Why Belt Drive Gearboxes Are Essential for Efficient Mechanical Systems

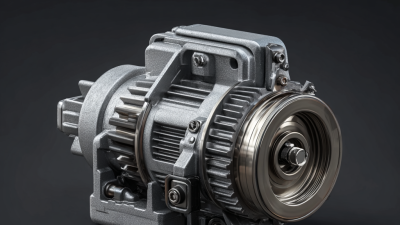

In the modern landscape of mechanical systems, the

Belt Drive Gearbox plays a pivotal role in enhancing operational efficiency and reliability.

According to a report by the International Engineering Consortium, the demand for robust and efficient gearboxes has surged, driven by advancements in technology and the need for energy-saving solutions.

Belt Drive Gearboxes, with their unique ability to transmit power seamlessly while minimizing energy loss, have emerged as a crucial component for industries ranging from automotive to manufacturing.

Recent studies indicate that organizations optimizing their mechanical systems with Belt Drive Gearboxes can achieve a

15-20% increase in efficiency, significantly reducing operational costs.

The linear power transmission and adjustable torque capabilities offered by these gearboxes not only enhance performance but also extend the lifespan of machinery.

As a result, businesses are increasingly recognizing the value of integrating Belt Drive Gearboxes into their systems, ensuring they remain competitive in a rapidly evolving market.

This article delves into the numerous benefits and essential considerations surrounding

Belt Drive Gearboxes, highlighting their significance in the quest for greater efficiency in mechanical applications.

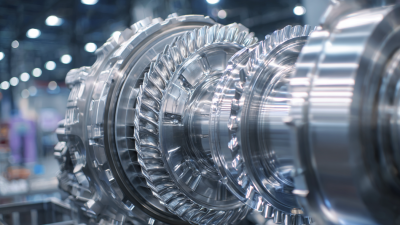

Understanding the Mechanics of Belt Drive Gearboxes in Modern Machinery

Belt drive gearboxes play a crucial role in enhancing the efficiency of mechanical systems by ensuring smooth power transmission. Understanding the mechanics behind these gearboxes reveals not only their functionality but also

their advantages over other transmission methods, such as continuously variable transmissions (CVTs). While CVTs are often criticized for their complexity and performance inconsistencies,

belt drive gearboxes offer a simpler, more robust alternative. These systems utilize belts that provide flexibility and reliability, enabling them to handle a variety of loads with ease.

Tips: When considering a belt drive gearbox for your machinery, pay attention to the material quality of the belts.

High-quality materials will improve durability and reduce maintenance needs. Additionally, ensure proper alignment during installation to prevent undue wear and prolong the lifespan of both the gearbox and the belts.

In modern machinery, belt drive gearboxes also adapt well to varying operational speeds, making them ideal for applications ranging from automotive to industrial use. The ability to transmit power efficiently while minimizing energy loss is key, and this is where

belt systems excel compared to more complex gear arrangements. Moreover, advancements in belt design have led to innovations that enhance compatibility with high-performance machinery, further solidifying their

essential position in mechanical systems today.

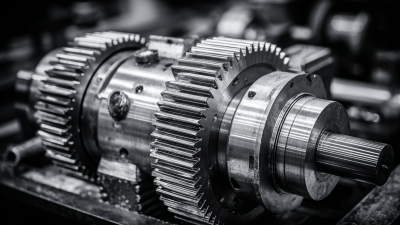

Key Factors Driving Efficiency in Mechanical Systems with Belt Drives

Belt drive gearboxes play a vital role in enhancing the efficiency of mechanical systems, primarily due to their ability to minimize energy losses through smooth power transmission. One key factor driving this efficiency is the optimal design of the belt drive system, which enables better torque transfer and faster response times. Efficient belt materials, such as polyurethane and composite fibers, can significantly reduce friction and wear, prolonging the lifespan of the system while maintaining high performance levels.

Tips: Regular maintenance is essential for ensuring longevity in belt drive systems. Check the tension of the belts periodically, as proper tension helps prevent slippage and wear. Additionally, keep the pulleys clean to minimize dirt accumulation, which can also contribute to inefficiencies.

Another important aspect is the precise alignment of the pulleys. Misaligned pulleys can lead to uneven tension and wear, negatively impacting the overall efficiency. Implementing alignment tools during installation can ensure that all components are adjusted correctly. Furthermore, selecting the right belt width and type for the specific application can enhance performance and reduce the risk of failure.

Industry Standard Performance Metrics for Belt Drive Gearbox Efficiency

Belt drive gearboxes play a critical role in the performance and efficiency of mechanical systems across various industries. One of the key metrics used to evaluate these gearboxes is the overall efficiency, which typically measures how effectively the gearbox transmits input power to output power. High-efficiency belt drive gearboxes minimize energy loss through friction and slippage, significantly contributing to reduced operating costs and enhanced system performance.

It is essential for manufacturers to focus on achieving optimal drive ratios and minimizing wear and tear to maintain high levels of efficiency.

Another vital performance metric is the torque transmission capacity of the belt drive gearbox. This metric allows engineers to assess whether the gearbox can handle the necessary loads under varying operational conditions. Additionally, the durability of the belts and pulleys involved in the system is pivotal for sustaining long-term performance and reducing maintenance frequency.

Regular monitoring of these metrics ensures that mechanical systems continue to operate at peak efficiency, thereby prolonging equipment lifespan and improving overall productivity. In summary, understanding and applying industry-standard performance metrics for belt drive gearbox efficiency is crucial for optimizing mechanical systems in any industrial application.

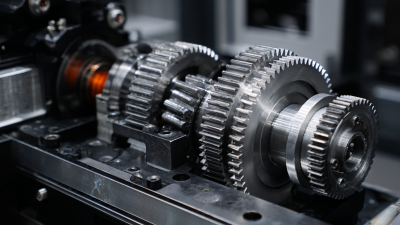

Comparative Analysis of Belt Drive Gearboxes vs. Other Drive Systems

Belt drive gearboxes play a crucial role in the efficiency of mechanical systems, particularly when compared to other drive systems like chain drives and direct couplings. One of the most significant advantages of belt drive systems is their ability to dampen vibrations and reduce shock loads, which can lead to longer equipment lifespan and less maintenance. The elasticity of belts allows for slight misalignments, making belt drive gearboxes more forgiving in dynamic environments compared to rigid chain drives that can transmit more shock and cause wear over time.

When conducting a comparative analysis, the efficiency of power transmission is another key factor. Belt drives often exhibit lower friction losses than chain drives, resulting in improved energy efficiency. Furthermore, they are quieter in operation, which is a critical consideration in applications requiring minimal noise levels. However, it is essential to acknowledge that belt drives can have limitations in high-load situations where chains may provide better performance. The selection between these drive systems ultimately depends on the specific application requirements, taking into account factors such as load, speed, and environmental conditions.

Why Belt Drive Gearboxes Are Essential for Efficient Mechanical Systems

| Feature |

Belt Drive Gearboxes |

Chain Drive Systems |

Shaft Drive Systems |

| Efficiency |

85-95% |

75-90% |

90-95% |

| Maintenance Frequency |

Low |

Medium |

Low |

| Noise Level |

Low |

Medium |

Low |

| Cost |

Moderate |

Low |

High |

| Torque Transmission |

Excellent |

Good |

Excellent |

| Weight |

Light |

Moderate |

Heavy |

Future Trends in Belt Drive Technology and Their Impact on Mechanical Efficiency

The future of belt drive technology is poised to significantly impact mechanical efficiency across various industries. Advancements in materials and design are leading to lighter, stronger belts that reduce energy loss and enhance performance. By incorporating smart technology, such as IoT sensors, manufacturers can monitor belt conditions in real-time, allowing for optimized maintenance schedules and reduced downtime. This proactive approach not only improves efficiency but also prolongs the lifespan of mechanical systems.

Moreover, as industries push towards sustainability, the integration of eco-friendly materials in belt production is becoming more common. Innovations such as biodegradable belts or those made from recycled materials are on the rise. This shift not only meets regulatory demands but also appeals to a more environmentally conscious market. As these trends continue to evolve, the role of belt drive gearboxes remains critical in achieving enhanced mechanical efficiency, energy savings, and reducing overall environmental impact.

Impact of Belt Drive Technology on Mechanical Efficiency

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor