Top 10 Servo Motor Applications Transforming Modern Automation

In the rapidly evolving landscape of modern automation, servo motors have emerged as pivotal components driving innovation across various industries. According to a recent report from Allied Market Research, the global servo motor market is projected to reach $11.94 billion by 2027, growing at a compound annual growth rate (CAGR) of 7.5% from 2020 to 2027. This surge reflects an increasing demand for precision control in applications spanning robotics, manufacturing, and aerospace.

As industry expert Dr. Emily Carter, a renowned mechanical engineer and automation specialist, aptly stated, “Servo motors are the heartbeat of modern automation systems, enabling unparalleled accuracy and efficiency.” These compact yet powerful devices are not only integral to enhancing operational capabilities but also serve as essential enablers of Industry 4.0 technologies such as smart factories and the Internet of Things (IoT).

In light of these developments, this article explores the top 10 servo motor applications transforming the automation landscape. From sophisticated robotics to advanced manufacturing processes, we will delve into the transformative role servo motors play, illustrating their significance in driving productivity and innovation in today’s automated world.

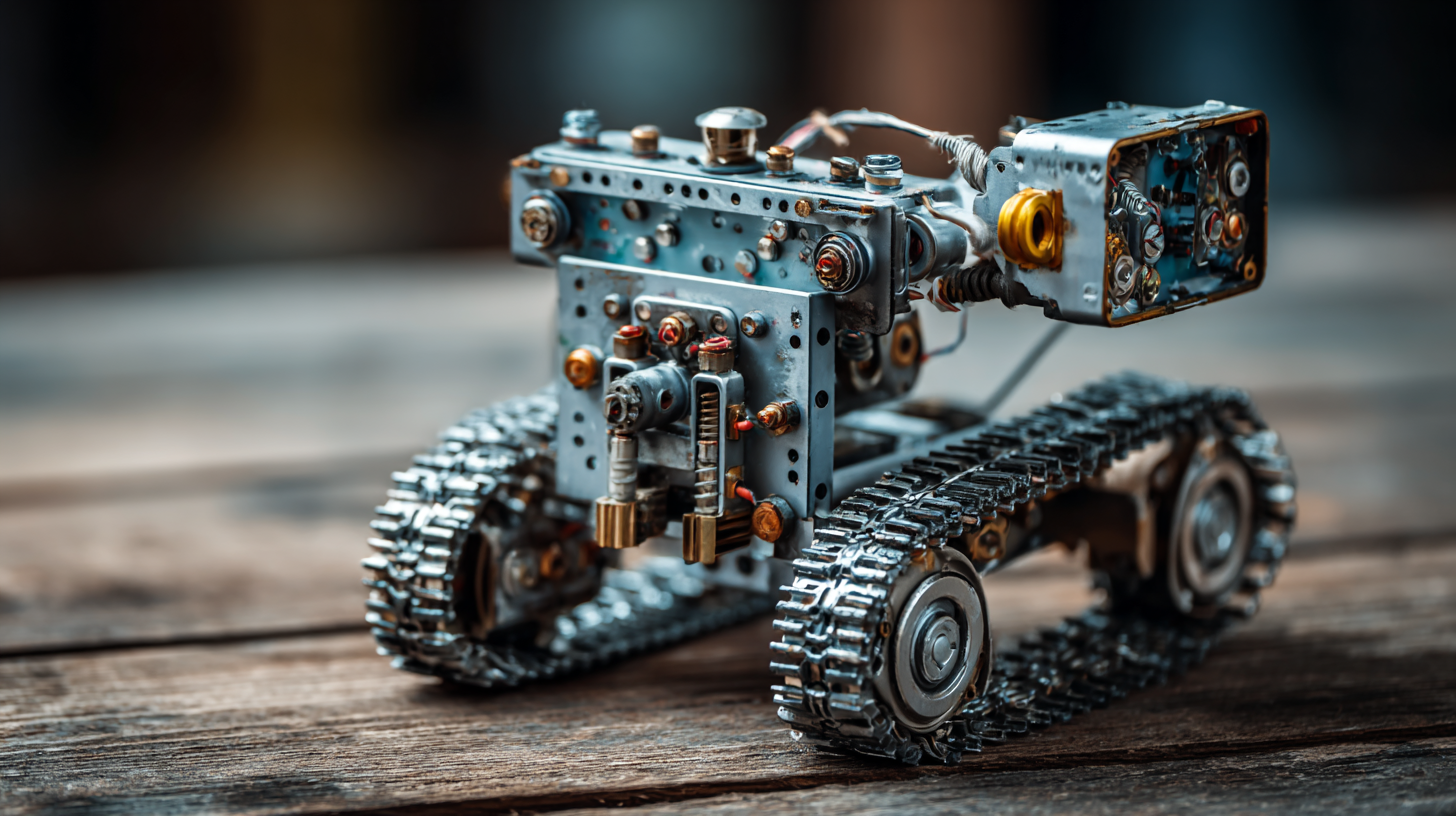

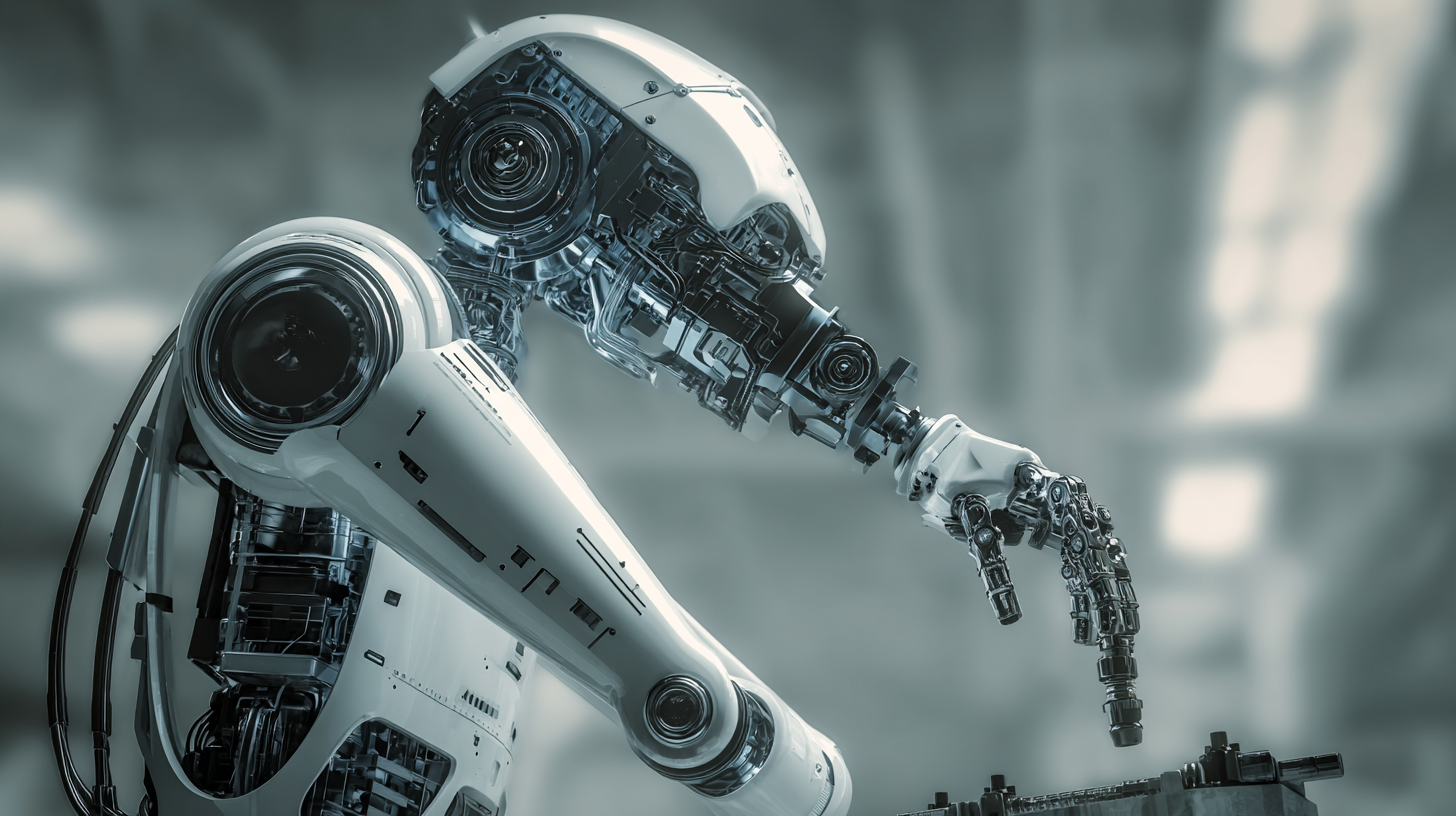

How to Utilize Servo Motors for Precision Robotics in Manufacturing

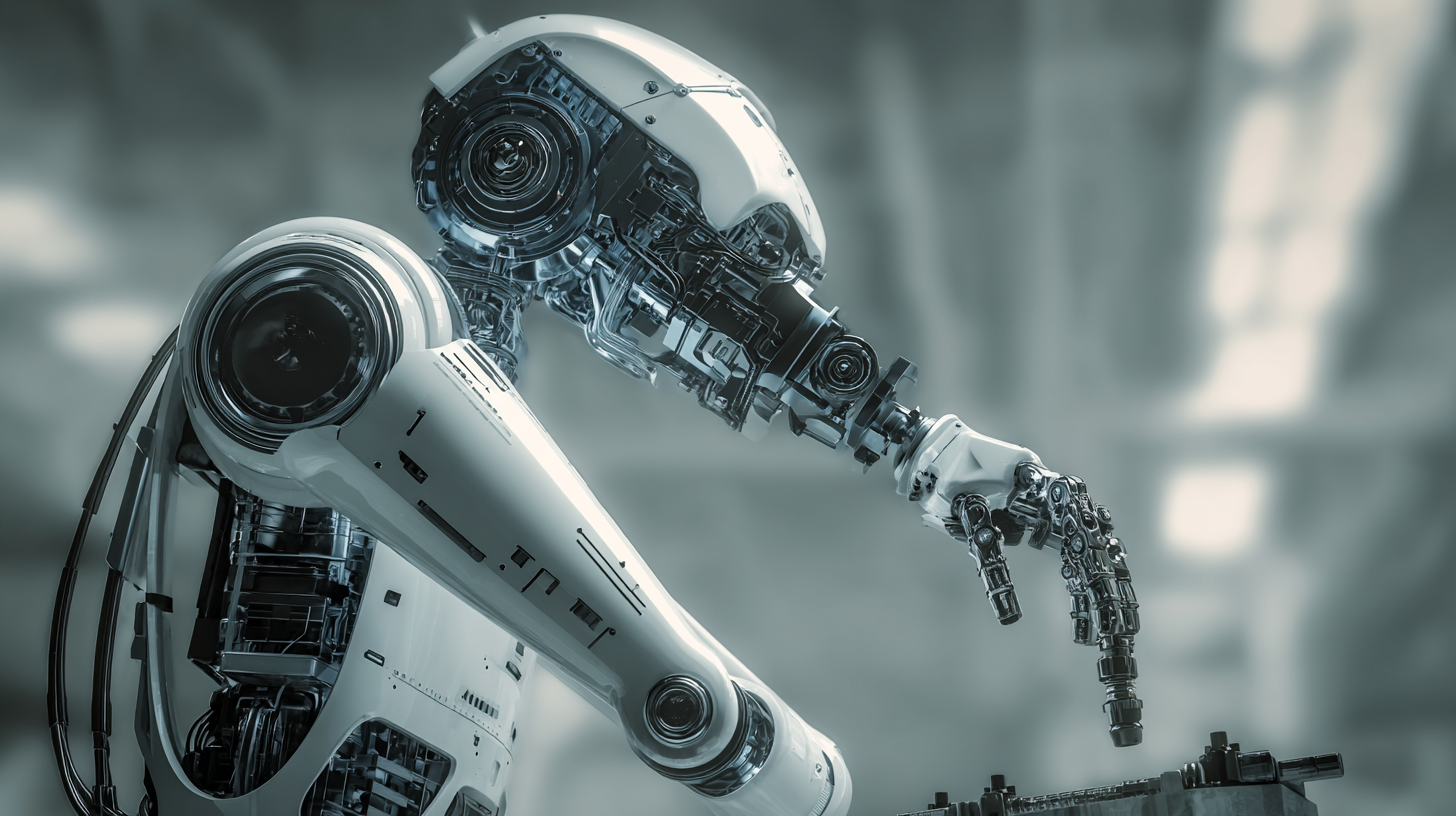

Servo motors play a crucial role in enhancing precision robotics within the manufacturing sector. According to a recent report by Mordor Intelligence, the global servo motor market is projected to grow from USD 5.5 billion in 2021 to USD 10.5 billion by 2026, indicating a compound annual growth rate (CAGR) of 14.1%. This rapid growth is largely driven by the increasing automation in manufacturing processes, where servo motors offer unparalleled accuracy and efficiency. Their ability to deliver precise control over speed, position, and torque makes them ideal for applications in robotics, enabling manufacturers to optimize production lines and reduce cycle times.

In particular, industries such as automotive, electronics, and consumer goods are leveraging servo motors for advanced robotic arms and assembly lines. A report from ResearchAndMarkets highlights that 77% of manufacturing companies have implemented robotics to improve their production capabilities. With the integration of servo motors into robotics, manufacturers can achieve tighter tolerances and faster response times, which are essential for maintaining competitive advantages in today's market. By employing servo motors, companies can not only enhance product quality but also reduce operational costs, thus transforming modern automation practices in the manufacturing landscape.

Top 10 Servo Motor Applications Transforming Modern Automation

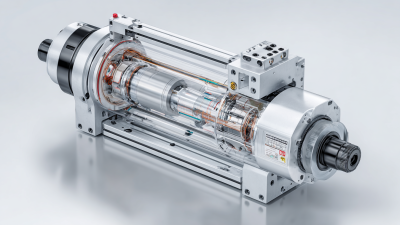

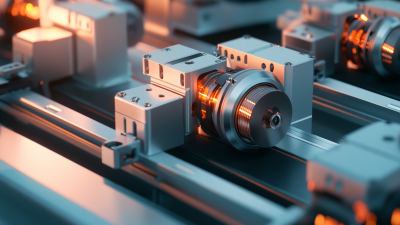

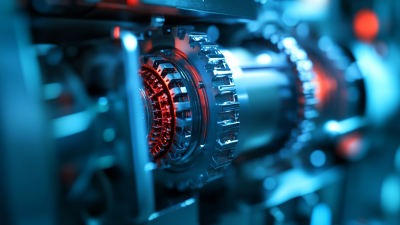

How to Optimize CNC Machining Processes with Advanced Servo Systems

Advanced servo systems are revolutionizing CNC machining processes by enhancing precision and efficiency. According to a report by IndustryARC, the global CNC machining market is projected to reach $100 billion by 2025, significantly driven by the integration of advanced servo motors. These systems offer high responsiveness, reduced vibration, and improved torque consistency, allowing manufacturers to produce intricate designs with minimal waste. For example, servo-controlled CNC machines can achieve positional accuracy within microns, which is essential for industries such as aerospace and medical device manufacturing.

Moreover, the ability of servo motors to provide real-time feedback plays a crucial role in process optimization. As stated in a study by ResearchAndMarkets, implementing servo systems can lead to an up to 30% increase in production efficiency. This enhancement stems from the motors’ capability to continuously adjust to changes in load and speed, ensuring stable performance even under varying operational conditions. With the ongoing trends towards Industry 4.0, where automation and data exchange are paramount, the adoption of advanced servo technology in CNC machining is not just an improvement—it's a necessity for staying competitive in today's manufacturing landscape.

How to Enhance Packaging Efficiency with Servo-Driven Automation

Servo-driven automation is revolutionizing packaging efficiency across various sectors, including automotive, healthcare, and robotics. In the automotive and transportation industries, servo motors are increasingly utilized in assembly line automation, where precision and speed are paramount. These motors enable streamlined operations, ensuring that components like steering columns are assembled with greater accuracy while minimizing downtime. The result is a significant boost in productivity and reliability, allowing manufacturers to meet today's fast-paced demands effectively.

In healthcare, the integration of servo motors in medical robots enhances not only precision but also the reliability of medical packaging processes. Servo-driven systems facilitate meticulous handling of sensitive instruments and pharmaceuticals, ensuring high standards of hygiene and safety. Moreover, HVAC robots equipped with servo technology improve the efficiency of packaging and installation, delivering a more adaptable and efficient approach to modern climate control systems. This level of automation not only meets strict industry standards but also leads to substantial cost savings and optimized operational workflows in various applications.

How to Implement Servo Motors in Automated Material Handling Solutions

Implementing servo motors in automated material handling solutions significantly enhances efficiency, precision, and flexibility in operations. According to a report by ResearchAndMarkets, the global automated material handling market is projected to reach $61.74 billion by 2026, growing at a compound annual growth rate (CAGR) of 8.6% from 2021. This growth is largely driven by the adoption of advanced technologies such as servo motors, which allow for finer control in applications such as conveyor systems, robotic arms, and automated guided vehicles (AGVs).

Servo motors are particularly beneficial in environments where rapid and accurate positioning is crucial. The International Federation of Robotics notes that the use of servo motors in robotics has increased efficiency by up to 30%, making these systems more responsive and reliable. When integrating servo motors into automated handling solutions, it's essential to consider factors such as load capacity, speed, and control precision. By leveraging these advanced motors, businesses can optimize workflows, reduce energy consumption, and minimize downtime, positioning themselves competitively in the evolving landscape of automation.

Top 10 Servo Motor Applications Transforming Modern Automation

| Application |

Industry |

Benefits |

Key Features |

| Robotic Arm Control |

Manufacturing |

Precision, repeatability |

High torque, speed control |

| CNC Machining |

Machinery |

Accuracy, efficiency |

Closed-loop control, flexibility |

| 3D Printing |

Additive Manufacturing |

Customization, speed |

Layer precision, multi-axis control |

| Automated Guided Vehicles (AGVs) |

Logistics |

Safety, automation |

Navigation, programmable paths |

| Packaging Machines |

Food & Beverage |

Speed, reliability |

Modular design, sensor integration |

| Textile Machinery |

Textiles |

Versatility, energy efficiency |

Variable speed drive, precision control |

| Printing Presses |

Printing |

Consistency, high output |

High-resolution control, fast setup |

| Sewing Automation |

Apparel |

Quality, speed |

Adaptive stitching, multi-tasking |

| Material Handling Systems |

Warehousing |

Efficiency, labor reduction |

Integration, conveyor control |

| Pharmaceutical Equipment |

Pharmaceuticals |

Compliance, precision |

Sterile handling, dosing accuracy |

How to Improve Performance in Medical Devices Using Servo Motor Technology

Servo motors play a crucial role in enhancing the performance of medical devices, particularly in applications requiring precision and reliability. According to a report by Markets and Markets, the global medical robotics market is expected to reach $20.4 billion by 2025, with a significant portion of that growth driven by advancements in servomechanism technologies. These motors enable precise movements in surgical robots, allowing for minimally invasive procedures that result in reduced recovery times and improved patient outcomes.

In addition to surgical robotics, servo motors are transforming medical applications such as prosthetics and rehabilitation equipment. A study published by the Journal of Mechanisms and Robotics highlights that the integration of servo motors in prosthetic limbs can enhance responsiveness and control, providing users with a more natural experience. The report emphasizes that such technologies can increase the efficiency of rehabilitation devices by up to 40%, thus allowing patients to regain mobility faster. By leveraging advanced servo motor technology, medical device manufacturers can not only improve the effectiveness of their products but also address the increasing demands for customization and adaptability in modern healthcare solutions.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor