Exploring Tailored Solutions for Your Unique Sewmkygearbox Needs

In today's rapidly evolving industrial landscape, the demand for customized solutions is more critical than ever, particularly when it comes to mechanical components like the Sewmkygearbox. According to a recent report by Market Research Future, the global gearbox market is projected to reach $36 billion by 2025, driven by the increasing need for enhanced operational efficiency and tailored applications in various sectors.

This trend emphasizes the importance of exploring alternatives that cater to unique operational requirements. As businesses strive for excellence and competitive advantage, understanding the nuances of Sewmkygearbox configurations can lead to significant improvements in performance and longevity. Consequently, this blog will delve into various tailored solutions for your specific Sewmkygearbox needs, helping you navigate through the myriad of alternatives available in the market.

Identifying Your Specific Sewmkygearbox Requirements

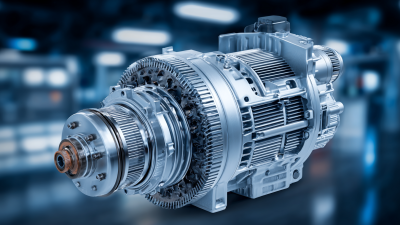

When diving into the world of Sewmkygearboxes, understanding your specific requirements is the first step towards finding the ideal tailored solution. Whether you are working with a unique machinery setup, specific load conditions, or distinct operational environments, identifying these needs is crucial. Start by analyzing the type of applications your Sewmkygearbox will serve. Consider factors such as speed, torque, and power transmission, which play a vital role in determining the right gearbox for your setup.

When diving into the world of Sewmkygearboxes, understanding your specific requirements is the first step towards finding the ideal tailored solution. Whether you are working with a unique machinery setup, specific load conditions, or distinct operational environments, identifying these needs is crucial. Start by analyzing the type of applications your Sewmkygearbox will serve. Consider factors such as speed, torque, and power transmission, which play a vital role in determining the right gearbox for your setup.

In addition to mechanical specifications, it’s important to assess the environmental conditions your gearboxes will face. Extreme temperatures, moisture, and exposure to corrosive materials can significantly impact performance and longevity. Tailoring your solution involves not only matching the physical attributes but also ensuring that the materials and designs align with your operating context. By conducting a thorough assessment of both the technical and environmental factors, you position yourself to make an informed decision that meets your unique needs effectively.

Assessing Performance Needs for Your Unique Applications

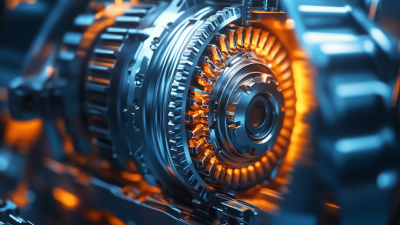

When considering tailored solutions for your unique sewmygearbox needs, assessing performance requirements is crucial for optimizing application efficiency. According to a recent industry report by the Global Market Insights, the global gearbox market is projected to reach $38 billion by 2026, driven by the increasing demand for customized gear solutions across various sectors. This emphasizes the significance of carefully evaluating the specific performance metrics required for your applications, including load capacity, speed, and operational environment.

Understanding the nuances of your unique application can also facilitate the selection of appropriate materials and design features. The American Gear Manufacturers Association (AGMA) highlights that nearly 70% of gearbox failures are attributed to inadequate design considerations for specific workloads. By prioritizing performance needs, companies can mitigate risks associated with gear failures, enhance reliability, and ultimately boost overall productivity. Furthermore, investing in bespoke solutions can lead to significant long-term savings, with reports indicating a 15-20% reduction in operational costs when utilizing gear systems precisely tailored to application demands.

Custom Design Options for Enhanced Functionality

When it comes to sewmkygearbox solutions, custom design options play a crucial role in enhancing functionality and performance. Every application presents unique challenges, and a one-size-fits-all approach often falls short.

Tailored designs ensure that the gearbox meets specific requirements, whether it’s for increased load capacity, faster processing speeds, or improved energy efficiency. By integrating the latest technologies and materials, custom gearboxes can provide solutions that are not only functional but also durable and reliable.

Moreover, embracing custom design options allows for greater flexibility in adapting to dynamic industry demands. For manufacturers and businesses looking to optimize their operations, personalized gearboxes can facilitate smoother workflows and reduce downtime. Collaborating with experienced engineers can lead to innovative designs that push the boundaries of conventional gearbox performance. This bespoke approach not only meets immediate needs but also positions businesses for future growth, ensuring they remain competitive in the evolving market landscape.

Integration of Tailored Solutions into Existing Systems

In today's rapidly evolving industrial landscape, the integration of tailored solutions into existing systems is paramount for achieving operational efficiency. According to a report by McKinsey & Company, companies that successfully adopt customized solutions can enhance performance by up to 20%. This significant improvement is particularly evident in sectors such as manufacturing and automotive, where intricate systems like Sewmkygearboxes demand precise compatibility with existing machinery.

When integrating tailored solutions, attention to the unique requirements of each system is crucial. For instance, recent data from Deloitte highlights that organizations investing in bespoke technologies often experience a 30% reduction in downtime. By aligning tailored innovations with current infrastructure, businesses can leverage their existing assets while minimizing disruptions. The strategic implementation of these solutions not only streamlines processes but also drives a sustainable competitive advantage, enabling firms to respond swiftly to market changes and customer demands.

Exploring Tailored Solutions for Your Unique Sewmkygearbox Needs

This chart represents the integration of tailored solutions into existing systems based on customer requirements across different industries. The data reflects the percentage of adoption of tailored solutions in various sectors.

Cost-Benefit Analysis of Customized Sewmkygearbox Solutions

When considering customized Sewmkygearbox solutions, a thorough cost-benefit analysis is essential. These tailored systems can significantly enhance efficiency and productivity, but it’s crucial to weigh the investment against the potential returns. Custom solutions may have a higher initial cost, but they often lead to long-term savings through improved performance, reduced maintenance, and minimized downtime. By evaluating the specific needs of your operation, you can determine whether the higher upfront cost translates to sustainable benefits.

**Tips:** When conducting your cost-benefit analysis, consider creating a comparison chart that highlights current operational costs versus anticipated savings from the customized gearboxes. This visualization can make it easier to present your findings to stakeholders and justify the investment. Additionally, gather testimonials or case studies from other companies that have successfully integrated customized solutions to reinforce your decision-making process.

Another important factor is the implementation timeline. A customized solution may require more time for design and testing, which can affect immediate production schedules. However, the long-term benefits often outweigh these temporary setbacks. **Tips:** Maintain clear communication with the customization provider to establish realistic timelines and expectations. Planning ahead can help mitigate disruptions during the transition to a tailored Sewmkygearbox solution.

Exploring Tailored Solutions for Your Unique Sewmkygearbox Needs - Cost-Benefit Analysis of Customized Sewmkygearbox Solutions

| Solution Type |

Initial Cost ($) |

Annual Maintenance Cost ($) |

Expected Lifespan (Years) |

Estimated ROI (%) |

| Standard Gearbox |

500 |

50 |

5 |

15% |

| High Efficiency Gearbox |

800 |

40 |

7 |

25% |

| Custom Heavy-Duty Gearbox |

1200 |

70 |

10 |

30% |

| Premium Custom Gearbox |

1500 |

60 |

12 |

35% |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor

When diving into the world of

When diving into the world of