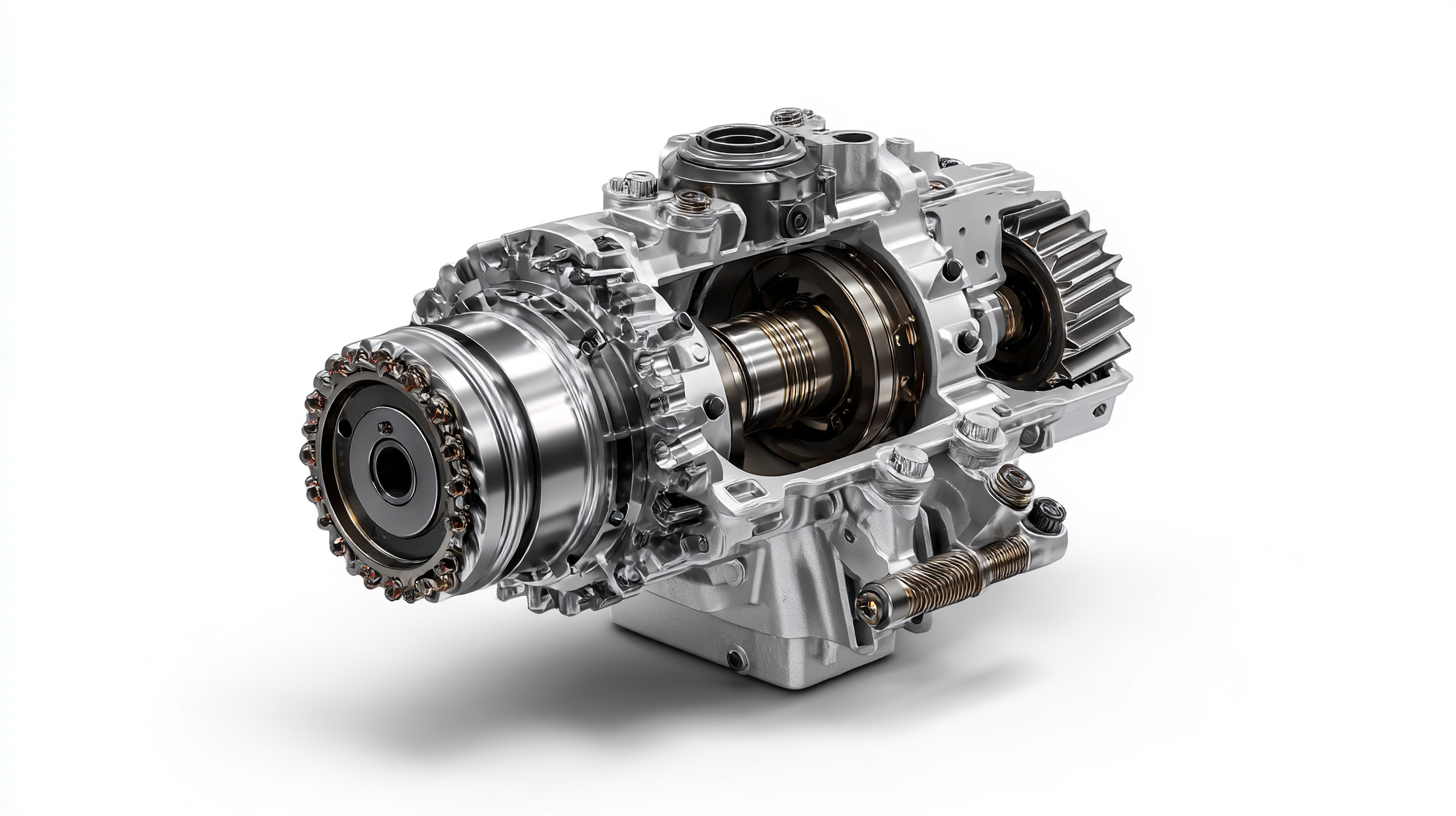

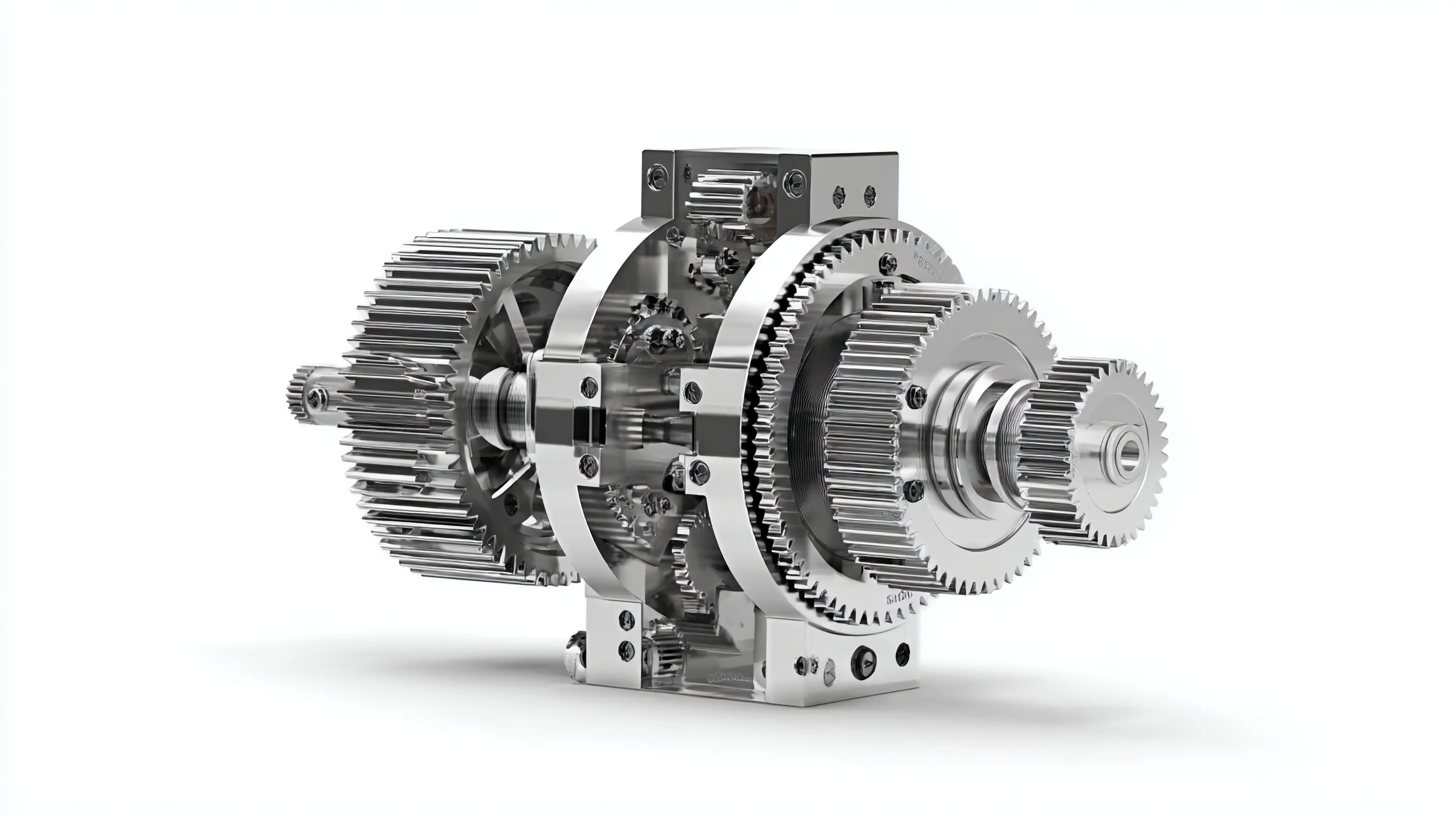

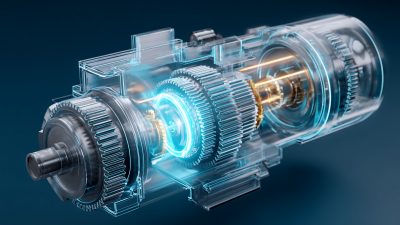

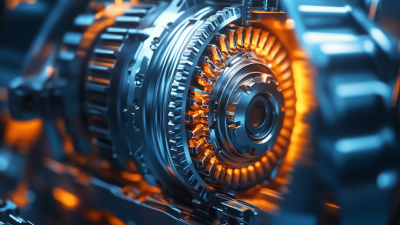

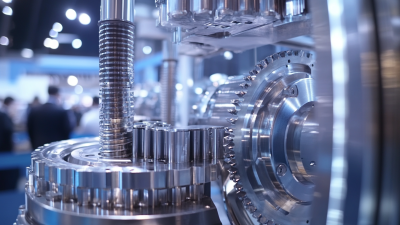

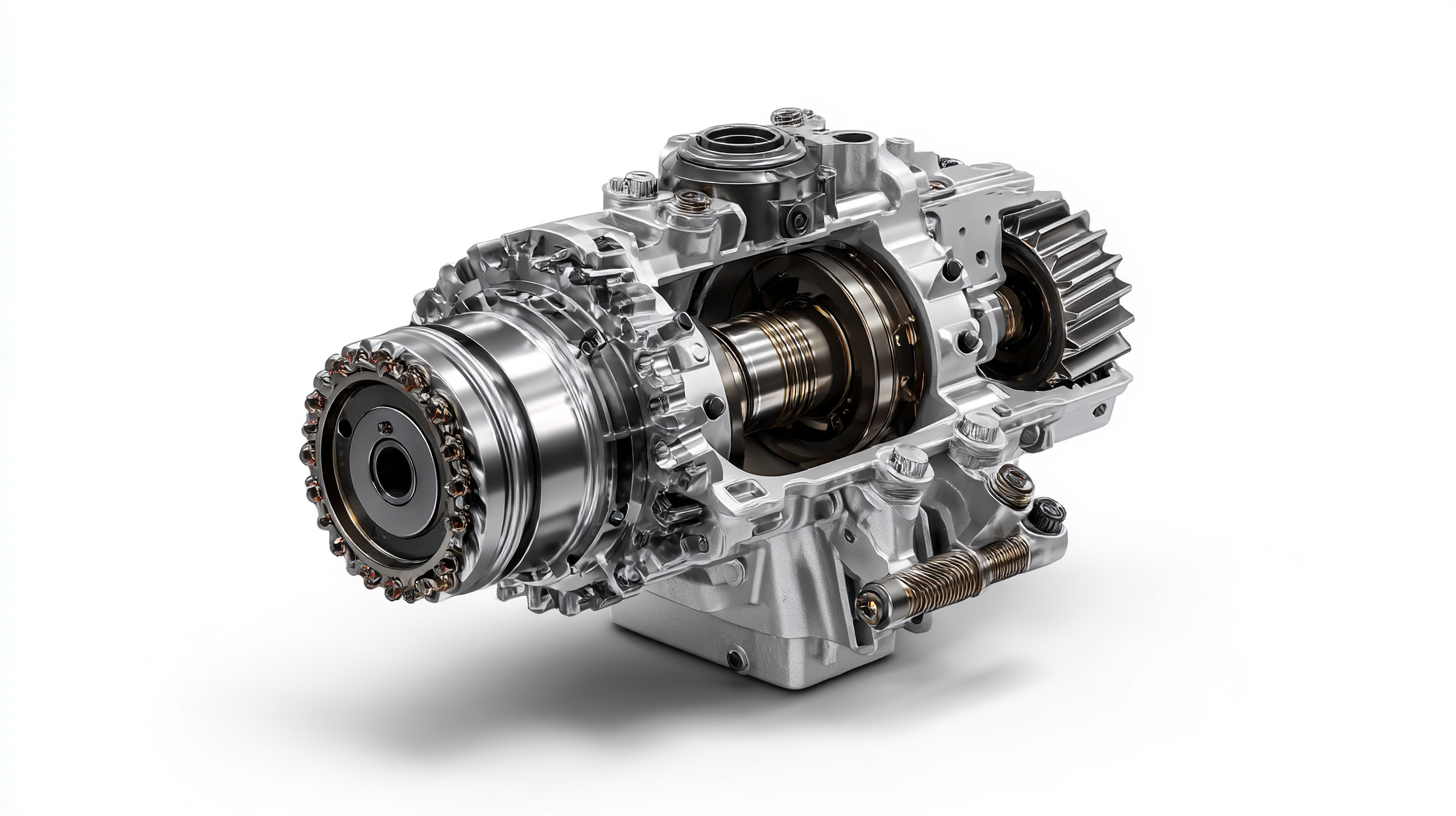

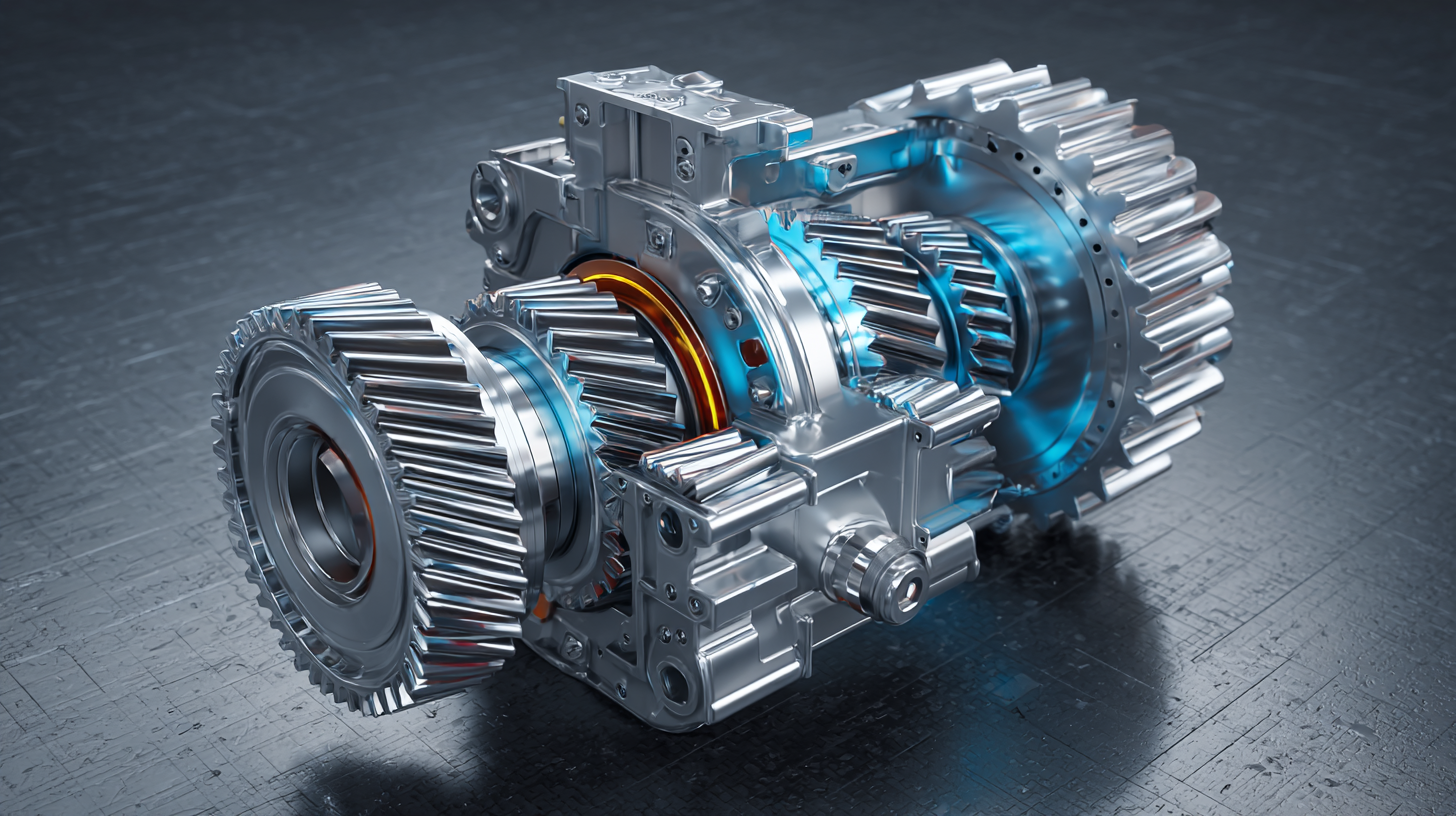

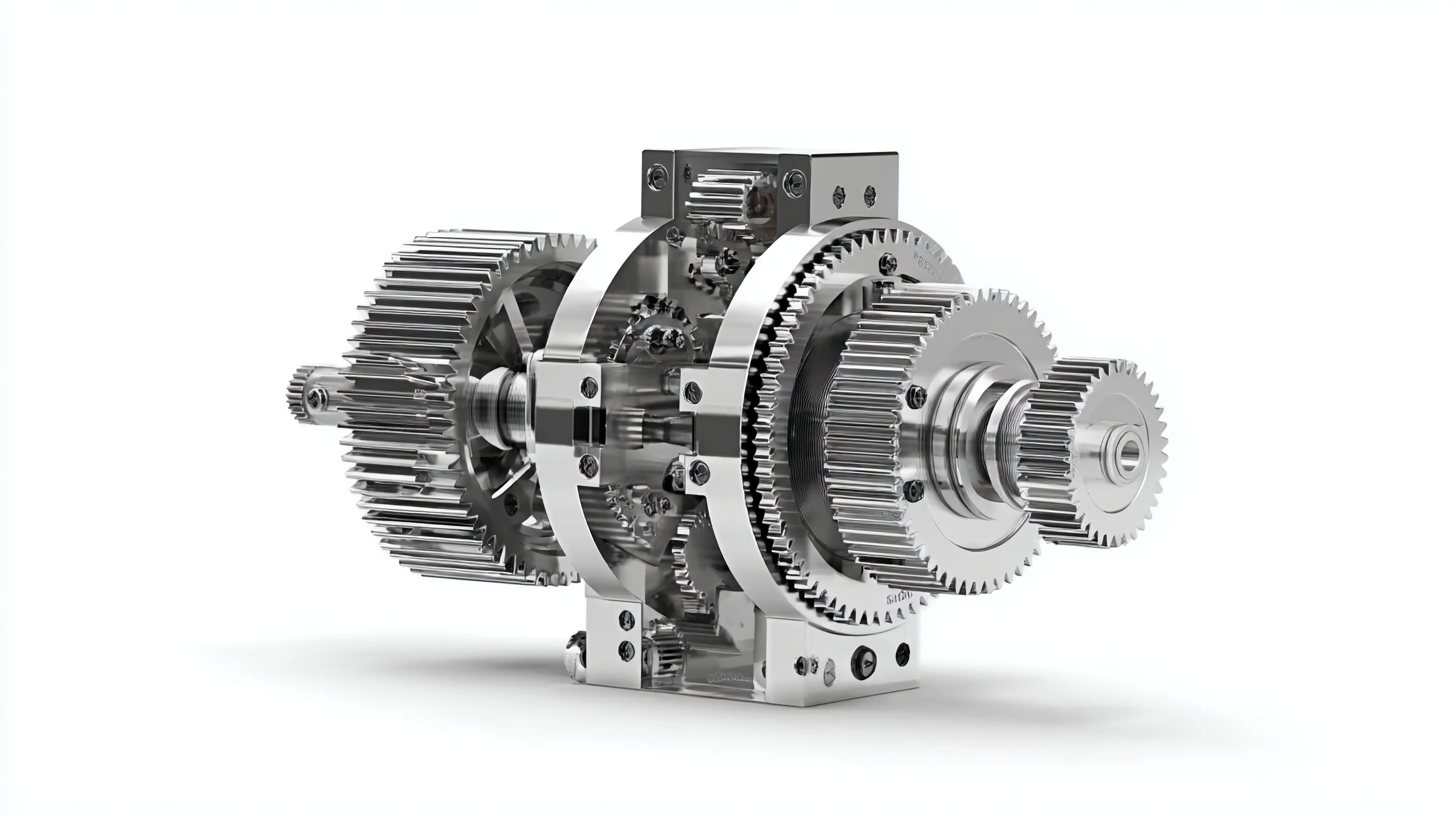

Bonfiglioli planetary gear systems are pivotal in modern engineering applications due to their unique design and functional advantages. These systems consist of a central sun gear, planet gears that orbit around it, and an outer ring gear, creating a compact and efficient mechanism for power transmission. This configuration allows for higher torque density, reduced size, and improved performance, making them ideal for applications where space and efficiency are crucial.

In various engineering sectors, such as automotive, aerospace, and manufacturing, Bonfiglioli planetary gear systems are employed for their ability to handle heavy loads while maintaining precision and reliability. Their modular design facilitates easy integration into existing systems, and the scalability ensures that they can be customized to fit specific requirements. Additionally, the smooth operation and low maintenance needs of these gear systems further enhance their desirability in complex machinery, where downtime is costly. Understanding these fundamentals is essential for engineers looking to optimize their designs and enhance productivity.

Key Technical Specifications of Bonfiglioli Gear Systems That Enhance Performance

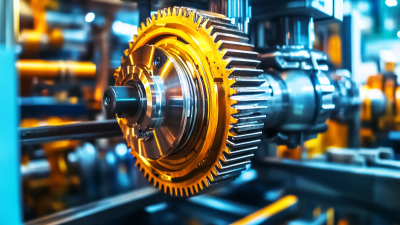

The Bonfiglioli planetary gear systems are engineered with several key technical specifications that significantly enhance their performance in modern engineering applications. One of the standout features is their compact design, which allows manufacturers to save valuable space without compromising on power output. This is particularly beneficial in applications where size constraints are critical, such as in robotics and aerospace. The high torque density of these gear systems ensures they can handle demanding loads while maintaining efficiency.

Another important specification is the advanced materials used in the construction of Bonfiglioli gears, which provides exceptional durability and resistance to wear. Utilizing high-strength alloys and innovative surface treatments, these gear systems are designed to withstand harsh operating conditions. Additionally, the precision manufacturing processes employed ensure minimal backlash, which is vital for maintaining accuracy in high-performance applications such as CNC machinery and automotive transmissions. These technical attributes collectively position Bonfiglioli planetary gear systems as a preferred choice for engineers seeking reliability and efficiency.

Benefits of Using Planetary Gear Systems for Torque and Speed Regulation

Planetary gear systems, particularly those manufactured by Bonfiglioli, offer significant advantages for torque and speed regulation in modern engineering applications. These systems utilize a central sun gear, multiple planet gears, and a ring gear to achieve high efficiency and compact designs. The arrangement allows for smooth power transmission, enabling the transmission of high torque while maintaining a relatively small footprint. This is especially beneficial in industries where space constraints are a major concern, such as robotics and aerospace engineering.

Another key benefit of using planetary gear systems is their ability to provide a wide range of gear ratios. This versatility allows engineers to fine-tune their designs for specific operational requirements, ensuring optimal performance in various scenarios. Moreover, the load distribution across multiple gears enhances the durability and lifespan of the system, reducing maintenance costs over time. As a result, Bonfiglioli’s planetary gear systems become a go-to solution for modern engineering challenges, balancing the needs for speed, torque, and efficiency effectively.

Exploring the Advantages of Gearbox Bonfiglioli Planetary Gear Systems in Modern Engineering - Benefits of Using Planetary Gear Systems for Torque and Speed Regulation

| Feature |

Advantage |

Application |

| High Torque Density |

Provides increased power output in compact designs |

Robotics, Industrial Machinery |

| Excellent Efficiency |

Low energy losses during operation |

Conveyors, Wind Turbines |

| Compact Design |

Saves space while delivering high performance |

Automotive Applications, Aerospace |

| Versatile Gear Ratios |

Customizable speed and torque settings |

Construction Equipment, Elevators |

| Low Maintenance |

Long service life with minimal upkeep |

Mining Equipment, Marine Applications |

Analyzing Cost-Effectiveness of Bonfiglioli Gearboxes in Various Industries

The cost-effectiveness of Bonfiglioli planetary gearboxes is a significant factor influencing their widespread adoption across various industries. These gear systems, known for their durability and efficiency, offer a superior performance-to-cost ratio compared to traditional gearing solutions. The compact design of Bonfiglioli gearboxes allows them to be integrated into machinery without requiring excessive space, which can lead to reduced material and installation costs. Furthermore, their robust construction means lower maintenance expenses and minimized downtime, making them an attractive option for manufacturers aiming to enhance productivity while controlling expenditures.

In industries such as automotive, renewable energy, and robotics, the specific advantages of Bonfiglioli gear systems are evident. For instance, in the automotive sector, their weight-saving characteristics contribute to improved fuel efficiency, aligning with economic and environmental goals. Similarly, in renewable energy applications, the efficiency of these gearboxes enables systems to utilize resources more effectively, thereby reducing operational costs. The versatility of Bonfiglioli gear systems to adapt to varying mechanical demands makes them not only cost-effective but also essential for driving innovation and efficiency in modern engineering projects across diverse sectors.

Case Studies: Successful Implementation of Bonfiglioli Gear Systems in Modern Engineering Projects

The successful implementation of Bonfiglioli planetary gear systems in various modern engineering projects highlights the versatility and efficiency of these advanced mechanisms. Case studies indicate that industries ranging from renewable energy to manufacturing have benefitted from the robustness and precision of Bonfiglioli gear systems. For instance, integrating these planetary systems in wind turbine designs has significantly improved energy conversion rates and reliability, addressing the growing demand for sustainable energy solutions.

Recent advancements in operational integration further amplify the potential of Bonfiglioli gear systems. The deployment of new integration solutions has streamlined process management and enhanced data flow, allowing engineering teams to optimize their designs and improve project outcomes. By leveraging cutting-edge technologies, companies can ensure that the advantages of planetary gear systems translate into tangible benefits, such as reduced operational costs and increased productivity. This progressive approach not only strengthens the practical applications of Bonfiglioli systems but also positions them as critical components in the evolution of modern engineering practices.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor