Unlocking Efficiency with Siemens Gearmotor Gearbox Solutions

In today's fast-paced industrial landscape, maximizing operational efficiency is essential for businesses striving to maintain a competitive edge.

Gearmotors play a pivotal role in enhancing performance across various applications, and

Siemens Gearmotor Gearbox solutions stand out as a benchmark in delivering optimal functionality.

By integrating advanced technology with robust design,

Gearmotorsiemensgearbox not only streamline processes but also reduce maintenance downtime, thereby increasing productivity and reliability.

This blog will explore the innovative features and benefits of Siemens Gearmotor Gearbox solutions, shedding light on how they unlock efficiency and drive success in diverse industries.

Join us as we delve into the transformative potential of these power transmission systems and discover why they are indispensable in the quest for operational excellence.

Understanding Siemens Gearmotor Gearbox Solutions and Their Applications

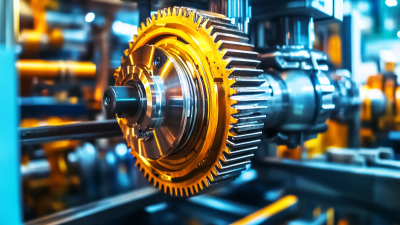

Siemens gearmotor gearbox solutions are increasingly regarded as a benchmark for efficiency in various industrial applications. With a strong emphasis on precision engineering and reliability, Siemens has positioned itself as a leader in the design and production of gearmotors that combine high torque with compact dimensions. According to a report by Research and Markets, the global gearmotor market is expected to reach $8.6 billion by 2026, highlighting the rising demand for efficient drive solutions across multiple sectors, including manufacturing, automotive, and energy.

Siemens gearmotor gearboxes are optimized for performance, offering features such as high energy efficiency, durability, and reduced operational noise. Their innovative technology ensures minimal energy loss, with studies showing that energy-efficient gearmotors can reduce energy consumption by up to 30% compared to traditional alternatives. This efficiency is critical, especially in industries where operational costs are tightly monitored, making Siemens solutions a viable choice for companies looking to enhance productivity while minimizing their carbon footprint. With their advanced engineering and diverse application range, Siemens gearmotor gearbox solutions are redefining standards in industrial performance.

Unlocking Efficiency with Gearmotor Gearbox Solutions

This bar chart illustrates the efficiency improvements gained from using various gearmotor gearbox solutions across different industries. The data represents the percentage increase in efficiency after implementing these solutions.

Key Industry Metrics Driving Gearmotor Efficiency and Performance

The global gear motor market is experiencing significant growth, expected to expand from $6.2 billion in 2024 to an impressive $23.4 billion by 2034, with a compound annual growth rate (CAGR) of approximately 5%. This surge is largely fueled by the rising demand for automation across various sectors, particularly in industrial machinery and energy-efficient applications. By leveraging advanced gearmotor gearbox solutions, businesses can enhance operational efficiency while meeting the increasing demands for sustainability and performance.

In the context of electric mobility, the e-bike motor market is anticipated to see exponential growth, projecting an increase from $12.79 billion in 2025 to $33.41 billion by 2032, with a staggering CAGR of 14.7%. This rise underscores the necessity for innovative gearmotor solutions that can deliver superior efficiency and longevity, making them a vital component in achieving the industry's evolving metrics for performance. As efficiency becomes a key industry metric, manufacturers are prioritizing gearmotor technologies that not only improve functionality but also align with the growing push for eco-friendly solutions.

The Role of Gearbox Configuration in Industrial Automation

In today's rapidly evolving industrial landscape, gearbox configuration plays a pivotal role in enhancing automation efficiency. A well-designed gearbox not only affects the performance of machinery but also influences energy consumption and overall operational costs. Siemens Gearmotor solutions offer a variety of gearbox configurations tailored to meet specific industrial needs, ensuring optimal torque and speed for any application.

When selecting a gearbox, consider the following tips:

- Assess the load requirements and operating environment. Understanding these factors will help in choosing a gearbox that can withstand the demands of your processes.

- Second, pay attention to the gear ratio; an optimal ratio can significantly improve efficiency and reduce energy loss.

- Lastly, collaborate with experts to customize gearbox solutions that align with your automation goals, ensuring that you get the most out of your equipment.

Siemens Gearmotor solutions exemplify how innovative gearbox configurations can streamline processes, reduce downtime, and ultimately drive productivity in industrial automation. By leveraging the right gearbox design, businesses can unlock a new level of operational efficiency and maintain a competitive edge.

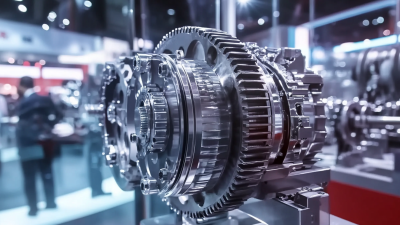

Innovative Technologies in Siemens Gearmotor Gearboxes Enhancing Productivity

In today's fast-paced industrial landscape, unlocking efficiency is paramount for businesses aiming to boost productivity.

Siemens Gearmotor gearbox solutions exemplify innovative technologies that significantly enhance operational performance.

By integrating advanced drive components, such as variable frequency drives and motion control motors, these gearboxes provide seamless functionality and precision control.

Such advancements not only simplify system design but also promote energy efficiency,

ensuring that operations remain sustainable without compromising on power.

The synergy of servo geared motors with cutting-edge control technology allows for meticulous coordination between various elements of the drive system.

This integration enables manufacturers to tailor their equipment to specific applications, optimizing processes in ways previously unattainable.

As businesses increasingly seek to maximize output while minimizing downtime, leveraging these innovative gearbox solutions becomes crucial for maintaining a competitive edge in the market.

Embracing these technologies will pave the way for enhanced productivity and streamlined operations, making them indispensable in modern industrial settings.

Case Studies: Real-World Impact of Siemens Gearmotor Solutions on Efficiency

Siemens gearmotor solutions have demonstrated significant real-world impacts on operational efficiency across various industries. In manufacturing, for instance, a leading automotive assembly line integrated Siemens gearmotors to streamline its production process. The result was a 20% increase in output due to enhanced torque delivery and optimized speed control. This upgrade not only minimized downtime but also improved the overall reliability of machinery, showcasing how advanced gearmotor technology can transform production lines.

In the food processing sector, a company faced challenges with energy consumption while maintaining product quality. By switching to Siemens gearmotors, they achieved a substantial reduction in energy usage—reporting up to 15% savings annually. The precise engineering of the gearboxes contributed to smoother operations, reducing wear and tear on equipment and cutting maintenance costs. These case studies highlight the profound effects Siemens gearmotor solutions can have on productivity and sustainability, making them an essential choice for businesses aiming to improve their efficiency.

Unlocking Efficiency with Gearmotor Gearbox Solutions - Case Studies: Real-World Impact on Efficiency

| Case Study |

Industry |

Operational Improvement (%) |

Energy Savings (%) |

Implementation Time (Months) |

| Case Study 1 |

Food Processing |

25% |

15% |

6 |

| Case Study 2 |

Packaging |

30% |

20% |

4 |

| Case Study 3 |

Textiles |

20% |

10% |

5 |

| Case Study 4 |

Automotive |

35% |

25% |

8 |

| Case Study 5 |

Pharmaceuticals |

28% |

18% |

7 |

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor