Understanding the Role of Gearbox Sew Gear Motors in Modern Automation Technologies

In the rapidly evolving landscape of modern automation technologies, the significance of Gearbox Sew Gear Motors cannot be understated. These advanced motor systems play a pivotal role in enhancing the efficiency and reliability of various automated processes across industries. According to a report by MarketsandMarkets, the global market for gear motors is projected to reach USD 32.5 billion by 2025, growing at a CAGR of 6.1%. This growth is driven by the increasing demand for high-performance machinery in sectors such as manufacturing, logistics, and robotics. Gearbox Sew Gear Motors, known for their robustness and precision, are integral to the seamless operation of integrated systems, ensuring sustainable performance and minimizing downtime. As industries continue to adopt smart automation solutions, understanding the functionality and application of Gearbox Sew Gear Motors becomes essential for engineers and decision-makers aiming to stay competitive in this dynamic environment.

The Basics of Gearbox Sew Gear Motors in Automation Systems

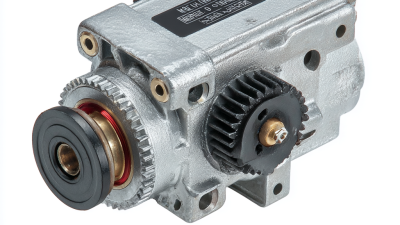

Gearbox sew gear motors play a crucial role in modern automation systems, serving as essential components that convert

electrical energy into mechanical motion. These motors combine a standard electric motor with a gearbox, which amplifies

torque and allows for precise control of speed and movement.

In automation systems, where efficiency and

accuracy are paramount, the integration of gearbox

sew gear motors ensures that machinery operates smoothly and reliably, catering to a wide range of

industrial applications.

Fundamentally, the design of gearbox sew gear motors allows them to handle varying loads while maintaining

optimal performance. The gear reduction aspect not only increases

the output torque but also minimizes the speed of the motor, making it suitable for tasks that require steady and

controlled movements. Additionally, their compact design enables

easy installation in confined spaces, which is often a requirement in modern manufacturing and robotics. By understanding

the basics of these gear motors, engineers can make informed decisions when selecting the right components for their

automation projects, ultimately enhancing productivity and operational efficiency.

Key Features that Enhance Performance in Automation Technologies

In modern automation technologies, gearbox sew gear motors play a pivotal role in enhancing performance across various industries, particularly with the integration of advanced machine learning (ML) and artificial intelligence (AI) tools. These motors, known for their efficiency and reliability, are pivotal in optimizing operations in fast-paced sectors like food processing. The adoption of AI vision technologies for quality control and predictive maintenance, as highlighted in recent studies, demonstrates a growing intersection where gear motors are utilized to improve operational efficiency, reducing downtime and enhancing production quality.

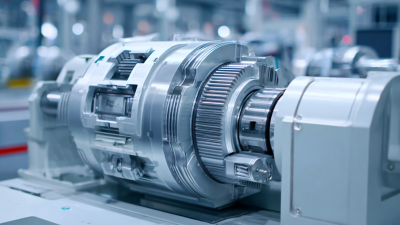

Furthermore, with the rise of Industry 4.0, the implementation of digital twins is revolutionizing how gearbox sew gear motors are monitored and managed. A digital twin provides a real-time virtual representation of these motors, enabling smarter diagnostics and proactive maintenance strategies. Research illustrates that organizations employing such technologies can achieve operational efficiencies of up to 30%, underscoring the importance of gearbox motors in this evolving landscape. As automation continues to drive business growth, enhancements in motor technology will undoubtedly play a crucial role in achieving competitive advantages across industries.

Understanding the Role of Gearbox Sew Gear Motors in Modern Automation Technologies - Key Features that Enhance Performance in Automation Technologies

| Feature |

Description |

Impact on Performance |

Typical Applications |

| High Efficiency |

Optimized gear design minimizes energy loss |

Increases overall system efficiency and reduces operating costs |

Conveyor systems, robotic arms |

| Compact Size |

Small footprint allows for space-saving designs |

Facilitates use in tight spaces while maintaining power |

Automated assembly lines, compact machines |

| Low Noise Operation |

Advanced materials and design reduce operational noise |

Improves workplace comfort and compliance with regulations |

Packaging machines, food processing |

| Variable Speed Control |

Allows precise motor speed adjustments |

Enables flexibility in operations and improved product quality |

Textile machinery, CNC machines |

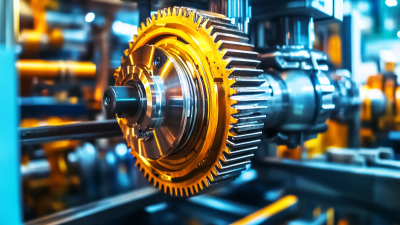

| High Torque Output |

Engineered to deliver maximum torque at low speeds |

Enhances the ability to handle heavy loads without performance loss |

Material handling, lifts |

Choosing the Right Gearbox Sew Gear Motor for Your Application

When selecting the appropriate Gearbox Sew Gear Motor for your specific application, it’s crucial to consider various factors that can significantly influence performance and efficiency. According to a report by Research and Markets, the global gear motor market is projected to reach USD 9.85 billion by 2025, driven by increased demand across various industries such as manufacturing, robotics, and renewable energy. The right gearbox motor not only enhances operational efficiency but also impacts the overall lifecycle costs of machinery.

One of the key considerations is the torque and speed requirements of your application. For instance, a report from Technavio highlights that gear motors with higher torque ratings are essential in industries like food processing and packaging, where the ability to handle heavy loads is critical. Additionally, understanding the environmental conditions—such as temperature and exposure to corrosive substances—will help determine the materials and designs best suited for your motor. By carefully evaluating these parameters and leveraging industry insights, you can ensure that your selection of Gearbox Sew Gear Motors supports optimal automation performance.

Understanding Gearbox Sew Gear Motors in Automation

Maintenance Tips for Longevity of Gearbox Sew Gear Motors

Maintenance is crucial for ensuring the longevity and optimal performance of gearbox sew gear motors, particularly as industrial users increasingly adopt integrated gear-motor packages. According to industry reports, properly maintained gear motors can lead to a reduction in unplanned downtime by up to 30%, greatly benefiting operational efficiency. Regularly scheduled maintenance that includes comprehensive inspections, lubrication checks, and alignment verification ensures that these motors operate smoothly and reduces wear and tear over time.

Moreover, advancements in planetary gear technology have significantly enhanced the durability and application versatility of these systems. Recent data indicates that these next-gen gearboxes can handle higher torque ratings while maintaining a compact footprint, making them ideal for modern automation applications. Users are advised to follow manufacturer guidelines closely, utilizing high-quality lubricants and ensuring that any abnormal noises or vibrations are addressed promptly. By investing in routine maintenance protocols, businesses can expect to maximize their equipment's lifespan and reliability, ultimately contributing to improved productivity in their operations.

Future Trends in Gearbox Sew Gear Motors Within Automation Solutions

The evolution of automation technologies has led to significant advancements in gearbox sew gear motors, highlighting their essential role within modern industrial systems. Future trends indicate a notable shift towards more compact and efficient motor designs that cater to increasing energy demands and sustainability goals. As industries embrace smart manufacturing, the integration of IoT capabilities into gear motors is expected to rise. This evolution will facilitate real-time monitoring and predictive maintenance, ultimately enhancing operational reliability and lifespan.

Moreover, the incorporation of advanced materials and innovative manufacturing techniques is set to redefine performance standards in gearbox sew gear motors. These advancements will not only improve power density and reduce noise levels but also enable greater compatibility with automation robotics and conveyor systems. As the push for automation continues to accelerate, the demand for intelligent and adaptable gear motors will drive research and development, ensuring that these components remain at the forefront of intelligent production solutions.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor