- SIEMENS Gearmotor

- NORD Industrial Gear Unit

- LENZE Gearmotor

- NORD Gearmotor

- SEW Planetary Gear Unit

- SEW Industrial Gear Unit

- SEW Gearmotor

- BONFIGLIOLI Precision Planetary Gearbox and Gearmotor

- BONFIGLIOLI Inverters and Servo drives

- BONFIGLIOLI Industrial Gear Unit

- BONFIGLIOLI Gearmotor

- FLENDER Coupling

- FLENDER Gear Unit

01

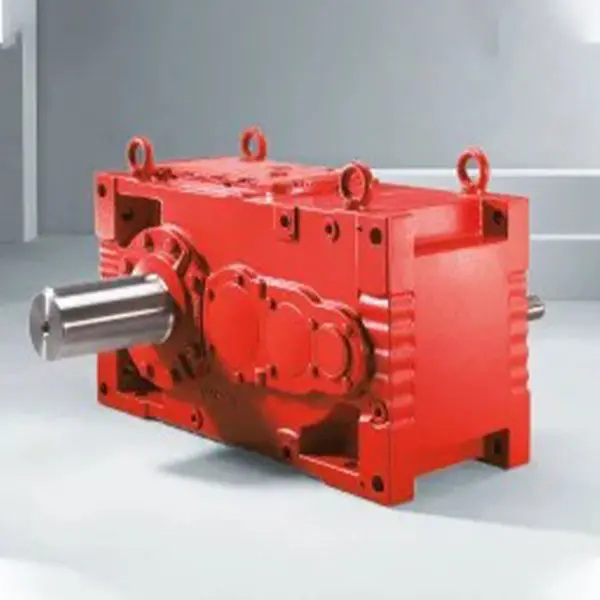

MC series industrial gear units gearunit gearbox

description

MC series industrial gear units are optimal for applications with high radial loads

The MC series helical gear units and bevel-helical gear units are equipped for high axial and radial loads. With our extended bearing distance (EBD) concept we reinforce the bearing in the gear unit. This is a benefit for you if you use agitating processes in process engineering plants. In many cases, you no longer need a separate agitator bearing. Or you avoid oversizing your industrial gear unit.

The concept is supplemented by standardised mounting flanges and an optional "Drywell" seal. The seal reliably prevents oil from leaking from the output shaft of your industrial gear unit. With it, you will reduce your maintenance costs to a minimum.

The modular concept of the MC series helical gear unit and bevel-helical gear unit also provides you with plenty of optional equipment. It includes motor adapters, belt drives, and backstops. These options means that we can always provide you with the drive solution that perfectly meets your requirements.

Your benefits

Variable assembly

with the one-piece, robust mono block, which enables horizontal, vertical and upright assembly.

Additional cost reductions

thanks to the extended bearing distance concept which reinforces the bearing in the gear unit and eliminates the need for a separate agitator bearing.

Minimal maintenance

as a result of the optional "Drywell" seal, which reliably prevent oil leakage from the output shaft of your industrial gear unit.

Easy expansion

with the modular concept consisting of many optional equipment such as motor adapters, belt drives and backstops.

Features

Independent industrial gear unit series

Helical gear units and bevel-helical gear units

Modular concept

Special designs are available

Block housing without parting line

Universal mounting position

All commercially available connection elements are possible at the input and output sides

EBD concept with predefined output bearing types depending on the requirement profile and application

Optional variable flange geometries and "Drywell" design

Optional in ATEX design (Group II, categories 2/3G and 2/3D, zones 1, 21, 2 and 22)

Technical data

| Gear unit type | Stages | Gear ratio i |

Nominal torque MN2 kNm |

|---|---|---|---|

| MC.P.. helical gear units: | 2- and 3-stage | 7.1 – 112 | 6 – 65 |

| MC.R.. bevel-helical gear units: | 2- and 3-stage | 7.1 – 112 | 6 – 65 |

Areas of application

As high-power drives, they are used in a variety of industrial sectors, for example, in the:

Construction materials industry, extractive industry, chemical industry, food and feed industries in materials handling systems

Environmental industry

Lumber industry

Paper industry

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150 SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage SIEMENS SINAMICS V90

SIEMENS SINAMICS V90 SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage FLENDER Gear Unit

FLENDER Gear Unit FLENDER Helical Gear Unit

FLENDER Helical Gear Unit Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox Playmaker In The Premium League

Playmaker In The Premium League Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200 Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships Reliable Power Generation on board

Reliable Power Generation on board Maximum performance level, fast deliverable

Maximum performance level, fast deliverable Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable. FLENDER Coupling

FLENDER Coupling ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance SEW Gearmotor

SEW Gearmotor R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor