- SIEMENS Gearmotor

- NORD Industrial Gear Unit

- LENZE Gearmotor

- NORD Gearmotor

- SEW Planetary Gear Unit

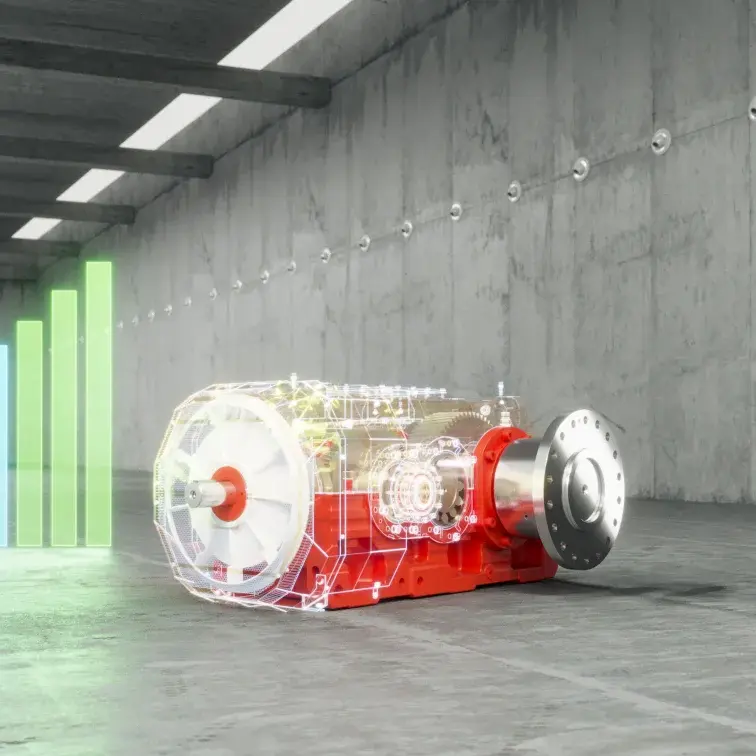

- SEW Industrial Gear Unit

- SEW Gearmotor

- BONFIGLIOLI Precision Planetary Gearbox and Gearmotor

- BONFIGLIOLI Inverters and Servo drives

- BONFIGLIOLI Industrial Gear Unit

- BONFIGLIOLI Gearmotor

- FLENDER Coupling

- FLENDER Gear Unit

01

X.e Helical Gear Unit / Bevel Helical Gear Unit

description

One standard product – numerous possibilities

For operators or original equipment manufacturers of machines and plants, it is crucial that the drives used there are robust, reliable and easy to maintain. The industrial gear units of the X..e series efficiently meet these requirements.

The intelligent, universal gear unit concept impresses with its fine size graduation, high installation variability and the large number of additional modular features and options such as motor adapters, backstop, various sealing and shaft systems, and many more. The wide ratio range of 6.3 - 450 and the robust design make the All-Rounder the right choice in many industries and applications. Whether crane, conveyor belt or mixer - with the X..e series and the industry know-how of SEW-EURODRIVE, you are opting for maximum availability and a reliable partner. And if our modular system does not have the right solution for you, we will customise our gear units for you.

Your advantages

Power

Increase in nominal torques even with additional external loads for a reduction in size. Result: lower investment costs and smaller installation space in the plant.

Safety

Installation individual rolling bearings with short delivery times such as thermal design according to simulated ambient conditions. Result: less maintenance intervals and higher plant availability.

Efficiency

A sustainable drive solution thanks to extensive adaptation and optimisation options. Result: reduced power loss, lower oil demand, and lower total cost of ownership.

Features

Properties and features of the X..e series industrial gear units

Independent industrial gear unit platform with 23 sizes

Helical gear units and bevel-helical gear units

Single-piece and split gear unit housing

Invertible gear unit housing

Universal mounting positions

Distinctive modular technology

Diverse predefined optional equipment and options

Customer-specific adaptations possible

Technical data

| Gear unit design | Stages | Gear ratio i | Nominal torque MN2 kNm |

| Helical gear unit X.F.100e – X.F.320e |

2 to 4 stages | 6.3 – 450 | 7.2 – 500 |

| Bevel-helical gear unit X.K.100e – X.K.320e |

2 to 4 stages | 6.3 – 450 | 7.2 – 500 |

| Bevel-helical gear unit* X.T.100e – X.T.250e |

3 and 4 stages | 12.5 – 450 | 7.2 – 185 |

Areas of application

Our helical and bevel-helical gear units are used wherever reliably high torques are required. The modular design with many additional features and options allows the X..e series to be individually adapted to your application-specific requirements.

In use worldwide:

Mining and open pit mining

Recycling industry

Crane technology

Water and wastewater technology

Steel industry

and many more

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150 SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage SIEMENS SINAMICS V90

SIEMENS SINAMICS V90 SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage FLENDER Gear Unit

FLENDER Gear Unit FLENDER Helical Gear Unit

FLENDER Helical Gear Unit Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox Playmaker In The Premium League

Playmaker In The Premium League Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200 Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships Reliable Power Generation on board

Reliable Power Generation on board Maximum performance level, fast deliverable

Maximum performance level, fast deliverable Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable. FLENDER Coupling

FLENDER Coupling ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance SEW Gearmotor

SEW Gearmotor R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor