How to Choose the Right Gearbox for Your Mechanical Applications in 2025

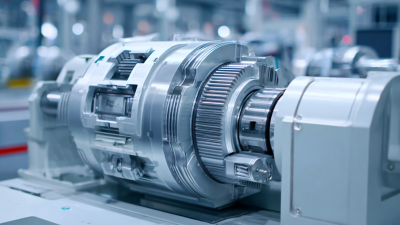

In 2025, the choice of gearbox in mechanical applications plays a pivotal role in enhancing efficiency, reliability, and overall system performance. With the global gearbox market projected to reach USD 40 billion by 2027, as reported by a leading industry analysis, the decision-making process for selecting the right gearbox becomes increasingly significant for industries ranging from manufacturing to robotics. Factors such as load requirements, speed ratios, and integration capabilities must be meticulously evaluated to ensure optimal function.

Among the various options available, the Siemensmkygearbox stands out due to its commitment to high performance and durability. Industry reports indicate that advanced gearboxes like the Siemensmkygearbox offer specialized solutions that not only reduce energy consumption but also extend equipment life cycles, thereby providing a competitive edge to businesses. As technologies in automation evolve, the demand for high-quality, efficient gear systems continues to surge, driving innovation and inspiring manufacturers to adapt to new standards. In this landscape, making an informed choice about gearboxes is crucial to achieving operational excellence and staying ahead in the market.

Understanding Gearbox Types for Mechanical Applications in 2025

When selecting a gearbox for mechanical applications in 2025, it's crucial to understand the different types available and their specific functionalities. Gearboxes are essential for speed reduction, torque multiplication, and direction control in various mechanical systems. The most common types of gearboxes include helical, bevel, worm, and planetary gearboxes, each tailored for specific applications. For instance, helical gears provide smooth and quiet operations, while worm gears offer high reduction ratios in compact spaces.

Tips: Assess the load requirements of your application before choosing a gearbox. Consider factors such as the maximum torque, speed, and the operating environment. This information will help you determine the necessary gearbox specifications, ensuring optimal performance and longevity.

Additionally, take into account the efficiency and maintenance needs of the gearbox type. Some designs may require more frequent lubrication or have higher wear rates, impacting long-term operational costs. By focusing on these characteristics, you can select a gearbox that not only meets your current requirements but also anticipates future needs as technology evolves.

How to Choose the Right Gearbox for Your Mechanical Applications in 2025

| Gearbox Type |

Torque Range (Nm) |

Gear Ratio |

Efficiency (%) |

Ideal Applications |

| Helical Gearbox |

10 - 500 |

1:5 to 1:100 |

95 |

Industrial Equipment |

| Planetary Gearbox |

20 - 1000 |

1:4 to 1:1000 |

90 |

Robotics, Automation |

| Worm Gearbox |

5 - 300 |

1:10 to 1:80 |

85 |

Conveyor Systems |

| Bevel Gearbox |

15 - 600 |

1:1 to 1:6 |

92 |

Agricultural Machinery |

| Rack and Pinion Gearbox |

8 - 400 |

1:1 |

88 |

CNC Machining |

Key Factors to Consider When Selecting a Gearbox

When selecting a gearbox for mechanical applications in 2025, several key factors come into play that can significantly affect performance and efficiency. First and foremost, the type of application should guide your choice. Consider whether the gearbox will be used in a constant speed application or a variable speed setting. This distinction will influence the gearbox's design and gearing layout, which are vital for achieving optimal torque and speed output.

Another essential factor is the load requirements. It's critical to evaluate the maximum load and the nature of the loads—static or dynamic. Gearboxes must be able to handle peak loads without compromising structural integrity or function over time. Additionally, understanding the duty cycle of your application can help in selecting a gearbox that can withstand the operational demands without unnecessary wear.

**Tips:** When choosing a gearbox, also consider the environment it will operate in. If the application involves extreme temperatures, moisture, or dust, selecting a gearbox with appropriate sealing and material properties is essential. Lastly, don't forget to factor in ease of maintenance, as gearboxes that are easier to service can minimize downtime and reduce operational costs over the lifespan of the equipment.

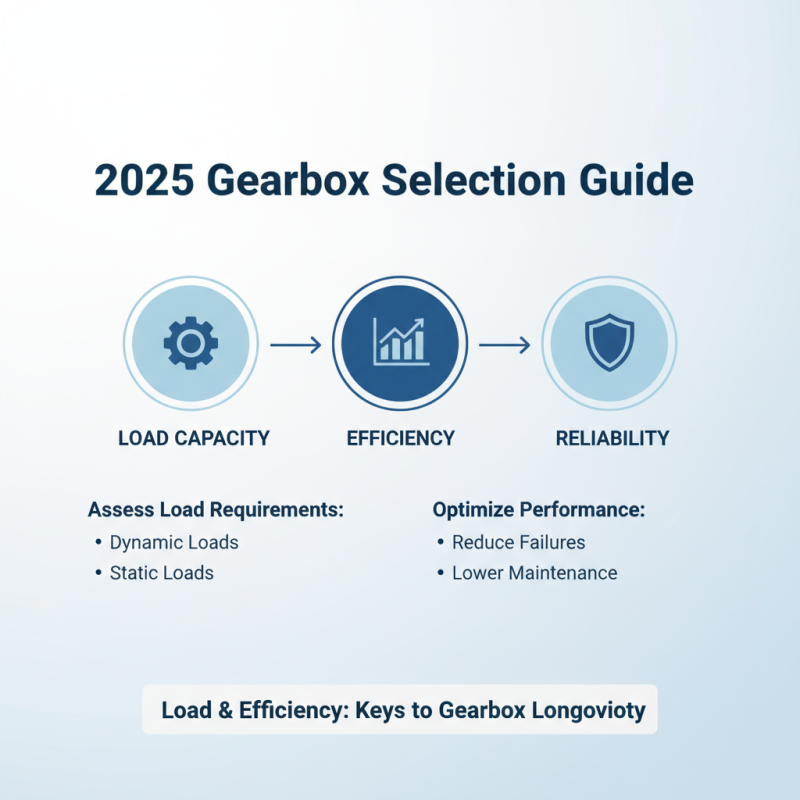

Evaluating Load Capacity and Efficiency in Gearbox Selection

When selecting a gearbox for mechanical applications in 2025, evaluating load capacity and efficiency is paramount. Understanding the load requirements of your application helps in choosing a gearbox that not only meets the necessary performance standards but also operates efficiently. Be sure to assess both the dynamic and static loads that the gearbox will need to handle. This will ensure that the gearbox can withstand the stresses it will encounter during operation, avoiding premature failures and maintenance issues.

Tips: Always consider the peak load your application might experience, as this impacts the gearbox's longevity. Additionally, look into the efficiency of the gearbox. Higher efficiency means less energy loss during operation, which can significantly reduce your operational costs. Selecting a gearbox with optimized gear profiles and minimal friction can lead to better overall performance.

Another aspect to consider is the gearbox’s integration with other components of your system. Compatibility with existing machinery, alignment precision, and ease of installation are crucial factors that contribute to both the efficiency and operational lifespan of the gearbox. Ensure that the gearbox aligns well with your application's requirements to minimize downtime and maximize productivity.

Emerging Technologies Shaping Gearbox Design in 2025

In 2025, the landscape of gearbox design is being profoundly influenced by emerging technologies that enhance efficiency, durability, and adaptability. One notable trend is the integration of smart technologies, where gearboxes become equipped with sensors that monitor performance in real-time. These sensors provide critical data on parameters such as temperature, vibration, and load, allowing for predictive maintenance and minimizing unexpected failures. As industries demand more from their machinery, this shift towards intelligent systems ensures that gearboxes can adapt to varying operational conditions, leading to optimized performance and reduced downtime.

Another significant development is the adoption of advanced materials and manufacturing techniques. Innovations such as additive manufacturing and lightweight composites are reshaping the way gearboxes are constructed. These materials not only contribute to weight reduction, which is essential for efficiency, but also enhance the strength and longevity of the components. Furthermore, with the rise of electric and hybrid systems, gearboxes designed with these materials can handle higher power densities while maintaining reliability. As these technologies continue to evolve, the selection process for gearboxes will increasingly prioritize adaptability to specific applications and the long-term sustainability of the materials used.

Gearbox Design Trends and Technologies in 2025

Best Practices for Maintenance and Longevity of Gearboxes

Proper maintenance is crucial for ensuring the longevity and optimal performance of gearboxes in any mechanical application. Regular inspections should be conducted to check for signs of wear, unusual noises, or leaks. Operators should develop a standard checklist to monitor the gearbox's condition, including checking oil levels, examining seals for any damage, and ensuring that all fastening elements are secure. Consistent adherence to the manufacturer's maintenance schedule can also help prevent unexpected failures and extend the lifespan of the gearbox.

Lubrication plays a vital role in gearbox maintenance. Selecting the appropriate lubrication method and using the correct type of lubricant can significantly enhance performance and reduce wear. Operators need to consider factors such as operating temperature, load conditions, and environmental factors when choosing the lubricant. Additionally, establishing a routine for cleaning and changing lubricants according to operating conditions is essential. By maintaining proper lubrication, the friction and heat generated during operation can be minimized, thus prolonging the gearbox's life and efficiency.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor