- SIEMENS Gearmotor

- NORD Industrial Gear Unit

- LENZE Gearmotor

- NORD Gearmotor

- SEW Planetary Gear Unit

- SEW Industrial Gear Unit

- SEW Gearmotor

- BONFIGLIOLI Precision Planetary Gearbox and Gearmotor

- BONFIGLIOLI Inverters and Servo drives

- BONFIGLIOLI Industrial Gear Unit

- BONFIGLIOLI Gearmotor

- FLENDER Coupling

- FLENDER Gear Unit

01

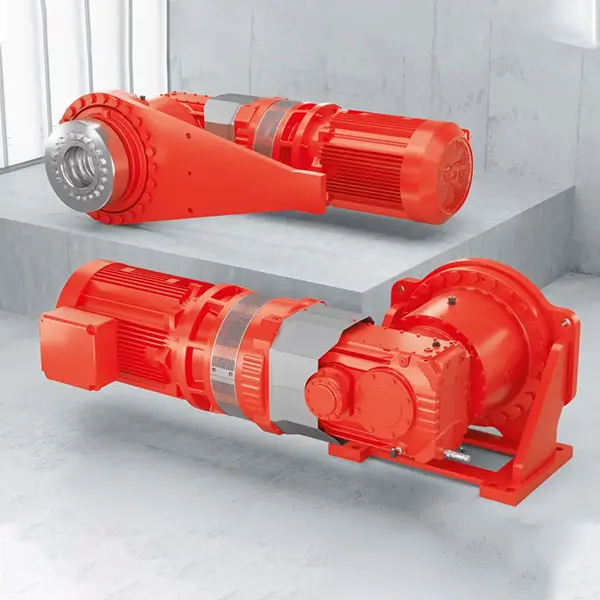

P-X.e Series Industrial Gear Unit Gearbox

description

High torque, high thermal rating

If you need a compact, cost-effective solution with high thermal ratings, our planetary gear units of the P-X.e series are the right solution. These standardised, powerful industrial gear units combine planetary gear units of the P series with primary gear units of the proven X.e series of industrial gear units. As an added benefit, all the mounting options and optional features of the X series are also available for this solution.

To achieve the best possible thermal ratings, we take a holistic approach to surface cooling in the P-X.e gear unit: On the one hand, the cooling fins on the primary gear unit housing significantly increase the surface area of the gear unit. On the other hand, the radial fan in the motor adapter generates a strong air flow. This effectively cools the areas where the main heat is generated.

In addition, a special feature provides even more cooling in the P-X.e transmission. The cast-on intermediate flange on the primary gearbox connects the two gear units, creating a shared oil chamber. This ensures optimum oil circulation between the two gear units. In this way, excess residual heat is dissipated from the planetary gear unit by cooling oil.

The P-X.e series planetary gear unit thus combines all the advantages of two pioneering industrial gear unit concepts.

Compact, flexible and economical

Whether hollow shaft or solid shaft, with or without a key, smooth or spline according to DIN 5480, horizontal, vertical or angled mounting position. The planetary gear units of the P-X.e series as well as the gear units of the P series and Generation X.e offer you all possibilities to adapt to your application.

Your benefits

Space saving

due to a more compact design than other common types of gearboxes of the same performance.

High operational reliability

through a robust gearbox design according to the latest calculation methods and through an FEM-optimized, bending-resistant housing design.

Reduced costs

thanks to the high thermal gear performance, which means that you can dispense with cost-intensive, external cooling systems, depending on the condition.

Flexibility

thanks to a wide range of attachment and equipment options, such as various output shafts, torque support, backstop, and much more.

Complete documentation

via our online support, which provides you with operating instructions, dimension sheets and 3D models at the push of a button.

Features

Features and properties:

High thermal rating

Universally applicable due to distinctive modular technology

Various, predefined additional equipment and options

Can be used in low temperature ranges < -25 °C

Customer specific adaptations are possible

Technical data

| Gear unit type | Gear ratio i |

Nominal torque MN2 kNm |

| P-X.e bevel-helical planetary gear unit: | 160 – 560 | 100 – 500 |

Areas of application

All applications that require mean output speeds and a high torque. For example:

Apron feeders and bucket wheel drives in mining

Filling processes in the cement industry

Material processing systems, e.g. mixers, rotary filters

Drum washing systems in the pulp and paper industry

Particle board systems in the wood industry

Shredding machines in the recycling industry

Drying processes in the construction materials industry

SIEMENS Helical Gearmotor Low Voltage

SIEMENS Helical Gearmotor Low Voltage SIEMENS Bevel Helical Gearmotor

SIEMENS Bevel Helical Gearmotor SIEMENS Parallel Shaft Gearmotor

SIEMENS Parallel Shaft Gearmotor SIEMENS Worm Gearmotor Low Voltage

SIEMENS Worm Gearmotor Low Voltage SIEMENS With Servo Motor Gearmotor

SIEMENS With Servo Motor Gearmotor SIEMENS Low Voltage Motor Low Voltage

SIEMENS Low Voltage Motor Low Voltage SIEMENS High Voltage Motor Low Voltage

SIEMENS High Voltage Motor Low Voltage SIEMENS Marine Motor Low Voltage

SIEMENS Marine Motor Low Voltage SIEMENS Servo Motor Low Voltage

SIEMENS Servo Motor Low Voltage SIEMENS SINAMICS S210 Low Voltage

SIEMENS SINAMICS S210 Low Voltage SIEMENS SINAMICS S150 Low Voltage

SIEMENS SINAMICS S150 Low Voltage SIEMENS SINAMICS S120 Low Voltage

SIEMENS SINAMICS S120 Low Voltage SIEMENS SINAMICS G130/G150

SIEMENS SINAMICS G130/G150 SIEMENS SINAMICS G120 Low Voltage

SIEMENS SINAMICS G120 Low Voltage SIEMENS SINAMICS G120C Low Voltage

SIEMENS SINAMICS G120C Low Voltage SIEMENS SINAMICS V90

SIEMENS SINAMICS V90 SIEMENS SINAMICS V70 Low Voltage

SIEMENS SINAMICS V70 Low Voltage FLENDER Gear Unit

FLENDER Gear Unit FLENDER Helical Gear Unit

FLENDER Helical Gear Unit Flender gear units for lifting and luffing gears

Flender gear units for lifting and luffing gears FLENDER Gear Unit gearunit gearbox

FLENDER Gear Unit gearunit gearbox Optimal Drive Solution For Maximum Performance

Optimal Drive Solution For Maximum Performance Strongly operating against biodegradable constituents

Strongly operating against biodegradable constituents SINGLE SCREW Special industry dedicated gearunit gearbox

SINGLE SCREW Special industry dedicated gearunit gearbox Playmaker In The Premium League

Playmaker In The Premium League Conveyor belts gearunit gearbox

Conveyor belts gearunit gearbox Paper And Pulp Preparation Sections

Paper And Pulp Preparation Sections Operational Reliability Even In Case Of The Highest Ventilation Forces

Operational Reliability Even In Case Of The Highest Ventilation Forces Reliable Gear Units For High Performance Vertical Conveyors 59/200

Reliable Gear Units For High Performance Vertical Conveyors 59/200 Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill

Maximum power density – PLANUREX 3 L individual drives for your sugar cane mill The proven all rounder gearunit gearbox

The proven all rounder gearunit gearbox Stirs and stirs and stirs gearunit gearbox

Stirs and stirs and stirs gearunit gearbox Flexibility on Board gearunit gearbox

Flexibility on Board gearunit gearbox The right gearbox for all Multi-Engine Ships

The right gearbox for all Multi-Engine Ships Reliable Power Generation on board

Reliable Power Generation on board Maximum performance level, fast deliverable

Maximum performance level, fast deliverable Efficient and compact – FLENDER Gear Units for Sugar Mills

Efficient and compact – FLENDER Gear Units for Sugar Mills Extremely strong. Extremely compact. Extremely stressable.

Extremely strong. Extremely compact. Extremely stressable. FLENDER Coupling

FLENDER Coupling ZAPEX ZW Torsionally Rigid Gear Coupling

ZAPEX ZW Torsionally Rigid Gear Coupling ZAPEX ZN Torsionally Rigid Gear Coupling

ZAPEX ZN Torsionally Rigid Gear Coupling N-EUPEX Flexible high performance Coupling

N-EUPEX Flexible high performance Coupling N-ARPEX Torsionally Rigid All-Steel Coupling

N-ARPEX Torsionally Rigid All-Steel Coupling ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts

ARPEX Torsionally Rigid All-Steel Coupling Spare and Parts RUPEX Flexible high performance Coupling

RUPEX Flexible high performance Coupling N BIPEX Flexible high performance coupling

N BIPEX Flexible high performance coupling ELPEX B Highly Flexible Coupling

ELPEX B Highly Flexible Coupling ELPEX S Highly Flexible Coupling high performance

ELPEX S Highly Flexible Coupling high performance ELPEX Highly Flexible Coupling high performance

ELPEX Highly Flexible Coupling high performance FLUDEX Fluid Coupling high performance

FLUDEX Fluid Coupling high performance SIPEX Backlash free Coupling high performance

SIPEX Backlash free Coupling high performance BIPEX S Backlash free Coupling high performance

BIPEX S Backlash free Coupling high performance FLENDER Coupling Spare Parts high performance

FLENDER Coupling Spare Parts high performance SEW Gearmotor

SEW Gearmotor R Series Helical Gearmotor low voltage

R Series Helical Gearmotor low voltage F Series Parallel Shaft Gearmotor low voltage

F Series Parallel Shaft Gearmotor low voltage K Series Helical Bevel Gearmotor low voltage

K Series Helical Bevel Gearmotor low voltage S Series Helical Worm Gearmotor low voltage

S Series Helical Worm Gearmotor low voltage W Series SPIROPLAN® Right Angle Gearmotor

W Series SPIROPLAN® Right Angle Gearmotor