0102030405

Innomotics SG Gearmotor products help hot dip galvanizing production line

2025-03-10

Chengdu Star Technologies Co.,Ltd.

Located in Hebei Province, the project has newly built two world-leading continuous hot-dip galvanizing production lines, which are committed to providing low-carbon, green and lightweight material solutions for new energy vehicles and high-end brand vehicles.

Located in Hebei Province, the project has newly built two world-leading continuous hot-dip galvanizing production lines, which are committed to providing low-carbon, green and lightweight material solutions for new energy vehicles and high-end brand vehicles.

It is understood that the project adopts high-strength ultra-thin specification process technology and unique galvanizing technology to produce high-strength hot-dip galvanized alloyed coated steel plates, which greatly improves the corrosion resistance, coating adhesion and welding performance of the material, and extends the service life of the car body and components. Innomotics-SG reduction motor products escort the project with high-efficiency motors, excellent Gearbox technology and mature drive solutions, and make positive contributions to the project's carbon reduction.

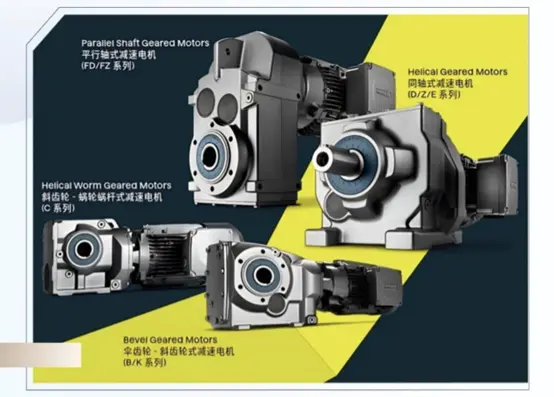

SG Gearmotors can provide comprehensive product solutions for steel mills. According to the gearbox type, they are divided into coaxial E/Z/D series, parallel shaft F series, right-angle shaft-helical bevel gear B/K series. According to the gearbox and the number of stages, the efficiency of the hardened tooth surface series is between 94-98%, which is leading in the industry. According to the current energy efficiency standards, the motors can currently be configured with IE3, IE4 and IE5 series high-efficiency motors. At the same time, according to the working conditions of the customer's steel mill, we can also provide IC410 fanless cooling motors, IC411 self-cooling fan motors and IC416 forced cooling fan motors; as well as customized reduction motor products according to special on-site needs.

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150 SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage SIEMENS SINAMICS V90

SIEMENS SINAMICS V90 SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage FLENDER Gear Unit

FLENDER Gear Unit FLENDER Helical Gear Unit

FLENDER Helical Gear Unit Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox Playmaker In The Premium League

Playmaker In The Premium League Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200 Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships Reliable Power Generation on board

Reliable Power Generation on board Maximum performance level, fast deliverable

Maximum performance level, fast deliverable Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable. FLENDER Coupling

FLENDER Coupling ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance SEW Gearmotor

SEW Gearmotor R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor