- SIEMENS Gearmotor

- NORD Industrial Gear Unit

- LENZE Gearmotor

- NORD Gearmotor

- SEW Planetary Gear Unit

- SEW Industrial Gear Unit

- SEW Gearmotor

- BONFIGLIOLI Precision Planetary Gearbox and Gearmotor

- BONFIGLIOLI Inverters and Servo drives

- BONFIGLIOLI Industrial Gear Unit

- BONFIGLIOLI Gearmotor

- FLENDER Coupling

- FLENDER Gear Unit

01

N-EUPEX Flexible high performance Coupling

Your benefits at a glance

N-EUPEX couplings are designed on the modular principle and have a very simple construction. N-EUPEX types are made up of subassemblies to suit requirements. The couplings are assembled by simply fitting the coupling halves together. Wear is restricted to the elastomer flexibles, which must be replaced at the end of their service life.

Depending on type, the elastomer flexibles can be changed without moving the coupled machines.

The coupling parts are readily available from stock and are mostly finish-machined, i.e. with finished bore, keyway, set screw and balancing.

application

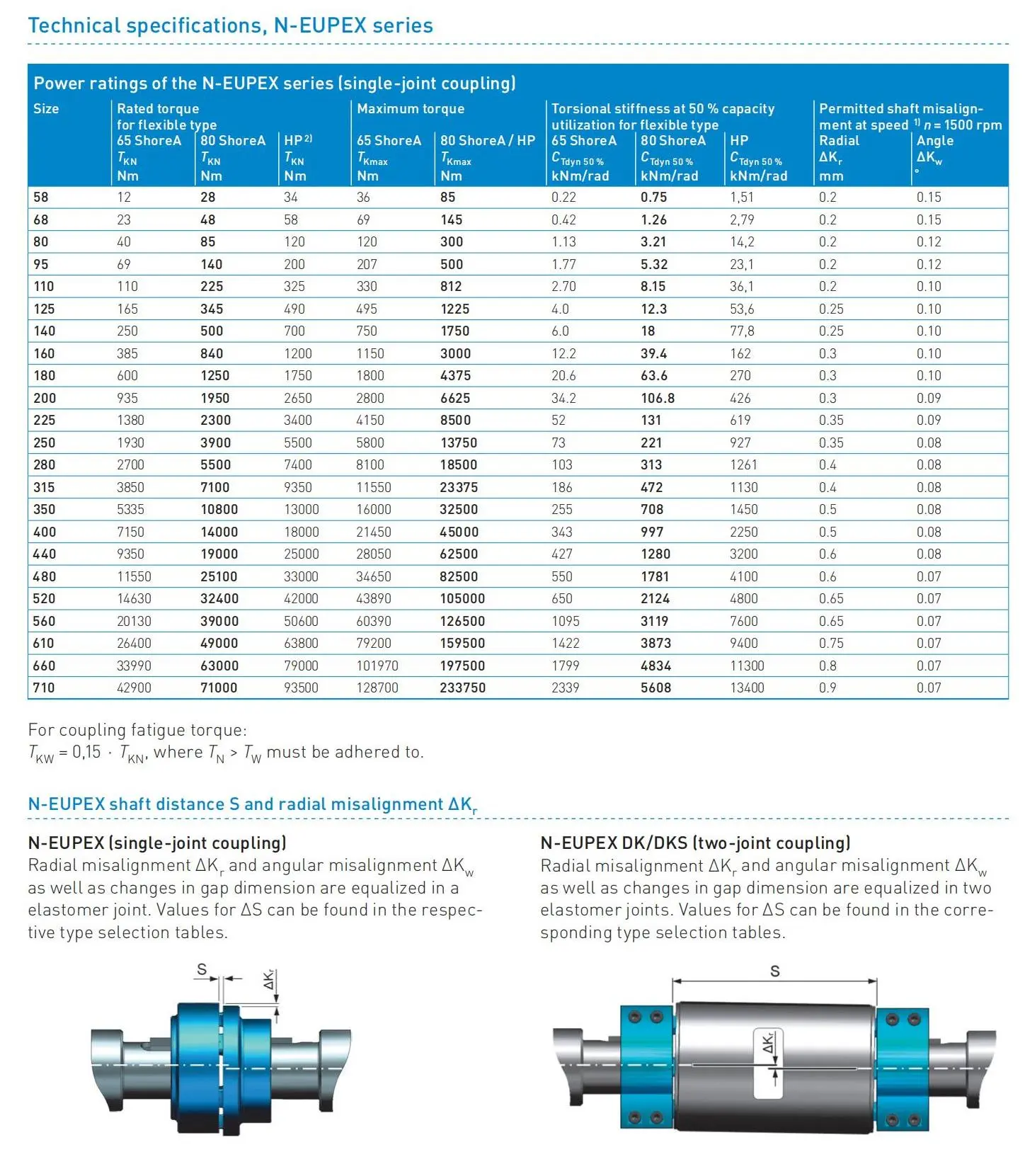

The N-EUPEX coupling is available as a catalog standard in 23 sizes with a rated torque of between 28 Nm and 71000 Nm. The coupling is suitable for ambient tempera tures of between -30 °C and +80 °C. By using alternative elastomer flexibles, the permissible ambient temperature range can be extended to between -50 °C and +100 °C.

Frequently, the coupling is used to connect the motor to the gear unit input shaft. The coupling is suitable especially for drives with uniform to average dynamic loads.

Examples of applications are pump drives, ventilator drives or crane running gear. Furthermore, N-EUPEX couplings can be used as add-on couplings, particularly on FLUDEX fluid couplings or ARPEX AKR safety couplings.

In the case of drives with a diesel engine, N-EUPEX couplings are suitable for driven machines with a low mass moment of inertia. In the case of diesel engine drives, the actual dynamic coupling load should be checked by measurement or torsional vibration calculations.

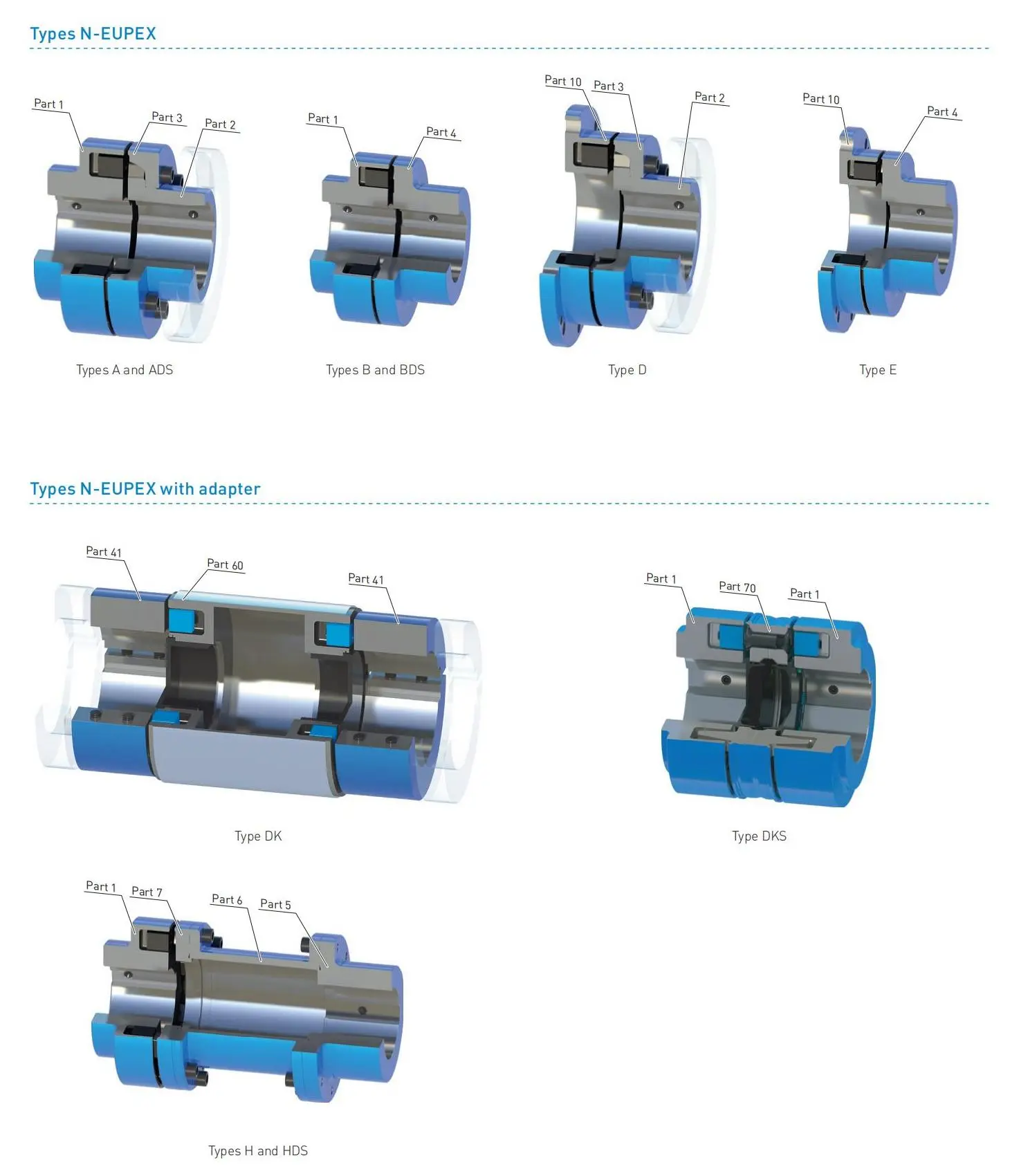

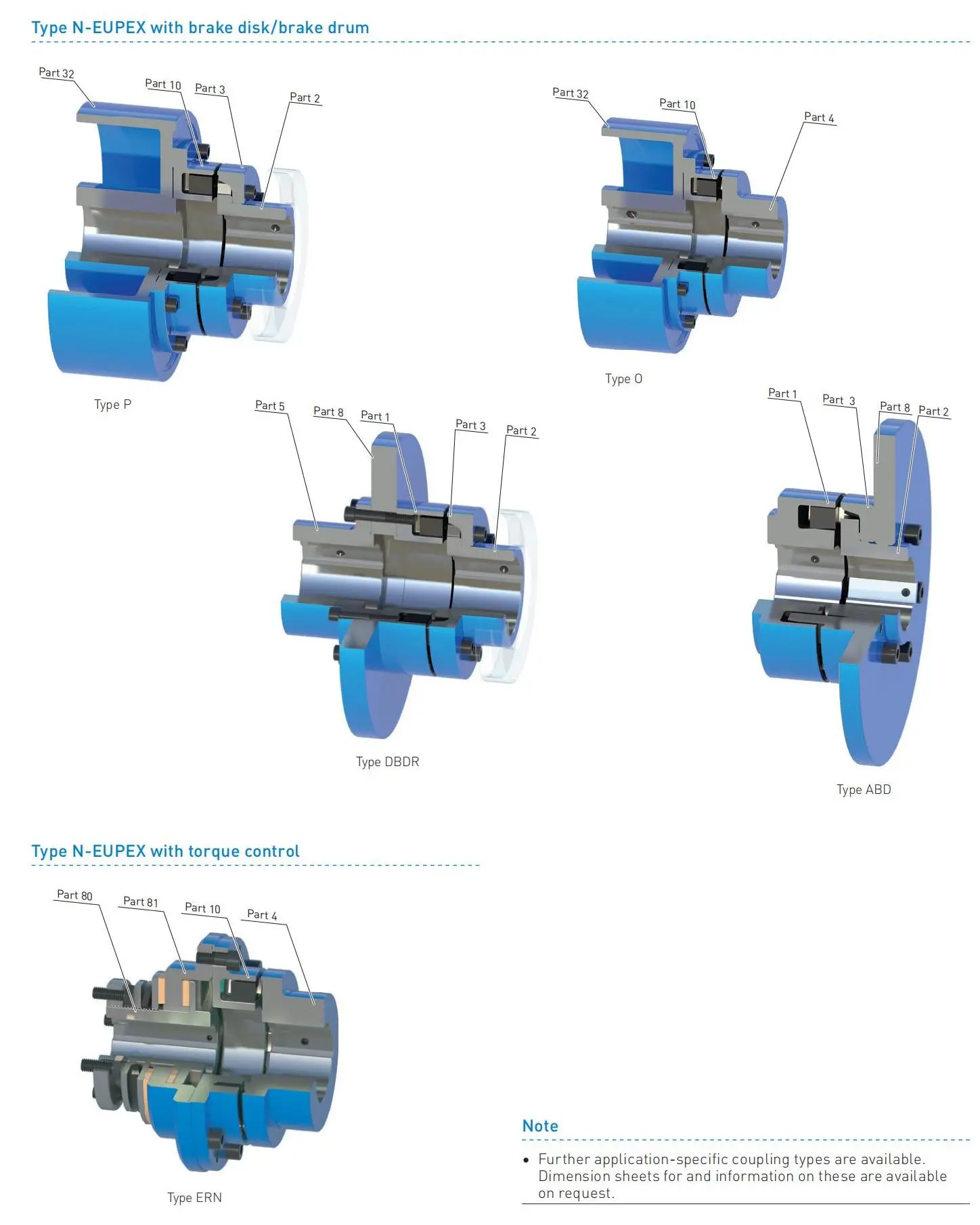

Design and configurations

The teeth are lubricated with grease. On the ZAPEX type

N-EUPEX and N-EUPEX DS couplings consist of two coupling halves mounted on the machine shafts. The

coupling parts are connected positively by means of elastomer flexibles. On the two-part variant, the elastomer flexibles can be changed only if one of the coupled

machines is moved.

On the three-part variants, the bolted cam ring can be released and moved to enable the flexible to be changed without moving the coupled machines.

Elastomer flexible of the N-EUPEX series

The flexibles of the N-EUPEX coupling are subjected to compression. This results in progressive torsion spring characteristics. If the flexibles are irreparably damaged, the hub parts come into contact with metal. This causes the torque to continue to be transmitted in “emergency

mode” for a short period of time.

Elastomer flexible of the N-EUPEX DS series

The flexibles of the N-EUPEX DS series are subjected to compression and bending forces. A linear torsion spring

characteristic curve is characteristic in this regard. If the flexibles are irreparably damaged, the metal parts turn against one another without contact, and the power trans mission is separated. Fitting new flexibles will make the coupling once more usable. The capacity of the N-EUPEX

DS series to shed overloads is especially in demand for highly sensitive machines.

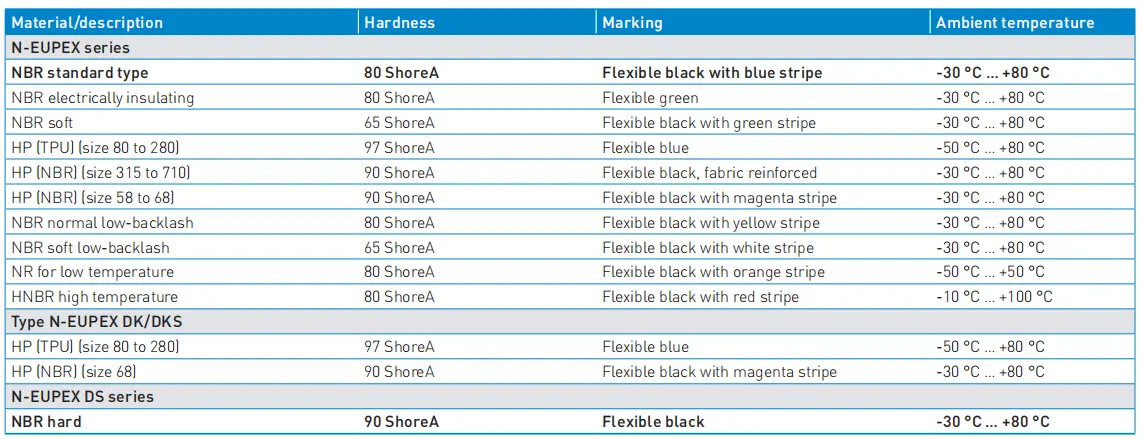

Materials

All coupling parts such as cam parts, pocket parts, spacers, hub parts and mounting parts are manufactured from high grade cast iron with lamellar or spheroidal graphite, or from steel. The sleeve pipes of the type DK spacers are made from aluminum.

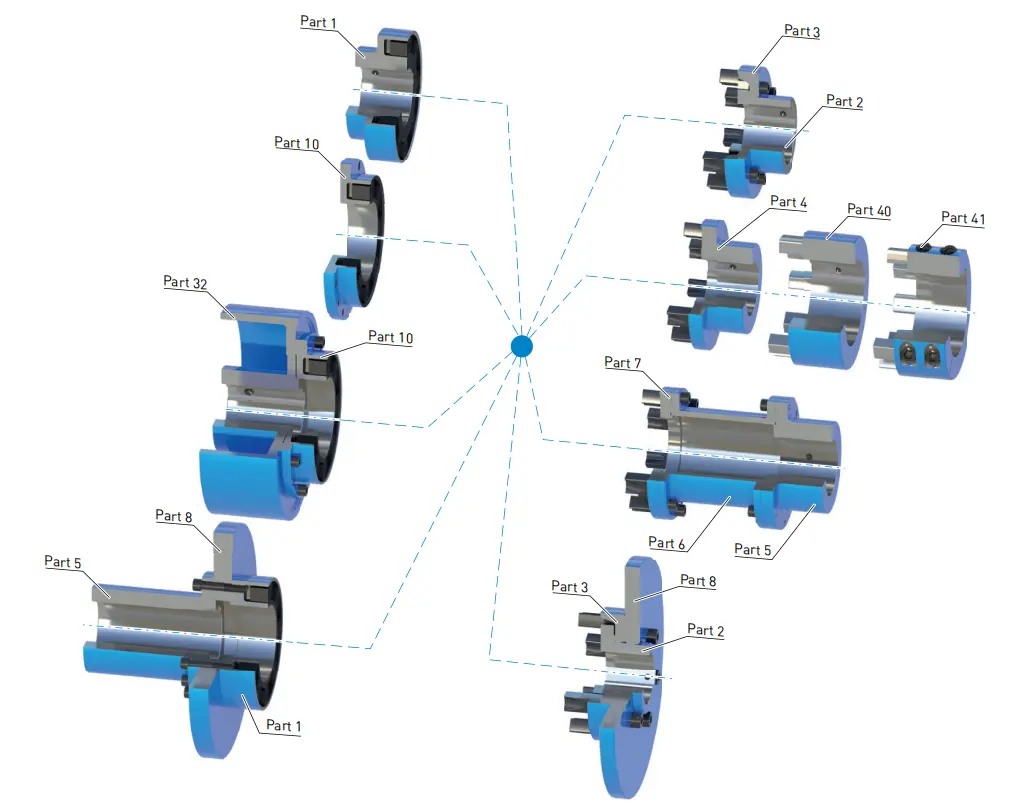

Modular principle of N-EUPEX types

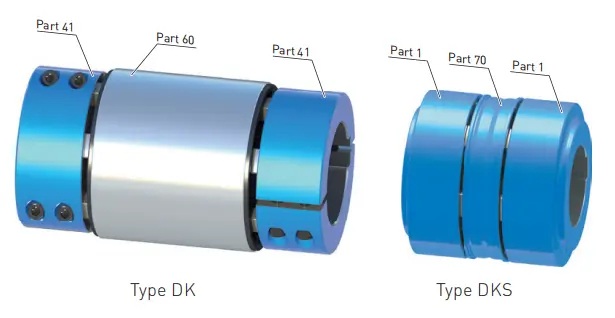

N-EUPEX DK/DKS

In the case of larger radial misalignment, double-cardanic N-EUPEX couplings can be supplied in addition to the modular system.

The spacer (part 60 resp. 70) is centered with the help of the N-EUPEX elastomer elements.

Any radial misalignment that emerges between the shaft ends will accordingly be equalized through a corresponding tilt angle

in the elastomer joints with this two-joint versions. In the DK version, the separated hubs (part 41) made from steel facilitate simple installation. The DKS version is characterized by a reduced shaft distance.

GENERAL

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150 SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage SIEMENS SINAMICS V90

SIEMENS SINAMICS V90 SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage FLENDER Gear Unit

FLENDER Gear Unit FLENDER Helical Gear Unit

FLENDER Helical Gear Unit Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox Playmaker In The Premium League

Playmaker In The Premium League Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200 Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships Reliable Power Generation on board

Reliable Power Generation on board Maximum performance level, fast deliverable

Maximum performance level, fast deliverable Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable. FLENDER Coupling

FLENDER Coupling ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance SEW Gearmotor

SEW Gearmotor R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor