Top Gearmotorbauer Gearbox Features and Benefits for Efficient Performance

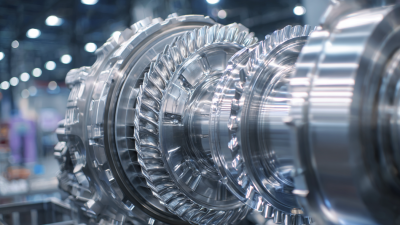

In today's fast-paced industrial landscape, the demand for efficient and reliable machinery is more crucial than ever. Among the key components that contribute to operational excellence are gearmotors, especially the Gearmotorbauergearbox. This cutting-edge technology combines the power of a motor with the precision of a gearbox to deliver enhanced performance across various applications. When designed thoughtfully, a Gearmotorbauergearbox not only maximizes efficiency but also minimizes maintenance needs, making it an ideal choice for manufacturers seeking to improve productivity and reduce operational costs.

The features and benefits of the Gearmotorbauergearbox are manifold, providing an array of advantages that address the diverse needs of modern industries. From compact designs that save space to advanced materials that enhance durability, these gearboxes are engineered for optimal performance. Furthermore, their adaptability to various environments allows them to perform consistently under different operational stresses. This versatility is crucial for enterprises aiming to maintain a competitive edge in a rapidly evolving market.

As we delve into the specific attributes of the Gearmotorbauergearbox, it becomes evident that understanding these key features and benefits is essential for decision-makers seeking to invest in innovative solutions that foster efficiency and reliability. By leveraging the strengths of these advanced gearmotors, businesses can position themselves for success in today's dynamic industrial ecosystem.

Top Gearmotorbauer Gearbox: Overview of Key Components

The Top Gearmotorbauer gearbox is designed with several key components that enhance its efficiency and performance in various applications. Central to its functionality is the gear set, which typically incorporates helical or spur gears. These designs provide smoother engagement and reduce noise levels during operation. According to industry studies, gear geometry plays a crucial role in torque transmission efficiency, with helical gears achieving up to 98% efficiency under optimal conditions. This efficiency not only boosts performance but also contributes to reduced energy consumption, a critical factor for industries aiming to enhance sustainability.

Another vital component is the motor coupling, which allows precise alignment between the motor and gearbox. Proper alignment minimizes wear and tear on both the motor and the gearbox, leading to longer service life. Research from the power transmission industry indicates that misalignment can decrease efficiency by as much as 30%, underscoring the importance of this aspect. Additionally, the use of high-quality materials for housing and bearings further reduces friction and heat generation, which can lead to improvements in overall system reliability and maintenance intervals.

Finally, the integration of advanced electronic controls in modern gearmotor systems allows for real-time monitoring and adjustments, optimizing performance based on load conditions. Data from reports in automation technology suggest that implementing smart controls leads to efficiency increases of up to 15%, making the Top Gearmotorbauer gearbox not just a mechanical component but an essential element of smart manufacturing strategies.

Top Gearmotorbauer Gearbox Features and Benefits for Efficient Performance

| Feature |

Description |

Benefits |

| Compact Design |

Space-saving construction allows for easier installation in tight spaces. |

Maximizes efficiency in limited areas and reduces overall machine footprint. |

| High Efficiency |

Designed to minimize energy loss, providing more output per input. |

Reduces operational costs and increases energy savings. |

| Customizable Options |

Available with various ratios, sizes, and configurations to suit specific needs. |

Enhances versatility and adaptability for different applications. |

| Durability |

Constructed with high-quality materials to withstand harsh conditions. |

Ensures long service life and reduces maintenance needs. |

| Noise Reduction |

Engineered to operate quietly, minimizing sound during operation. |

Improves work environment and complies with noise regulations. |

Advantages of High-Quality Gearboxes in Gearmotors

High-quality gearboxes play a pivotal role in enhancing the performance and efficiency of gearmotors. One of the primary advantages of using superior gearboxes is their ability to provide precise control of speed and torque. This level of control is crucial in applications where precise operations are necessary, such as in robotics and automation systems. By optimizing the gear ratio, high-quality gearboxes ensure that gearmotors operate at their most efficient levels, reducing energy consumption and prolonging the lifespan of the entire motor system.

Another significant benefit of high-quality gearboxes is their durability and reliability. Constructed from robust materials and designed with advanced engineering techniques, these gearboxes can withstand harsh environments and heavy loads without compromising performance. This reliability not only minimizes maintenance costs but also enhances operational uptime, providing users with consistent functionality over time. The combination of enhanced control, energy efficiency, and durability makes high-quality gearboxes an invaluable component in gearmotors, ultimately leading to superior performance in various industrial applications.

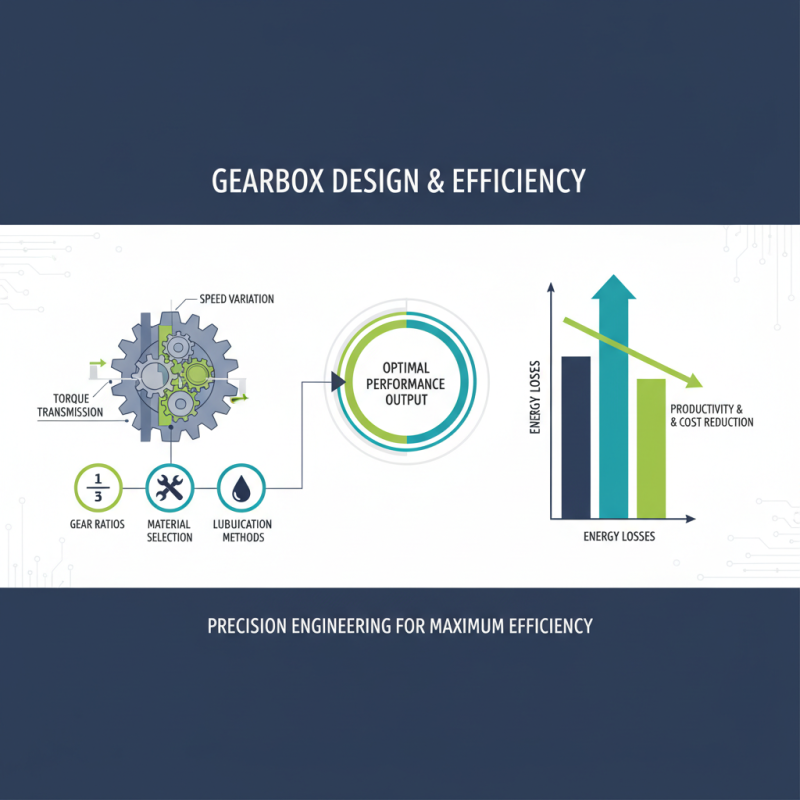

Performance Efficiency: How Gearbox Design Impacts Output

The design of gearboxes plays a pivotal role in determining the overall performance efficiency of gearmotors. A well-engineered gearbox can significantly enhance the torque transmission and speed variation, allowing a gearmotor to operate optimally within its intended application. Factors such as gear ratios, material selection, and lubrication methods are crucial components that influence the performance output. By maximizing efficiency through precise design and engineering, the gearbox can minimize energy losses and improve responsiveness, ultimately leading to better productivity and reduced operational costs.

Additionally, the integration of innovative features such as helical gears and planetary configurations can further optimize performance. Helical gears, for instance, offer smoother operation and reduced noise levels compared to spur gears, which can be beneficial in noise-sensitive environments. Planetary gear sets contribute to a compact design while delivering high torque output and excellent load distribution. These design advancements not only enhance the reliability and lifespan of gearmotors but also allow for greater flexibility across various applications, from industrial machinery to renewable energy systems. Ultimately, the impact of gearbox design on output efficiency cannot be understated, as it directly correlates with performance, durability, and the overall success of the system.

Maintenance Tips for Extending Gearmotor Lifespan

Proper maintenance of gearmotors is essential for enhancing their lifespan and ensuring optimal performance. Regular checks can help identify potential issues before they escalate, which saves time and money in the long run. One effective tip is to ensure that the gearmotor is adequately lubricated. Over time, lubricants can degrade or become contaminated, leading to increased friction and wear. Regularly inspecting and replacing lubricants as recommended can help prevent these problems.

Another important aspect of maintenance is checking the alignment of the gearmotor components. Misalignment can lead to excessive wear, vibrations, and even catastrophic failure. It is advisable to periodically assess the alignment and make necessary adjustments to ensure that all parts are operating harmoniously. Additionally, keeping the gearmotor clean from dirt and debris contributes significantly to its longevity. A clean environment reduces the risk of contamination and overheating, both of which can severely impact performance. By implementing these maintenance tips, you can greatly extend the lifespan of your gearmotor and maintain its efficiency.

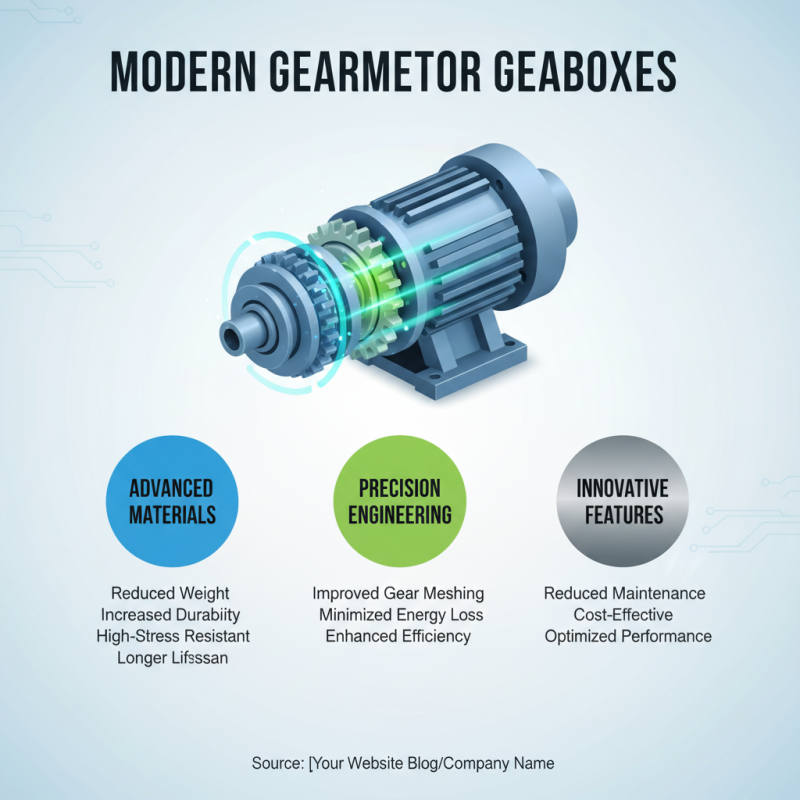

Innovative Features in Modern Gearmotor Gearboxes

Modern gearmotor gearboxes have evolved to incorporate innovative features that significantly enhance their performance and efficiency. One standout feature is the integration of advanced materials, which reduces weight and increases durability. These materials are engineered to withstand high-stress environments, ensuring a longer lifespan and reducing maintenance costs. Additionally, manufacturers are focusing on precision engineering, which not only improves gear meshing but also minimizes energy loss during operation, leading to better overall efficiency.

Another key innovation is the incorporation of smart technology into gearmotor gearboxes. These systems can monitor performance in real time, providing valuable data on operation metrics such as temperature and load. This insight allows for predictive maintenance, reducing unexpected downtimes and optimizing operational efficiency. Furthermore, many modern gearboxes are designed with modular components, making them easier to customize and maintain according to specific application needs.

Tip: When selecting a gearmotor gearbox, pay attention to these innovative features as they can vastly improve your system's performance and longevity. Engaging with suppliers who offer customizable options can lead to a tailored solution that best suits your operational demands. Explore the benefits of smart technology integration and consider how real-time monitoring can transform your maintenance approach.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor