7 Essential Tips for Choosing the Right Gearboxsewgearmotor for Your Business Needs

In the ever-evolving landscape of industrial machinery, selecting the right

Gearboxsewgearmotor is crucial

for enhancing operational efficiency and achieving optimal performance. As businesses

strive to remain competitive, making informed decisions about the gearbox and

gearmotor that best suit specific applications can significantly impact

productivity and

reliability. This guide will

provide you with seven essential tips

to help navigate the complexities of choosing the appropriate

Gearboxsewgearmotor for your unique

business needs. From assessing load requirements to considering environmental factors,

each tip is designed to empower you with the knowledge necessary to make the best

investment. By understanding the key features and variations among gearbox and

gearmotor options, you will be better positioned to enhance your operational

capabilities and ensure long-term success.

Understanding Your Business's Specific Requirements for Gearmotors

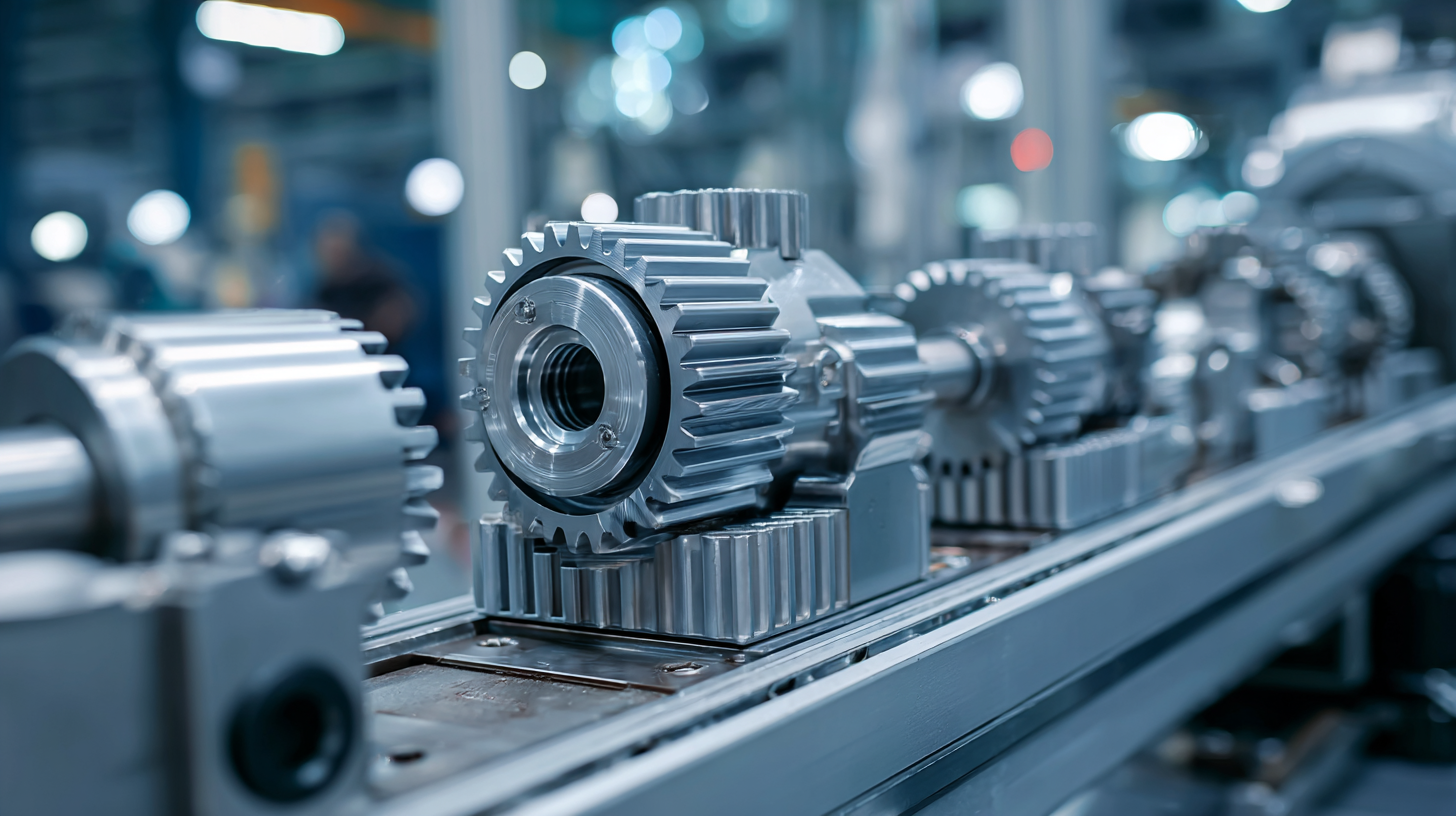

When selecting the right gearbox or gearmotor for your business, understanding your specific requirements is crucial to optimizing performance and efficiency. Begin by analyzing the operational demands of your machinery. Consider factors such as load capacity, speed, and torque. Different applications may require varied gearmotors; for instance, a conveyor system will have distinct needs compared to a packaging machine. Clarifying these specifications will help narrow down suitable options and prevent costly mismatches.

Additionally, it’s important to evaluate the environment in which the gearmotor will operate. Factors such as temperature, humidity, and exposure to contaminants can influence the selection process. For example, if your business operates in an environment prone to dust or liquid exposure, choosing a gearmotor with appropriate sealing and durability ratings is vital. This ensures that the gearmotor not only performs reliably but also has a longer lifespan, ultimately contributing to more efficient operations and reduced downtime.

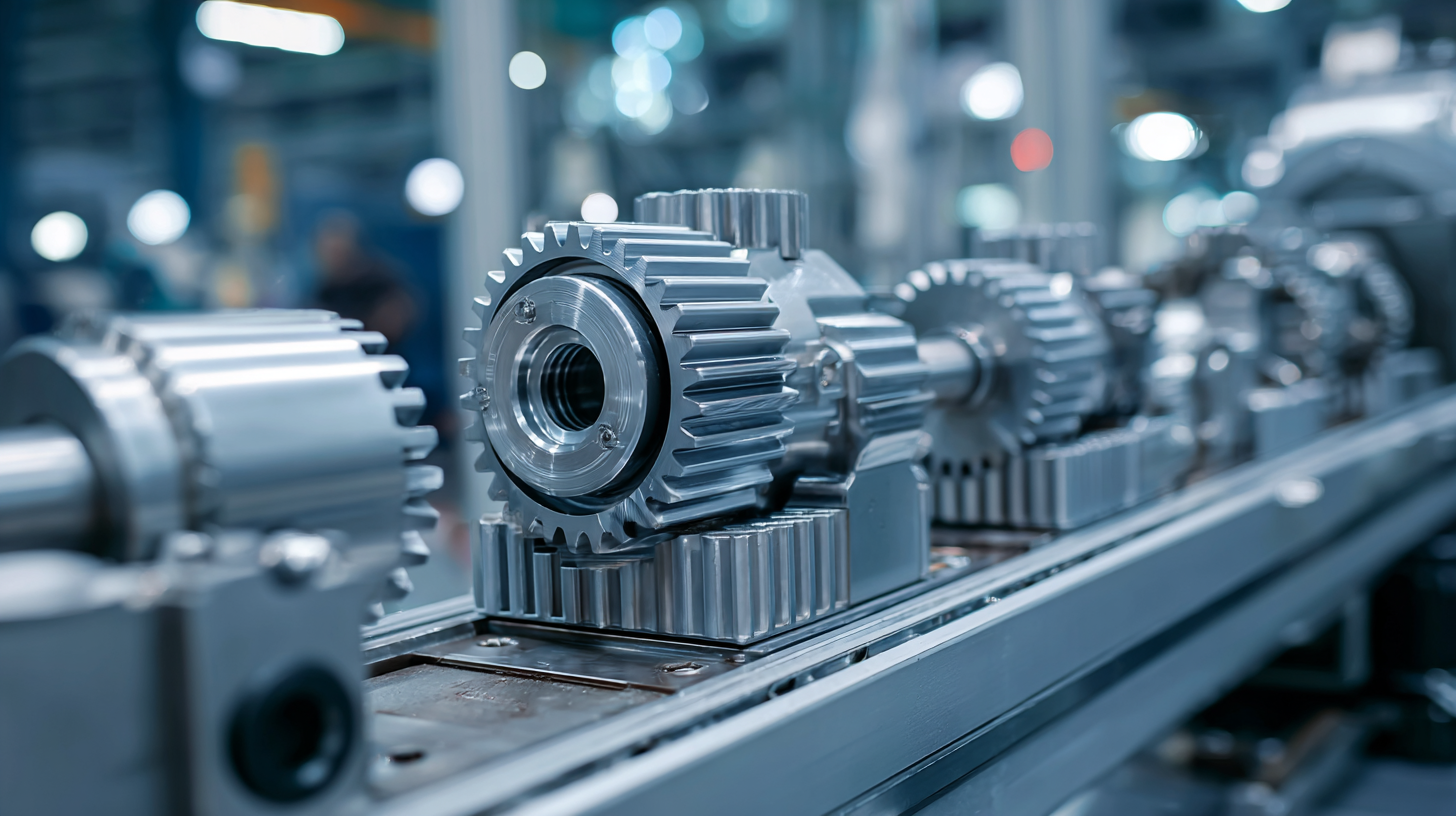

Essential Gearboxsewgearmotor Types for Business Needs

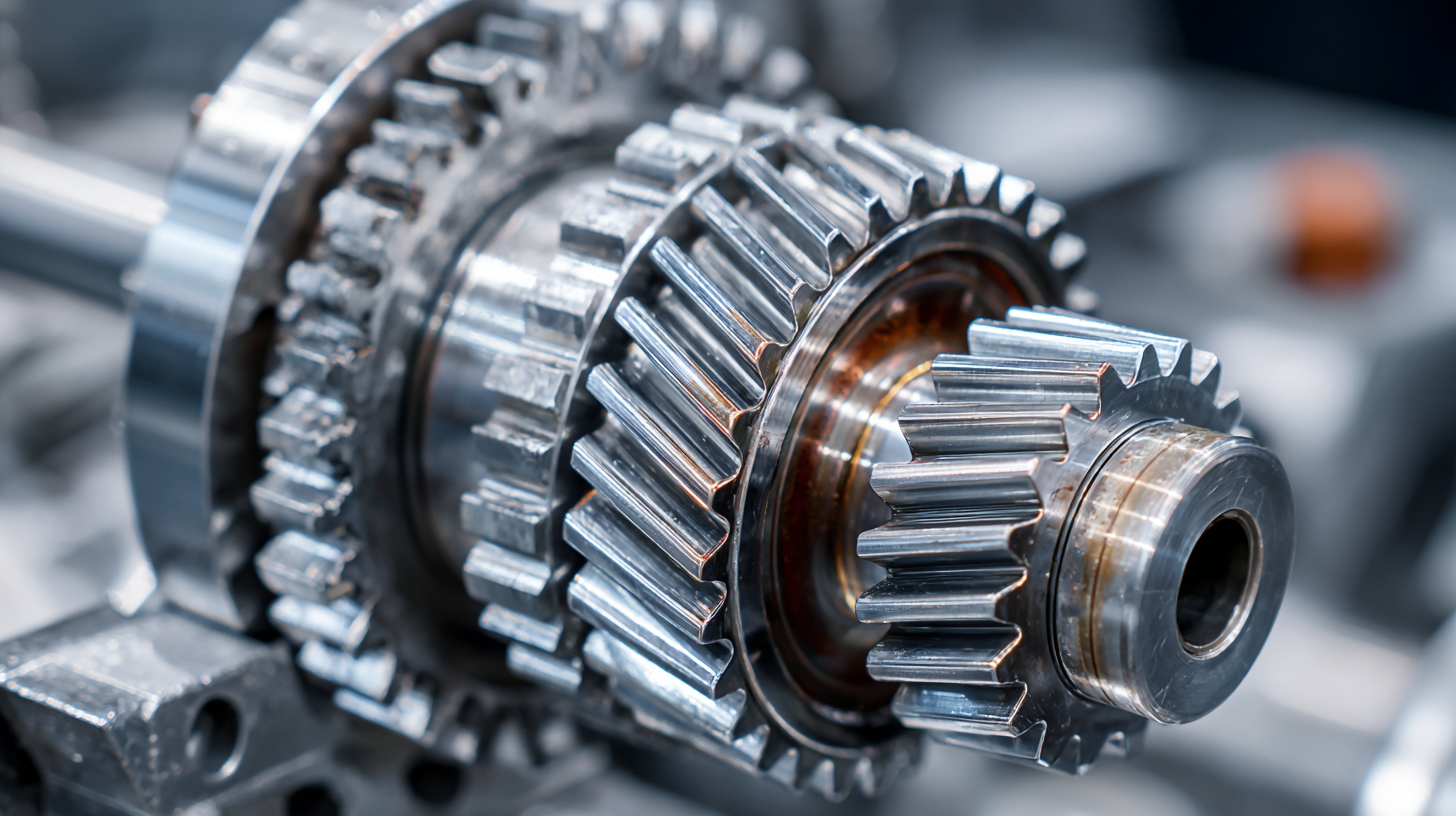

Evaluating the Performance and Efficiency of Different Gearbox Types

When selecting a gearbox for business applications, particularly in robotic systems, assessing the performance and efficiency of different gearbox types is crucial. Recent studies indicate that a motor-gearbox arrangement typically delivers high power density, making it an essential choice for drive units in robot-like systems. The efficiency of these arrangements can significantly affect operational productivity, with efficient gearboxes enabling smoother operations and minimizing energy consumption. Reports highlight that the selection of gear parameters, such as gear ratio and material composition, directly influences the torque output and overall durability of the gearbox.

Furthermore, ongoing research emphasizes the importance of robust monitoring frameworks to evaluate the performance of various gearboxes in real-time applications. These frameworks are key to understanding how gear defects can impact the efficiency and reliability of machinery. For instance, examining the filtration efficiency of materials used in gearbox construction can also provide insights into their resilience against environmental factors that might compromise performance. The integration of advanced monitoring technologies is expected to enhance the design and operational capabilities of gearboxes, ensuring they meet the rigorous demands of modern industrial applications, particularly in high-energy settings such as thermal power plants and automated production lines.

7 Essential Tips for Choosing the Right Gearbox / Sew Gear Motor for Your Business Needs - Evaluating the Performance and Efficiency of Different Gearbox Types

| Gearbox Type |

Efficiency (%) |

Torque Output (Nm) |

Weight (kg) |

Common Applications |

| Spur Gearbox |

90 |

30 |

12 |

Conveyor Systems |

| Planetary Gearbox |

92 |

50 |

15 |

Robotics |

| Helical Gearbox |

85 |

40 |

10 |

Mixers |

| Worm Gearbox |

80 |

25 |

14 |

Elevators |

| Bevel Gearbox |

87 |

35 |

11 |

Industrial Machinery |

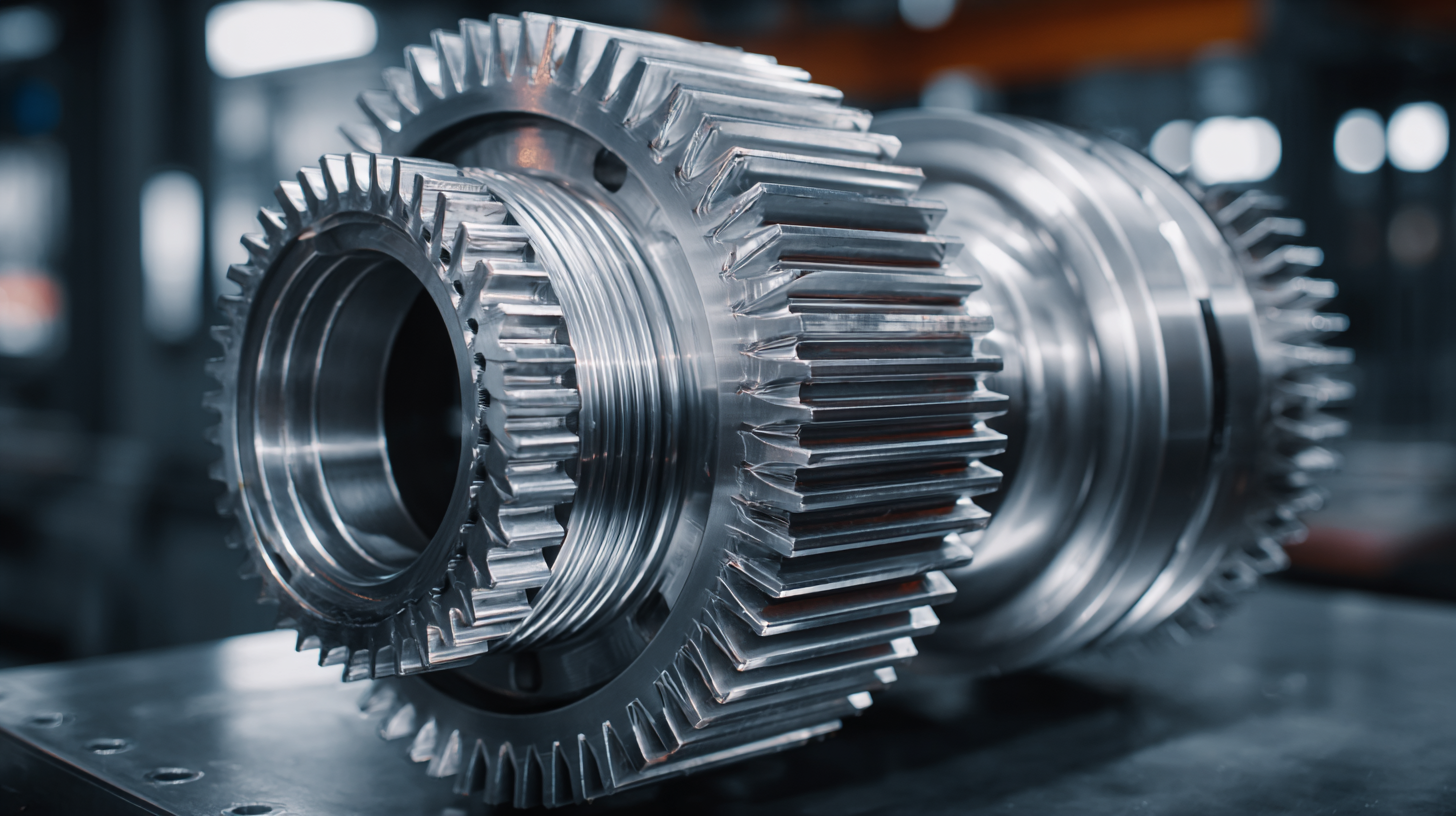

Assessing the Load Capacity and Torque Needs for Your Applications

When selecting a gearbox or gearmotor for your business needs, one of the foremost considerations is assessing the load capacity and torque requirements specific to your applications. Properly matching these parameters is critical to ensuring reliability and efficiency in your operations. According to a recent industry report by Research and Markets, the global gearbox market is expected to grow substantially, driven by the increasing demand for high-efficiency machines. This growth underscores the necessity of understanding the torque needs of your machinery, as insufficient torque can lead to mechanical failure or inefficient performance.

Calculating the load capacity involves evaluating the maximum weight that the gearbox will need to support during operation, while torque needs are determined by the rotational force required to drive your application. A study from the American Gear Manufacturers Association indicates that 60% of gearbox failures stem from incorrect sizing and load calculations. Businesses must carefully analyze their operating conditions, including acceleration needs and duty cycles. For instance, applications with high startup torque demands will require gearboxes that can handle such stress, which may involve selecting a model with higher torque ratings to avoid premature wear and damaging breakdowns.

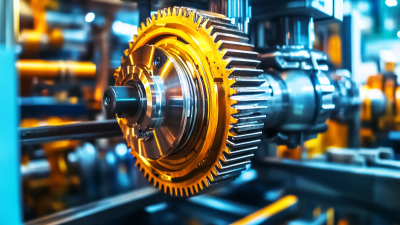

Considering Environmental Factors and Operating Conditions for Gear Selection

When selecting the right gearbox or gearmotor for your business, understanding environmental factors and operating conditions is crucial. For instance, temperature fluctuations can significantly affect the lubricant properties and ultimately the performance of the gearbox. If your application operates in extreme heat or cold, consider components made from materials that can withstand such conditions, ensuring longevity and reliability.

Additionally, the operating environment—whether it's dusty, wet, or corrosive—should influence your choice of gearbox. Enclosures that provide protection against these elements, such as IP-rated housings, can prevent contamination and corrosion. It is also important to consider the load type and frequency of operation; high cyclic load applications may require a robust design with enhanced durability. By evaluating these factors, businesses can ensure they select a gearbox that not only meets their performance needs but also endures the specific environmental challenges of their operations.

Examining Warranty, Support, and Maintenance Options for Longevity

When selecting a gearbox or gearmotor for your business, examining warranty, support, and maintenance options is crucial for ensuring long-term reliability. A robust warranty not only reflects the manufacturer's confidence in their product but also provides peace of mind to the buyer. Extended warranties can mitigate unexpected repair costs and indicate the manufacturer's willingness to stand behind their products in case of defects or performance issues.

Support is another vital aspect to consider. Reliable customer service can assist in troubleshooting and ensure that any operational issues are promptly addressed. Companies that offer comprehensive support services, including technical assistance and training, can greatly enhance the usability of the gearbox or gearmotor. Additionally, understanding the availability of spare parts and the manufacturer’s responsiveness in case of inquiries can significantly affect the ease of maintenance.

Lastly, consider the maintenance options provided by the manufacturer. Routine maintenance can extend the life of the gearbox, reducing downtime and improving overall efficiency. Manufacturers that offer maintenance services or detailed guides on proper upkeep demonstrate a commitment to their customers' operational success. Prioritizing these aspects during the selection process can lead to a more informed decision that aligns with your business's longevity and performance goals.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor