Top 5 Gearmotorbauergearbox Models You Need for Your Next Project

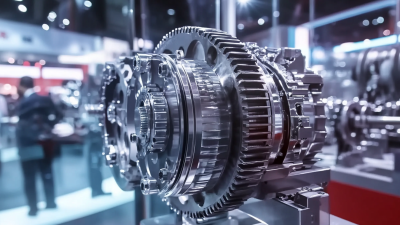

In the ever-evolving landscape of mechanical engineering, selecting the right components can significantly impact the efficiency and success of any project. Among the crucial elements, the Gearmotorbauergearbox stands out as a versatile and reliable choice for various applications. These gearmotor models not only enhance performance but also optimize power transmission, making them essential for projects that demand precision and durability. As we move toward 2025, understanding the top gearmotorbauergearbox models available on the market will equip engineers and project managers with the knowledge needed to make informed decisions.

This article dives into the "Top 5 Gearmotorbauergearbox Models You Need for Your Next Project," highlighted in our comprehensive "2025 Top 10" list. We will explore key features, performance metrics, and application suitability of each model, reflecting the latest advancements in development and technology. Whether you are designing a new system or upgrading existing equipment, our curated selection aims to guide you through the myriad options available, ensuring that you choose the best gearmotorbauergearbox to meet your specific needs. Join us as we uncover the top contenders that can elevate your project's success and efficiency.

Top Features to Consider When Choosing Gearmotors for Your Project

When selecting gearmotors for your next project, understanding the key features can significantly influence the efficiency and effectiveness of your application. One critical factor to consider is the gear ratio, which directly affects the torque and speed of the output. According to a report by the International Electromechanical Commission, optimizing gear ratios can improve energy efficiency by over 15%, which is essential for sustainable engineering practices. A suitable gear ratio helps tailor the motor's performance to specific tasks, increasing productivity while reducing energy costs.

Another pivotal feature is the motor type, particularly the choice between AC and DC gearmotors. AC gearmotors are generally more robust and suited for high-load applications, with studies indicating that they can handle heavier loads compared to their DC counterparts. However, DC gearmotors offer greater precision and control, making them ideal for applications requiring fine adjustments. The choice of motor should align with the project's demands, reinforcing that understanding the specific requirements of your application is vital in making an informed decision.

Key Industry Applications for Gearmotor and Gearbox Models

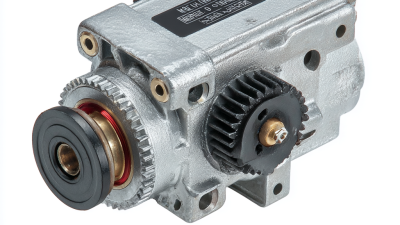

When considering gearmotor and gearbox models for your next project, it is essential to understand their key industry applications. These systems are widely utilized across various sectors, providing reliable operation and efficiency. In manufacturing, for instance, gearmotors power conveyor belts and assembly lines, facilitating smooth material handling. Their ability to handle heavy loads and provide precise control makes them indispensable in this environment.

Another critical application is in the automotive industry, where gearmotors play a vital role in electric vehicles. They drive essential components such as windows, seats, and steering systems, ensuring seamless functionality. Additionally, in the robotics field, gearmotors are used to enable precise movements and control in robotic arms and autonomous vehicles, where accuracy and reliability are paramount. Understanding the specific requirements of these industries will guide you in selecting the right gearmotor and gearbox models tailored to your project's needs.

Top 5 Gearmotor and Gearbox Models for Key Industry Applications

Comparative Analysis of Efficiency Ratings in Leading Gearmotor Models

When selecting gearmotors for a project, understanding the efficiency ratings of leading models is critical for optimal performance and energy conservation. Efficiency ratings provide insight into how much energy is converted into useful work, which is essential for both cost-saving and sustainability considerations. Models with higher efficiency ratings not only reduce operational costs but also contribute to longer life spans, making them a wise investment for any engineering endeavor.

Comparative analysis of efficiency among the top gearmotor models reveals significant differences that can impact application suitability. For instance, some models excel in high-torque applications due to their robust design and precision engineering, while others are tailored for more energy-sensitive uses. By closely examining these ratings, project managers can choose gearmotors that align closely with their requirements, ensuring that the selected models deliver maximum output with minimal energy loss. This informed decision-making process ultimately leads to more efficient, reliable, and cost-effective project outcomes.

Trends in Gearmotor Technologies: What Projects Demand in 2023

In 2023, project demands in the realm of gearmotor technologies are increasingly focused on

efficiency, compactness, and

versatility. Engineers are continually seeking solutions that not only meet

strict performance standards but also adapt to varying application requirements. The latest trends emphasize the integration

of smart technology, allowing gearmotors to communicate and operate within larger,

more complex systems. This connectivity facilitates predictive maintenance and enhanced operational efficiency, reducing

downtime and overall project costs.

Moreover, sustainability is shaping the design and manufacture of gearmotors.

Use of eco-friendly materials and energy-efficient designs are becoming non-negotiable factors in project specifications.

As industries strive to lower their carbon footprint, gearmotor manufacturers are innovating to provide solutions that

align with these environmental goals. This shift not only attracts

environmentally conscious clients but also ensures compliance with increasingly stringent regulations across various

sectors. The gearmotor models of 2023 reflect these advancements, positioning themselves as essential components for

any forward-thinking project.

Budgeting for Quality: Cost-Effectiveness of Top Gearmotor Options

When embarking on a new project, the selection of gearmotors can significantly influence both performance and budget. According to a report from Research and Markets, the global gearmotor market is projected to grow at a CAGR of 5.8% from 2023 to 2030, highlighting the increasing demand for efficient power transmission solutions. Choosing the right gearmotor model not only enhances operational efficiency but also ensures that you’re making a cost-effective investment. For instance, high-efficiency gearmotors can reduce energy consumption by up to 20%, which is a crucial consideration in budgeting for quality.

In terms of cost-effectiveness, investing in well-engineered gearmotor models can provide superior longevity and reduced maintenance costs. A study by Transparency Market Research found that quality gearmotors can yield a return on investment (ROI) through lower operational costs and increased productivity. For projects requiring reliability and performance, models like those from top manufacturers are not just an upfront expense; they represent a strategic investment in the long-term success of your operations. Therefore, carefully evaluating and selecting gearmotor options based on their durability, efficiency, and overall value can lead to substantial savings in both project execution and lifecycle costs.

Top 5 Gearmotor Models You Need for Your Next Project

| Model |

Power (W) |

Torque (Nm) |

Speed (RPM) |

Efficiency (%) |

Price (USD) |

| Model A |

200 |

1.5 |

150 |

85 |

250 |

| Model B |

300 |

2.0 |

100 |

90 |

350 |

| Model C |

400 |

2.5 |

75 |

88 |

450 |

| Model D |

150 |

1.0 |

200 |

80 |

220 |

| Model E |

500 |

3.0 |

50 |

95 |

600 |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor