Maximizing Efficiency with Flendermkygearbox A Comprehensive Guide for Global Buyers

In today's fast-paced industrial landscape, maximizing efficiency is a pivotal goal for manufacturers around the globe. The Flendermkygearbox stands out as a vital component in achieving this objective, evidenced by recent market analysis that reveals the global gearbox market is projected to reach $36 billion by 2027, growing at a CAGR of 6.5%. As industries strive to optimize their operations, the choice of gearbox technology can significantly impact productivity and operational costs.

The Flendermkygearbox, with its advanced engineering and adaptability across various applications, offers solutions that can help organizations streamline processes and enhance performance. This comprehensive guide for global buyers delves into the benefits, specifications, and strategic advantages of investing in Flendermkygearbox technology, ensuring that stakeholders are equipped to make informed purchasing decisions that drive efficiency in their operations.

Understanding Flendermky Gearbox: Key Features and Benefits

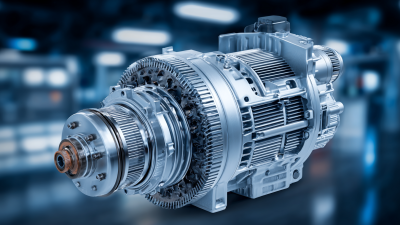

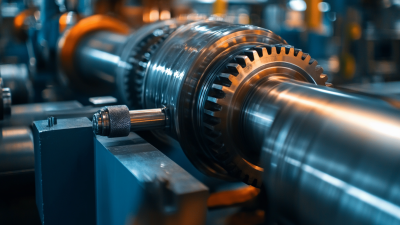

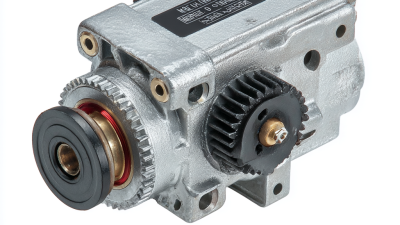

The Flendermky gearbox stands out in the market due to its innovative design and robust performance, making it a sought-after choice for global buyers seeking efficiency and reliability. One of the key features of this gearbox is its compact structure, which allows for easy installation in various applications without compromising on space. Additionally, the advanced materials used in its construction contribute to its durability, ensuring longevity and reduced maintenance costs, a critical factor for industries aiming to maximize operational uptime.

The Flendermky gearbox stands out in the market due to its innovative design and robust performance, making it a sought-after choice for global buyers seeking efficiency and reliability. One of the key features of this gearbox is its compact structure, which allows for easy installation in various applications without compromising on space. Additionally, the advanced materials used in its construction contribute to its durability, ensuring longevity and reduced maintenance costs, a critical factor for industries aiming to maximize operational uptime.

Another significant benefit of the Flendermky gearbox is its high performance under a wide range of operating conditions. Engineered with precision, it offers exceptional torque transfer and energy efficiency, which can lead to significant cost savings over time. The versatility of the Flendermky gearbox makes it suitable for diverse industries, from manufacturing to renewable energy. By understanding these key features and benefits, global buyers can make informed decisions, ultimately enhancing their operational efficiency and competitiveness in the market.

Types of Flendermky Gearboxes: A Deep Dive into Options Available

When exploring the diverse world of Flendermky gearboxes, it’s essential to categorize your options effectively. The primary types include planetary, helical, and worm gearboxes, each serving unique functions and applications.

Planetary gearboxes are praised for their compact design and high efficiency, making them ideal for applications requiring considerable torque in a limited space. Helical gearboxes, on the other hand, are known for their quiet operation and high load capacities, suitable for heavy industry. Lastly, worm gearboxes offer a unique advantage of high reduction ratios, perfect for applications that demand significant speed reduction.

Tips for Selecting the Right Flendermky Gearbox:

- Assess Your Requirements: Before making a decision, evaluate your application’s torque, speed, and space constraints. This assessment will guide you in choosing the right type of gearbox.

- Consider Material and Build Quality: Opt for gearboxes constructed from durable materials that can withstand operational stress. A robust build ensures longevity and reliability in demanding environments.

- Consult with Manufacturers: Engaging directly with manufacturers can provide invaluable insights into which gearbox aligns best with your specific needs, taking into account any unique operational challenges you might face.

Factors to Consider When Selecting a Flendermky Gearbox

When selecting a Flendermky gearbox, there are several crucial factors to consider to ensure maximum efficiency and performance. First and foremost, understanding the application requirements is essential. Different industries demand unique characteristics from gearboxes – from torque capacity to speed ratios, every aspect can significantly impact operational efficiency. For instance, a gearbox designed for high-speed applications will differ fundamentally from one optimized for heavy-duty tasks.

Another important consideration is the material quality and construction design of the gearbox. The lifespan and reliability of the gearbox often hinge on these factors. Opting for a unit made from high-grade materials and featuring robust construction can lead to lower maintenance costs and enhanced performance over time. Additionally, prospective buyers should assess the manufacturer's reputation and support services. A reliable manufacturer not only provides quality products but also offers crucial support, such as maintenance tips and replacement parts, ensuring that users get the most out of their investment. This comprehensive approach will significantly contribute to achieving optimal efficiency and longevity in gearbox performance.

Maintenance Tips for Optimal Performance of Flendermky Gearboxes

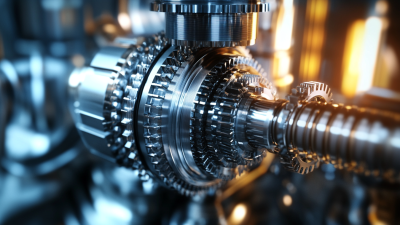

When it comes to maximizing the efficiency of Flendermky gearboxes, maintenance plays a vital role in ensuring optimal performance. Regular upkeep is essential to extend the lifespan of these gearboxes and to prevent unexpected failures that can disrupt operations. One key maintenance tip is to regularly check and replace lubricants, as this helps minimize friction and wear during operation. Additionally, inspecting the seals and gaskets can prevent leaks and protect the internal mechanisms from contaminants.

Another important aspect is the alignment of the gearbox with other system components. Misalignment can lead to increased stress and premature wear, so a careful alignment check is necessary during installation and routine maintenance. Implementing a scheduled maintenance plan that includes these inspections and adjustments will contribute significantly to the overall performance and reliability of Flendermky gearboxes. By focusing on these maintenance tips, global buyers can ensure they get the most out of their gearboxes, ultimately maximizing efficiency and productivity in their operations.

Maximizing Efficiency of Gearboxes: Maintenance Insights

Global Market Trends and Demand for Flendermky Gearboxes

The demand for Flendermky gearboxes has been significantly influenced by the global market trends shaping various industries. According to a recent report by MarketsandMarkets, the global gearbox market is projected to reach $32.9 billion by 2026, growing at a CAGR of 4.7% from 2021. This growth is largely driven by advancements in automation and the increasing need for energy-efficient solutions across sectors such as manufacturing, oil and gas, and renewable energy. Flendermky gearboxes, known for their reliability and efficiency, are being increasingly adopted to help businesses meet these evolving demands.

Moreover, a report from Grand View Research highlights that the rise in industrialization, particularly in emerging economies, is propelling the demand for high-performance gear systems. As industries increasingly focus on reducing energy consumption and improving operational efficiency, Flendermky gearboxes have emerged as a preferred choice. Their cutting-edge design and ability to withstand demanding applications resonate with industries that prioritize sustainability and efficiency, further intensifying their global market presence. With such trends indicating a robust demand, Flendermky gearboxes are well-positioned to capture significant market share in the coming years.

Maximizing Efficiency with Flendermkygearbox A Comprehensive Guide for Global Buyers

| Region |

Market Demand (Units) |

Expected Growth Rate (%) |

Major Industries Using Gearboxes |

| North America |

150,000 |

5.2 |

Automotive, Aerospace |

| Europe |

200,000 |

4.8 |

Manufacturing, Renewable Energy |

| Asia-Pacific |

250,000 |

6.0 |

Construction, Mining |

| Latin America |

80,000 |

3.5 |

Agriculture, Oil & Gas |

| Middle East & Africa |

60,000 |

4.0 |

Mining, Construction |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor

The Flendermky gearbox stands out in the market due to its innovative design and

The Flendermky gearbox stands out in the market due to its innovative design and