How to Choose the Right Nordmkygearbox for Your Industrial Needs

In today's competitive industrial landscape, selecting the right equipment is crucial for optimizing performance and ensuring operational efficiency. One essential component that often plays a significant role in mechanization is the Nordmkygearbox, renowned for its reliability and durability across various applications. According to a recent industry report by Research and Markets, the global gearbox market is projected to reach $38 billion by 2026, growing at a CAGR of 5.2% from 2021 to 2026. This growth highlights the increasing reliance on quality gear systems that can handle demanding conditions while providing consistent output. As industries evolve, understanding the specific needs for gearboxes, such as torque capacity, efficiency, and environmental constraints, becomes imperative. This guide aims to equip you with the knowledge to choose the right Nordmkygearbox tailored to your operational requirements, ensuring that your machinery operates at peak performance with the best possible return on investment.

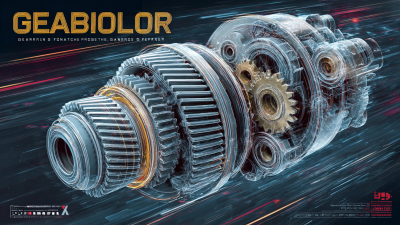

Understanding the Different Types of Nordmkygearboxes Available

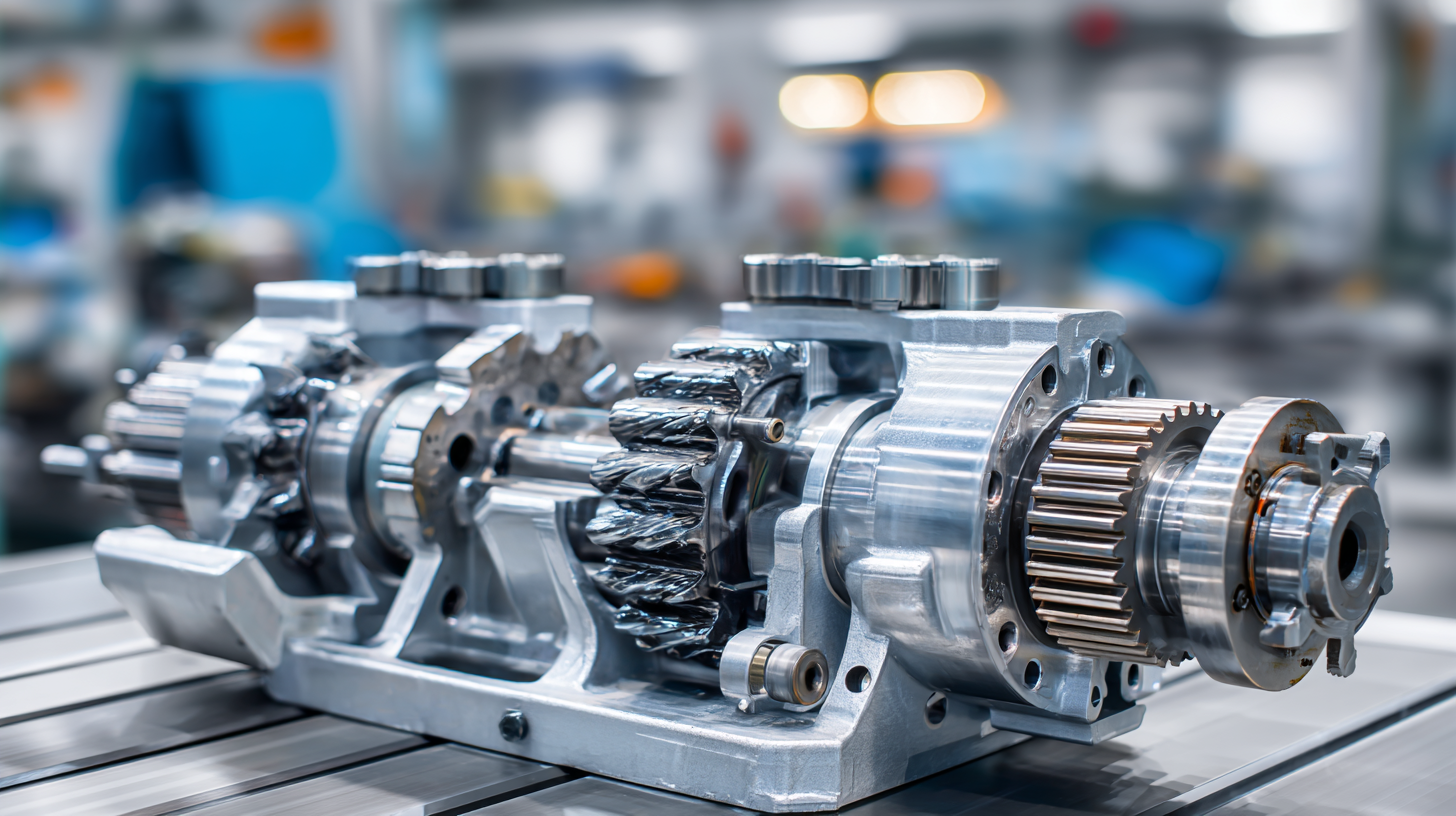

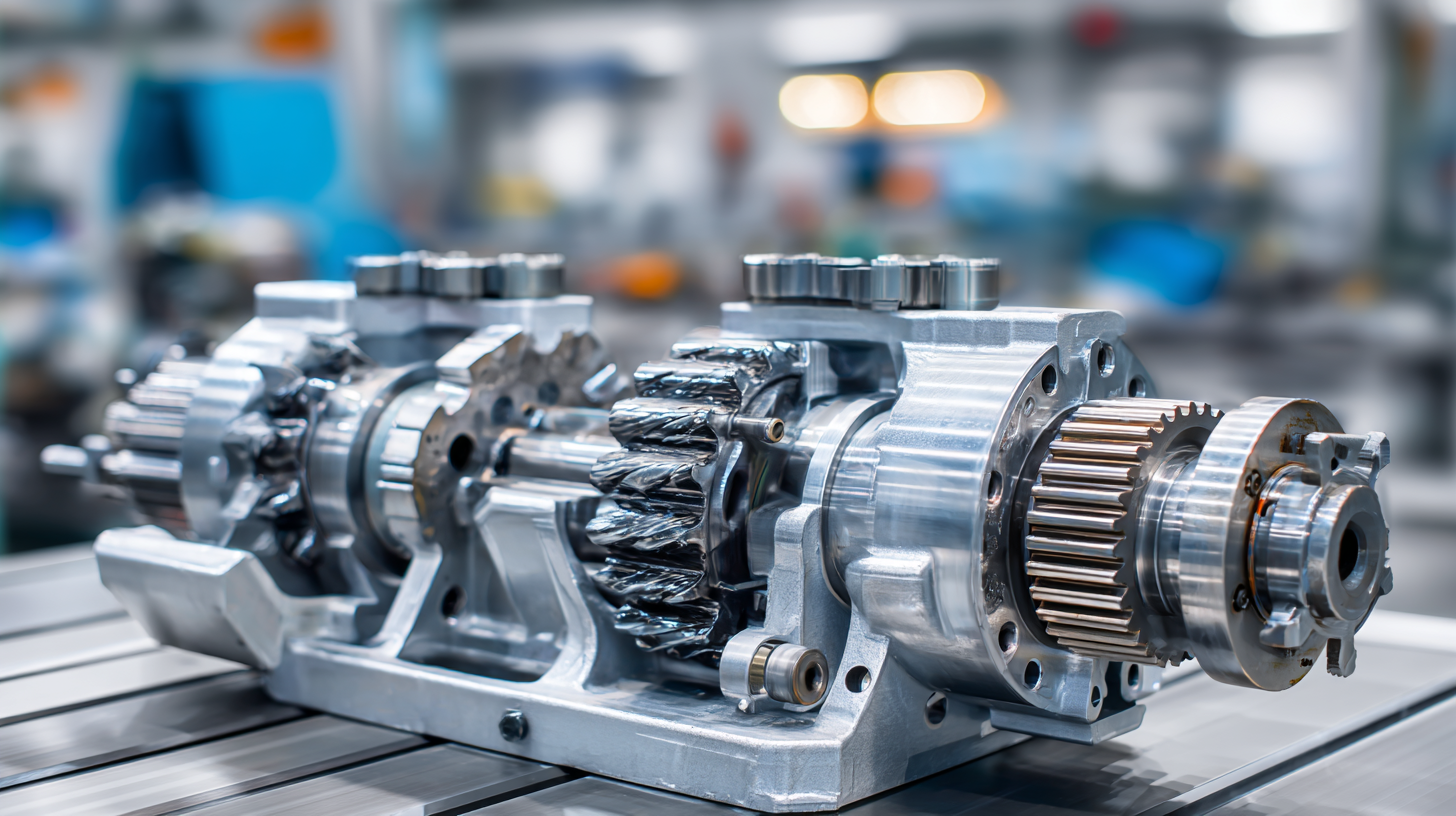

When selecting the right Nordmkygearbox for industrial applications, understanding the various types available is crucial. Nordmkygearbox options come in several forms, including inline gearboxes, right-angle gearboxes, and specialized designs tailored to specific needs. Each type offers distinct advantages in terms of torque capacity, space efficiency, and operational speed, making it essential to evaluate your operational requirements before making a choice.

Inline gearboxes are ideal for applications where space is a concern, as they allow for compact designs while providing efficient power transfer. On the other hand, right-angle gearboxes are perfect for scenarios requiring direction change in drive systems, making them versatile for various machinery setups. Additionally, specialized gearboxes can be engineered to meet unique specifications, ensuring maximum efficiency in niche applications. By gaining a comprehensive understanding of these different types, you can make an informed decision that aligns with your industrial needs, ultimately enhancing performance and productivity.

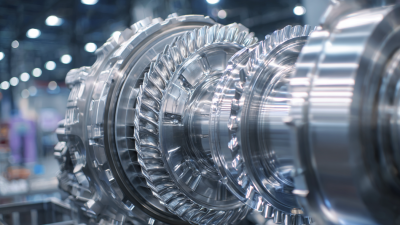

Key Factors to Consider When Selecting a Nordmkygearbox

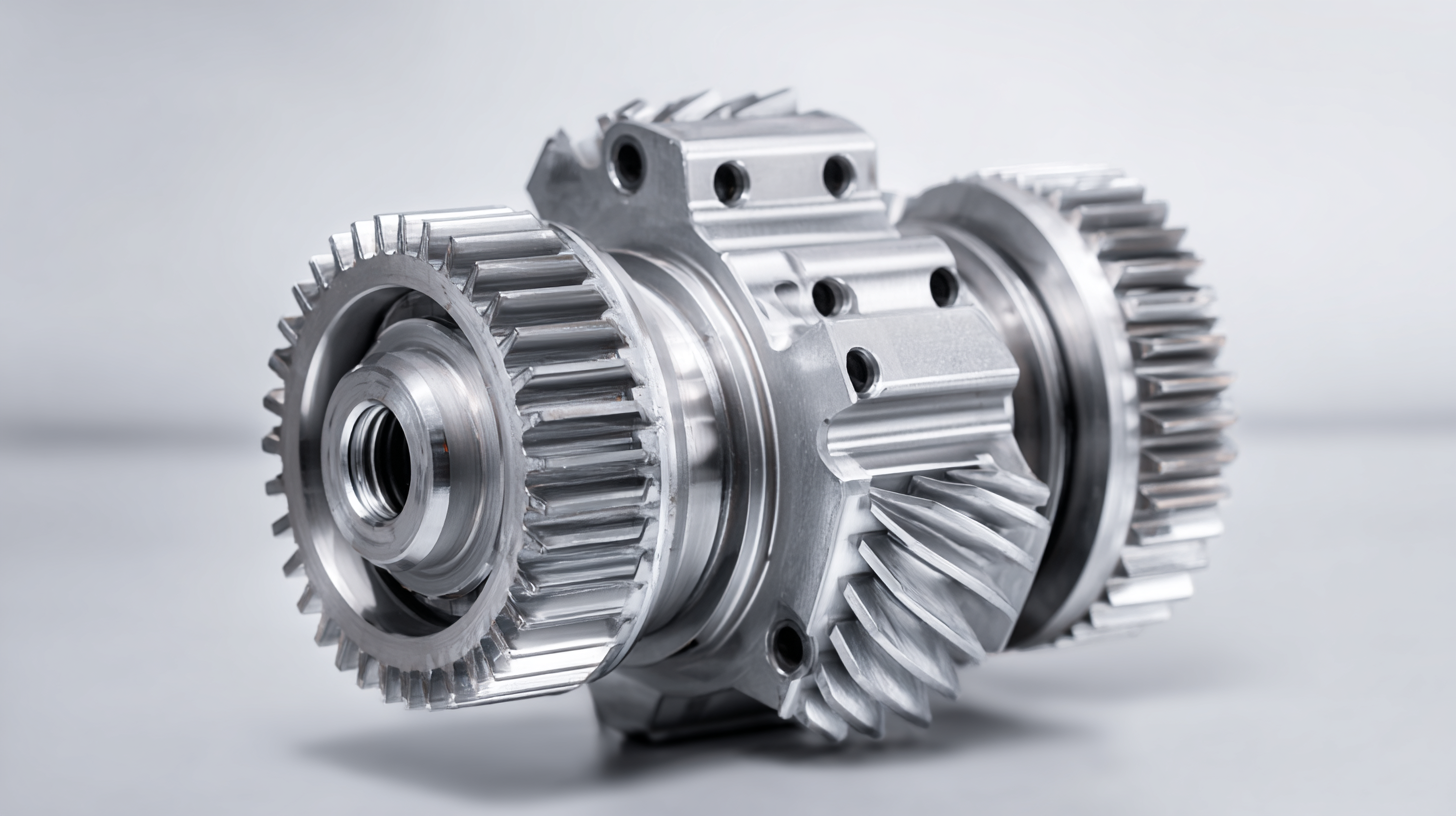

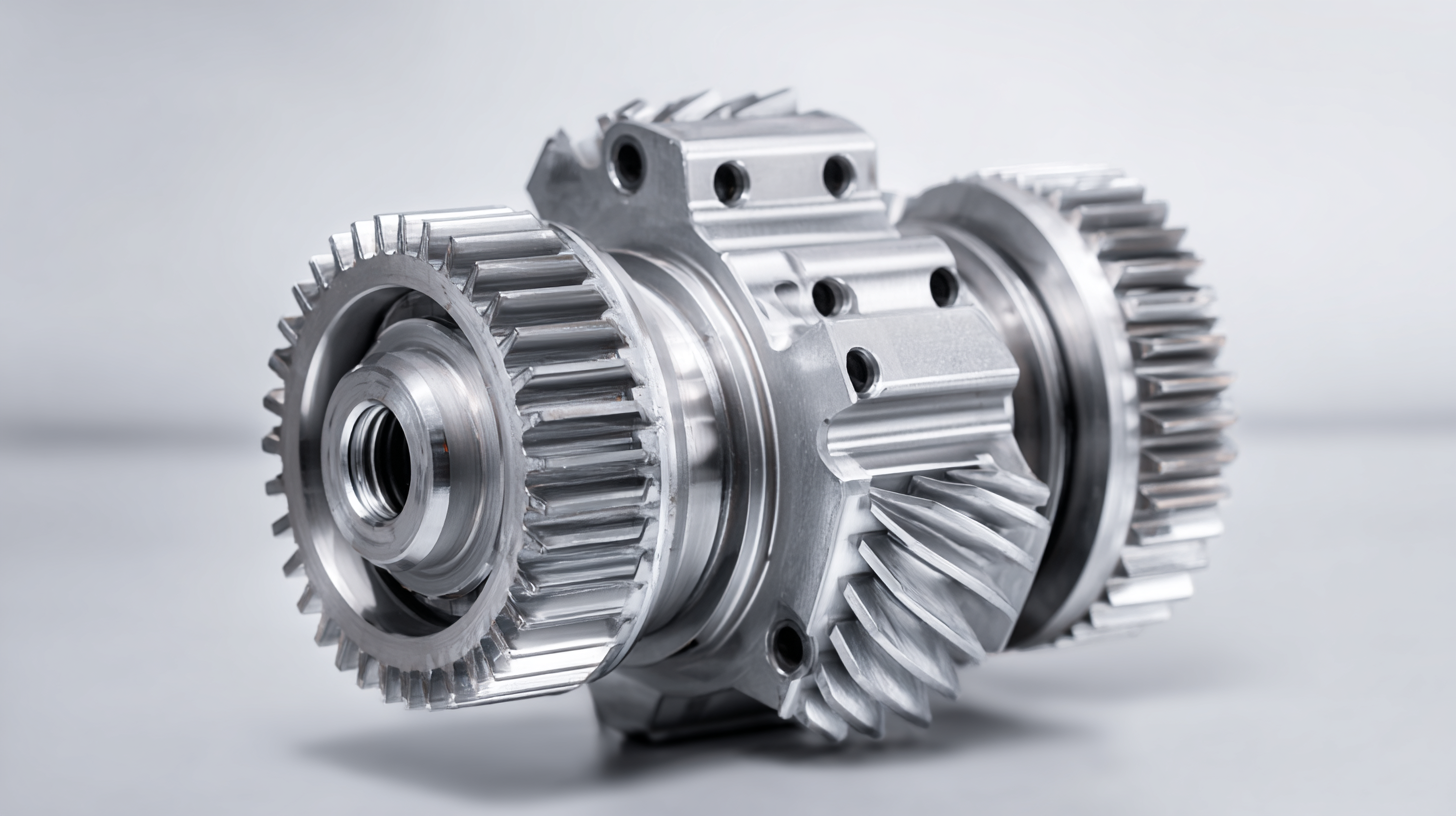

When selecting the right Nordmkygearbox for your industrial needs, several key factors come into play. First and foremost, it is essential to assess the specific requirements of your application. Consider the load capacity, speed range, and output torque needed for optimal performance. Different models are designed to handle varying power levels, so matching your requirements with the specific capabilities of the gearboxes available is crucial.

When selecting the right Nordmkygearbox for your industrial needs, several key factors come into play. First and foremost, it is essential to assess the specific requirements of your application. Consider the load capacity, speed range, and output torque needed for optimal performance. Different models are designed to handle varying power levels, so matching your requirements with the specific capabilities of the gearboxes available is crucial.

Tip: Always consult the manufacturer’s documentation to understand the technical specifications better. This will ensure that you are well-informed about the performance limitations and advantages of the different gearboxes before making a purchase.

Another critical factor is the environment in which the gearbox will operate. High humidity, extreme temperatures, or exposure to corrosive substances can significantly impact the longevity and efficiency of the gearbox. Therefore, selecting a model that is designed to withstand these conditions is vital.

Tip: Investing in a gearbox with proper sealing and protection against environmental factors can greatly enhance its lifespan and reduce maintenance costs, ensuring smooth operations over time.

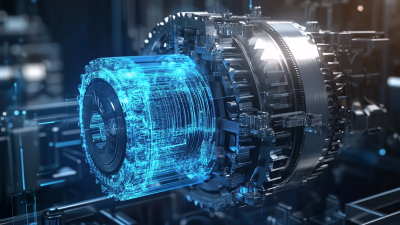

Comparing Performance Metrics of Various Nordmkygearbox Types

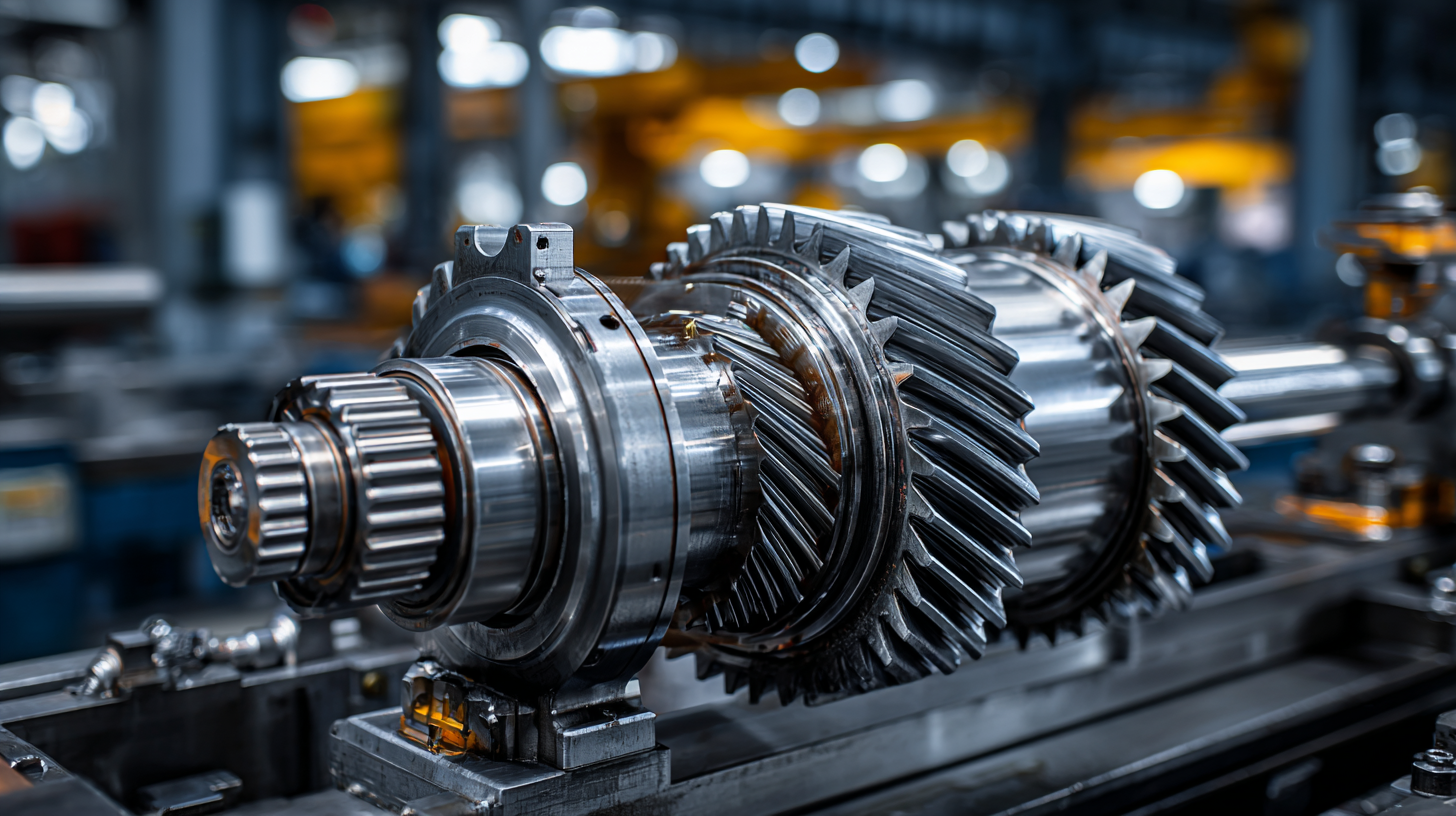

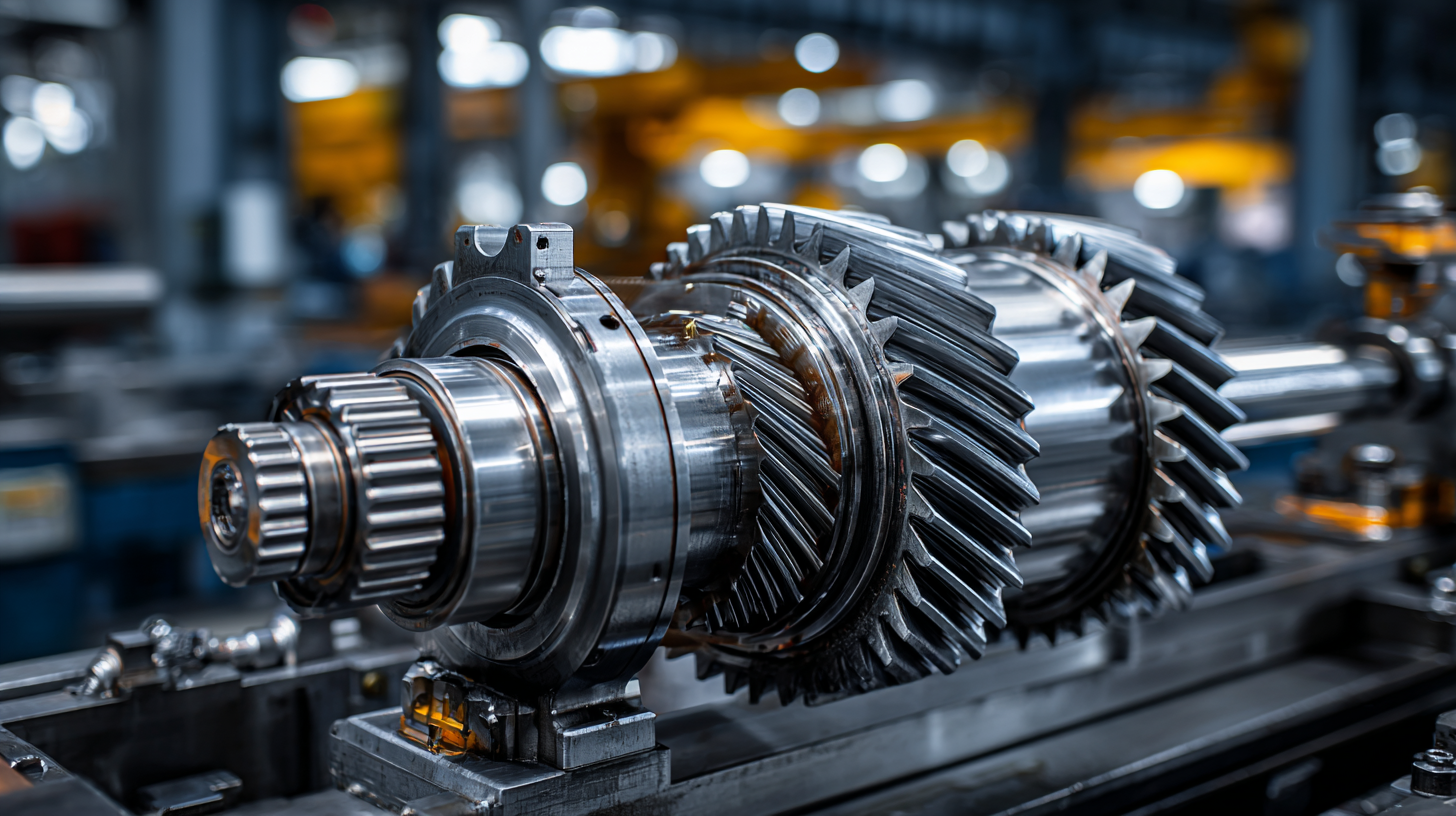

When selecting the appropriate Nordmkygearbox for industrial applications, understanding the performance metrics of various gearbox types is crucial. A recent report from the American Gear Manufacturers Association (AGMA) highlights that gearboxes account for over 90% of industrial drive systems, making their efficiency vital for reducing operational costs. In particular, Nordmkygearboxes are noted for their robustness and high torque capabilities, with torque ratings that can range from 25 Nm to over 50,000 Nm, depending on the model. For instance, the Nord SK 9000 series excels in performance within high-load applications, achieving efficiency ratings of up to 98%, which is essential for energy conservation in heavy-duty operations.

Additionally, comparing input speed performance reveals significant differences among gearbox designs. Standard Nordmkygearboxes can accommodate input speeds from 1,000 to 3,000 RPM, while specialized variants, such as inline and worm gear models, offer lower speed options that ensure enhanced durability under load. According to a recent article by the International Journal of Mechanical Engineering, choosing a gearbox that correlates with specific application requirements can lead to a reduction in energy consumption by as much as 30%. This selection process not only enhances performance but also prolongs service life, thereby securing a favorable return on investment for industrial operations.

Performance Metrics of Various Nordmkygearbox Types

Industry Applications: Choosing the Right Nordmkygearbox for Your Needs

When selecting a Nordmkygearbox for industrial applications, it’s essential to consider the specific needs of your operation. Different industries have varying requirements regarding torque, speed, and efficiency. For instance, a report from the International Energy Agency (IEA) highlights that industrial motors consume about 70% of the total electricity used in industrial applications, underlining the importance of choosing a gearbox that optimizes energy consumption. Factors such as load capacity and environmental conditions should also be evaluated, as these directly influence the performance and durability of the gearbox.

**Tip:** Always assess the load requirements of your machinery prior to selection, as this will guide you in choosing a Nordmkygearbox that can handle peak values without risking failure.

Furthermore, industry-specific applications such as material handling, food processing, and mining all demand distinct features from gearboxes. According to a report by MarketsandMarkets, the global market for industrial gearboxes is expected to grow significantly, driven by the need for increased efficiency and higher performance across various sectors. It’s crucial to match the gearbox specifications not just with your current needs but also with future expansions to ensure longevity and reliability.

**Tip:** Consult with your machinery manufacturer to obtain precise specifications that align with your operational requirements, ensuring the selected gearbox can adapt to potential changes in production processes.

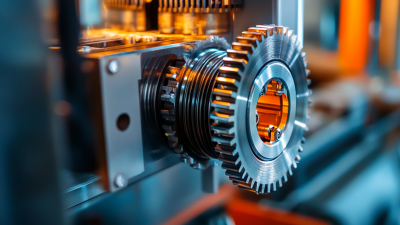

Maintenance and Durability: What to Look for in a Nordmkygearbox

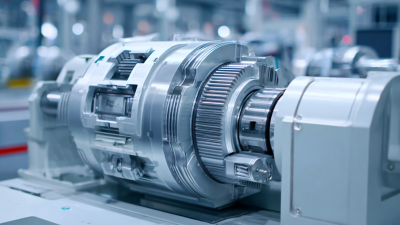

When selecting the right gearbox for industrial applications, maintenance and durability are paramount. The increasing demand for automated systems and energy-efficient machinery has led the gearbox and gear motors market to surging estimates, projected to reach approximately $23.4 billion. A robust gearbox not only contributes to the longevity of the machinery but also ensures that operational downtime is minimized—a crucial factor for maintaining productivity in industrial settings.

In evaluating gearbox options, focus on the materials used in construction. High-quality gearboxes are designed to withstand harsh operating conditions and offer resistance to wear and tear. Features such as sealed bearings and corrosion-resistant finishes can significantly extend the service life of a gearbox. Recent advancements in flexible drive electronics further enhance the performance of modern gearboxes, providing tailored solutions that meet specific industrial needs. As the market continues to innovate, investing in a gearbox with proven durability will ensure reliable performance and support the growing trends towards automation and energy efficiency in the industry.

Home

Products

SIEMENS Gearmotor

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage  SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor  SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor  SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage  SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor  SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage  SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage  SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage  SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage  SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage  SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage  SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage  SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150  SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage  SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage  SIEMENS SINAMICS V90

SIEMENS SINAMICS V90  SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage  FLENDER Gear Unit

FLENDER Gear Unit  FLENDER Helical Gear Unit

FLENDER Helical Gear Unit  Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears  FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox  Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance  Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents  SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox  Playmaker In The Premium League

Playmaker In The Premium League  Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox  Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections  Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces  Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200  Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill  The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox  Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox  Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox  The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships  Reliable Power Generation on board

Reliable Power Generation on board  Maximum performance level, fast deliverable

Maximum performance level, fast deliverable  Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills  Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable.  FLENDER Coupling

FLENDER Coupling  ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling  ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling  N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling  N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling  ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts  N-EUPEX DS Flexible High Performance Coupling

N-EUPEX DS Flexible High Performance Coupling  RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling  N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling  ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling  ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance  ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance  FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance  SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance  BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance  FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance  SEW Gearmotor

SEW Gearmotor

Our Company

News

Case

Contact Us

R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor